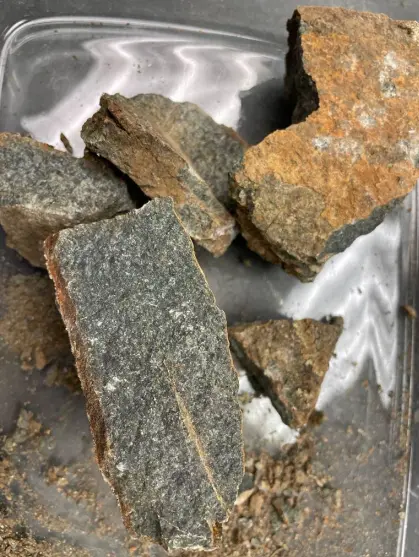

We create high-volume, yield-boosting, biochar-enhanced fertilizers and soil amendment products. Because businesses must take responsibility for their hard-to-abate emissions today. Our biochar materials are carbon-negative, because the production process removes more carbon from the atmosphere than it adds. Myno was founded with the goal of removing as much carbon from the atmosphere as possible, as fast as possible, for Ella and future generations to live in a world free from the climate crisis.

Bainbridge Island, United States

Founded in 2020

1-10 Employees

Startup

Working industry

Environment, Disposal and Recycling

Type of company

Service provider

Ownership structure

Privately Held

Locations

1 Headquarter

Number of products

3 Products

Specialised areas

CleanTech, Environmental Engineering, Sustainability

Myno Carbon offers a wide range of products and services

Product

Myno Wins State-wide Grant to Develop Carbon Capture, Utilization, and Storage Technology - MYNO Carbon Corp.

Go to product >

Product

New Washington State Law Passes to Incentivize Biochar Application and Production - MYNO Carbon Corp.

Go to product >

Product

From Oilfields to Climate Warriors: Myno Carbon's Journey to Sustainable Innovation - MYNO Carbon Corp.

Go to product >

An estimation about the ESG values based on digital data and signals. Important: The ESG scores are only based on information about the country, not the actual company itself

Country:

United States

Overall risk estimation:

Low

The ESG Data of countries are based on public sources

Environment

D

Grade (A-E)

View details

Social

A

Grade (A-E)

View details

Governance

A

Grade (A-E)

View details

Get insights into the use cases of Myno Carbon

Use case

Myno’s first biochar application project hits the ground - MYNO Carbon Corp.

Myno’s first large-scale biochar application project will be in the greater Stevens County region in Washington State supporting regenerative agriculture. Myno in partnership with Stevens County Conservation District (SCCD), Colville Reservation Conservation District (CRCD), Washington State University Extension (WSU), Avista Corporation, and the WA Sustainable...

Myno Carbon operates in 1 country around the world

Get an overview of the locations of Myno Carbon

Location

Country

State

City

Headquarter

United States

Washington

Bainbridge Island

Some frequent questions that have been asked about Myno Carbon

Where is Myno Carbon located?

The company headquarter of Myno Carbon is located in Bainbridge Island, Washington, United States. It's worth noting, that the company may have more locations

How many employees does Myno Carbon approximately have?

As of the latest available information Myno Carbon has around 1-10 employees worldwide.

When was Myno Carbon founded?

Myno Carbon was founded in 2020

In which industries does Myno Carbon mainly work?

The company Myno Carbon has it's main focus in the industries of Environment, Disposal and Recycling

What is the current company status of Myno Carbon?

Based on the founding year and the amount of employees the company Myno Carbon seems to be a Startup at the current state. Note that over time that status can change

Check out some interesting alternative companies to Myno Carbon

NetZero

Paris, France

51-100 Employees

2021

NetZero's mission is to bring biochar at scale in the tropics – for climate and people, now. NetZero is a Milestone Award winner of Musk Foundation's XPRIZE Carbon Removal competition, a recipient of the ‘Efficient Solution’ label from Solar Impulse Foundation, a Green Tech prize winner of the Tech for Good Awards, and a certified carbon-removal project under the Puro Standard. It is a scientifically proven way to perform high-permanence carbon removal from the atmosphere while durably improving soil quality, allowing for higher yields and lower fertiliser use in agriculture. Our unique model makes biochar affordable for farmers, helps companies neutralise their unavoidable emissions, and co-generates renewable energy – all at once.

Origin BioChar

Newtownstewart, United Kingdom

1-10 Employees

2020

Our products harness Biochar, recognised for centuries as natures remedy for digestive problems. We are a Northern Ireland based business specializing in the manufacture of 100% biochar. We use hardwoods as this produces the highest quality FeedChar product for animals due to the material’s nanopore structure. Emissions and production capacity posed barriers in early trials to how the process could be commercialised and material produced on a continuous basis as opposed to a batch kiln fired system. This process, therefore, provides us with FeedChar and thermal energy that we can use at our site for heating and manufacturing. As the FeedChar is fed to animals it can be assumed that the carbon will be passed through the animal naturally and incorporated into the soil either directly or spread as stored manure or slurry in a farming scenario at which point it becomes a permanent carbon addition and capture therefore a “CO2-negative” heating process. This process feeds into our QMS with all necessary information captured to ensure our products are produced safely and to the highest possible standards. Our journey to develop and refine our products is one based on continuous learning.

Carbon Plus Sdn Bhd

Malaysia

1-10 Employees

2020

We produce high quality biochar, wood vinegar, and pyrolytic oil (bio-oil) through biomass gasification technology, using a wide range of feedstocks, for applications in soil as well as industrial applications. We produce high temperature biochar, wood vinegar and bio-oil through biomass gasification technology, using a wide range of feedstocks at large scales. Our goal is to encourage the widespread adoption of biochar as a carbon negative product for agricultural applications (e.g. Carbon Plus works to remove atmospheric carbon through the production and application of Biochar (recognized by the IPCC as a Negative Emission Technology and listed as one of Project Drawdown’s solutions), Wood Vinegar, and Pyrolytic Oil.

Thai Carbon Co. Ltd.

Bangkok, Thailand

1-10 Employees

2021

We are the first commercial producer in Asia to utilize a US patented slow pyrolysis process to produce high quality biochar. Biochar is a truly remarkable and versatile technological material. It can also reduce the carbon footprint of the manufacturing of these materials. By carefully documenting the carbon footprint of each step from sustainable production of feedstocks, environmentally friendly conversion to biochar, value-add utilization and final sequestration, a carbon removal credit can be issued on several established carbon trading platforms.

Biochar Life

Phrao, Thailand

11-50 Employees

-

At Biochar Life, we're on a mission to tackle climate change, enhance public health, and alleviate rural poverty by working with smallholder farmers. Biochar enhances soil fertility and crop yields, reducing chemical fertilizer reliance. Biochar Life champions social equality by offering equal opportunities to marginalized agricultural groups, empowering women, youth, and disadvantaged communities in the sustainable agriculture sector. Biochar Life and Warm Heart Worldwide have been teaching farmers how to make biochar for over 10 years. We train communities in the creation of biochar and help them generate c-sink credits, putting more money back into their hands while making a global impact. Through our training and support, smallholder farmers can generate additional income by producing biochar and earning c-sink credits. By teaching farmers to create biochar, we protect the planet by advancing sustainable agriculture, sequestering carbon, reducing emissions, and fostering corporate carbon-offset partnerships to amplify our environmental impact.

Husk Ventures

Barcelona, Spain

1-10 Employees

2017

We are the world’s leading producer of biochar-based fertilizers. We are part of a growing ecosystem of individuals and organizations committed to improving smallholder farmers’ lives through regenerative agriculture. That is why Heloise Buckland and Carol Rius co-founded this innovative, impact-driven business in Barcelona (Spain), and Phnom Penh (Cambodia). Our team includes agronomists, biologists, engineers and experts in biochar and regenerative agriculture… but above all, we are a group of committed individuals who want to make a difference. The rice plant absorbs carbon dioxide, and we use the husk to create products for the soil: organic biochar, carbon based fertilizers and biopesticides in Cambodia, using a smokeless process known as pyrolysis, we have created the world’s first biochar plant in a rice mill. When the farmers apply our products on their crops, the carbon is buried in the soil, where it remains for hundreds of years. HUSK biochar products are vegetables, fruit and nut trees and arable crops and can significantly increase yields from the first application. HUSK biochar products help farmers increase long term profitability, regenerate degraded soils and improve yields** becoming more resilient to climate change.