The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Precision Plastic Products, Inc.

Portland, United States

B

11-50 Employees

1981

Key takeaway

The company is a trusted manufacturer with over 35 years of experience in precision plastic injection molded parts, ready to assist in transforming concepts into high-quality molded products.

Reference

Core business

Precision Plastic Products

Superior Plastics

Fort Worth, United States

B

11-50 Employees

2006

Key takeaway

The company highlights its expertise in custom injection-molded plastics, detailing the process where polymer beads are melted and injected into molds to create precise shapes. This commitment to quality ensures that customers receive outstanding products, often at a better value than competitors.

Reference

Service

custom-injection-molding

Murray Plastics

Gainesville, United States

B

- Employees

1998

Key takeaway

The company is a top-tier custom plastic injection molding provider, known for its precision and quality in manufacturing a wide range of plastic parts, from small components to those weighing over 2 pounds. With a commitment to American-made products and excellent customer service, they support every stage of the production process, ensuring that each part undergoes a rigorous design and engineering process to meet customer needs.

Reference

Service

Plastic Injection Mold Manufacturing & Production

We offer mass production and manufacturing of plastic injection molding parts. Manufacture parts weighing a fraction of an ounce to over 2 pounds.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Xiamen Jingwei Industry & Trade Co., Ltd

Xiamen City, China

D

51-100 Employees

2009

Key takeaway

Xiamen Jingwei Industry & Trade Co., Ltd specializes in providing professional custom injection molded plastic products, offering services such as free quotes, part design reviews, and a Lifetime Mold Guarantee. With over 15 years of experience, they are committed to delivering cost-effective solutions for the design and manufacturing of plastic injection molded parts.

Reference

Core business

Plastic Injection Molding,Custom injection Molds&Parts

PIONEER PLASTICS

Dixon, United States

B

11-50 Employees

1962

Key takeaway

Pioneer Plastics specializes in custom injection molding, offering design and manufacturing services that ensure high-quality plastic parts. Their commitment to producing everything in the United States allows for substantial savings in both time and costs.

Reference

Service

Custom Injection Molding | Pioneer Plastics

Pioneer Plastics handles custom injection molding and plastic part design with quality and precision, lowering your labor costs, saving you time and money.

K.C.S. PTY. LTD.

Melbourne, Australia

A

11-50 Employees

1982

Key takeaway

KCS Pty Ltd specializes in custom injection molded plastic, offering in-house tool and product forming with clamping capacities ranging from 80 to 650 tonnes. Their state-of-the-art facilities support the complete development of ideas, from prototyping to large-scale manufacturing.

Reference

Service

Custom Injection Moulding

PELCO TOOL & MOLD INC.

Glendale Heights, United States

B

11-50 Employees

-

Key takeaway

Pelco Tool and Mold specializes in high-quality precision injection molds, capable of handling high cavitation plastic injection molds for various industries. Their dedicated team and in-house designers ensure efficient development and production of durable molds, making them a valuable partner for custom injection molded plastic projects.

Reference

Service

Precision Injection Mold Services - Pelco Tool & Mold

Glendale Mouldings

Glenrothes, United Kingdom

A

11-50 Employees

2000

Key takeaway

The company is an established manufacturer of custom injection molded plastics, providing a comprehensive service from concept to final product, and offering a wide range of materials from commodity to engineering polymers.

Reference

Service

Injection Moulding | Glendale Mouldings

Plastimold Products

Delray Beach, United States

B

11-50 Employees

1996

Key takeaway

Plastimold specializes in custom injection molded plastic parts, leveraging over 20 years of experience to ensure high quality and timely delivery. Their services include design optimization and engineering support to enhance part accuracy while reducing costs.

Reference

Core business

Home – Plastic Injection Molding – Plastimold

Plastic injection molding company with 22+ years experience. Florida manufacturer offering engineering, tooling, injection molding, assembly

HEBEI FINE ART CO. LTD.

Shijiazhuang, China

D

51-100 Employees

2007

Key takeaway

The company specializes in custom injection molded plastic services, offering a comprehensive range of solutions from mold engineering and manufacturing to technical support and after-sales service. With over 15 years of experience, they focus on delivering high-quality products for various applications, including cosmetics, electronics, and auto parts.

Reference

Core business

Custom Molded Plastics-Fine Art

We provide high quality custom molded plastics services, including various cosmetic products, electronic component products, auto parts mold making, etc.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Plastic Injection molding Service

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Plastic parts

medical, auto, industry

molded gaskets molded gasket extruded gaskets custom gasket manufacturing custom silicone gaskets custom gaskets near me molded rubber gasket rubber molded gasket molded rubber gaskets rubber compression gasket o ring molded gasket custom molded gaskets custom viton gaskets custom molded gasket moulded rubber gaskets rubber gasket molding bottle injection molding injection moulding bottles molded silicone gasket epdm gasket compression best plastic for gears bush gear fabrication bush gear custom fabrication fabrication gussets extruded o ring custom ring mold custom molded o rings o ring fabrication epdm seals molded seals rubber seal types custom rubber seals pu injection wheels extruded rubber seals seal rubber products molded rubber seals rubber seal mouldings rubber seal molding custom nylon washers bumper injection

Use case

Plastic parts

medical, auto, industry

molded gaskets molded gasket extruded gaskets custom gasket manufacturing custom silicone gaskets custom gaskets near me molded rubber gasket rubber molded gasket molded rubber gaskets rubber compression gasket o ring molded gasket custom molded gaskets custom viton gaskets custom molded gasket moulded rubber gaskets rubber gasket molding bottle injection molding injection moulding bottles molded silicone gasket epdm gasket compression best plastic for gears bush gear fabrication bush gear custom fabrication fabrication gussets extruded o ring custom ring mold custom molded o rings o ring fabrication epdm seals molded seals rubber seal types custom rubber seals pu injection wheels extruded rubber seals seal rubber products molded rubber seals rubber seal mouldings rubber seal molding custom nylon washers bumper injection

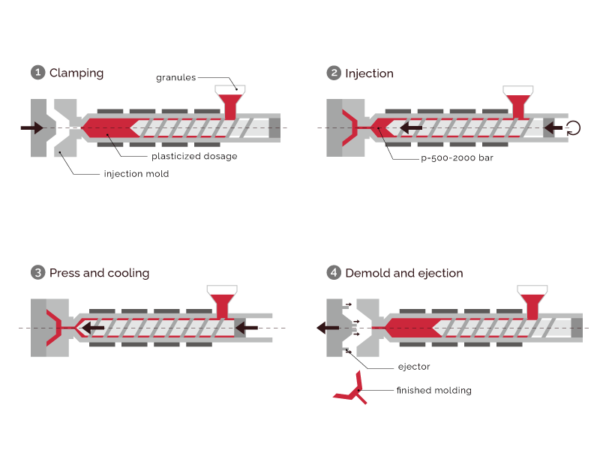

Custom injection molded plastic refers to a manufacturing process that involves creating plastic parts by injecting molten plastic into a mold. This technique allows for high precision and the ability to produce complex shapes that are consistent in quality and performance. The process begins with designing a mold that reflects the desired specifications of the product. Once the mold is created, plastic pellets are heated until they melt and then injected into the mold under high pressure. After cooling, the mold is opened, and the finished part is ejected. This method is widely used across various industries due to its efficiency and versatility. It supports the production of both small and large quantities of parts, making it ideal for everything from prototypes to mass production. Custom injection molded plastic can accommodate a wide range of materials and offers opportunities for surface finishes, colors, and additional features, making it a popular choice for manufacturers looking to meet specific design and functionality requirements.

Custom injection molded plastic is manufactured through a precise and efficient process. Initially, raw plastic material, typically in the form of pellets, is fed into a heated barrel where it is melted. Once the plastic reaches the appropriate viscosity, it is injected into a mold cavity under high pressure. This mold is designed to shape the plastic into the desired form. After the plastic cools and solidifies, the mold is opened, and the finished product is ejected. This method allows for high-volume production of complex shapes with tight tolerances, making it ideal for various applications across industries. The entire process can be automated, ensuring consistency and reducing production time.

Custom injection molded plastic is widely utilized across various industries due to its versatility and efficiency.

1. Automotive Industry

In the automotive sector, custom injection molded plastics are used for manufacturing components like dashboards, door panels, and various interior and exterior parts, contributing to weight reduction and design flexibility.

2. Consumer Goods

This process is essential for producing everyday items such as containers, packaging, and household appliances. The ability to create intricate designs allows brands to enhance functionality and aesthetics.

3. Medical Devices

In the medical field, custom molded plastics are critical for creating devices that require high precision and sterility, including surgical instruments, drug delivery systems, and various diagnostic equipment.

4. Electronics

Custom injection molding supports the production of housings and components for electronic devices. This ensures durability and protection for sensitive internal components.

5. Industrial Applications

Industries utilize custom molded plastics for manufacturing tools, machinery parts, and equipment housings, benefiting from the material's strength and resistance to chemicals.

These applications illustrate the broad impact of custom injection molded plastics across diverse sectors, driving innovation and efficiency.

Custom injection molded plastic products can be made from a variety of materials, each offering unique properties suited to different applications. Thermoplastics are among the most commonly used materials. These plastics become moldable upon heating and can be remolded multiple times, making them versatile and easy to work with. Examples include polyethylene, polypropylene, and polystyrene. Another significant category is thermosetting plastics. Unlike thermoplastics, these materials harden permanently after being molded, providing excellent durability and heat resistance. Common thermosetting plastics include epoxy and phenolic resins. Additionally, engineering plastics such as nylon and polycarbonate are often utilized for their strength and performance in demanding environments. Each material choice impacts the final product's characteristics, such as strength, flexibility, and thermal stability.

1. Design Flexibility

Custom injection molded plastic allows for intricate designs and shapes that may not be achievable with other manufacturing methods. This flexibility enables companies to create highly specialized products tailored to their specific needs.

2. Cost Efficiency

Once the initial mold is created, the cost per unit decreases significantly with large production runs. This efficiency makes custom injection molding a cost-effective solution for producing high volumes of plastic parts.

3. Consistency and Quality

Injection molding produces parts that are uniform and consistent in quality. This reliability is essential for industries where precision and adherence to specifications are critical.

4. Material Variety

There is a wide range of plastic materials available for custom injection molding. This variety allows manufacturers to choose the best material for their application, whether it requires strength, flexibility, or resistance to chemicals.

5. Reduced Waste

The process is designed to minimize waste, as excess plastic is often recycled back into the production cycle. This sustainable approach not only benefits the environment but also reduces overall production costs.

Some interesting numbers and facts about your company results for Custom Injection Molded Plastic

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 9830 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1962 |

| Youngest suiting company | 2009 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Custom Injection Molded Plastic

What are related technologies to Custom Injection Molded Plastic?

Based on our calculations related technologies to Custom Injection Molded Plastic are Aromatics, Desiccants, Refrigerants, Resins, Green Chemistry

Which industries are mostly working on Custom Injection Molded Plastic?

The most represented industries which are working in Custom Injection Molded Plastic are Plastics, Other, Manufacturing, Machinery Manufacturing, Packaging

How does ensun find these Custom Injection Molded Plastic Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.