Use Case

Roughness measurement

Roughness measurement is a Use Case of:

Service

Software Development

Go to product

Interested in this use case? An employee of www.3plusplus.com is at your disposal.

Dirk Fromme

Managing Director

Get insights into the use cases of www.3plusplus.com

Use Case

Roughness measurement

automotive, automotive suppliers, automation, metrology, metal processing, engineering

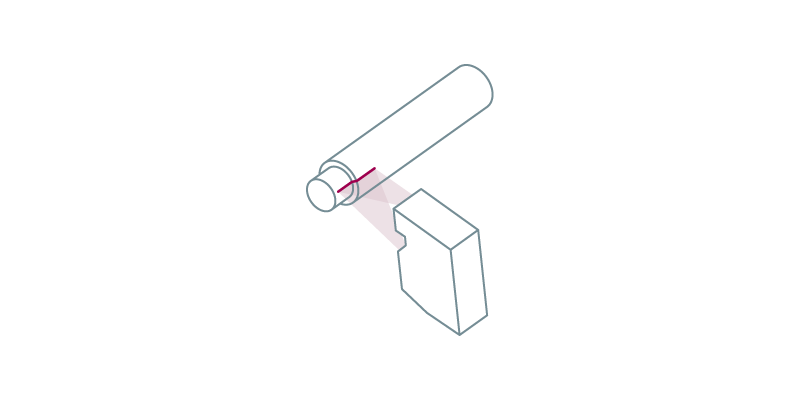

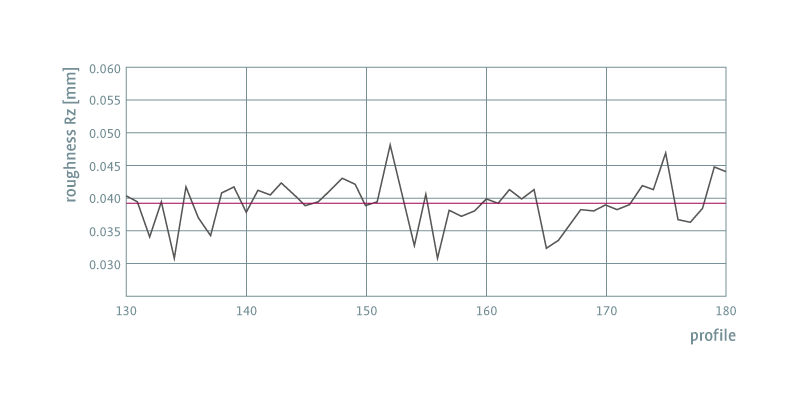

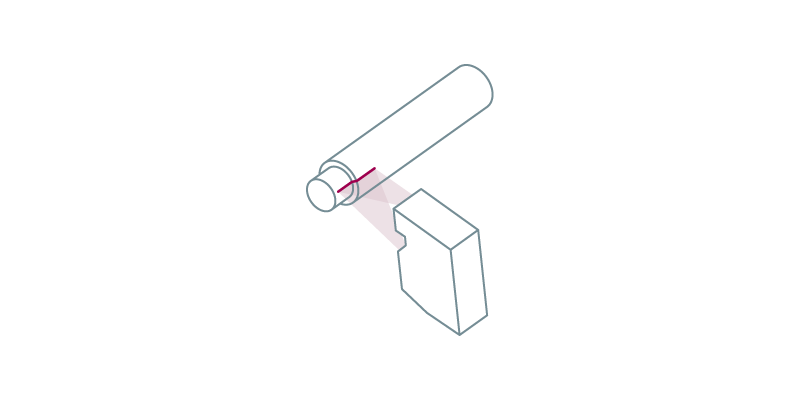

A laser triangulation sensor is used to measure the workpiece surface. It can be integrated into the machine for inline measurement or used as an offline device at a measuring station. Besides roughness, geometrical parameters can be determined and structural elements like undercuts or chamfers can be inspected. Integrated into the machine, the sensor facilitates the assessment of workpiece geometry and casting of the tool cutting edge. Therefore, the timing of tool change can be determined accurately. Adaption rules for the process-specific control parameters can be derived as well. An adaptive control can continuously adjust process parameters automatically by comparing the profile data with the required values. Our software 3++ Surface.R offers the measurement of the workpiece roughness by using a laser triangulation sensor as offline device at a measuring station. Further functionalities can be added individually according to your requirements.

Use Case

Undercut measurement

automotive, automotive suppliers, automation, metrology, metal processing

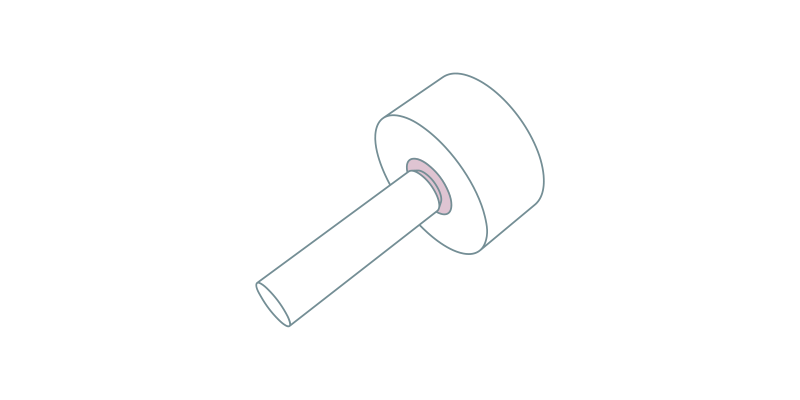

3plusplus uses profile sensors for the testing of undercuts. This contactless process simplifies the entire measuring setup and the measurement itself can be carried out significantly faster compared to using tactile sensors. The module offers the measurement of undercuts according to DIN 509 for the forms E, F, G and H. Further special forms can be integrated. The software is developed according to the customer’s requirements. Additional functionalities, like inspection of the workpiece geometry and roughness measurement, can be merged into one application.