Use Case

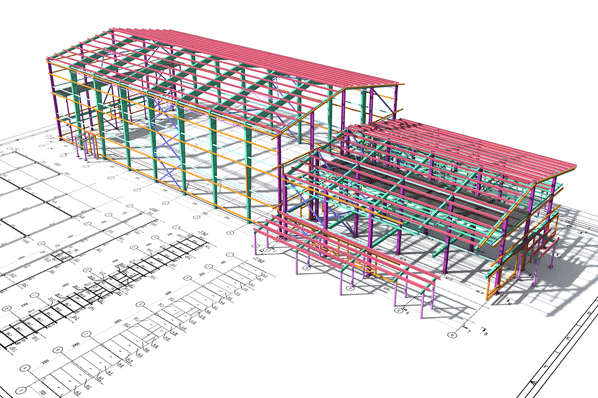

University of Michigan Steel Detailing

University of Michigan Steel Detailing is a Use Case of:

Service

Steel Detailing Services

Go to product

Interested in this use case? An employee of Production Modeling India Pvt. Ltd. is at your disposal.

Himanshu Charde

Manager - Steel Detailing

Get insights into the use cases of Production Modeling India Pvt. Ltd.

Use Case

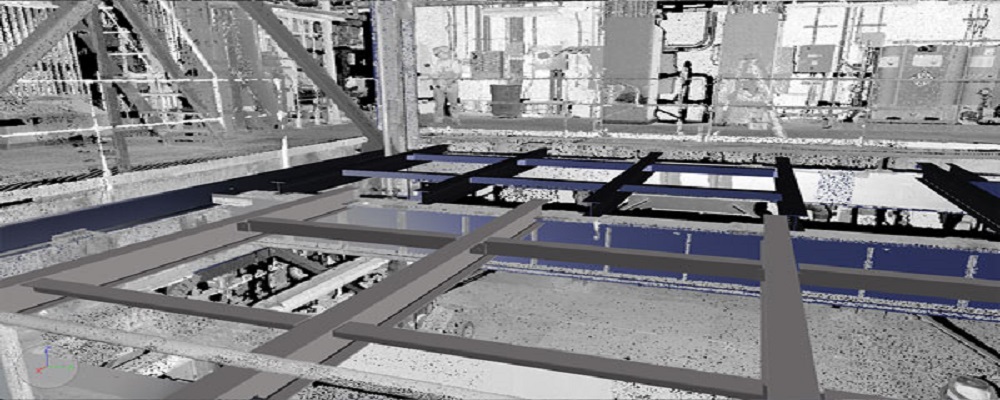

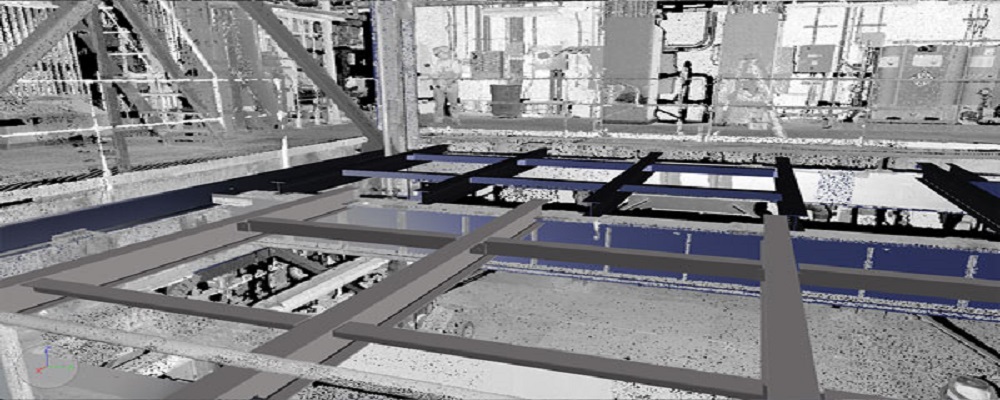

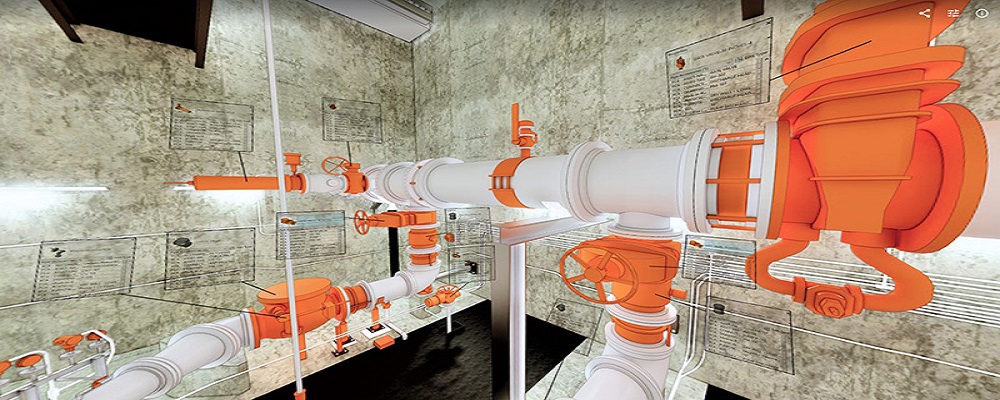

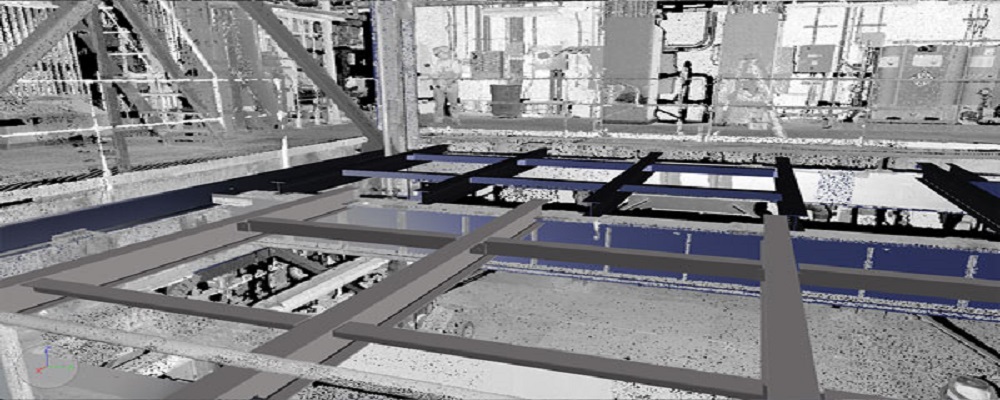

Reality Capture + Asset Information Modeling

Manufacturing, Factory, Production Plant

PMI was asked to participate in a pump station renovation in which asset and building life cycle management were high priority. Capturing post demolition conditions with terrestrial laser scanning assisted with the design process, and scanning final construction validated construction, graduating the design documents to as record drawing relevant for management of the building life cycle. The record drawings feature asset data such as model information and serial numbers for major equipment, key information for maintenance and repair.

Use Case

MODAPTS Study for a Major Automotive Supplier OEM

Automotive,, Automotive Manufacturing, Logistics & Supply Chain, Warehouse and Logistics, Industrial Manufacturing, Food and Beverage, Renewables, Oil, and Gas, Aerospace

A third-party supplier manufactures plastic automotive interior components for various automotive customers. The facility where this project was conducted comprises injection molding components, painting components and assembling part and sub-assemblies. The objective of this study was to calculate operator efficiency for automotive and to categorize operator utilization as under-utilized, efficiently utilized or over-utilized/worked.

Use Case

University of Michigan Steel Detailing

Architecture, Energy and Utilities, Multi-residential Structures, Commercial Structures, Aerospace and Airports, Bridge Construction

The Central Power Plant (CPP) team runs the CCP, which supplies steam, electricity, compressed air, and hot water to the University of Michigan's Central and Medical Campuses. It's a combined-cycle cogeneration plant with seven boilers that have a total steam capacity of over 1 million pounds. As part of the University's push towards a more environmentally friendly approach, it has launched several initiatives to reduce its carbon footprint.