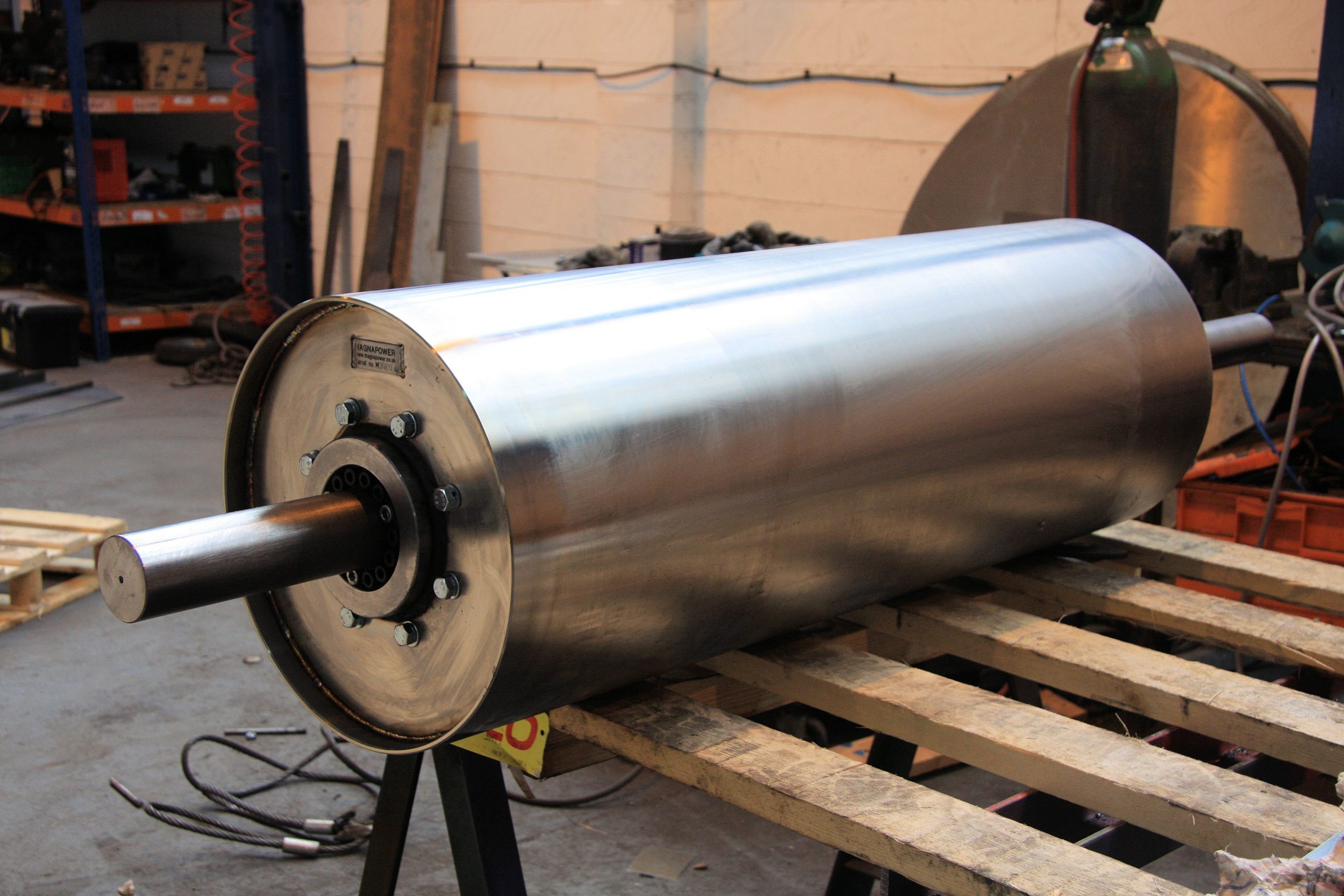

We are a customer focused business and dedicate our metal separation expertise to providing the right solution every time. Magnapower are at the forefront of metal separation technology and our experience in the design, manufacture and application of magnetic equipment has given us the leading edge in metal separation technology. Magnapower offer as a minimum a 12 month guarantee with each machine and excellent service and back up are provided as standard. Magnapower installation of ECS in wood processing plant. The Magnapower Eddy Current Separator is the world leading non-ferrous metal separator. The Magnapower range of Overband Magnet Separators are designed and manufactured to provide the highest possible ferrous metal recovery rates in the toughest environments. The Magnapower range of Drum Magnet Separators are designed and manufactured to provide the highest possible ferrous metal recovery rates. The Magnapower magnetic head pulley is widely used in the recycling and material handling industries for the continuous removal of ferrous metal.

Bromsgrove, United Kingdom

Founded in 1992

11-50 Employees

Working industry

Machinery Manufacturing

Type of company

Manufacturer

Ownership structure

Privately Held

Locations

1 Headquarter

Number of products

13 Products

Number of services

3 Services

Specialised areas

Eddy Current Separator, Overband Magnet, Drum Magnet, Magnetic Head Drum, Electro Magnets, Rare Earth Rolls, Electro Drum Magents, Magnettic Separation, food industry, Recycling Equipment

Magnapower Equipment Ltd offers a wide range of products and services

Product

Metal Separation Plants | Magnapower

Go to product >

Product

Magnetic Head Pulley | Magnapower

Go to product >

Product

Food Industry Magnets - Magnapower Equipment Ltd

Go to product >

Product

Ferrous Metal Separator | Magnapower

Go to product >

Product

Suspension Magnets - Magnapower Equipment Ltd

Go to product >

Product

Stainless Steel Separation - Magnapower Equipment Ltd

Go to product >

Product

Copper Cleaning - Magnapower Equipment Ltd

Go to product >

Product

Conveyors, Vibratory Feeders & Trommels - Magnapower Equipment Ltd

Go to product >

An estimation about the ESG values based on digital data and signals. Important: The ESG scores are only based on information about the country, not the actual company itself

Country:

United Kingdom

Overall risk estimation:

Very low

The ESG Data of countries are based on public sources

Environment

A

Grade (A-E)

View details

Social

A

Grade (A-E)

View details

Governance

A

Grade (A-E)

View details

Get insights into the use cases of Magnapower Equipment Ltd

Use case

Scrap Metal Separation - Magnapower Equipment Ltd

Scrap metal processing is usually undertaken in large purpose built plant. We recognise the need for product quality and purity. We focus our experience and knowledge of this application to provide separation equipment which leads the industry. Separation processes will vary depending on materials / size and can include: Stage 1 Size reduction (shredding) Primary ...

Use case

WEEE Processing - Magnapower Equipment Ltd

WEEE stands for Waste Electrical and Electronic Equipment. Separation processes will vary depending on materials / size and can include: Metering of product to separation line at a consistent rate Size reduction – shredding Fines removal Separation of ferrous metal – usually with an overband or drum magnet Separation of remaining ferrous – usually with ...

Magnapower Equipment Ltd operates in 1 country around the world

Get an overview of the locations of Magnapower Equipment Ltd

Location

Country

State

City

Headquarter

United Kingdom

England

Bromsgrove

Some frequent questions that have been asked about Magnapower Equipment Ltd

Where is Magnapower Equipment Ltd located?

The company headquarter of Magnapower Equipment Ltd is located in Bromsgrove, England, United Kingdom. It's worth noting, that the company may have more locations

How many employees does Magnapower Equipment Ltd approximately have?

As of the latest available information Magnapower Equipment Ltd has around 11-50 employees worldwide.

When was Magnapower Equipment Ltd founded?

Magnapower Equipment Ltd was founded in 1992

In which industries does Magnapower Equipment Ltd mainly work?

The company Magnapower Equipment Ltd has it's main focus in the industries of Machinery Manufacturing

Check out some interesting alternative companies to Magnapower Equipment Ltd

IPES International INC.

Pittsburgh, United States

11-50 Employees

-

Our vision was to provide high quality and high powered magnets for magnetic separation and magnetic material handling equipment worldwide to a wide variety of industries and providing great service before and after the sale. Ranging from food manufacturing to construction recycling, we can provide the appropriate magnetic separator to fit your individual application. All of our Magnetic Separators and Magnetic Sweeper Pickup Tools are manufactured in the USA. We pride ourselves on our high strength magnets, innovative magnetic designs, durability and outstanding performance, all at the most competitive pricing. Quality and value are principles we have committed to providing in every facet of our business and which have made us an industry leader in the fields of super strong magnets for Magnetic Separation, Magnetic Floor Sweepers and Magnetic Pickup Tools.

Mozelt GmbH & Co.KG Anlagentechnik

Duisburg, Germany

1-10 Employees

-

We develop and source state-of-the-art magnetic systems for construction, recycling, and scrap industries, across the globe. We are committed to being a safe, environment-friendly, and socially responsible company. We believe in understanding your exact needs and responding with appropriate solutions while providing top-notch services. We constantly strive to deliver systems that optimize productivity with technology that can cope with future challenges.

Puritan Magnetics Inc.

Oxford, United States

11-50 Employees

1995

Magnetic separators for capturing, controlling and removing ferrous tramp metal contaminants from products and processing systems. These magnetic separators will ensure product purity and protect processing equipment from tramp metal damage. Puritan Magnetics manufactures a wide range of permanent and electro type magnets, components, and devices for holding, lifting, conveying, fanning and other material handling applications. From flat laser cut sheet metal to completely fabricated products we can provide what you need. We specialize in stainless steel, but work with all types of materials. These magnetic separators will ensure product purity and protect processing equipment from tramp metal damage. Material Handling products can improve employee safety and automate existing systems. Powerful opposing magnets uniquely mounted to the outside of the housing inlet helps direct product towards the magnets for outstanding performance in all grain and feed industry applications.

Fushun Ejet Magnetic Equipment Co.Ltd

Fushun, China

11-50 Employees

2006

Thus we are fully aware of this responsibility in sorting resources field for nonferrous metal. We are one of the earliest manufacturers of eddy current separators in China. In the year 2006, with 25 years of magnetic experience, Ejet Magnet was Established. Keeping improvement for all kinds of magnetic separators, to provide high-quality and high-performance products is our own responsibility, moreover, offering the best solution and the most effective service is one of the higher-standard targets we are pursuing. With 4 members team, in the beginning, Ejet has grown through continuous product innovation and worldwide expansion to over 5000 square feet of manufacturing space and more than 100 employees. The main products eddy current separators, magnetic separators, sensor sorters and AI technology machines for recycling industries had been exported to more than 50 countries. Ejet had been focused on magnetic separator design, and manufacturing for more than 17 years with rich experience. Ejet® is a One-stop Source for Recycling Equipment used in Material Recovery Facilities, conveyors, Screening, and Magnetic Technology for all kinds of industry fields: Automotive Shredder Residue (ASR).

Electro Zavod (India) Pvt. Ltd

-

51-100 Employees

1973

We are a preferred partner to all major OEMs, EPCs and end-users from Steel, Power,Metals& Mining, Chemicals & fertilisers, Mineral Processing, Recycling, Port & Shipyards,Cement & Defence sectors. We provide customised solutions to cater the most stringent of applications.Our product portfolio includes Magnetic Separators,Cable & Hose Reeling Drums, Special Electrical Slip Ring Assemblies, Electromagnets, Permanent Magnets,Suspended Magnets, Lifting Magnets, Magnetic Pulleys, Drum Magnetic Separators, MetalDetector, Vibratory Feeders & Vibratory Screens. We are a prominent manufacturer of specialised machinery for the bulk material handling industry for nearly 50 years. We are an Engineering Company, founded in 1973 and a leader in the Bulk Material Handling equipment industry. Electro Zavod was founded in 1973 with a vision to provide world class & versatile material handling solutions to the industry. As a prominent manufacturer of specialised machinery for the bulk material handling industry for nearly 50 years, our technologies are derived from technological association with world leaders as well as in-house Technology Development to tune our products to the rugged demands of the industry. Our state of the art 40,000 sq.ft ISO 9001-2015 certified manufacturing facility is equipped with the latest machinery and modern technology earning a reputation for exceptional quality, durability and performance.Our highly experienced and skilled manufacturing and design teams ensure consistent innovations to ensure high product quality and consistent standards ofexcellence.We pride ourselves on our on-time schedule of delivery and installation and prompt,efficient service back up. Our state-of-art manufacturing facility is equipped with the latest machinery and modern technology earning a reputation for exceptional quality, durability and performance.

Magnattack Global

Wollongong City Council, Australia

11-50 Employees

1969

We are the Food Industry’s most reliable partner in Foreign Metal Control. We are very impressed with this installation and the high level of expertise and service from the manufacturer, Magnattack® Global. We are very impressed with Magnattack®'s high level of expertise, on-site presence and service to the dairy industry, as the manufacturer here in Australia, and would have no hesitation in recommending their innovative magnetic separator solutions for sanitary dairy applications. We are grateful to WJB Engineering for their ready assistance with this problem and have no hesitation in recommending them as magnet suppliers for difficult retrieval problems where the appropriate strength, shape and size combinations can make the retrieval a success.". Magnattack® Global is a family-owned and operated company specialising in foreign metal fragment control and magnetic separation solutions for the food processing industry worldwide. With over 50 years of experience in food industry magnetics, the company manufactures high-quality RE80® Magnetic Separation Systems designed to reduce metal contamination risks and improve food safety. Our main manufacturing facility and global headquarters is located in NSW Australia, and our US headquarters is located in Minnesota USA. Metal fragment contamination control is a high priority of all food processors.