The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

S1 Optics GmbH

Nürtingen, Germany

A

1-10 Employees

2001

Key takeaway

S1 Optics GmbH specializes in providing high-quality optical coatings, including dielectric coated and metallized reflectors, essential for various industrial applications. Their expertise encompasses the necessary analysis technology to ensure coating quality, making them a key player in the optical coatings market since 2005.

Reference

Service

Optical coatings for your components

Bte Bedampfungstechnik GmbH

Elsoff (Westerwald), Germany

A

51-100 Employees

1992

Key takeaway

The company specializes in innovative coating designs that modify the physical surface properties of glasses, plastics, and metals, influencing their reflection, transmission, and emission behavior to meet specific application requirements. Their expertise includes the use of color effect filters for selective adjustment of transmission in the visible spectrum, making them well-equipped to address diverse needs in fields like medical technology, sensor technology, and automotive applications.

Reference

Service

Optical Coating

Bte Born is your partner for designing and manufacturing high precision dielectric and metallic optical coatings using thin-film technology. We offer customised coating solutions that exactly adapt to the requirements of your component. Our expertise extends across various substrates, including glass, metal, plastic, and ceramic, allowing us to coat a wide range of surfaces to meet diverse industry needs. From mirrors and highly reflective coatings to various optical filters, beam splitters, metallic coatings and AR coatings, well-known suppliers from a wide range of industries rely on our solutions. We also offer ITO coatings.

AccuCoat Inc.

City of Rochester, United States

B

11-50 Employees

1998

Key takeaway

AccuCoat Inc. specializes in custom and standard optical coatings, offering a variety of high-efficiency anti-reflective coatings and beamsplitter coatings on multiple substrates, including Zeonex®, Ultem®, and Gorilla Glass 6. Their expertise includes thin film coatings such as antireflective, dichroic, and filters, making them a key player in the optical coating industry.

Reference

Core business

AccuCoat Inc. - World-class Optical Coatings

AccuCoat produces a wide range of thin film optical coatings such as antireflective, beamsplitters, dichroic and metal mirrors, filters, ITO, and hydrophobic coatings

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Colorado Thin Films Inc.

Denver, United States

B

1-10 Employees

2016

Key takeaway

Colorado Thin Films, Inc. specializes in providing high-quality optical coatings, including custom solutions for various applications such as anti-reflective and infrared coatings. With over 20 years of experience and advanced coating technologies, they are dedicated to delivering precise and reliable optical thin film coatings tailored to specific requirements.

Reference

Core business

Optical Coatings | Colorado Thin Films | Denver

Colorado Thin Films is recognized for high-quality optical coatings with unreal turnaround times. Using state-of-the-art equipment with an experienced team to ensure every coating meets the highest standards of precision and performance.

Cascade Optical Coating, Inc.

Santa Ana, United States

B

11-50 Employees

1975

Key takeaway

Cascade Optical Corporation focuses on advancing optical research and thin film design, offering innovative optical solutions and specializing in custom thin film coatings.

Reference

Core business

Cascade Optical Corporation - Coating, Thin Films, Optics

Custom Thin Film Specialists, Coating Deposition Assisting The Optical Industry With Innovative Optical Solutions Since 1975

KUPO Optics

New Taipei, Taiwan

51-100 Employees

1992

Key takeaway

The company has nearly thirty years of experience in sophisticated optical coating, emphasizing their expertise in providing tailored optical solutions, including anti-reflection coatings.

Reference

Product

KUPO Optics - Anti Reflection Coatings

Vortex Optical Coatings Ltd

United Kingdom

A

1-10 Employees

2008

Key takeaway

Vortex Optical Coatings is well-equipped to meet your optical coating needs, offering high-volume infrared filters and anti-reflective coatings through long-term contracts. They provide a coat-only service for quick turnaround times and can also supply both optics and coatings, ensuring a streamlined process from concept to production.

Reference

Core business

Vortex Optical Coatings |

Blue Ridge Optics

United States

B

11-50 Employees

2006

Key takeaway

Blue Ridge Optics specializes in the development and production of thin film coatings, including advanced optical coatings for high-energy laser systems. With over 20 years of experience, they offer a range of coatings such as ITO, AR, and dielectric coatings, ensuring high-quality optical components for various applications.

Reference

Core business

Blog - Blueridge Optics

Evaporated Coatings, Inc.

Upper Moreland Township, United States

B

11-50 Employees

-

Key takeaway

Evaporated Coatings, Inc. has over 60 years of experience in supplying high precision optical coatings, utilizing advanced vacuum deposition technology. Their expertise includes a variety of coatings, such as anti-reflective coatings and band-pass filters.

Reference

Core business

Thin Film Optical Coatings Company - Evaporated Coatings, Inc

ECI has been supplying high precision optical coatings for over 50 years. From AR Coatings to Band-Pass Filter to Mirror Coatings. Contact us 215-659-3080

SOLAYER GmbH

Karlstein am Main, Germany

A

51-100 Employees

2008

Key takeaway

SOLAYER GmbH specializes in high-precision thin film coating and optical layers, utilizing advanced vacuum coating systems and plasma technology. Their expertise in sputtering technologies positions them as a key player in the optical coating sector.

Reference

Product

Optical Coating – SOLAYER GmbH

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Optical coating: Copper mirror

Go to product

Service

Highly Reflective Mirrors

Go to product

Service

Optical Coating

Go to product

Service

Mirror Coatings

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Optical Coatings for Automotive Applications

Automotive

Optical coatings with thin-film technology are used in Head-up-Displays in order to display driving data on the windshield. At Bte Born, we coat optical components so that they reduce reflections, prevent double images, and enhance thermal resistance, improving visibility and usability for drivers. With over 25 years of experience in this field, Bte Born provides reliable solutions tailored to HUD applications.

Use case

Coating solutions for reverse vending machines

Recycling, Reverse vending, Packaging Solutions

Deposit return machines use sensors to scan the returned empties and read the barcode. With Bte Boen vapour deposition technology, we coat components of the recognition unit, which is made of glass. The machines use the sensors to detect the single-use deposit logo and the printed barcode. The weight, shape and colour of the bottle are also determined. It is particularly important to minimise reflection and avoid distracting reflections. This is the only way the recognition system can work quickly.

Use case

Optical Coatings for UV apllications

Tanning technology, Sun simulation systems, UV drying, UV curing, UV reflectors, Material crack detection, UV detectors (black light), printing presses, packaging industry, Automotive, Laser cutting, UV disinfection

Optical coatings for UV applications Light has become a versatile "tool" in numerous industrial processes, such as laser cutting. UV-curable printing inks are used in the packaging industry and UV-curable adhesives in the automotive industry. Coated components are also utilised for disinfection and sterilisation, solar simulation, and UV testing. Dielectric coatings help to produce UV transmitters that allow the desired components of ultraviolet radiation to pass through while blocking others, for example, transmitting components of UVA radiation and blocking UVB radiation. For instance, UV blockers can block short wave UV radiation.

Use case

Optical Coatings for Automotive Applications

Automotive

Optical coatings with thin-film technology are used in Head-up-Displays in order to display driving data on the windshield. At Bte Born, we coat optical components so that they reduce reflections, prevent double images, and enhance thermal resistance, improving visibility and usability for drivers. With over 25 years of experience in this field, Bte Born provides reliable solutions tailored to HUD applications.

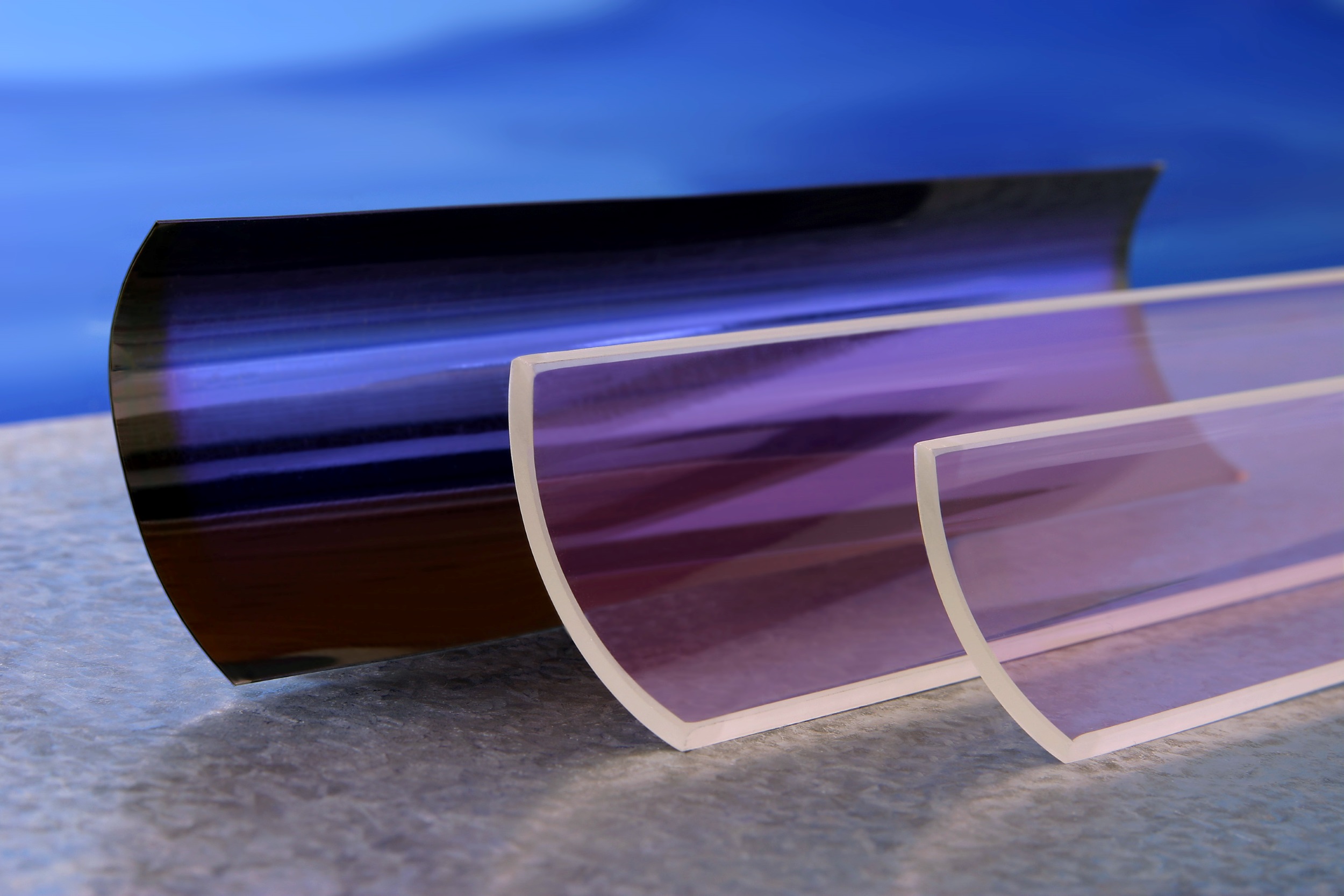

Optical coating refers to the process of applying thin films to the surface of optical components, such as lenses and mirrors, to enhance their performance. These coatings can improve various optical properties, including reflection, transmission, and absorption of light. By using different materials and thicknesses, manufacturers can achieve specific effects, such as anti-reflective coatings that reduce glare or reflective coatings that enhance the brightness of optical devices. These coatings are crucial in a wide array of applications, from eyeglasses and camera lenses to high-performance lasers and scientific instruments. The precision in the coating process ensures that the optical components perform optimally, meeting the demands of various industries, including telecommunications, healthcare, and aerospace.

Optical coating significantly enhances lens performance by reducing reflections and increasing light transmission. By applying thin layers of specialized materials to the lens surfaces, these coatings minimize glare and ghosting, which can distort images. This leads to improved clarity and contrast, allowing more light to pass through the lens. Additionally, certain optical coatings can provide protection against scratches and environmental factors, extending the lifespan of the lenses. Coatings such as anti-reflective, mirror, and UV-blocking layers are tailored to specific applications, ensuring optimal functionality for various optical devices.

Optical coatings are typically made from a variety of materials designed to enhance the performance of optical components. Metallic coatings, such as aluminum and silver, are commonly used for their high reflectivity. These materials are often applied to mirrors and beamsplitters. Additionally, dielectric coatings utilize multiple layers of dielectric materials like titanium dioxide and silicon dioxide. These layers work together to create interference effects that increase transmission or reflection at specific wavelengths. The choice of materials depends on the desired optical properties and the application of the coated component.

1. Anti-Reflective Coatings

These coatings minimize reflection and maximize light transmission through lenses, enhancing visibility and clarity in optical devices.

2. Reflective Coatings

These coatings are designed to enhance reflection, often used in mirrors and other optical components to improve performance by increasing the amount of light reflected.

3. Beam Splitters

This type of coating allows light to be split into two or more beams, facilitating various applications in lasers and imaging systems.

4. Hard Coatings

These coatings provide durability and scratch resistance to optical surfaces, ensuring longevity and maintaining performance under harsh conditions.

5. Filter Coatings

Filter coatings selectively transmit or reflect specific wavelengths of light, useful in applications like photography, spectroscopy, and laser systems.

Optical coating is applied to surfaces using various techniques, with the most common methods being vacuum deposition and sputtering. In vacuum deposition, a material is vaporized in a vacuum chamber and then deposited onto the substrate. This process allows for precise control over the thickness and uniformity of the coating, which is essential for achieving the desired optical properties. Sputtering, on the other hand, involves bombarding a target material with high-energy particles, causing atoms to be ejected and then deposited on the substrate. This technique can be advantageous for creating coatings with specific characteristics, such as durability and adhesion. Both methods ensure that the optical coatings enhance the performance of surfaces in applications like anti-reflective coatings, mirrors, and filters.

Some interesting numbers and facts about your company results for Optical Coating

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 7705 |

| Amount of suitable service providers | 6172 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1975 |

| Youngest suiting company | 2016 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Optical Coating

What are related technologies to Optical Coating?

Based on our calculations related technologies to Optical Coating are Aromatics, Desiccants, Refrigerants, Resins, Green Chemistry

Which industries are mostly working on Optical Coating?

The most represented industries which are working in Optical Coating are Other, Electronics and Electrical engineering, Chemicals, Manufacturing, Medical

How does ensun find these Optical Coating Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.