The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

MetaCoat

Lummen, Belgium

A

11-50 Employees

2000

Key takeaway

MetaCoat specializes in powder coating for all types of metals, including aluminum, steel, and galvanized steel, and offers comprehensive services such as shot blasting, chemical treatment, and quality control.

Reference

Service

Metacoat - Services

MetaCoat specializes in the powder coating of all types of metals. Aluminium, steel and galvanized steel can undergo an appropriate mechanical and/or chemical pre-treatment in several steps. For more information, check out our website.

Electro Coatings

-

11-50 Employees

-

Key takeaway

Electro-Coatings specializes in a variety of metal coating services, including electroplating and electroless nickel plating, which are essential for enhancing durability and performance. Their commitment to quality and effective communication makes them a preferred choice for customers in the coatings industry.

Reference

Core business

Industrial Metal Coating & Plating Services | Electro-Coating

Metal Cladding

City of Lockport, United States

B

- Employees

-

Key takeaway

The company offers a wide range of advanced coatings, including metal coatings, with expertise in innovative applications like fluoropolymers and antimicrobial technologies. Their operations are designed to handle various volumes, catering to specific coating requirements from small parts to large-scale production.

Reference

Service

Services - Coil Coating - Ecoat - Industrial Metal Coatings

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Active Metal Finishing Company Ltd.

Canada

A

11-50 Employees

1956

Key takeaway

The company, The Metal Finishing Center, specializes in comprehensive metal coating and powdercoating services, particularly for large and technically challenging projects. With extensive experience and a commitment to quality, they support a diverse range of industries, making them a key player in the metal finishing sector.

Reference

Core business

Metal Finishing | Toronto, Burlington, Hamilton, Southern Ontario

Experts in high volume and large size requirements for metal finishing, electroplating, powdercoat, shotblast, metal cleaning and assembly.

Certified Enameling

Los Angeles, United States

B

- Employees

1953

Key takeaway

Certified Enameling, Inc. specializes in metal coating services, offering a range of options like Kynar® coating, powder coating, and their proprietary technology, Cenamelize. With a strong reputation since 1953, the company is a leader in architectural metal finishes and coatings.

Reference

Service

Metal Coating Services |Certified Enameling, Inc.

CONQUEROR INDUSTRIES LIMITED

North Hertfordshire, United Kingdom

A

11-50 Employees

1991

Key takeaway

Conqueror Industries is a leader in the metal coating and finishing industry, offering a wide range of services such as powder coating and wet paint spraying. With a commitment to quality and reliability, they serve clients across various sectors throughout the UK.

Reference

Core business

Powder Coating | Wet Paint Spraying | Metal Coating | Conqueror

Conqueror Industries offers a comprehensive range of metal coating services. Established in 1992 serving customers across the UK.

Progressive Metal Service Inc.

United States

B

11-50 Employees

1981

Key takeaway

Progressive Metal Service, Inc. (PMSI) operates a comprehensive coating facility, specializing in various industrial applications. Their expertise in coating, combined with a commitment to quality and quick turnaround times, makes them a reliable partner for industries such as aerospace and defense.

Reference

Service

Coating | Progressive Metal Service

Metal Coatings Corp.

Houston, United States

B

51-100 Employees

1974

Key takeaway

Metal Coatings Corp. specializes in the protective industrial metal coating of machined components, fasteners, and assemblies, using advanced techniques for applying thermosetting fluoropolymers and other coatings. Their extensive production area and commitment to quality ensure efficient processing and compliance with industry standards.

Reference

Core business

Protective Industrial Metal Coatings Services | Metal Coatings

Al Asriah (Metal Coating W/shop)

Musaffah, United Arab Emirates

C

51-100 Employees

-

Key takeaway

The company specializes in advanced metal coating services, offering a variety of finishes suitable for different metals, including aluminum and steel, which is highly relevant for applications in the electronics industry. Their expertise includes various plating techniques, ensuring high-quality results for diverse shapes and sizes.

Reference

Core business

About Us – Alasriah Powder Coating Dubai

County Coatings

Lincoln, United Kingdom

A

- Employees

-

Key takeaway

County Coatings specializes in applying protective powder coatings to metal surfaces, offering a wide range of colors and finishes for both large and small items. Their expertise and competitive pricing make them a go-to choice for various sectors, including gates, railings, and metalworking.

Reference

Core business

County Coatings

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

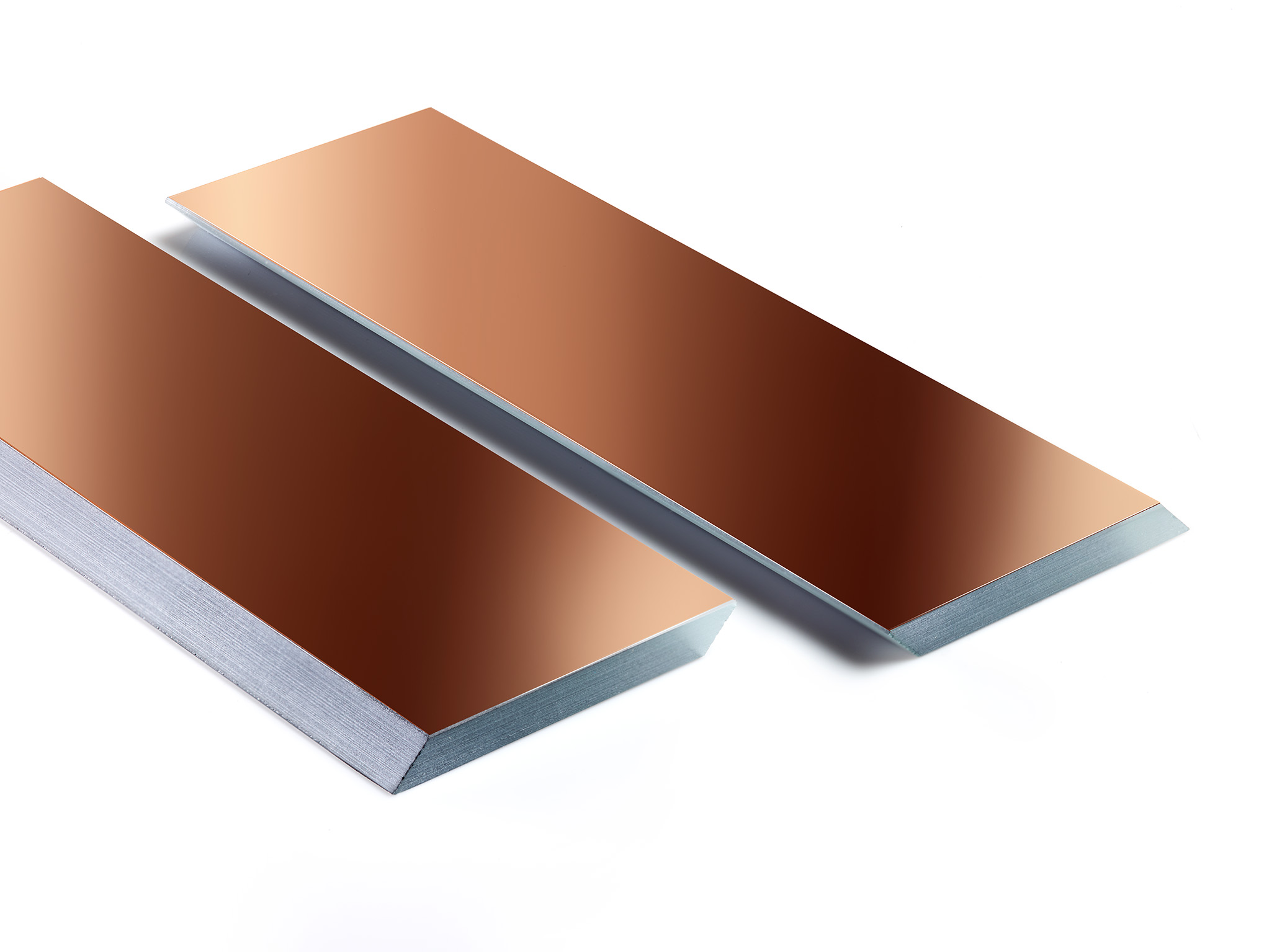

Service

Optical coating: Copper mirror

Go to product

Product

Metal Fabrication Parts

Go to product

Product

ITO Target for PVD

Go to product

Product

Zr target for PVD

Go to product

Metal coating refers to the application of a protective layer on metal surfaces to enhance durability, corrosion resistance, and aesthetic appeal. This process can involve various techniques, including electroplating, galvanizing, powder coating, and anodizing. Each method serves specific purposes, such as improving wear resistance or providing a decorative finish, while also extending the lifespan of the metal components in various applications. By utilizing metal coating, manufacturers can ensure their products perform optimally in challenging environments, thereby reducing maintenance costs and enhancing overall functionality.

1. Corrosion Resistance

Metal coating significantly enhances the corrosion resistance of base materials. This is crucial for items exposed to harsh environments, as it prevents rust and degradation over time.

2. Improved Aesthetic Appeal

Coatings can provide a visually appealing finish, which is important for consumer products. This aesthetic enhancement can also increase the market value of items by making them more attractive to buyers.

3. Enhanced Durability

A coated surface typically exhibits greater durability. This increased toughness protects against scratches, wear, and tear, ensuring that the product maintains its integrity over an extended period.

4. Thermal and Electrical Conductivity

Certain coatings can optimize thermal and electrical conductivity. This property is vital in applications such as electronics, where efficient heat dissipation and electrical performance are essential.

5. Environmental Protection

Metal coatings can serve as a barrier against environmental factors, protecting the substrate from exposure to moisture, chemicals, and UV radiation. This protection is especially beneficial in outdoor applications.

Metal coating is typically applied through various processes, each designed to enhance the surface properties of metals. One common method is electroplating, where a metal coating is deposited onto a substrate via an electric current in a solution containing metal ions. This process ensures a uniform layer that adheres well to the base metal. Another widely used technique is thermal spraying, which involves heating metal powders or wires and spraying them onto the surface to create a protective layer. This method allows for thicker coatings and can be used to build up worn surfaces. Both methods are effective in improving corrosion resistance, wear resistance, and overall durability of metal components.

Various materials can be utilized for metal coating, enhancing the properties of the base metal.

1. Zinc

Zinc coatings, commonly known as galvanization, are used to protect steel from corrosion.

2. Aluminum

Aluminum coatings provide excellent resistance to oxidation and corrosion, making them ideal for outdoor applications.

3. Chrome

Chrome coatings offer a high level of hardness and a reflective finish, often used in decorative applications.

4. Nickel

Nickel coatings improve wear resistance and corrosion protection, frequently applied to automotive parts and industrial components.

5. Copper

Copper is used for its excellent electrical conductivity and is often applied in electronic components.

6. Polymer Coatings

Polymer coatings can be applied to metals for added chemical resistance and aesthetic finishes.

These materials are chosen based on the specific requirements of the application, such as environmental exposure, desired durability, and aesthetic preferences.

1. Automotive Industry

Metal coating is extensively used in the automotive sector to enhance durability and resistance to corrosion. This ensures that vehicle components can withstand harsh environmental conditions.

2. Aerospace Industry

In aerospace, metal coatings are critical for protecting components from extreme temperatures and wear. The coatings improve performance and longevity, which is essential for safety and efficiency in flight.

3. Electronics Industry

The electronics industry utilizes metal coatings to improve conductivity and protect sensitive components from oxidation. This is crucial for maintaining the reliability of electronic devices.

4. Construction Industry

In construction, metal coatings are applied to structural elements and fixtures to prevent rust and extend the lifespan of buildings and infrastructure. This contributes to overall safety and maintenance costs.

5. Marine Industry

Marine applications often require metal coatings to resist saltwater corrosion. This is vital for the longevity and maintenance of ships and offshore structures.

Some interesting numbers and facts about your company results for Metal Coating

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 9115 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1953 |

| Youngest suiting company | 2000 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Metal Coating

What are related technologies to Metal Coating?

Based on our calculations related technologies to Metal Coating are Aromatics, Desiccants, Refrigerants, Resins, Green Chemistry

Which industries are mostly working on Metal Coating?

The most represented industries which are working in Metal Coating are Other, Construction, Manufacturing, Mining, Chemicals

How does ensun find these Metal Coating Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.