Use Case

Foam Replacement with Additive Manufacturing

Foam Replacement with Additive Manufacturing is a Use Case of:

Product

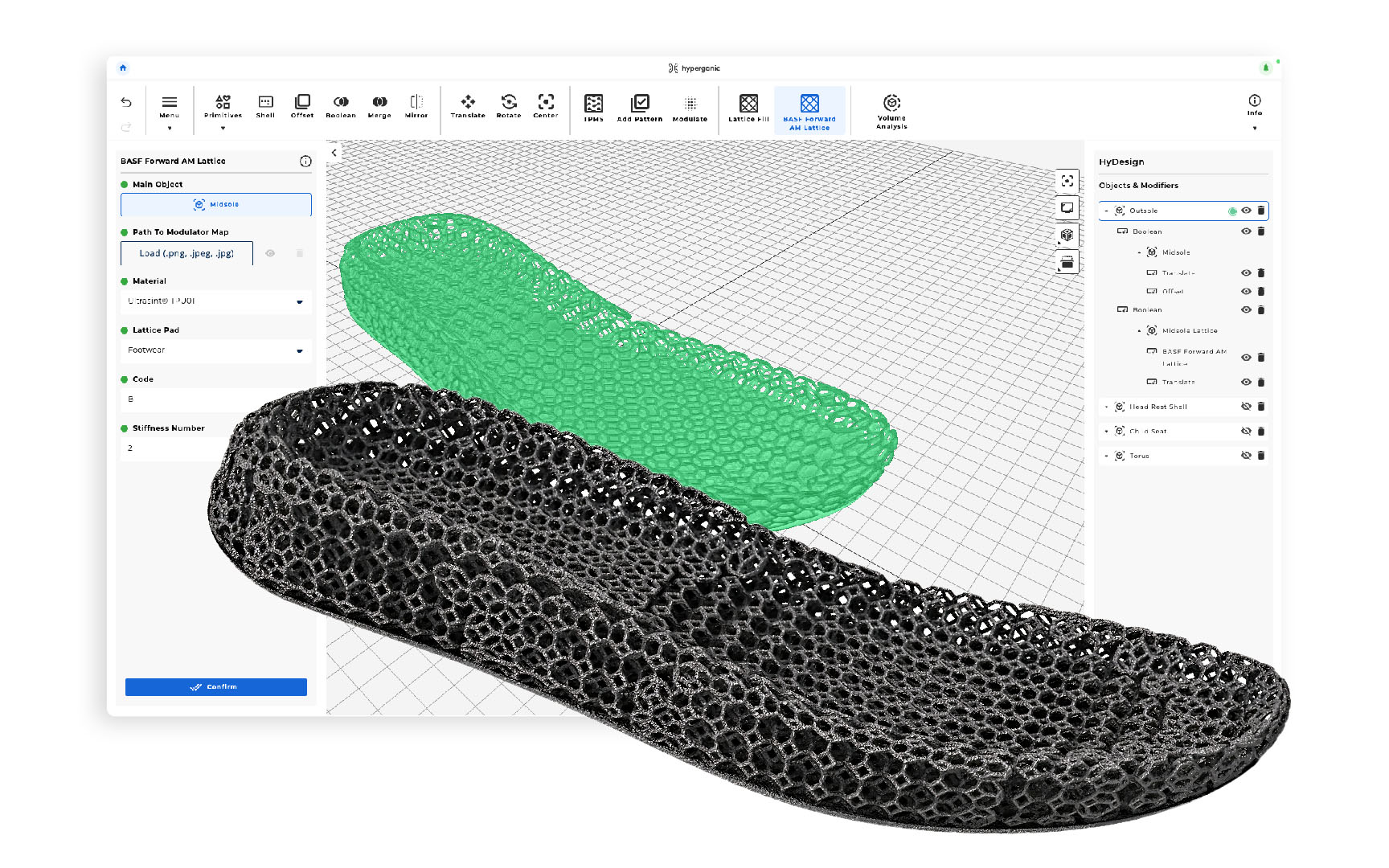

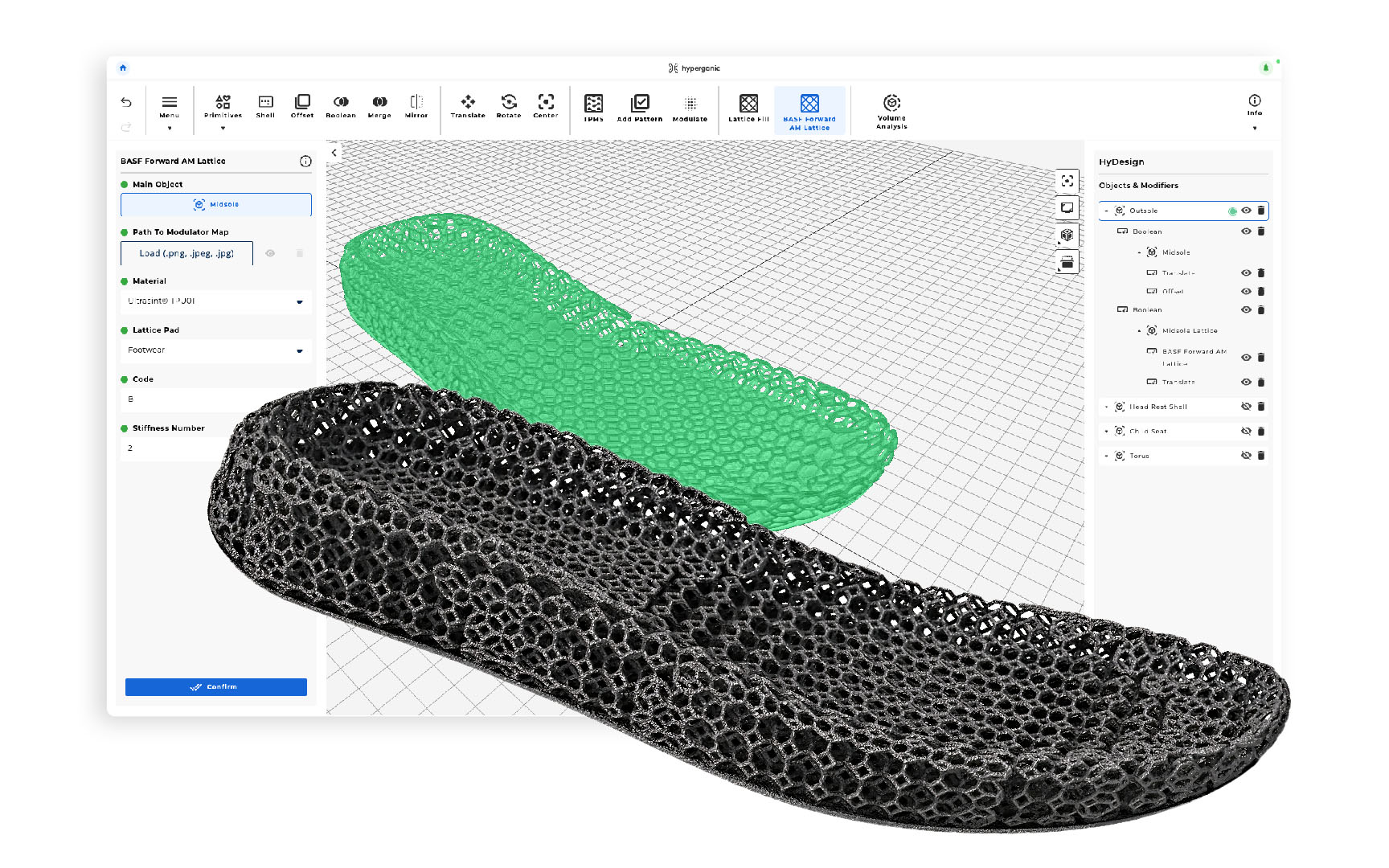

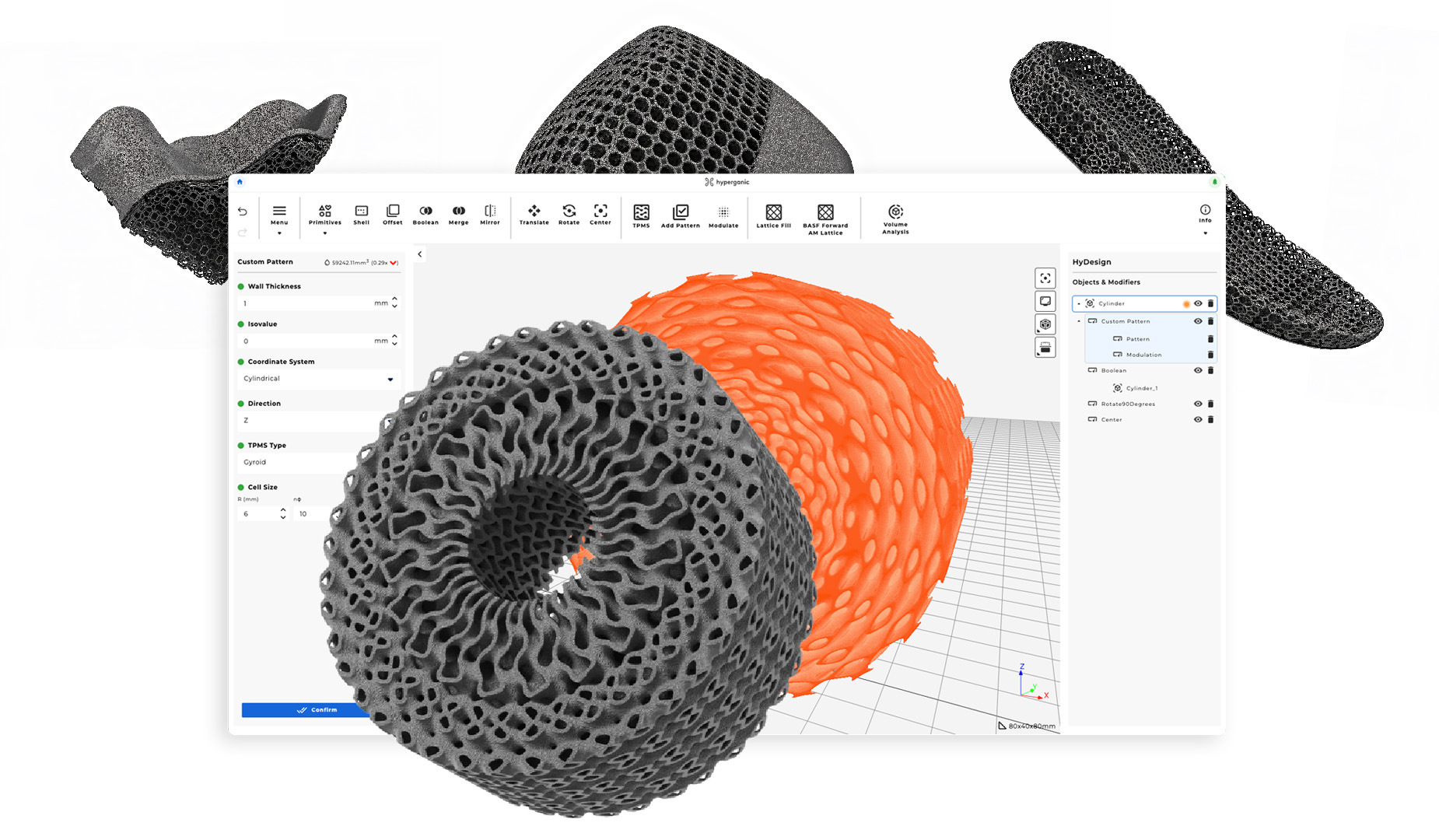

HyDesign

Go to product

Interested in this use case? An employee of Hyperganic is at your disposal.

Technical Marketing Team

Get insights into the use cases of Hyperganic

Use Case

Foam Replacement with Additive Manufacturing

Automotive, Consumer Goods, Sportwear, Fashion, Sporting Goods, Orthotics, Medical

Mass Customization with HyDesign: HyDesign allows manufacturers to replace conventional, inflexible production methods with highly adaptable and scalable additive manufacturing techniques. This enables the production of custom-fit products ranging from automotive parts to personalized medical devices. By integrating customer-specific data, such as body scans or usage patterns, directly into the design process, HyDesign ensures each product is uniquely tailored to meet individual specifications. Foam Replacement in Manufacturing: Foam components are ubiquitous in products requiring cushioning, insulation, or lightweight structures. However, traditional foam can be limited in terms of structural optimization and environmental impact. HyDesign addresses these issues by enabling the design of lattice structures that can mimic or even surpass the properties of foam. These structures are not only lighter and stronger but also more sustainable, as they can be manufactured from recyclable materials without the waste associated with traditional foam cutting. Customization with 2D Bitmaps: A standout feature of HyDesign is its ability to modulate the thickness of lattice beams using 2D bitmap images. This technology is ideal for industries where customization is key, such as: Healthcare: Creating patient-specific implants and prosthetics. Sports Equipment: Developing customized protective gear and performance-enhancing apparatus. Furniture and Ergonomics: Producing custom seating solutions and ergonomic tools.