Automatic type Extrusion Blow Molding Manchine JN Series - Design for continuous production with auto deflash, auto recycle, and auto loader. Drive by hydraulic. Features Highly automation, suitable for mass production. Driven by hydraulic and pneumatic systems, stable and easy for maintenance. Compared to the traditional tie bar type design clamping system, toogle type design helps the mold template bearing larger clamping force under average power distribution. Including the auto-deflashing device, so the output is the finished product without secondary procession to keep the cost reduction. Automatic alarm system to make sure the safety of the operator without any damage caused by the improper operation. Optional for the resin auto loader, automatic material recycle system, and automatic inspection system to reach the goal of comprehensive automation. Optional for the servo hydraulic system for mold clamping which can save enormous power. Optional for hydraulic parison control or servo parison control to save energy and increase the production strength. Main components supplied by internationally famous brands from Germany, Japan, Sweden, etc. that are located globally with well after service as well as the stability and high effectiveness of the products.

The customer has great reputation in engine oil industry of Peru who wants to make a new serial bottle family and the customer requests fully automated production. As such, we propose the blow molding machine integrated the needful accessories which including material feeding and conveying, crushing, material recycle, take out robot, finished bottle collection and conveying and Leak Detector…etc. The features of blow molding machine with automated integration system include. Labor cost less Product quality assurance Power saving Eventually, the customer is satisfied with the performance of Jonh Huah machine which is completely meet the their’s requirements. Both the automation and power saving design could make the customer’s quick payback on the investment, a strong competitive edge for the customer to keep its leading position in Peru county. With the success of this project, customer continues to buy two more similar automation systems in three consecutive years.

Full electric type Extrusion Blow Molding Manchine JD Series - Full automatic, save energy, less noise, less maintenance, higher performance. Features High automation, high precision, high cleanliness, suitable for the mass productions with high value-added, such as the pharmaceutical industry, food, and cosmetics. The machine is driven by servo system and pneumatic system with advantages of power saving, high speed, quiet, high precision, lower cost of maintenance, and without the contamination from the hydraulic oil. Parameters reading after mold changing by digital design, adjusting time is shorter for labor saving and increases the utilization rate. Compact mechanism design, less space needed, faster, shorter cycle time, and more output. Optional for servo drive parison control to save energy and increase the production strength. Auto-deflashing device is the standard accessory, the output is the finished product without secondary procession keeps the cost reduction. Automatic alarm systems to make sure the safety of the operator without any damage caused by the improper operation on the machine. Optional for the resin auto loader, automatic material recycle system, and automatic inspection system to reach the goal of comprehensive automation. Main components supplied by internationally famous brands from Germany, Japan, Sweden, etc. that are located globally with well after service as well as the stability and high effectiveness of the products.

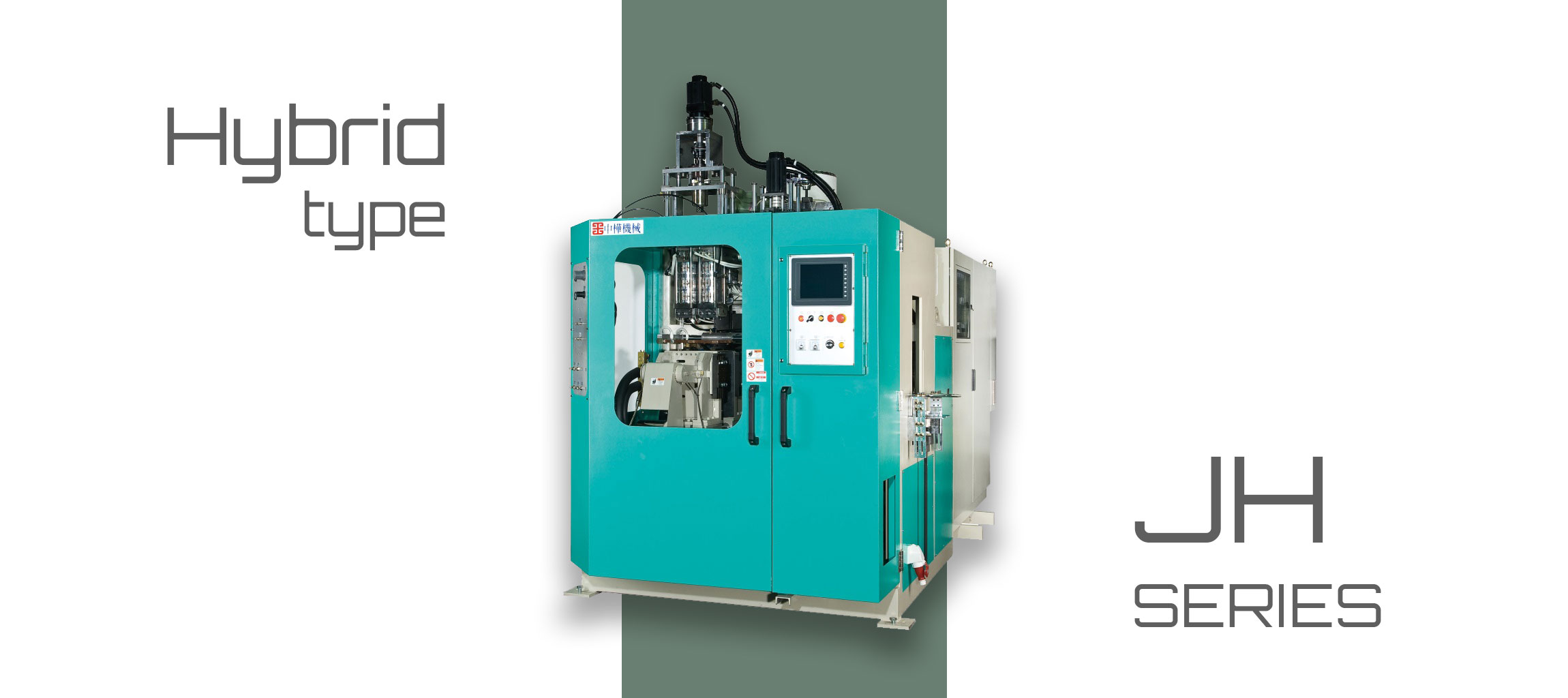

Hybrid type Extrusion Blow Molding Manchine JH Series - Same automatic producing, but it is new design, new system. Base on servo motor driving, and it is flexible to choose servo hydraulic. Features High automation, high precision, high cleanliness, suitable for the mass productions that request high value-added. The mold movement device is driven by servo system with advantages of high speed, quiet, high precision, volume boost, yield rate increasing, and without the contamination from the hydraulic oil. Servo drive system for the blowing device is optional with advantages of high speed, quiet, high precision, no contamination from hydraulic oil, and is suitable for medical products, food, and cosmetics. Optional for hydraulic parison control or servo parison control to save energy and increase the production strength. Mold clamping driven by the servo hydraulic system which saves enormous power. Including the auto-deflashing device, so the output is the finished product without secondary procession to keep the cost reduction. Automatic alarm system to make sure the safety of the operator without any damage caused by the improper operation. Optional for the resin auto loader, automatic material recycle system, and automatic inspection system to reach the goal of comprehensive automation. Main components supplied by internationally famous brands from Germany, Japan, Sweden, etc. that are located globally with well after service as well as the stability and high effectiveness of the products.

Basic type Extrusion Blow Molding Manchine JS Series - Simple producing, design for starting business or small quantity producing. Features Easy for operation and learning. The lower cost of the machine is suitable for the buyer who has a limited budget. The space for mold changing is big enough for the operator who changes the mold usually with the productions requesting low quantity and multiple types. Optional for hydraulic parison control system to save energy and increase the production strength. Driven by hydraulic and pneumatic systems, stable and easy for maintenance. Optional servo motor driven for the hydraulic system that can save enormous power. Automatic alarm systems to make sure no damages caused by any improper operation on the machine. No auto-deflasing, but optional for the spin trimmer, auto resin auto loader, automatic material recycle system, and automatic inspection system. Main components supplied by internationally famous brands from Germany, Japan, Sweden, etc. that are located globally with well after service as well as the stability and high effectiveness of the products.

Accumulator type Extrusion Blow Molding Manchine ENS Series - Design for big size products, something like automotive parts, hospital bed, mobile toilet...etc. Taking out robot is optional. Features The mold template is big, the space for die head tooling replacement is big, suitable for large size production. Driven by hydraulic and pneumatic systems, stable and easy for maintenance. Re-designed extrusion seat adjustment device makes it easier to slightly adjust the position of the die head. Compared to the older type design, the mold template of re-designed mold clamping device can load more clamping force. Re-designed extrusion system extrudes more for the production that requests more extrusion volume, but with stable and not easily increasing temperature. Supporting upper blowing, side blowing, and optional for bottom blowing device, parison stretch device, parison sealing device, mold temperature control system, hydraulic auxiliary mold, pneumatic auxiliary mold, to satisfy the various requirements of productions. Optional for robot take out device, resin auto loader, automatic material recycle system, to reach the goal of comprehensive automation. Automatic alarm system and photoelectric cell protection system make sure the machine will not be damaged by improper operation. And the most important is to ensure the safety of the operators. Optional servo motor driven for the hydraulic system that can save enormous power. Using the parison control system to save material and increase the production strength. Main components supplied by internationally famous brands from Germany, Japan, Sweden, etc. that are located globally with well after service as well as the stability and high effectiveness of the products.

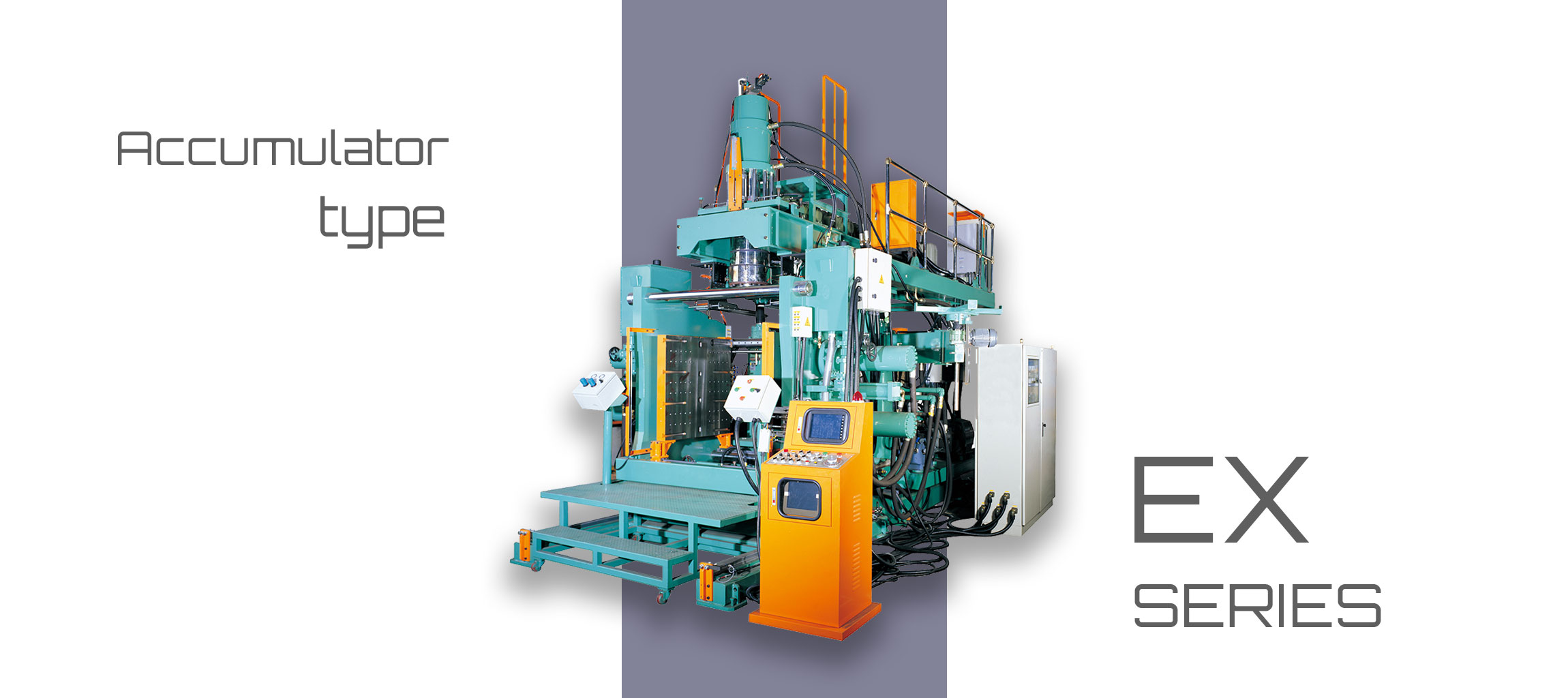

Advantage accumulator type Extrusion Blow Molding Manchine Ex Series - Design for big size products, but it is more stronger, more flexible to fit any kind of mold. Specialize in automotive parts. Features The mold template is large, the space for die head tooling replacement is sufficient, and much more options for mold exercises control. It is suitable for large size products that need complicated mold design. Mold open direction is left-right, so the product can be taken out from the front place, a better view for factory management. Driven by hydraulic and pneumatic systems, stable and easy for maintenance. Compared to the older type design, the mold template of re-designed mold clamping device can load more clamping force. Re-designed extrusion system extrudes more for the production that requests more extrusion volume, but with stable and not easily increasing temperature. Supporting upper blowing, side blowing, and optional for bottom blowing device, parison stretch device, parison sealing device, mold temperature control system, hydraulic auxiliary mold (slide mold), pneumatic auxiliary mold (slide mold), to satisfy the various requirements of productions. Optional for robot take out device, resin auto loader, automatic material recycle system, to reach the goal of comprehensive automation. Automatic alarm system and photoelectric cell protection system make sure the machine will not be damaged by improper operation. And the most important is to ensure the safety of the operators. Optional servo motor driven for the hydraulic system that can save enormous power. Using the parison control system to save material and increase the production strength. Main components supplied by internationally famous brands from Germany, Japan, Sweden, etc. that are located globally with well after service as well as the stability and high effectiveness of the products.

In the beginning, the customer came to Jonh Huah referred by a other company. This customer is a multinational corporation who is supplying the bellow/dust cover and its serial products to a variety brands of automobile makers in Korea, Japan, India and US who impose critical request for the products based on endurable and safety concern. Regarding this project, the challenges including below: TPE melting index is very fast, not easy to control the precision of parison / wall thickness. (CPK) of the long product. The CPK requirements on product thickness in every area of product body is very strict. Auto deflash Top and bottom scrap auto deflash. To meet the all above high quality request, we make new design by modifying JS-550E and integration of drying system and gravimetric dosing system for the TPE material which requires special treatment in process. It is accumulator type and very high speed and high precision injection design is adopted to assure the quick injection for the parison. Eventually, Jonh Huah has built up a new Extrusion Blow Molding Machine design which is completely meet the customer’s requirements. And now the machines are promoting to North America (US, Canada and Mexico) and India.

The customer is the large-scale packaging film manufacturer in the south of Taiwan specializes in a variety of high value-added food packaging. Since 2012, they have developed a close partnership with JOHN HUAH. JOHN HUAH has won the appreciation and recognition of Taiwan's index packaging film manufacturers for our solid and powerful machine appearance structure design, simple and flexible humanized control interface and energy-efficient integration of core units. Through close technical exchanges and positive interaction between the two parties, JOHN HUAH has built a number of simple and efficient Extrusion Blow Molding Machine for this customer, which has been well received with continuous and stable mass production. Our automation design bring the customer a full automatic production from blowing process to leak testing and labeling process. “It is just like the fully automatic money printing machine” said the customer. JONH HUAH will continue to focus on the concept of “Made Simple”, listening to customers' needs, aiming at providing customers with the most efficient solutions and integrating the most advanced technology to satisfy customers. The value of the brand “JONH HUAH” will be deeply rooted in every customer.

In the beginning, the customer came to Jonh Huah referred by a other company. This customer is a multinational corporation who is supplying the bellow/dust cover and its serial products to a variety brands of automobile makers in Korea, Japan, India and US who impose critical request for the products based on endurable and safety concern. Regarding this project, the challenges including below: TPE melting index is very fast, not easy to control the precision of parison / wall thickness. (CPK) of the long product. The CPK requirements on product thickness in every area of product body is very strict. Auto deflash Top and bottom scrap auto deflash. To meet the all above high quality request, we make new design by modifying JS-550E and integration of drying system and gravimetric dosing system for the TPE material which requires special treatment in process. It is accumulator type and very high speed and high precision injection design is adopted to assure the quick injection for the parison. Eventually, Jonh Huah has built up a new Extrusion Blow Molding Machine design which is completely meet the customer’s requirements. And now the machines are promoting to North America (US, Canada and Mexico) and India.

Owning up to 10 set of Jonh Huah’s accumulator type Extrusion Blow Molding Machine, the customer produces and supplies the necessities of cooking oil over the Madagascar in Africa. With business booming year by year, the customer consistently purchase machine from Jonh Huah and gives high credit to Jonh Huah’s outstanding machine on its quality, durability, and the after sales service Jonh Huah provide. ‘’Thanks to Jonh Huah’s blow molding solution, the container stay firm without damage or leaking during the long-distance delivery.’’ The distance between customer’s factory to the dealer sometimes last more than thousands of miles, by passing curvy mountain road with bad traffic condition, and most of the time it damage half amount of the container during the delivery, not until they have met Jonh Huah, Jonh Huah have changed their container design as well as the artistic of blow molding. It is always happy to see customer booming business after using Jonh Huah’s Extrusion Blow Molding Machine.

Owning up to 10 set of Jonh Huah’s accumulator type Extrusion Blow Molding Machine, the customer produces and supplies the necessities of cooking oil over the Madagascar in Africa. With business booming year by year, the customer consistently purchase machine from Jonh Huah and gives high credit to Jonh Huah’s outstanding machine on its quality, durability, and the after sales service Jonh Huah provide. ‘’Thanks to Jonh Huah’s blow molding solution, the container stay firm without damage or leaking during the long-distance delivery.’’ The distance between customer’s factory to the dealer sometimes last more than thousands of miles, by passing curvy mountain road with bad traffic condition, and most of the time it damage half amount of the container during the delivery, not until they have met Jonh Huah, Jonh Huah have changed their container design as well as the artistic of blow molding. It is always happy to see customer booming business after using Jonh Huah’s Extrusion Blow Molding Machine.