Production stoppages, bottlenecks, and delays in pallet handling are expensive and inefficient. Enter Global AGV! Our intuitive logistics solution takes care of routine tasks, eradicates delays, and removes limitations. Global AGV is easy to use, simple to install, and guarantees safety within existing environments in just 2-3 days. In other words, streamline internal transportation through easy automation, suited for businesses of any type and size.

Nykøbing Mors, Denmark

Founded in 2016

11-50 Employees

Working industry

Automation, Logistics, Supply Chain and Transportation

Type of company

Manufacturer, Service provider

Locations

1 Headquarter

Number of products

2 Products

Specialised areas

AGV, Automated Guided Vehicle

www.global-agv.com offers a wide range of products and services

Product

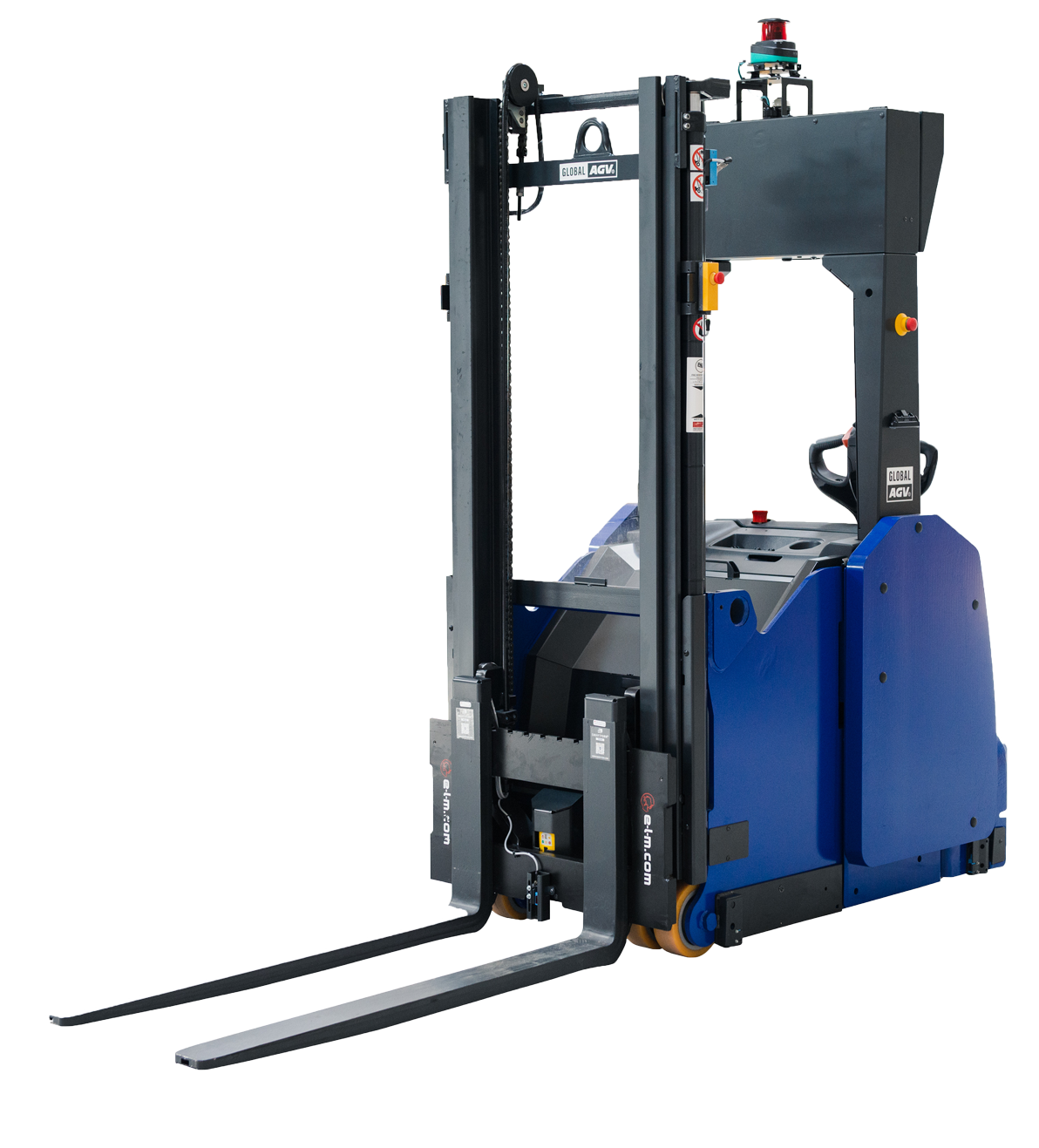

Global AGV L14

Go to product >

Product

Global AGV L12

Go to product >

An estimation about the ESG values based on digital data and signals. Important: The ESG scores are only based on information about the country, not the actual company itself

Country:

Denmark

Overall risk estimation:

Very low

The ESG Data of countries are based on public sources

Environment

A

Grade (A-E)

View details

Social

A

Grade (A-E)

View details

Governance

A

Grade (A-E)

View details

Get insights into the use cases of www.global-agv.com

Use case

MillPart extends production time 7 hours with Global AGV

Metal

Extended production time by 6-7 hours MillPart provides hydraulic components to global companies and boasts one of Denmark's most advanced machine facilities. Prioritising quality without compromise, MillPart places a strong emphasis on leveraging automation in both production processes and enhancing the working environment. Their recent investment in a new robot cell presented the perfect opportunity to incorporate Global AGV to automate numerous heavy pallet transfers to and from these robot cells.

Use case

Welltec leverages employee resources better with Global AGV

Metal

Welltec leverages employee resources better with Global AGV With Global AGV, Welltec can enhance production by efficiently transporting raw materials from saw to manufacturing, optimising employee resource utilisation, achieving smoother production, and ensuring a future-proof production environment.

www.global-agv.com operates in 1 country around the world

Get an overview of the locations of www.global-agv.com

Location

Country

State

City

Headquarter

Denmark

North Denmark Region

Nykøbing Mors

Some frequent questions that have been asked about www.global-agv.com

Where is www.global-agv.com located?

The company headquarter of www.global-agv.com is located in Nykøbing Mors, North Denmark Region, Denmark. It's worth noting, that the company may have more locations

How many employees does www.global-agv.com approximately have?

As of the latest available information www.global-agv.com has around 11-50 employees worldwide.

When was www.global-agv.com founded?

www.global-agv.com was founded in 2016

In which industries does www.global-agv.com mainly work?

The company www.global-agv.com has it's main focus in the industries of Automation, Logistics, Supply Chain and Transportation

Check out some interesting alternative companies to www.global-agv.com

Kollmorgen Automation

Mölndals kommun, Sweden

1001-5000 Employees

-

Automated Guided Vehicles (AGVs) and Mobile Robots improve efficiency in manufacturing and warehousing without heavy investments.

NDC SOLUTIONS LTD

United Kingdom

1-10 Employees

-

Automated Guided Vehicles (AGVs) and Mobile Robots improve efficiency in manufacturing and warehousing without heavy investments.

AGV America

San Antonio, United States

1-10 Employees

2020

We are professional SMEs representing nearly 100 years of working knowledge and experience. We are conveniently located in San Antonio, TX, ideally situated to respond to your needs quickly and efficiently. At AGV America, we are dedicated to providing innovative and reliable automated solutions that help our clients achieve their business goals. With our state-of-the-art technology and experienced team of professionals, we are committed to improving your material handling operations and increasing your bottom line, allowing you to stay productive in the fast-paced world of manufacturing and industrial automation. Our automated systems are designed to operate in complex environments and handle a variety of payloads. At AGV America, we understand that every manufacturing facility is unique, and that’s why we take a collaborative approach to designing and implementing our AGV solutions. Our experienced team of engineers and technicians provides complete turnkey solutions, from initial consultation and design to installation and ongoing maintenance. We also offer comprehensive training to ensure that your team can operate and maintain our AGV systems with ease.

Active Space Automation

Coimbra, Portugal

11-50 Employees

2017

Our automated solutions for transporting materials and goods in manufacturing and storage facilities are highly flexible, efficient and adapted to customers' infrastructure and organization. Design, develop and manufacture of AGVs from scratch, on all components (mechanical, control and electronics). Development of automation parallel to AGV processes in order to deliver turnkey systems.

The Rubic

Calgary, Canada

1-10 Employees

2020

Unlock the potential of automation with a warehouse-agnostic, autonomous robotic system, designed to operate seamlessly within your existing facilities, exactly as they are. Our patented stabilization system provides us with the assurance to safely maneuver at height and high speeds with minimal sway, and maximum safety.

Robotic Automation

Sydney, Australia

11-50 Employees

1988

We are an automation company that specialises in the automation of repetitive tasks and processes at your site to maximise productivity, quality, safety and efficiency while reducing damages and costs. Our services can start with an obligation-free audit of your site’s automation potential. We accepted the challenge presented to us by the Royal Adelaide Hospital. This challenge was to modernise their Hospital AGV System (Automated Guided Vehicle) in a fully functioning and active hospital of 800 beds. What were the Hospital AGV System upgrade requirements? A life cycle upgrade was needed for the Royal Adelaide Hospital’s Automated Guided Vehicle system consisting of a ….