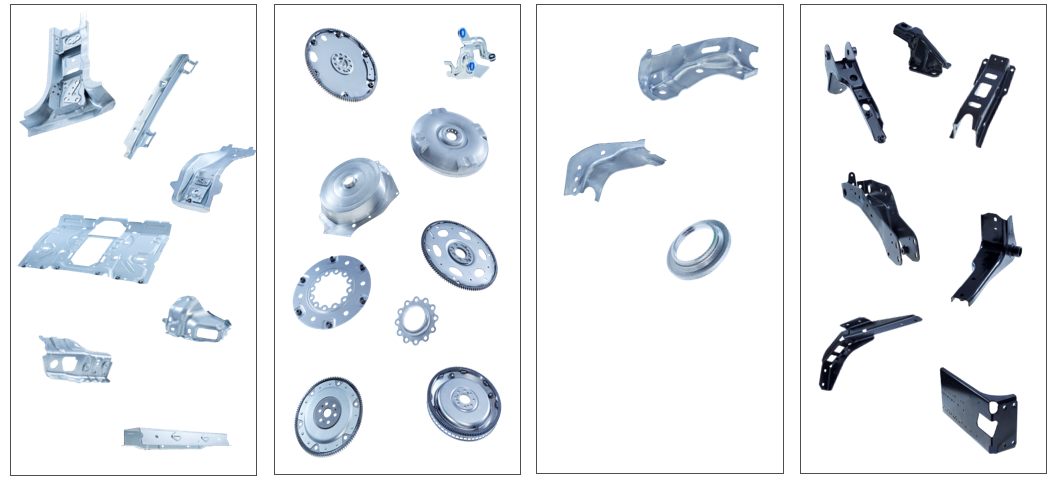

Mühlhoff looks back at a long company history. Founded in 1832 and situated in Uedem, the company currently produces complex formed components for the automotive industry. Our customers consist of almost all notable vehicle manufacturers and their suppliers worldwide. They value our high degree of reliability and competence which they experience in cooperation with us. In addition, and not least the friendly contact with Mühlhoff that goes without saying. Mühlhoff produces elements and components for bodywork, framework, chassis and powertrain. We process steel and aluminium by manner of cold working, at our site in Uedem. Daily, more than 365 qualified employees ensure absolute precision and compliance of highest quality standards using ultra-modern forming and joining technology.

Uedem, Germany

Founded in 1832

251-500 Employees

Medium-Sized

Working industry

Automotive, Manufacturing, Business Supplies and Equipment, Consulting, Printing, Automation, Business Services

Type of company

Service provider, Manufacturer

Locations

1 Headquarter

Number of services

3 Services

Specialised areas

Automotive, Service, Engineering, Projectmanagement, Sourcing , Relocations, Toolshop, Cold Forming, Joining technology

Mühlhoff Umformtechnik GmbH offers a wide range of products and services

Service

Sheet Metal Parts and Components

Go to product >

Service

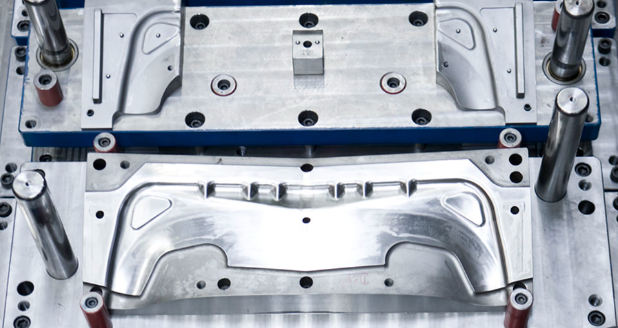

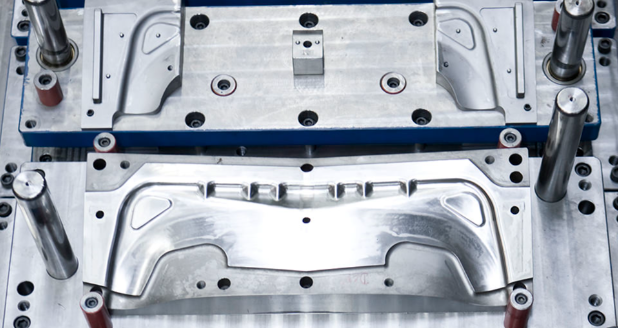

Engineering for die tooling

Go to product >

Service

Relocation Projects

Go to product >

An estimation about the ESG values based on digital data and signals. Important: The ESG scores are only based on information about the country, not the actual company itself

Country:

Germany

Overall risk estimation:

Very low

The ESG Data of countries are based on public sources

Environment

A

Grade (A-E)

View details

Social

A

Grade (A-E)

View details

Governance

A

Grade (A-E)

View details

Get insights into the use cases of Mühlhoff Umformtechnik GmbH

Use case

Car Body in White

Automotive, Industry

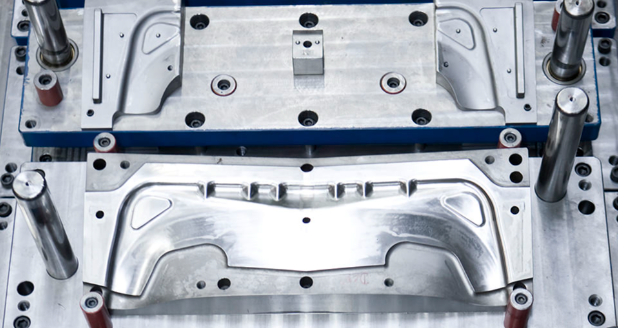

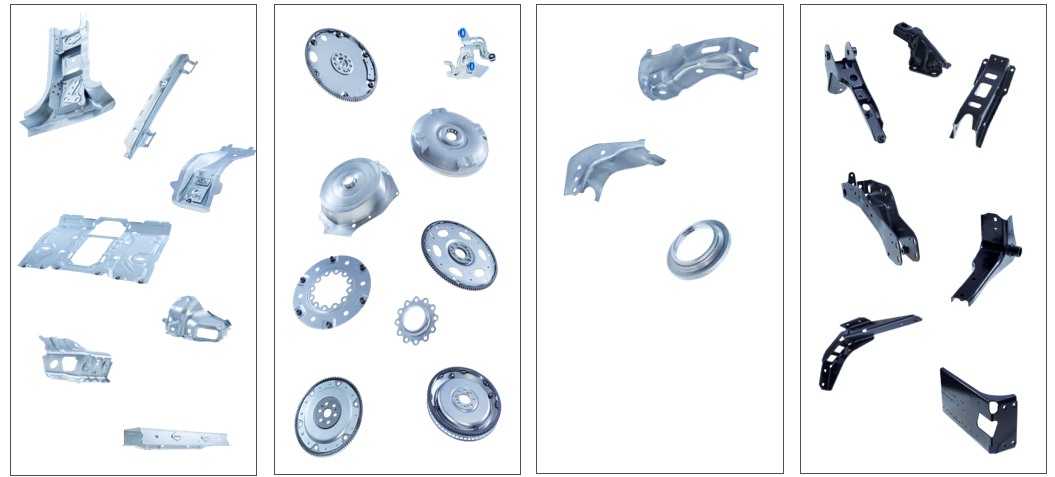

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

Use case

China Sourcing

Automotive, Industry, Cold Forming

At Mühlhoff, we specialize in the efficient and reliable sourcing of high-quality forming tools from China, ensuring you get the right tools for the job—on time, and at the best value. Leveraging years of experience and deep industry connections, we handle the entire procurement process for you, from supplier selection to quality assurance and logistics. With our expertise, you can rest easy knowing that every tool we source meets the highest standards of precision and durability. Why choose Mühlhoff for your tool procurement in China? Expert Knowledge: We know the Chinese market inside and out, ensuring you get the best tools available. Cost Efficiency: Access top-quality forming tools at competitive prices, without compromising on quality. Full Service: From sourcing and supplier audits to logistics and final delivery, we handle every step of the process. Quality Assurance: Rigorous inspections and testing to ensure your tools meet the highest standards. Let us simplify your supply chain and help you focus on what matters most—your production. Partner with Mühlhoff for the precision, reliability, and cost-effectiveness you need in forming tool procurement. Contact us today to learn more!

Mühlhoff Umformtechnik GmbH operates in 1 country around the world

Get an overview of the locations of Mühlhoff Umformtechnik GmbH

Location

Country

State

City

Headquarter

Germany

North Rhine-Westphalia

Uedem

Some frequent questions that have been asked about Mühlhoff Umformtechnik GmbH

Where is Mühlhoff Umformtechnik GmbH located?

The company headquarter of Mühlhoff Umformtechnik GmbH is located in Uedem, North Rhine-Westphalia, Germany. It's worth noting, that the company may have more locations

How many employees does Mühlhoff Umformtechnik GmbH approximately have?

As of the latest available information Mühlhoff Umformtechnik GmbH has around 251-500 employees worldwide.

When was Mühlhoff Umformtechnik GmbH founded?

Mühlhoff Umformtechnik GmbH was founded in 1832

In which industries does Mühlhoff Umformtechnik GmbH mainly work?

The company Mühlhoff Umformtechnik GmbH has it's main focus in the industries of Automotive, Manufacturing, Business Supplies and Equipment, Consulting, Printing, Automation, Business Services

What is the current company status of Mühlhoff Umformtechnik GmbH?

Based on the founding year and the amount of employees the company Mühlhoff Umformtechnik GmbH seems to be a Medium-Sized at the current state. Note that over time that status can change

Check out some interesting alternative companies to Mühlhoff Umformtechnik GmbH

Mühlbauer Parts & Systems

Roding, Germany

1001-5000 Employees

2011

One Stop Shop, Precision Parts Manufacturer, Everything from One Source. Die Erfolgsgeschichte um unseren Inhaber Josef Mühlbauer begann 1981 mit einer einzigen Drehmaschine, mittlerweile ist die Mühlbauer Group ein weltweit agierender Konzern mit über 3.500 Beschäftigten.Unterteilt in drei Geschäftsbereiche Tecurity®, Automation und Parts & Systems ist die MPS das Herzstück der Mühlbauer Gruppe mit Hauptsitz in Roding – hier entstehen alle Teile und Systeme, die ebenfalls für Lösungen der Automation, sowie der Tecurity® benötigt werden. Profitieren auch Sie vom Know-how des Marktführers und nutzen Sie die enormen Synergien durch eine Partnerschaft mit unserem Haus. Denn um Ihre Innovationen und Lösungen flexibel, schnell, in hoher Qualität und trotzdem mit geringem Aufwand umzusetzen, bedarf es vor allem eines – Möglichst alles aus einer Hand!Kurz zusammengefasst liegt unsere wohl größte Stärke in der Vielfalt unserer technologischen Möglichkeiten, welche wir alle unter einem Dach vereinen. Angefangen von Fräsen, Drehen, Blechbearbeitung, Schleifen, Erodieren, Schweißen über eine eigene Montage (inkl.

Muhlack Kiel

Kiel, Germany

11-50 Employees

1931

Carefully selected materials and modern equipment are indispensable starting points in the manufacture of an outstanding product. But what really determines quality is the experience and know-how of the people who are involved in the product’s manufacture.Since its foundation as a cabinet-maker’s workshop in 1931, Muhlack Kiel has systematically extended its product range and now has major in-house manufacturing depth and design skills in all aspects of its operations.We train staff in four disciplines and employ about 60 people. Selected materials and modern processing facilities are indispensable foundations for the manufacture of a special product. However, the experience and know-how of the people involved in its manufacture remain decisive for quality. Whether for mobile use, as stand-alone furniture or as a modular system - we develop and produce furniture and displays suitable for series production that are precisely tailored to your wishes and your presentation.

Kurt Erxleben GmbH & Co KG

Wildeshausen, Germany

251-500 Employees

-

Headquartered in Wildeshausen, we produce sheet metal, welded and machined parts for the automobile industry, agricultural machines and other industries that process sheet metal. Ever since the company was founded, it has been our philosophy to perfect your product with our services. In close collaboration with the largest automobile companies worldwide, we manufacture your products until final delivery. In an area of 12,000 m², we carry a product assortment consisting of more than 2,500 components that are precisely tailored to your requirements. A car body construction manufacture and vehicle painting evolved from a wheelwright. This is particularly due to the fact that the company had solely focused on manufacturing sheet metal parts as of 1994. When the company in 2000 re-located its production facility from Delmenhorst to a 32,500 m² area in an industrial section of the city of Wildeshausen, room was created for additional expansion activities. We accept the responsibility that your product deserves.

H & K Müller GmbH & Co. KG

Engelskirchen, Germany

51-100 Employees

1934

We produce all of our products in our production facility in Engelskirchen, which was one of the first production facilities in Germany to be certified according to three different standards as it has been since 2014. We are proud to count many renowned brand and contract manufacturers across a range of industries among our customers. As a full-service provider, H&K Müller realises customers’ projects – from the design and development to a logistics concept tailored to their individual needs. For decades, our company has been dedicated to striking a balance between economic success and social responsibility in everything we do. Sustainable business practices and their long-term effects make us a particularly innovative and forward-looking company on the market. H&K Müller is especially committed to energy and resource efficiency. Hugo and Katharina Müller founded the company in 1934, at a time when the plastics industry was still at the beginning of its development and pioneering spirit was in demand. It also offered optical advantages by allowing for different colours and surface textures, and it could be printed on.

Müller Stahl- u. Metallbau

Gemünden, Germany

1-10 Employees

-

Die Firma Müller in Gemünden wurde 1924 gegründet und befindet sich bereits in der vierten Generation. Als Metallbau-Meisterbetrieb aus Hessen bearbeiten wir alle Materialien rund um das Thema Stahl- und Metall.

Kuhlmann GmbH & Co. KG

Lage, Germany

51-100 Employees

1926

Seit 1923 sind wir, die Kuhlmann GmbH & Co. KG, als mittelständisches, inhabergeführtes Großhandelsunternehmen mit Sitz in Lage tätig. Angefangen hat alles mit dem „Eisenhandel“ und der Lieferung von Werkzeugen, Schrauben und Kugellagern. Mit unseren Kunden ist auch unser Lieferprogramm im Laufe der Jahre in Breite und Tiefe gewachsen. Heute sind wir ein moderner Stahl- und Werkstoffhandel, der zusätzlich zum Stahlmaterial auch sämtliche Werkzeuge, Maschinen und technischen Artikel für die Metall-, Holz- und Kunststoffverarbeitung liefert.