The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Aero-Space Fasteners and Electronics

Bloomington, United States

B

11-50 Employees

1963

Key takeaway

Aero-Space specializes in engineered fasteners and electro-mechanical components, catering to the aerospace sector among others. Their extensive inventory and partnerships with top manufacturers ensure high-quality solutions for electronic enclosures and power management applications.

Reference

Core business

Aero-Space Computer Supplies - Minneapolis, Minnesota | Engineered Fasteners, Electronic Components, Cable Assemblies, Aero-Space, Industry

Aero-Space Fasteners and Electronics Specializes in Engineered Fasteners, Electronic Components, Cable Assemblies, Castings, Plastics, Mechanical Hardware, Printed Circuit Boards, and More. Established in 1963, Aero-Space is an AS9120 certified and factory authorized distributor. Through our large inventory and creative supply chain solutions, we partner with our manufacturers to provide the best customer

AsteelFlash

Neuilly-Plaisance, France

A

5001-10000 Employees

1999

Key takeaway

Asteelflash is a prominent aerospace electronics manufacturer that offers advanced electronic manufacturing services specifically tailored for the aerospace sector, including in-flight entertainment and avionics. With dedicated Aerospace Excellence Centers, Asteelflash emphasizes innovative manufacturing solutions and technical expertise to enhance competitiveness in the aerospace market.

Reference

Service

Aerospace Electronics Manufacturer | Asteelflash

High-end EMS aerospace solutions. From in-flight entertainment to avionics, Asteelflash is a leading aerospace electronics manufacturer backed by experience.

INTERPOINT SOLUTIONS LIMITED

Cherwell District, United Kingdom

A

1-10 Employees

-

Key takeaway

Crane Aerospace & Electronics specializes in providing innovative design and manufacturing engineering capabilities for rugged commercial aviation, defense, and space applications. With a strong commitment to quality and customer care, they serve as a comprehensive source for various aerospace electronics solutions.

Reference

Core business

Crane Aerospace & Electronics

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

esc Aerospace

Taufkirchen, Germany

A

51-100 Employees

1999

Key takeaway

The esc Aerospace group of companies specializes in innovative R&D and complex systems development, making it a key player in the aerospace electronics sector. With over 20 years of experience and a team of experts, they offer full-service systems integration and solutions in areas such as sensor integration and autonomy.

Reference

Core business

esc-aerospace.com – esc Aerospace

Heico

Hollywood, United States

B

1001-5000 Employees

1949

Key takeaway

HEICO Corporation specializes in aerospace and electronics, providing high-reliability components for demanding applications like aircraft and spacecraft. Their Electronic Technologies Group designs and manufactures critical electronic components used in aviation, defense, and space exploration.

Reference

Core business

HEICO - Camtronics

SPECTRUM LASER & TECHNOLOGIES INC

Colorado Springs, United States

B

11-50 Employees

-

Key takeaway

The company specializes in high-reliability electronic manufacturing services, including circuit card assembly and cable/harness manufacturing, specifically for the military and aerospace sectors.

Reference

Service

Military / Aerospace Electronics – Spectrum

Aerospace Embedded Solutions

Munich, Germany

A

51-100 Employees

2013

Key takeaway

AES Aerospace Embedded Solutions GmbH specializes in providing safety-critical hardware and software components for the aerospace industry. With a focus on high-performance embedded solutions and a team of experienced engineers, the company ensures engineering excellence throughout the product lifecycle, making it a key player in aerospace electronics.

Reference

Core business

AES | Aerospace embedded solutions

AES is a leading provider of safety critical hardware and software components. We deliver

Advionics nv

Oostkamp, Belgium

A

51-100 Employees

1960

Key takeaway

Advionics specializes in the development and manufacturing of advanced avionic systems, providing high-tech electronic solutions for the aviation industry. With over 50 years of experience in RF electronics, the company ensures the quality and reliability of its products through rigorous testing and a comprehensive service offering that covers the entire product life cycle.

Reference

Core business

Advionics - An Intersoft Electronics Company

Based on a vast experience in avionics and wave technology we offer high-tech electronic solutions for the aviation industry.

Axis Aerotech, Inc.

Naples, United States

B

1-10 Employees

1998

Key takeaway

Axis Aerotech specializes in avionics sales and services for both military and commercial systems, highlighting its expertise in aerospace electronics. Their modern repair facility is equipped with advanced test equipment, ensuring high-quality support for avionics.

Reference

Core business

Axis Aerotech, Inc. – Avionics Repair and Overhaul Services

Aerospace Orbit

Spokane, United States

B

11-50 Employees

2017

Key takeaway

Aerospace Orbit is a dedicated procurement platform that provides next-generation solutions for the aerospace and defense industries, supplying over 3 billion parts from trusted manufacturers like Airbus and Boeing. With a focus on responsive account management and a comprehensive supply-chain network, they specialize in sourcing hard-to-find aviation parts and electronic components.

Reference

Core business

Aircraft Parts, NSN Parts, Electronic Components Distributor - Aerospace Orbit

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Custom Electronics

Go to product

Service

PCB assembly

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

Use case

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

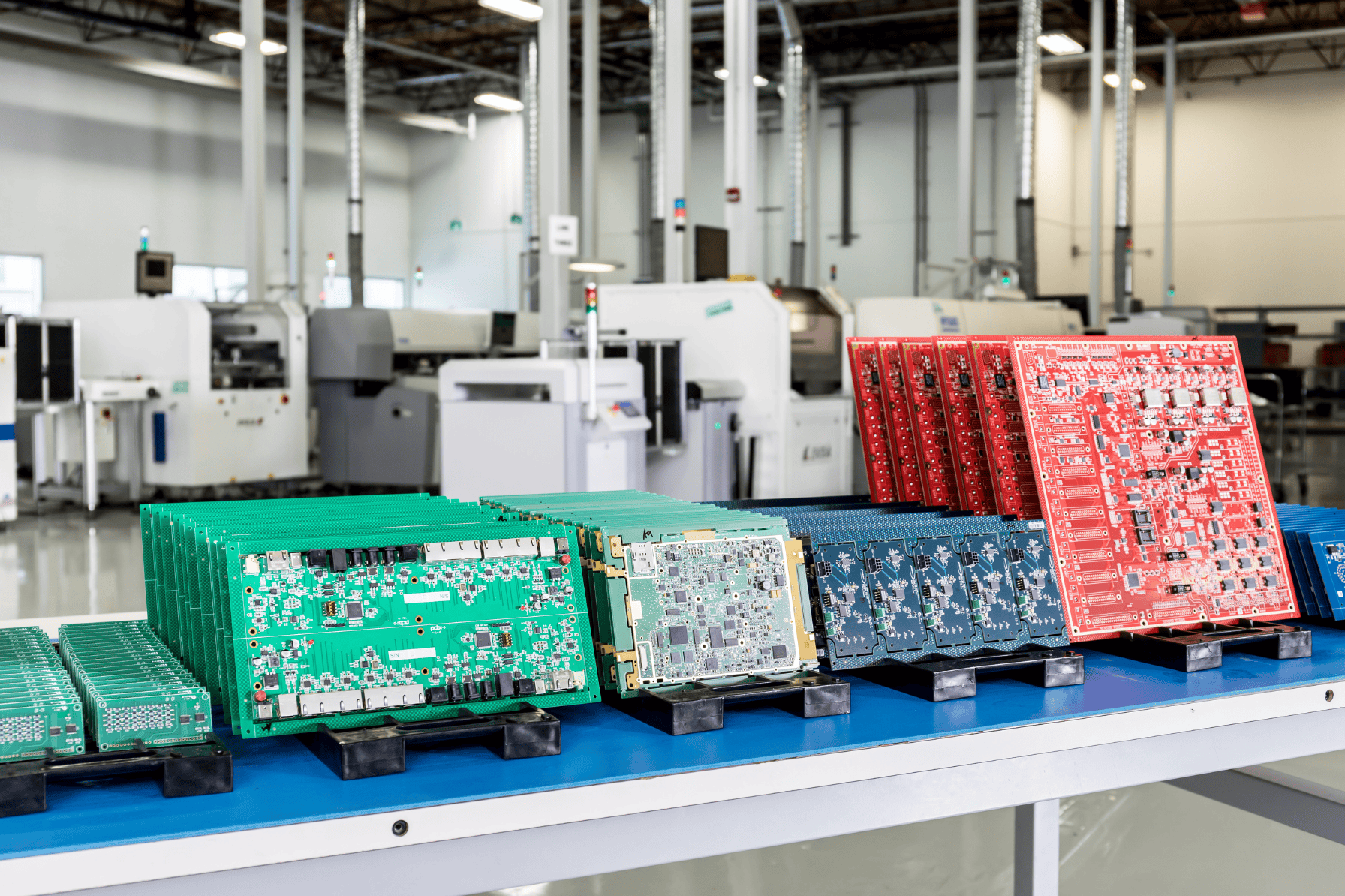

Aerospace electronics refers to the specialized electronic systems and components used in aircraft, spacecraft, and related systems. These electronics are crucial for various functions, including navigation, communication, flight control, and monitoring of aircraft systems. Designed to withstand extreme conditions, aerospace electronics must meet rigorous standards for reliability and performance. Components like avionics systems, sensors, and actuators play a vital role in ensuring safe and efficient operations. The development of these electronics often involves advanced technologies, such as embedded systems, to enhance functionality and reduce weight. As the aerospace industry continues to evolve, the demand for innovative aerospace electronics is growing, driving advancements in technology and design.

Aerospace electronics play a vital role in enhancing aircraft performance through advanced systems that optimize various functions. These electronics support avionics systems, which include navigation, communication, and flight control. By integrating sophisticated sensors and data processing units, aerospace electronics provide real-time information to pilots, enabling more informed decision-making and improved situational awareness. Moreover, they contribute to fuel efficiency by monitoring engine performance and optimizing flight paths. This not only reduces operational costs but also minimizes environmental impact. The continuous advancements in aerospace electronics, such as fly-by-wire systems and automation, lead to increased reliability and safety, ultimately enhancing overall aircraft performance in both commercial and military applications.

1. Avionics Systems

These are essential for communication, navigation, and monitoring within aerospace vehicles. They integrate various instruments and components that enhance situational awareness and operational efficiency.

2. Flight Control Systems

These components are critical for the stability and control of an aircraft. They include autopilot systems, fly-by-wire technology, and other mechanisms that ensure precise maneuverability and safety during flight.

3. Power Management Systems

Power distribution and management are vital in aerospace electronics. These systems regulate energy supply to various components, ensuring that all electronic systems function optimally without interruption.

4. Sensors and Data Acquisition

Sensors play a crucial role in gathering real-time data on environmental conditions, aircraft performance, and system health. This information is vital for decision-making and operational adjustments during flights.

5. Display Systems

These systems provide pilots and crew with critical information through various interfaces. Advanced display technologies, such as heads-up displays (HUDs) and multifunction displays (MFDs), enhance situational awareness and improve operational efficiency.

Aerospace electronics play a crucial role in satellite technology, enabling various functionalities essential for communication, navigation, and observation. These electronics include components such as sensors, processors, and communication systems that facilitate data transmission between satellites and ground stations. The integration of advanced avionics ensures that satellites can operate effectively in the harsh environment of space, providing reliable performance over extended periods. Moreover, aerospace electronics contribute to the satellite's ability to process data onboard, allowing for real-time analysis and decision-making. This capability is vital for applications like Earth observation, where timely data collection enhances monitoring of environmental changes. Enhanced signal processing and power management systems also ensure that satellites can maintain stable operations, thus maximizing their lifespan and utility in various missions.

Recent advancements in aerospace electronics focus on improving performance, efficiency, and safety in aviation systems. One significant development is the integration of advanced materials like lightweight composites and flexible electronics, which enhance the durability and reduce the weight of avionics systems. Another notable trend is the adoption of artificial intelligence and machine learning in avionics for predictive maintenance and enhanced decision-making processes. These technologies enable real-time data analysis, improving system reliability and reducing operational costs. Additionally, advancements in satellite communication and navigation systems are enabling more accurate and efficient air traffic management, resulting in improved safety and capacity in increasingly crowded airspace.

Some interesting numbers and facts about your company results for Aerospace Electronics

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1949 |

| Youngest suiting company | 2017 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Aerospace Electronics

What are related technologies to Aerospace Electronics?

Based on our calculations related technologies to Aerospace Electronics are Space Technologies, Military, Commercial Aviation, Airport Security

Which industries are mostly working on Aerospace Electronics?

The most represented industries which are working in Aerospace Electronics are Electronics and Electrical engineering, Other, Aviation and Aerospace, IT, Software and Services, Defense

How does ensun find these Aerospace Electronics Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.