Use Case

Minimum footprint with maximum productivity in spot welding

Minimum footprint with maximum productivity in spot welding is a Use Case of:

Product

SpeedCell

Go to product

Interested in this use case? An employee of LEWA Attendorn GmbH is at your disposal.

David Remmel

Sales joining systems

Get insights into the use cases of LEWA Attendorn GmbH

Use Case

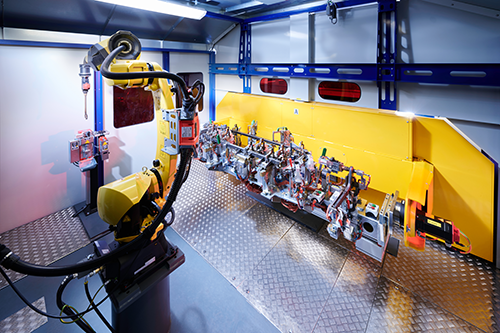

Minimum footprint with maximum productivity in spot welding

automotive, e-mobility, manufacturing

We explain how the LEWA Attendorn guarantees minimum footprint with maximum productivity in spot welding. With the SpeedCell SPOT 2.0, our developers have succeeded in making the super-fast SpeedLine components run even faster - in a very small space. Maximum flexibility for production through high standardization and stringent modularization Maximum flexibility through easy internal and external relocation of compact production systems ... and much more!

Use Case

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Use Case

Production system for MIG welding of a seat assembly

automotive

esign of a production system for MIG welding of a complex, heavy duty vehicle seat assembly consisting of backrest (60% and 40%) and seat bench. The goal is 30,000 units per year in a maximum of 616 seconds per seat assembly. The production system is to be manned by one operator. We developed a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.