At pacemaker.ai, we work with passion and ambition on AI-based solutions that make it possible to make the best data-based decisions for a sustainable supply chain. We use your data and the industry knowledge of your experts to create highly accurate forecasts and CO₂ balances using machine learning algorithms. For a cost-optimized, more efficient & sustainable supply chain.

Münster, Germany

Founded in 2022

11-50 Employees

Startup

Working industry

Environment, Disposal and Recycling, IT, Software and Services

Type of company

Service provider

Locations

1 Headquarter

Number of services

7 Services

Specialised areas

Carbon intelligence, Demand forecasting, Supply chain, Sustainability, Product carbon intelligence, PCI, Demand Planning, SaaS, AI, Artificial intelligence

pacemaker.ai offers a wide range of products and services

Service

Demand Forecasting

Go to product >

Service

Product Carbon Intelligence

Go to product >

Service

Transport Emissions

Go to product >

Service

Corporate Carbon Footprint

Go to product >

Service

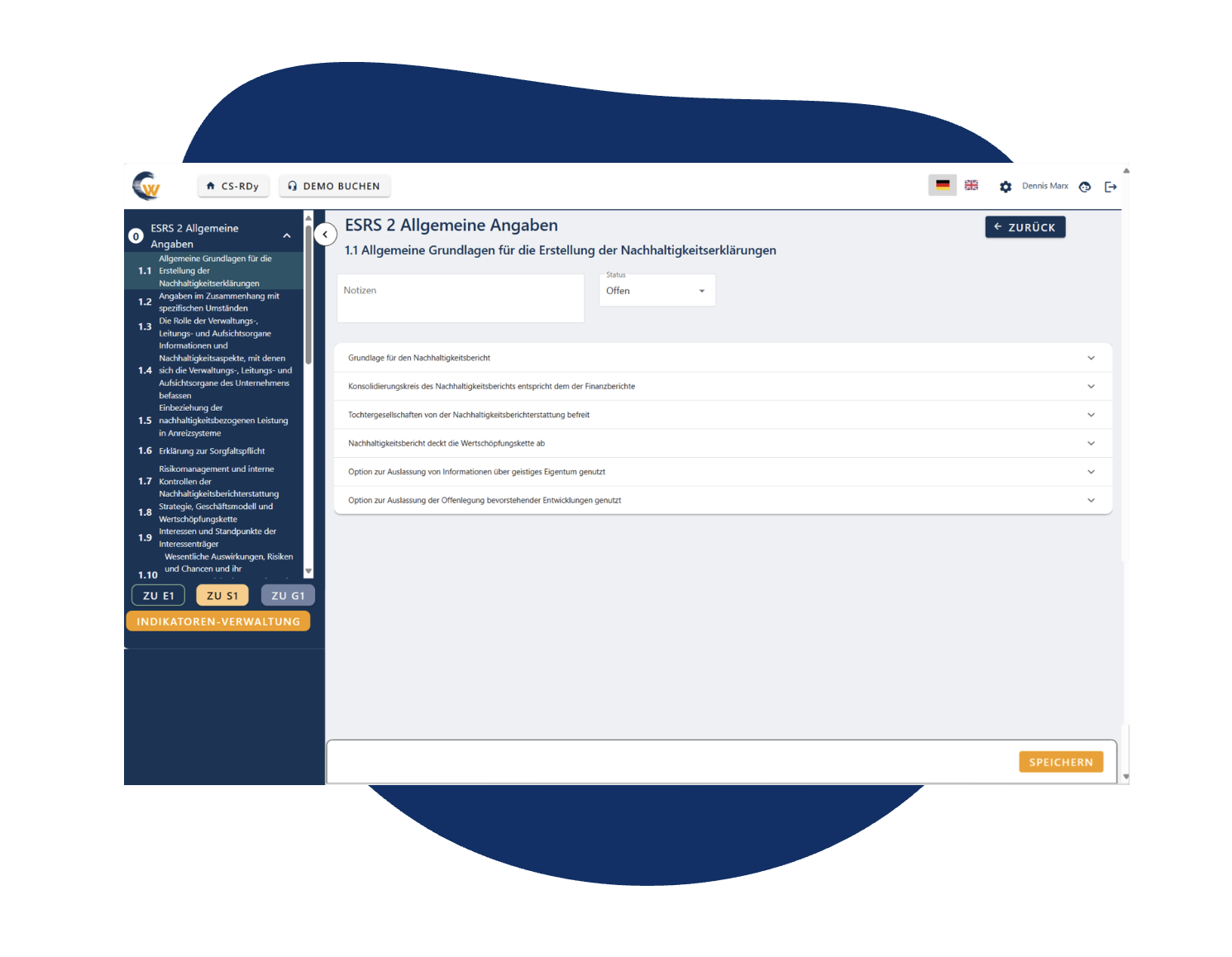

CS-RDy

Go to product >

Service

TAXONOFY

Go to product >

Service

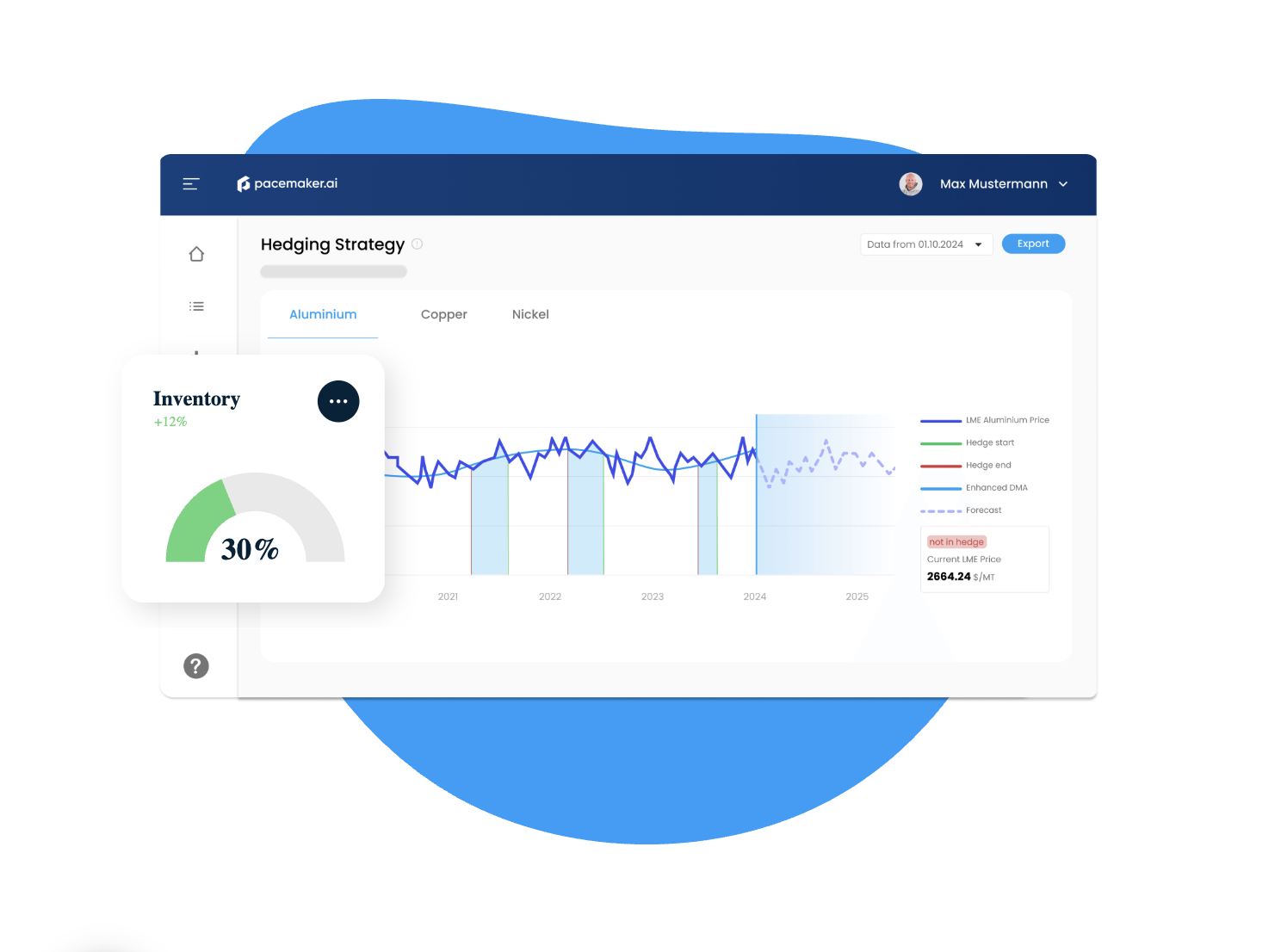

Raw Material Forecasts

Go to product >

An estimation about the ESG values based on digital data and signals. Important: The ESG scores are only based on information about the country, not the actual company itself

Country:

Germany

Overall risk estimation:

Very low

The ESG Data of countries are based on public sources

Environment

A

Grade (A-E)

View details

Social

A

Grade (A-E)

View details

Governance

A

Grade (A-E)

View details

Get insights into the use cases of pacemaker.ai

Use case

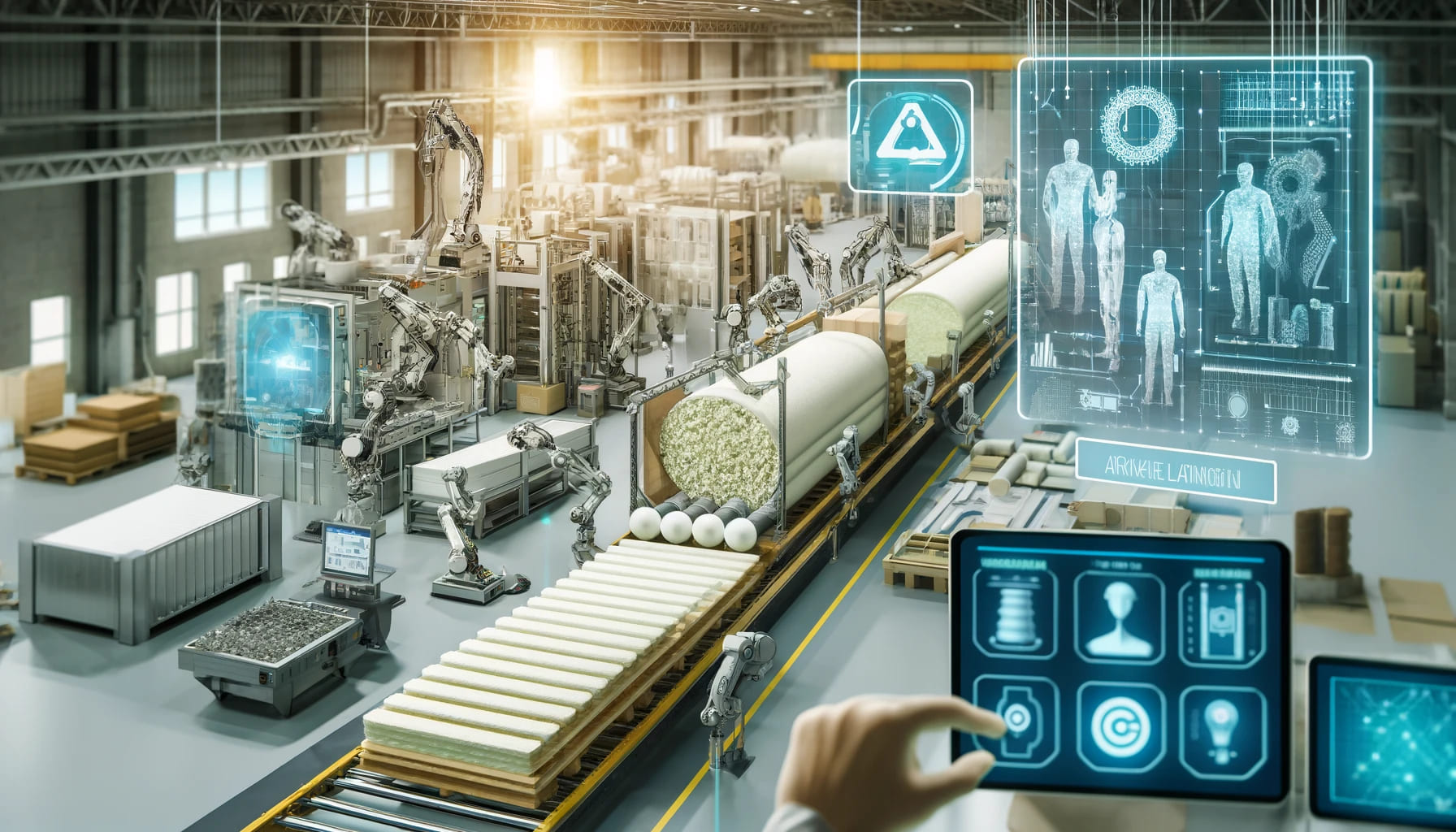

Forecasting methodology in the insulation material industry through AI integration

Dämmaterial, Dämmaterial Industrie, Insulation Material, insulation material industry, supplier, construction, construction industry

In the complex industrial landscape of insulation materials, in which multiple market segments and diverse product lines coexist, precise forecasting and strategic planning based on this is essential. For a multinational manufacturer in this sector, forecasting plays a critical role, as it is the basis for budget distribution across the various departments. Previous forecasting methods relied on manual calculations and the use of Excel-based solutions, which often only work with simple averages. This high level of manual and personnel effort not only limited the accuracy of the forecasts, but also their timeliness and frequency. The forecasting methods were also vulnerable to unpredictable market changes, which often led to delays in the supply chain. The introduction of an AI-based forecasting tool marked a turning point for the manufacturer. This advanced tool not only uses internal historical data, but also integrates external influencing factors such as special calendar events, past and future expected inflation indices and building permits into its analyses. As a result of this comprehensive data integration, the accuracy of forecasts was significantly increased to 91.4%.The increased forecast accuracy led to numerous positive effects on operations. A more reliable forecast enabled a more efficient and targeted budget allocation, which made it possible to achieve significant cost savings. Improved predictability and speed of response to market changes also contributed to a reduction in delivery times. The implementation of AI technology thus strengthened operational safety and sustainably improved the company's competitiveness.By using innovative AI technologies in forecasting practice, the insulation material manufacturer was not only able to optimize its processes, but also make it more adaptive and resilient to market fluctuations. This case study impressively demonstrates how technological advances can be used specifically to solve specific industry-specific challenges in order to promote operational efficiency and economic stability.

Use case

Aerospace supply chain planning

Aerospace, industrial, industry, supply chain, aerospace industry, supplier

Customers from various industrial sectors, including original equipment and the aftermarket, are facing similar challenges. A specific example of this is a supplier to leading aerospace companies. It must predict the developments of over 4,000 material types in various market segments. For one of its main end customers, the planning processes were previously carried out manually and exclusively using Excel. In the past, this method of planning led to inaccurate results, which in turn led to both inventory shortages and excessive inventories. To overcome these challenges, pacemaker.ai provides a solution that provides automated, regularly updated forecasts. These forecasts serve as a basis for replenishment planning and help to precisely define the quantities to be purchased at the level of individual products.The planning is based on a forecast period of 18 months, during which the delivered materials are carefully reviewed. An important feature of the pacemaker.ai solution is the implementation of a five-level grouping structure. Within this structure, Cluster A materials are given priority, with a total of 215 articles being prioritized based on ABC/XYZ analysis.The current accuracy of pacemaker.ai's predictions is over 80%. Continuously refining and adjusting these forecasts is a key part of pacemaker.ai's commitment. This shows the company's efforts to constantly optimize its customers' supply chains and maximize their efficiency through innovative approaches in data analysis and machine learning.The integration of advanced, data-driven forecasting tools such as those from pacemaker.ai can significantly help solve traditional supply chain planning problems. The use of automated systems not only improves the accuracy and efficiency of inventory management, but also prevents costly overstocks and shortages. This represents enormous added value for suppliers in highly dynamic industries such as aerospace.

pacemaker.ai operates in 1 country around the world

Get an overview of the locations of pacemaker.ai

Location

Country

State

City

Headquarter

Germany

North Rhine-Westphalia

Münster

Some frequent questions that have been asked about pacemaker.ai

Where is pacemaker.ai located?

The company headquarter of pacemaker.ai is located in Münster, North Rhine-Westphalia, Germany. It's worth noting, that the company may have more locations

How many employees does pacemaker.ai approximately have?

As of the latest available information pacemaker.ai has around 11-50 employees worldwide.

When was pacemaker.ai founded?

pacemaker.ai was founded in 2022

In which industries does pacemaker.ai mainly work?

The company pacemaker.ai has it's main focus in the industries of Environment, Disposal and Recycling, IT, Software and Services

What is the current company status of pacemaker.ai?

Based on the founding year and the amount of employees the company pacemaker.ai seems to be a Startup at the current state. Note that over time that status can change

Check out some interesting alternative companies to pacemaker.ai

Quantics.io

Vienna, Austria

1-10 Employees

2020

Our mission is to enable a sustainable future. Therefore, we do our best every day to pioneer innovations in the field of AI and supply chain planning to enable agile, integrated, and sustainable business operations. A team with great passion for data science, innovation & supply chain management. We are a honest & reliable partner for all our stakeholders. We are open for new ideas & actively drive innovation.

Westphalia DataLab

Münster, Germany

51-100 Employees

2017

We combine artificial intelligence, technology and people for data-based decisions. Thus, we enable an efficient and sustainable supply chain. Our demand forecasting solution helps you plan for the future. It calculates historical sales data, factors in external data, and forecasts future demand so you can make better data-driven decisions. Secure cloud hostingDeployed with our trusted cloud partner, Microsoft Azure.

Carbon13

Cambridge, United Kingdom

11-50 Employees

2019

We are developing AI tools to analyse embodied carbon, forecast CBAM costs, model the knock-on effects on prices, and report back on resulting sustainability metrics. Our products will address the needs of importers, who pay CBAM directly, as well as their suppliers and their customers. Leveraging their expertise in mathematical optimization, machine learning, and chemical synthesis, they have conceptualized and are currently testing a groundbreaking process that not only consumes significantly less energy than existing commercial DAC solutions but also provides permanent storage solutions for both small and large-scale CO2 emitters. The lightweight, thin-film product is a replacement for the current plastic, and can be installed on existing structures – unlocking gigawatts of solar power on plastic greenhouses. With an initial focus on parking infrastructure, they leverage existing technologies to serve their customers’ needs now. Using 100% renewable energy and sustainable batteries, they can reduce the CO2e emission by 95% compared to an average charging process. Biomanufacturing is at a pivotal moment, needing accelerated R&D to unleash its full potential, currently constrained by traditional and iterative lab-centric methods. One of its most notable benefits is the ability to enhance nitrogen use efficiency by 50%.

Digitech Oasis

Manchester, United Kingdom

1-10 Employees

2019

We are a leading AI-powered platform that transforms the landscape of data-driven workflows. We are committed to high creative and technical excellence standards. Intelligent automation increases worker productivity, reduces overtime costs, and seamlessly scales as your business grows. Digital transformation that enhances decision-making - eliminating unproductive walking time to significantly improve productivity and lower cycle times. Imagine data-powered warehouses where our AMRs intelligently navigate, optimize, and deliver real-time insights. We believe that working together helps us develop new systems, solutions and products to put you ahead of your competition.

Lakeside Analytics

London, United Kingdom

1-10 Employees

-

We are your beacon in the AI revolution, offering transformational workshops and sessions that ensure your organization not only adapts but thrives in the AI era. Our expertise in data analytics, machine learning, and strategic consultancy empowers organizations to navigate the complexities of technological advancement. With over 25 years of experience, we are dedicated to crafting bespoke AI solutions that foster innovation, efficiency, and sustainable growth. Join us in leading the AI revolution, where your business’s future is reimagined for competitive advantage. In an era where data is the new oil, are you maximizing its potential? Innovative In-house Workshop: Immerse yourself in our exclusive In-House Workshop on Leveraging AI, specifically for your organization. Transporeon, the leading Transportation Management Platform, announced on August 22nd, 2022 the acquisition of Tracks, a Berlin-based start-up with the mission to decarbonise the transport industry. Tracks is a carbon visibility tool providing data solutions to monitor and manage carbon emissions across all transport modes.

POSTX

London, United Kingdom

1-10 Employees

2023

Our vision is to change the way the world delivers by training the most advanced machine learning models to design, sort and decide complex logistics decisions, with zero carbons. Our goal is to lead in developing new delivery innovations in partnership that unlock opportunities to enhance the delivery experience, reduce costs and drive growth. We're dedicated to solving complex transportation and logistics challenges, making it easier to eliminate emissions from your deliveries.