We manufacture all flow iron products to API 6A material requirements, and test to ensure adherence to these specifications. Quality is critical to our mission success, and we treat it that way, with a rigorous inspection and testing program for every piece that ships from our factory. We have substantial experience both in the manufacturing and use of these products in the field.

Canada

Founded in 2018

11-50 Employees

Working industry

Oil, Energy and Gas

Type of company

Manufacturer

Ownership structure

Privately Held

Locations

1 Headquarter

Number of products

16 Products

Specialised areas

Plug Valves, Choke Valves, 1502 Fittings, 602 Fittings, Weco fittings, 1502 Tee, 1502 Cross, 1502 Wing, 1502 Thread, Choke Trim

Integral Flow Equipment offers a wide range of products and services

Product

Integral Flange Adaptors | High Pressure Flow Control | IFE

Go to product >

Product

Debris Catchers | Flowback & Well Testing | Integral Flow Products

Go to product >

Product

Needle Valves - Integral Flow Equipment

Go to product >

Product

Desco Lubricants, Sealants & Injectable Packing - Integral Flow Equipment

Go to product >

Product

Ball Valves - Integral Flow Equipment

Go to product >

Product

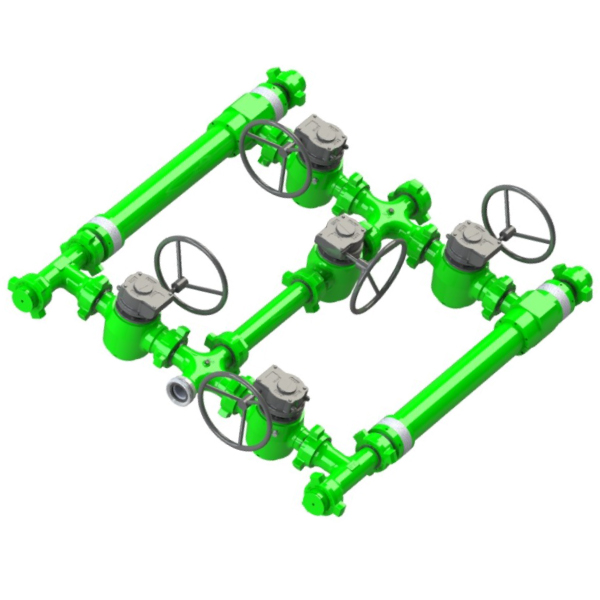

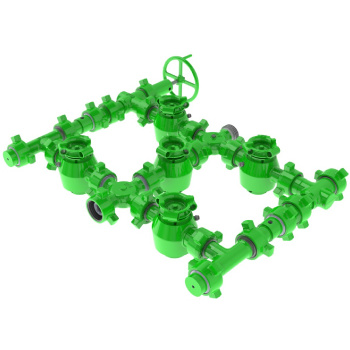

Choke Manifold Systems | Flowback & Well Testing | IFE

Go to product >

Product

Plug Valve Repair Kits | Flow Control | Integral Flow Equipment

Go to product >

Product

Integral Flow Line Pipe & Pup Joints | High Pressure Flow Control

Go to product >

An estimation about the ESG values based on digital data and signals. Important: The ESG scores are only based on information about the country, not the actual company itself

Country:

Canada

Overall risk estimation:

Very low

The ESG Data of countries are based on public sources

Environment

A

Grade (A-E)

View details

Social

A

Grade (A-E)

View details

Governance

A

Grade (A-E)

View details

Integral Flow Equipment operates in 1 country around the world

Get an overview of the locations of Integral Flow Equipment

Location

Country

State

City

Headquarter

Canada

Alberta

-

Some frequent questions that have been asked about Integral Flow Equipment

Where is Integral Flow Equipment located?

The company headquarter of Integral Flow Equipment is located in Alberta, Canada. It's worth noting, that the company may have more locations

How many employees does Integral Flow Equipment approximately have?

As of the latest available information Integral Flow Equipment has around 11-50 employees worldwide.

When was Integral Flow Equipment founded?

Integral Flow Equipment was founded in 2018

In which industries does Integral Flow Equipment mainly work?

The company Integral Flow Equipment has it's main focus in the industries of Oil, Energy and Gas

Check out some interesting alternative companies to Integral Flow Equipment

MBP Engineers & Procurement Services (Pty) Ltd

Boksburg, South Africa

11-50 Employees

2006

Our vision is to provide a customised value added solution to suit every customer’s unique needs. Our products meet the highest quality levels and comply with all international standards such as ISO, ANSI, API JIS, BS and SABS. We employ highly skilled individuals to ensure excellent quality and on-time delivery. The most important aspect during fabrication is the quality and accuracy of the end product. A quality control plan (QCP) is used as the blueprint for manufacturing and clients can give input during the fabrication stage.

DAVINCI VALVES

Chengdu, China

1-10 Employees

2017

We are in position to offer you the best quality tested products as we value our products’ safety and performance more than anyone else. Our products are tested for work pressure, leakage, performances, etc. We have a diverse range of products, accessories and pipe fittings in water section. We have a selective range of fire protection products. Our industrial valves cover fields from mining industry, food and beverage, paper manufacture, climatic projects and even pharmaceutical field. The exhaustive and comprehensive controls during the manufacturing processes of our products account for our attention to quality throughout the manufacturing process. We also provide special testings according to customer's requirements. We focus on not only in-depth knowledge of our products and services, but also profound collaboration with our business partners to reach the final and highest goal: great products and services that our customers satisfy with!

FLOW TECHNOLOGY LIMITED

Calderdale, United Kingdom

11-50 Employees

1990

We are committed to offering a high level of service in producing an accurate and reliable response to your enquiries and purchases. We are committed to offering a high level of service in producing an accurate and reliable response to your enquiries and purchases. Flow Technology manufacture Stainless Steel and High Nickel Alloy products to all the relevant UK and International standards. Our manufacturing and processing capabilities ensures a rapid turnaround from receiving your enquiry to completion of your order. This includes sliding head technology is used to supply products from stock and manufacture non-standard, special components and fittings on a short lead time. This approval and strict quality control ensures that the product meets your exact requirements. Our Test Certificate system ensures total material traceability and certification is provided as a matter of course. The service we offer gives you the benefit of 40 years involvement in the Stainless Steel and High Nickel Alloy pipeline component market.

Cangzhou Pipeline System Pipe Technology Co.,Ltd

-

- Employees

-

Our products are manufactured to conform to international standards. Our products range to 3200 mm OD, with a maximum WT of 150 mm, and PN up to 42 Mpa. Our main products are anti-hydrogen and anti–sulfur fittings, alloy heavy all fittings with high pressure, stainless steel heavy wall fittings with high pressure, bimetal fittings and other regular fittings, flanges . Cover an area of 13.3 hectares focusing on manufacturing high quality products for worldwide business partners in the industry. Each product has Mill Test Certificate to ensure product quality. The company has 3000 tons raw material storage and 4000 pcs products to match the demand of market. Pipeline System cooperates with all customers with the inspection and warmly welcome customers from all over the world to visit our factory. Weld Overlay is a process governed by API 5LD.

ACIS ACTUATORS S.L.

Castellar del Vallès, Spain

1-10 Employees

1969

Our facilities are equipped to guarantee the quality in the whole manufacturing process: assembling, testing, painting and packing. In order to hold the upmost quality in products and service, IBOR owns several international requirements according to design development, order processing, purchasing, production such as ISO 9001, API Q1 and PED. IBOR work focus on customer service, safety product development. Our staff is continuously developing design innovation and production and technology command. The company’s products include Valves and Municipal Environmental Protection Equipments (Source Control Interception Equipments and Storage Tanks, etc.). We want to be your partner providing solutions focus on reduce cost and increase lifetime.

QUAM SRL

Fiorenzuola d'Arda, Italy

11-50 Employees

2001

Our products have been type tested and our design activities are audited and certified to PED, API 6D and API 6A standards. Quam and all our products are long life Service. We are always ready to help our Customers by doing our best for them. Our Service includes Commissioning & Start Up, Maintenance, Testing and Upgrading activities, which allow us to provide our Clients with the best possible assistance. QUAM is a customer oriented company and a short lead-time manufacturer specializing in fast track projects and Severe Service applications. This is our main target and it is the reason why we do our best to ensure our Clients’ requirements are achieved with the highest level of capability, professionalism and quality, at the lower possible cost in a reasonable short time. Based on our Customers’ necessities our products can be designed, manufactured and tested according to the main international standards like API, ISO, ASME, ASTM, NACE. Since QUAM was founded, each and every product is 100% Hydrostatically and Functionally tested, controlled and EN 10204 3.1 certified before leaving the plant.