We are always eager to extend the functionality of SPIN. Our technology is patented and allows us to offer amazing inspection solutions throughout the most complex of requirements. In-line inspection, where the structure is inspected directly after the manufacturing process, is the best way to ensure quality and increase yield. From Automotive, Consumer Electronics to Pharmaceuticals our customers produce leading technology. We want to always be at the forefront of technology with our products, while offering an efficient and at the same time pleasant, productive working environment for our employees. In- and Off-Line Inspection as well as any degree of automation can be delivered.

Puchheim, Germany

Founded in 2003

1-10 Employees

Working industry

Other

Type of company

Manufacturer

Locations

1 Headquarter

Number of products

3 Products

Specialised areas

Navigational, Measuring, Electromedical, and Control Instruments Manufacturing, Machinery, Equipment, and Supplies Merchant Wholesalers, Computer and Electronic Product Manufacturing, Manufacturing, Surface area analyzers Measuring and testing equipment, electrical

Stratus Vision GmbH offers a wide range of products and services

Product

Inspections Solutions - Stratus Vision AOI

Go to product >

Product

Software Engineer - Stratus Vision AOI

Go to product >

Product

SPIN - Stratus Vision AOI

Go to product >

An estimation about the ESG values based on digital data and signals. Important: The ESG scores are only based on information about the country, not the actual company itself

Country:

Germany

Overall risk estimation:

Very low

The ESG Data of countries are based on public sources

Environment

A

Grade (A-E)

View details

Social

A

Grade (A-E)

View details

Governance

A

Grade (A-E)

View details

Get insights into the use cases of Stratus Vision GmbH

Use case

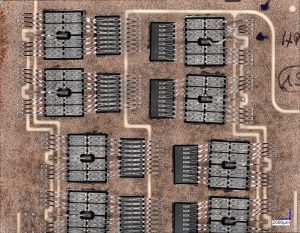

AOI Applications - Stratus Vision AOI

Wirebond Inspection Learn more about unique CAD based wirebond inspection. This will allow you to inspect your bond wires faster and more efficiently LEARN MORE Laser Trim Inspection Learn more about the automated Laser Trim Inspection for screen printed resitors LEARN MORE Print Shift Inspection Learn more about the automated print offset calculation of ceramic… Read More »AOI Applications

Use case

Wirebond Inspection - Stratus Vision AOI

Wirebond Inspection Easily generate wirebond inspection based on CAD Data Effortlessly create applications with AI-driven technology Comprehensive inspection of your electronics – from wirebond to chip and conductor Wirebond error detection – uncovering all common issues Rapid wirebond inspection for large-scale electronics – 8″x8″ are inspected in just 30 seconds Stratus Visions… Read More »Wirebond Inspection

Stratus Vision GmbH operates in 1 country around the world

Get an overview of the locations of Stratus Vision GmbH

Location

Country

State

City

Headquarter

Germany

Bavaria

Puchheim

Some frequent questions that have been asked about Stratus Vision GmbH

Where is Stratus Vision GmbH located?

The company headquarter of Stratus Vision GmbH is located in Puchheim, Bavaria, Germany. It's worth noting, that the company may have more locations

How many employees does Stratus Vision GmbH approximately have?

As of the latest available information Stratus Vision GmbH has around 1-10 employees worldwide.

When was Stratus Vision GmbH founded?

Stratus Vision GmbH was founded in 2003

In which industries does Stratus Vision GmbH mainly work?

The company Stratus Vision GmbH has it's main focus in the industries of Other

Check out some interesting alternative companies to Stratus Vision GmbH

Inndeo Engineering

Zaragoza, Spain

11-50 Employees

2014

At INSPECTRA we design and manufacture machine vision equipment with the latest technologies, selecting the most suitable and adapting them to each client and product. Our equipment offers the highest inspection performance on the market and is easily integrated into production lines and customer management systems. We digitise 100% of production: INSPECTRA equipment inspects 100% of production, digitising all data and facilitating access to its processing and interpretation to optimise the production process, improve supplier control and reduce penalties for end customers. We design and manufacture artificial intelligence vision machines tailored to the quality processes of our customers, we select the most appropriate vision technology for each project, carrying out initial feasibility tests in our laboratory. Our equipment is integrated into the production management systems, reporting in real time the productivity and quality indicators of the production line, providing the following benefits:. We avoid quality issues in the products: We inspect 100% of the production, which allows us to avoid quality issues in the products that in many occasions produce the rejection of a batch of products, avoiding the over costs of destruction, replacement and transport of the defective items. We digitize quality and production data: Our equipment captures data from all production, which allows us to obtain information on the quality of the data that allows us to establish objective evaluation criteria for raw material suppliers, and also allows us to improve processes based on the analysis of production data. In some of our inspection equipment such as the SLICE INSPECTOR we integrate high-speed matrix cameras, allowing us to monitor processes that happen at very high speed, such as slicing, in which images are captured by tracking the position of the blade on the block, determining the frames in which there is no occlusion of this on the product and the slice can be captured in an ideal way, to process it through our vision and artificial intelligence programs on the slice.

Retina Systems Inc.

Seymour, United States

1-10 Employees

-

Quite simply, we are in the business of helping our customers build trust and keep operational promises to gain a competitive advantage. We are trusted by the aerospace industry for inspection of critical fastener applications that keep aircrafts operating safely. Building long-term partnerships with each customer, no matter the production size, products, or ticker symbol. Automated turnkey inspection systems and applications will deliver “Zero Defect” part inspection for defined attributes and real-time information to ensure quality assurance, reduce scrap, and no returned shipments. Our team can assist in adding new parts, troubleshoot issues, or provide training remotely and restore your operations to maximum efficiency with minimal downtime. We have the resources available on-site to support our equipment in pharmaceutical manufacturing with a team of service, application, and support technicians on demand, putting medical safety and health at the forefront. Boost your plastic production quality with our state-of-the-art quality assurance and process control solutions. Every quality promise, every delivery commitment represents an opportunity to build that trust.

SINGA

Varsseveld, Netherlands

11-50 Employees

1996

Our goal is to help businesses improve their production quality and ensure that consumers receive top-notch products. In doing this, we are deeply committed to making a positive impact on the world by supporting the Sustainable Development Goals and setting the bar high in prioritizing People, Planet, and Profit concerns. Our unique Twinport 360 is a revolutionary 3D Vision quality control system. It enables us to scan products in 3D with exceptional speed and precision. With this technology, we perform accurate measurements and identify defects, optimizing production processes and helping companies save costs. With our groundbreaking technology, we offer a reliable and efficient solution for quality monitoring in the honeycomb production process. At SINGA, we believe that technology and AI are the keys to solving complex problems. We're passionately dedicated to developing Vision & AI systems that make products more efficient and outstanding.

SINGA

Varsseveld, Netherlands

11-50 Employees

1996

Our goal is to help businesses improve their production quality and ensure that consumers receive top-notch products. In doing this, we are deeply committed to making a positive impact on the world by supporting the Sustainable Development Goals and setting the bar high in prioritizing People, Planet, and Profit concerns. Our unique Twinport 360 is a revolutionary 3D Vision quality control system. It enables us to scan products in 3D with exceptional speed and precision. With this technology, we perform accurate measurements and identify defects, optimizing production processes and helping companies save costs. With our groundbreaking technology, we offer a reliable and efficient solution for quality monitoring in the honeycomb production process. At SINGA, we believe that technology and AI are the keys to solving complex problems. We're passionately dedicated to developing Vision & AI systems that make products more efficient and outstanding.

SPIN 360

Milan, Italy

11-50 Employees

2009

That’s our vision and it is why SPIN 360 exists – we want to accompany companies on their path to sustainable growth. SPIN 360 has since grown and now operates in several industries: Fashion & design, Leather, Textile & Apparel, Footwear, Electricity, Automotive, Batteries, Wood and Furniture, Banking & Finance, Electric Energy Production & Distribution, Pulp & Paper. Our raw materials are the industry’s needs, our products are analyses, projects and tools that aim to improve the way people and businesses operate. Every day, we help companies and institutions implement innovative development models that generate profit while improving their environmental and social sustainability and that contribute to professional growth and to the improvement of individual working conditions. This means providing customers with our expertise and network of experts to develop advanced services in support of the research and implementation of long-term sustainability solutions for industries and their supply chains. This is what constitutes progress and it is the key to the future success of a business. Over the years, we have built a network of contacts operating in different countries and with different skill sets. They include researchers, consultants and top-notch companies that offer very specific solutions.

QES Group

Shah Alam, Malaysia

101-250 Employees

1991

We aim to be the leading integrated solutions provider serving customers with world class products in analytical, inspection, test, measuring, automation, and related services. We excel in every area of our technology-driven products and services, striving to be a sustainable business that meets the needs of our clients. By focusing on these key areas, we have built a reputation for excellence that sets us apart from the competition. We have evolved into a value-added solutions provider over the past three decades, expanding our reach into diverse market segments that include semiconductor, automotive, electrical and electronics, petrochemical, research and development, metal and mining, environment and renewable energy. With our broad portfolio of products and solutions, we are committed to serving your needs in the semiconductor industry and beyond. Whether you are in research and development or large-scale manufacturing, we have the expertise and resources to help you succeed. Our company is a leading global manufacturer of inspection and handling equipment, thanks to our cutting-edge technology and highly skilled staff. Our strong R&D program and technology partnerships allow us to offer a wide range of products, including optical-based stereo, macro, and micro inspection tools, as well as fully automatic 2D and 3D vision systems.