The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Vergason Technology

Town of Van Etten, United States

B

11-50 Employees

1985

Key takeaway

Vergason Technology, Inc. specializes in developing PVD coating solutions, utilizing advanced techniques like sputtering and thermal evaporation to apply durable thin films to various substrates. Their commitment to ISO 9001 standards ensures high-quality products and services in the field of wear-resistant PVD coatings.

Reference

Service

PVD Wear Resistant Coating - Vergason Technology, Inc.

Vergason Technology, Inc. (VTI) is a leading PVD wear resistant coating and treatment company using specialized evaporation vacuum coating machines.

Surftech Inc

Austinburg, United States

B

1-10 Employees

1995

Key takeaway

PVD (Physical Vapor Deposition) coating is a surface coating technology that enhances the wear resistance, corrosion resistance, and surface hardness of materials by depositing a thin film through a vacuum process. Specialized companies offer PVD coating services, ensuring high-quality application for improved performance of components.

Reference

Core business

PVD Coating Companies & Suppliers | Ceramic Coating Service

PVD Coating Companies: Are you looking for decorative, custom pvd coating suppliers? We provides ceramic coating services, thin film coating based Ohio.

Dayton Coating Tech | Certified Tool Grinding

Dayton, United States

B

11-50 Employees

1985

Key takeaway

Dayton Coating Technologies specializes in PVD coating, providing quick turnaround and tailored surface preparation solutions for various applications, including medical and aerospace parts manufacturing. With over three decades of experience, they emphasize quality and reliability in their coating services.

Reference

Core business

About PVD Coating | Dayton Coating Technologies

We are a quick turn PVD Coating facility offering unique surface preparation and engineering solutions tailored to your individual application.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

PVD Products

Wilmington, United States

B

11-50 Employees

1995

Key takeaway

PVD Products, Inc. specializes in custom thin film deposition systems, including large-area pulsed laser deposition (PLD) systems, which are essential for PVD coating applications. With a strong commitment to research and development, they support various sectors, helping to meet diverse deposition system demands.

Reference

Core business

About PVD Products

PVD Products, Inc. is the leading manufacturer of custom thin film deposition systems, reel-to-reel deposition equipment, and combinatorial deposition tools.

Richter Precision

East Petersburg, United States

B

51-100 Employees

1978

Key takeaway

Richter Precision specializes in PVD coating, utilizing advanced technology to create strong, tailored coatings with enhanced physical and structural properties. Their expertise in both PVD and CVD processes ensures they can provide the best coating solutions for various applications.

Reference

Core business

PVD Coatings | CVD Coatings - Richter Precision

Spectrum PVD Coating

Bengaluru, India

D

11-50 Employees

2018

Key takeaway

PVD Coating is a specialized thin-film coating process that enhances the surface of furniture with attractive finishes, improving both aesthetics and durability. Spectrum PVD Coating, a leading expert in this technology, emphasizes its importance in luxury furniture, offering long-lasting and visually stunning coatings that are ideal for high-end manufacturers and designers.

Reference

Core business

Spectrum PVD Coating

The Best decorative PVD coating services on Stainless Steel Furnitures and Glass products. Inspire Located in the heart of Bangalore, Spectrum PVD Coating is quickly earning itself a strong professional reputation as unique specialists in PVD coating applications. The fully automated plant is run by an experienced, efficient and highly qualified team of engineers and administrators.

PVT Plasma und Vakuum Technik GmbH

Bensheim, Germany

A

51-100 Employees

-

Key takeaway

PVT is a pioneer in PVD (Physical Vapor Deposition) coating technology, developing vacuum coating processes and systems that cater to various protective coating requirements. Their expertise includes the use of large-area arc evaporation, highlighting their innovative approach in the field.

Reference

Service

PVT | PVD - Physical Vapor Deposition

PVT gilt als einer der Pioniere der Hartstoffbeschichtung mittels PVD-Verfahren, insbesondere unter Einsatz der großflächigen Lichtbogenverdampfung.

Titanium Coating Services Inc.

Anaheim, United States

B

11-50 Employees

2016

Key takeaway

The company specializes in a wide range of PVD coatings, offering tailored solutions that address various friction and wear challenges. Their extensive selection of PVD coatings features extremely high hardness levels, allowing customers to choose the most suitable option for their specific applications.

Reference

Core business

Home - PVD - Titanium Coating Services

PVD, Technology, Quality, Service - Its time for perfection

Element Surface Technology Inc.

Pomona, United States

B

11-50 Employees

2016

Key takeaway

Element Surface Technology specializes in high-quality PVD coating, offering expertise in various coatings such as TiAlN, AlTiN, and TiN, which enhance lifespan and preserve strength for applications in aerospace, automotive, medical, energy, and cutting tools industries. Their commitment to quality and advanced cleaning processes ensures outstanding performance and durability of the coatings.

Reference

Core business

PVD Coatings | Los Angeles | Element Surface Technology | Pomona

At Element we are experts in PVD Coatings (physical vapor deposition) - TiAlN, AlTiN, TiN, TiCN, CrN, ZrN, AlCrN, AlTiCrN, AlTiSiN.

swiss-PVD Coating AG

Grenchen, Switzerland

A

1-10 Employees

2005

Key takeaway

swiss-PVD Coating AG specializes in high-quality PVD coating solutions that enhance the wear protection, performance, and durability of tools and components for various applications, including decorative uses and the medical sector. Their commitment to quality is underscored by their ISO 9001:2015 and ISO 13485:2016 certifications.

Reference

Core business

swiss-PVD Coating AG |

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

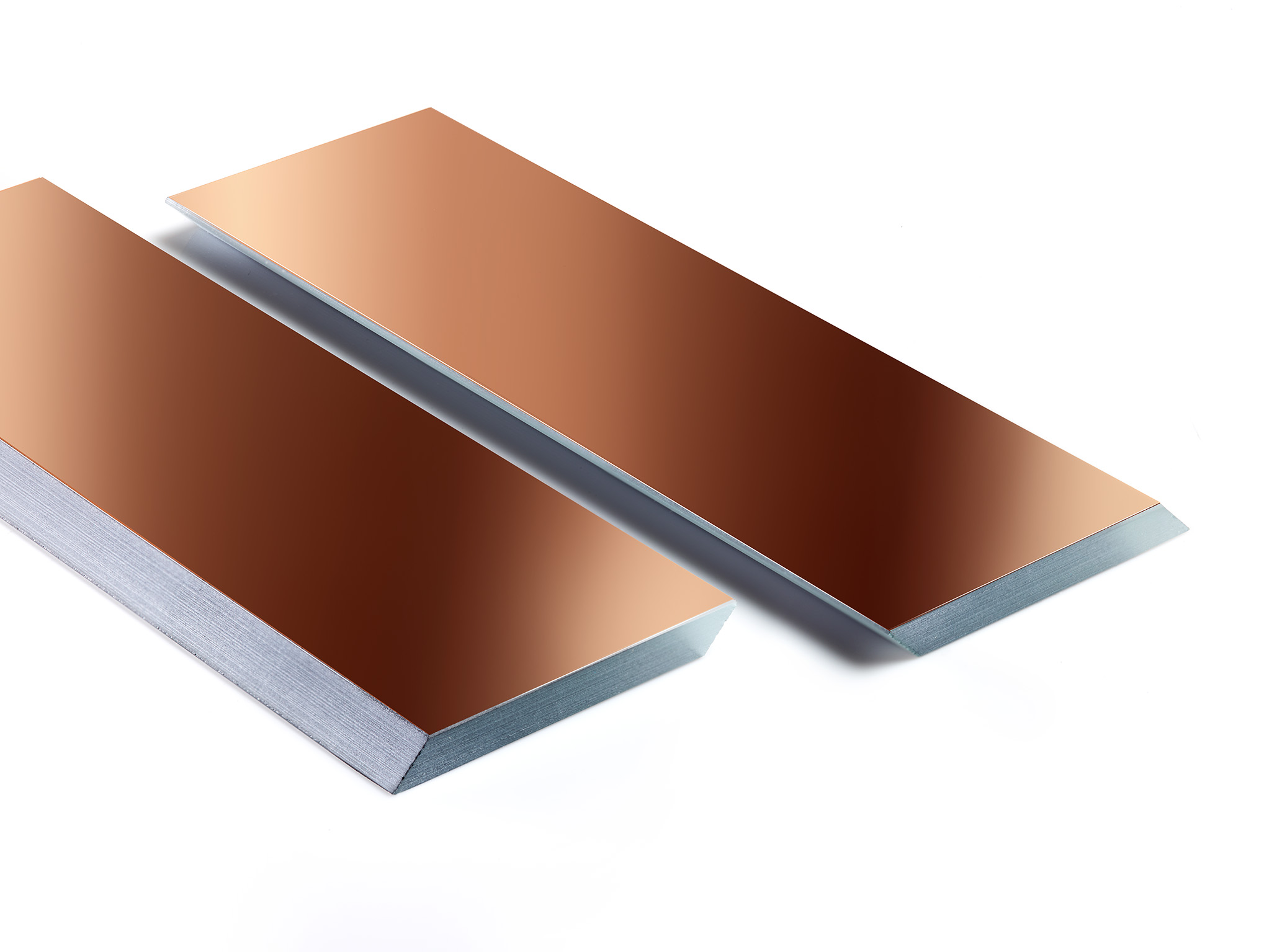

Optical coating: Copper mirror

Go to product

Product

Zr target for PVD

Go to product

PVD coating, or Physical Vapor Deposition coating, is a vacuum coating process used to produce thin films on various substrates. This technique involves the vaporization of solid materials, which then condense onto the surface of the substrate, forming a dense and durable coating. The resulting films are known for their exceptional hardness, corrosion resistance, and aesthetic qualities. Industries commonly utilize PVD coatings for applications in tool manufacturing, decorative finishes, and electronics, providing significant enhancements to the performance and longevity of the coated materials.

PVD (Physical Vapor Deposition) coating is a sophisticated process that involves the transformation of solid materials into vapor, which then condenses onto a substrate to form a thin film. The process begins with the evaporation or sputtering of a target material in a vacuum chamber, where the vaporized particles travel through the chamber and adhere to the surface of the item being coated, which is often pre-treated to enhance adhesion. During this process, high-energy particles collide with the substrate, creating a strong bond between the coating and the surface. The result is a durable, wear-resistant layer that can enhance both the aesthetic and functional properties of the coated item. PVD coatings are widely used in various industries, including aerospace, automotive, and medical devices, due to their versatility and excellent performance characteristics.

PVD coating is versatile and can be applied to a variety of materials. Metals such as stainless steel, aluminum, and titanium are commonly coated to enhance their properties, including wear resistance and aesthetic appeal. Additionally, ceramics and glass can also undergo PVD treatment, making them suitable for applications that require a durable surface finish. The ability to coat these materials allows for improved performance in various industries, including automotive, aerospace, and medical devices.

1. Durability

PVD coating significantly enhances the surface hardness of materials, making them resistant to scratches, wear, and corrosion. This increased durability extends the lifespan of products, reducing the need for frequent replacements.

2. Aesthetic Appeal

PVD coatings come in various colors and finishes, allowing for customization that improves the visual appeal of products. This variety enables manufacturers to create distinctive and attractive items that stand out in the market.

3. Environmental Friendliness

The PVD coating process is more environmentally friendly compared to traditional coatings. It does not involve harmful chemicals or solvents, resulting in lower emissions and a reduced environmental impact.

4. Adherence

PVD coatings bond exceptionally well to substrates, ensuring superior adhesion. This strong bond prevents peeling or flaking, contributing to the longevity and effectiveness of the coating.

5. Thermal Stability

PVD coatings can withstand high temperatures, which is beneficial in applications where thermal resistance is required. This property makes them suitable for use in demanding environments without compromising their performance.

PVD coating is widely used in various industries due to its versatility and effectiveness. In the **automotive sector**, it enhances the durability and aesthetic appeal of components such as wheels and decorative trims. The **aerospace industry** benefits from PVD coating by improving the wear resistance of engine parts and structural components. Additionally, in the **electronics field**, PVD coatings are applied to protect sensitive components and improve their conductivity. The **medical industry** utilizes PVD for instruments and implants, ensuring biocompatibility and resistance to corrosion. Overall, PVD coating is essential for enhancing the longevity and performance of products across these diverse applications.

Some interesting numbers and facts about your company results for PVD Coating

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6956 |

| Amount of suitable service providers | 6577 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1978 |

| Youngest suiting company | 2018 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for PVD Coating

What are related technologies to PVD Coating?

Based on our calculations related technologies to PVD Coating are Aromatics, Desiccants, Refrigerants, Resins, Green Chemistry

Which industries are mostly working on PVD Coating?

The most represented industries which are working in PVD Coating are Other, Construction, Manufacturing, Chemicals, Plastics

How does ensun find these PVD Coating Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.