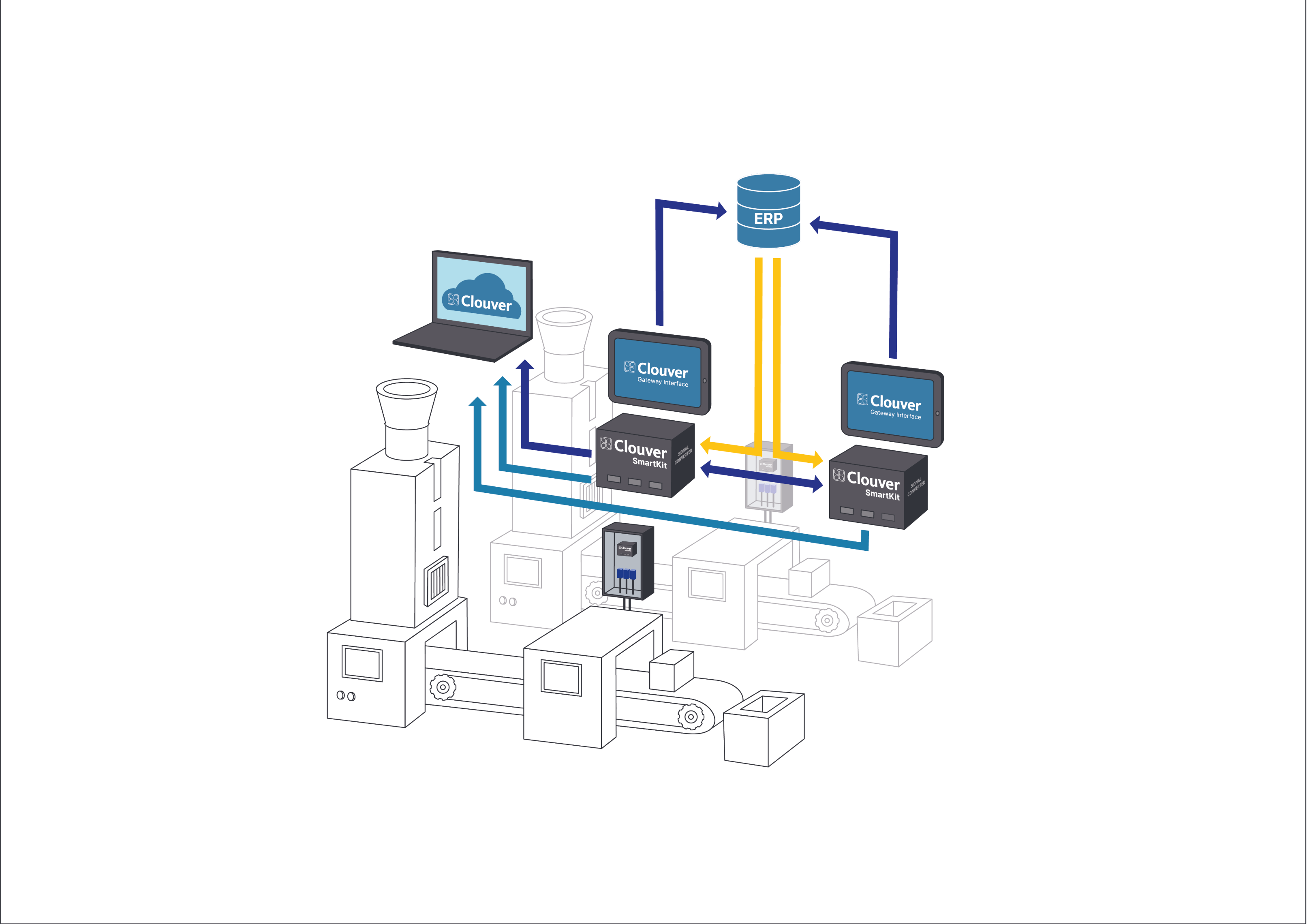

ProCom Automation products combine precision, agility, and speed to take your machines to new levels of performance. Explore the CNC300 control solution – specialised for a wide range of cutting technologies – and the IIoT platform Clouver to take pathbreaking steps forward together with us. ProCom products are ready for the future – today. Discover the world of ProCom Automation products and benefit from the powerful added values that will enhance your production and elevate your products. Clouver provides you with a quick and effortless entry into a digitalised production. With our IIoT platform for manufacturing companies you have the means to optimise production processes, minimise your downtimes, and achieve significantly enhanced efficiency throughout your production. With our help, you will quickly and easily make your production fit for the future!

Founded in 1977

11-50 Employees

Working industry

Automation

Type of company

Manufacturer, Service provider

Number of products

1 Product

Number of services

4 Services

Specialised areas

Automatisierung, Automatisierungslösungen, CAM, Clouver, PorCom, CNC, Entwicklungspartnerschaft, Industrie 4.0, Industrie of Things, IoT

ProCom Automation GmbH offers a wide range of products and services

Product

CNC300

Go to product >

Service

Clouver - IIoT Production Monitoring

Go to product >

Service

Clouver SmartKit

Go to product >

Service

Clouver Paperless

Go to product >

Service

CNC300 Software

Go to product >

Get insights into the use cases of ProCom Automation GmbH

Use case

Tailored Implementation

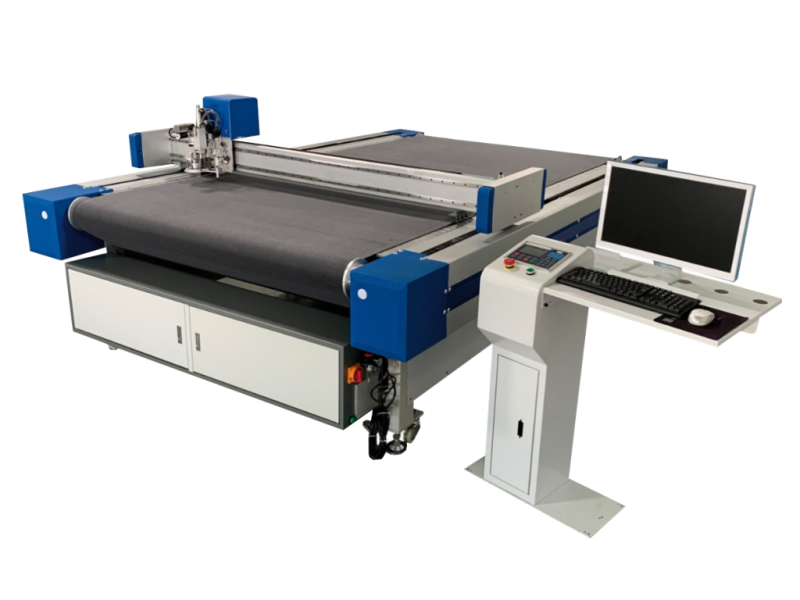

Automation, CNC, CuttingTechnology

ProCom Automation Carries Out the Commissioning of Its CNC300 Control System at Balacchi Srl in Record Time! Balacchi Srl, a leading manufacturer of precision machines, was faced with the challenge of modernising its CNC controls in Italy to increase both the productivity and precision of the machine. ProCom Automation took on the task and used its expertise to ensure a seamless transition from the outdated solution to the new one. The result exceeded all expectations.

Use case

Faster and More Efficient Thanks to Procom Control Solution

Automation, CNC, CuttingTechnology

ProCom Automation and bullmer are pleased to announce an important milestone in their long-standing cooperation. Thanks to innovative software optimisations in ProCom’s CNC controls, bullmer’s machines now cut 6% faster. This progress marks a significant gain in productivity for bullmer, the market leader in cutting and laying technology.

Some frequent questions that have been asked about ProCom Automation GmbH

How many employees does ProCom Automation GmbH approximately have?

As of the latest available information ProCom Automation GmbH has around 11-50 employees worldwide.

When was ProCom Automation GmbH founded?

ProCom Automation GmbH was founded in 1977

In which industries does ProCom Automation GmbH mainly work?

The company ProCom Automation GmbH has it's main focus in the industries of Automation

Check out some interesting alternative companies to ProCom Automation GmbH

ProCom Automation

Aachen, Germany

51-100 Employees

1973

All around us, we are surrounded by products created with the control solutions of ProCom Automation. Learn more about our products, services, and potential collaboration, as well as entry opportunities or partnerships. Insights gained from customer projects serve as catalysts for ongoing product evolution. With our cleverly designed products, you gain the added value that grants you the essential competitive edge in your market. Our support team is always readily available to provide professional advice and speedy support, prioritising your satisfaction above anything else. Our experts look forward to a personal exchange! ProCom products are ready for the future – today. Discover the world of ProCom Automation products and benefit from the powerful added values that will enhance your production and elevate your products.

Weidmüller GTI Software GmbH

Marktheidenfeld, Germany

11-50 Employees

1987

PROCON-WEB ES is a future-proof web HMI for ctrlX AUTOMATION. Our HMI applications support a wide range of requirements with state-of-the-art technology - from mechanical engineering to extensive SCADA solutions in industry. In addition, we also offer conception and design as an in-house service. The modular software kit offers numerous software elements that can be combined flexibly and without interface issues in order to create countless individual solutions that fit into the existing system landscape. In addition, there is the option of depositing and analysing the data via a cloud or OnPrem. With ResMa®, we offer an innovative, web-based system for the cross-site collection and evaluation of measured values from different measurement and control systems. Promote your energy efficiency and sustainably reduce CO² emissions with ResMa® and the diverse possibilities of the visualisation software. In addition, you can use our products for HMI/SCADA applications, resource and energy management and automated machine learning for your use cases and combine them with the modular elements.

PCam

Cadenazzo, Switzerland

11-50 Employees

1994

PCamMES, an intelligent digital manufacturing solution designed to optimize your operations, generate better cost control and traceability, and create optimal scheduling. Each of our products is designed to simplify production processes and maximize your production potential. When you choose PCam.com, you are investing not just in a product, but in a future of intelligent manufacturing. Experience the future today with PCam.com, the market leader in automation and software for tool and mold making in the age of Industry 4.0. PCam offers innovative Industry 4.0 solutions in process automation and integration, specifically developed for tool and mould making. We specialize in advanced software, state-of-the-art control systems, state-of-the-art robots and comprehensive remote monitoring for machine tools. PCam RoboCube, our flexible automation system, was developed to unlock more productive potential with little investment. PCamMonitor is an industry-leading CNC machine monitoring system specifically designed for the precision machining, tooling, injection molding, stamping and extrusion industries.

CNC PROS

Phoenix, United States

1-10 Employees

2004

We are pleased to announce that AME, Inc. As the CNC PROS team has continued to grow, and add world-class products to our portfolio, the CNC PROS team comes first and, as we like to say, “the founding partners will always eat last!”. To remain competitive in today’s market, you have to offer your customers a better solution than your competition. Delivering CNC Machine Tool Sales & Service, Automation, & Engineering Excellence to Arizona & Colorado. We offer a full range of CNC sales, service, automation, and engineering solutions from our offices in Arizona and Colorado. We can recommend a fully engineered turnkey solution, delivered to your floor. CNC PROS exists to provide excellence to our customers, so you can provide excellence to yours. CNC PROS is proud to have the most diverse and wide-ranging product offering in the Arizona and Colorado CNC markets.

ComPro International

Burlington, Canada

1-10 Employees

-

All our products and services have been developed to ensure maximum longevity both mechanically and technologically. At Compro we strive to provide the best solution to our clients while maintaining a cost effective approach. Allan Rogen has conceived, formulated and commercialized new products, and received 12 patents in renewable products. Vince Neves leads the development, market entry and expansion of new technologies, products and business units and has over 40 years of experience in mechanical engineering in the manufacture of pressure vessels, heat exchangers, and process piping. Compro International is a leader in the design and manufacture of packaged systems and process modules for the oils and fats industry. Companies recognize that system components are most efficiently engineered and integrated off-site and then delivered on site as preassembled modules. This turnkey approach means that we are accountable to our customers at every stage of the project. The systems are available in a number of sizes embracing a broad range of production rates.

ProMetronics

Berlin, Germany

1-10 Employees

-

ProMetronics is a customised solution for supplementing and expanding the existing process control system with sensor data; it can be used for all levels of automation and does not interrupt any established processes.Data exchange with the existing process control is realised via universal connectors such as an Enterprise Service Bus. Implement the ProMetronics engine to your production management system. Prometronics' mobile app service offers users of our solution access to data and control functions directly on the shop floor or in the R&D lab. Data-Driven material analysis integrated to the process control in manufacturing enables dynamic automation, process optimization, and real time quality control. Data driven material analysis enables to manufacture optimized functionality on products. Introduce AI analysis & material sensorics to the production line to accelerate machine tuning, minimize loss and minimize cost. Create customized quality standards for your portfolio and enhance production management and speed up workflow control. The Software solution is extremely easy to operate.