The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

TEAM D TECHNOLOGIES

Bengaluru, India

D

51-100 Employees

2006

Key takeaway

TEAM D is an industrial engineering business with significant expertise in injection molding, serving various sectors including automotive, aerospace, and healthcare. With over 18 years of experience, they focus on precision manufacturing and engineering services, providing tailored solutions that help reduce time-to-market and costs for global companies.

Reference

Service

Injection Molding

Precision Plastic Products, Inc.

Portland, United States

B

11-50 Employees

1981

Key takeaway

The company is a trusted manufacturer with over 35 years of experience in precision plastic injection molding, ready to assist with all your injection molding needs.

Reference

Core business

Precision Plastic Products

Superior Plastics

Fort Worth, United States

B

11-50 Employees

2006

Key takeaway

The company highlights its expertise in plastic injection molding, where polymer beads are melted and injected into molds to create specific shapes, ensuring high-quality products.

Reference

Service

custom-injection-molding

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

PELCO TOOL & MOLD INC.

Glendale Heights, United States

B

11-50 Employees

-

Key takeaway

Pelco Tool and Mold specializes in creating high-quality precision injection molds, capable of handling high cavitation molds for various industries. Their experienced in-house designers can assist in developing new parts and optimizing mold design for efficiency and durability.

Reference

Service

Precision Injection Mold Services - Pelco Tool & Mold

J&L Plastic Molding

Wallingford, United States

B

11-50 Employees

1972

Key takeaway

J&L Plastic Molding specializes in injection molding, offering expertise in processing highly-engineered thermoplastic resins for demanding applications. With a dedicated facility in Connecticut and a range of injection molding machines, they are well-equipped to handle both prototype and production needs efficiently.

Reference

Core business

Plastic Molding Expertise - J&L Plastic Molding

J&L Plastic Molding is an injection molding company helping companies meet their Quality and Delivery requirements.

IMO Plastic Mold

Shenzhen, China

D

11-50 Employees

2008

Key takeaway

IMO Plastic Mold is a prominent injection molder in China, specializing in low to mid-volume plastic injection molding for a range of projects, from prototypes to full production. The company's commitment to high-quality manufacturing services extends across various industries, ensuring comprehensive solutions for complex and precision parts.

Reference

Product

IMO Plastic Mold Offers Low To Mid Volume Plastic Injection Molding

Jade Group International, LLC

West Bend, United States

B

1-10 Employees

2007

Key takeaway

The company emphasizes its ability to provide high-quality injection molds at competitive prices, which is crucial for winning production jobs in a global market. Their services include custom injection mold making and rapid prototyping, ensuring that clients can compete effectively.

Reference

Service

Rapid Prototyping | Injection Molding Services China | USA

ICOMold

Holland, United States

B

51-100 Employees

2003

Key takeaway

ICOMold specializes in custom plastic injection molding, offering low prices and fast turnaround for both low and high-volume production. With a focus on delivering high-quality parts quickly, ICOMold is a leading choice for all your injection molding needs.

Reference

Core business

ICOMold® (Online Quotes in 30 Seconds)

We provide custom plastic injection molding, CNC machining of plastic and metal, and urethane casting. Low cost and fast turnaround. Get an instant quote.

Precision Injection Molding Inc

City of Langley, Canada

A

1-10 Employees

1996

Key takeaway

PRECISION is a contract manufacturer with extensive injection molding capabilities, providing both individual components and complete product solutions. Their modern facility near Vancouver ensures efficient engineering and manufacturing services for national and international clients.

Reference

Core business

Precision Injection Molding

Xiamen Jingwei Industry & Trade Co., Ltd

Xiamen City, China

D

51-100 Employees

2009

Key takeaway

Xiamen Jingwei Industry & Trade Co., Ltd specializes in providing professional plastic injection molded products, offering services such as free quotes, part design reviews, and a Lifetime Mold Guarantee. With over 15 years of experience in the custom plastic injection molding industry, they are well-equipped to transform designs into finished products.

Reference

Core business

Plastic Injection Molding,Custom injection Molds&Parts

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

OperAID

Go to product

Service

Plastic Injection Moulding

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

HLH helps Kombo Audio injection mould their innovative amp speakers

Audio Technology

Denmark-based startup, Kombo Audio, uses HLH's multi-cavity tooling, injection molding and sheet metal services to build their Innovative Amp System. ✔ Provided in-depth DFM report and suggestions to take a 90% complete design to 100% readiness for manufacturing. ✔ Completed in-depth DFM analysis, tooling, and T1 samples within 3 weeks. ✔ Manufactured a total of 5 tools to support 8 designs. ✔ Precision laser-cut and black anodized 200 sets of sheet metal speaker meshes and rear covers. ✔ Delivered 4k+ parts (200 sets of speakers) in time for Kombo’s Demo and Launch Event in Copenhagen.

Use case

HLH helps SOL Reader injection mould the their e-reader VR Glasses

Electronics, VR Glasses

U.S. tech company, SOL Reader, uses HLH's rapid tooling and silicone overmoulding services to build their cutting-edge SOL e-ink glasses. ✔ Completed in-depth DFM analysis, tooling, and T1 samples within 2.5 weeks. ✔ Manufactured 300 sets of 20+ individual components (mechanical, optical, tight-fit assembly designs and silicone overmoulded components). ✔ Initially used HLH's vacuum casting service to achieve satin, matte, clear, frosted and several other high-quality finishes and textures on their prototypes ✔ Seamlessly progress from prototyping to production and then to market, ✔ HLH successfully delivers 300 sets of injection molded e-reader VR glasses, with tooling readily available for future orders.

Use case

HLH helps Kombo Audio injection mould their innovative amp speakers

Audio Technology

Denmark-based startup, Kombo Audio, uses HLH's multi-cavity tooling, injection molding and sheet metal services to build their Innovative Amp System. ✔ Provided in-depth DFM report and suggestions to take a 90% complete design to 100% readiness for manufacturing. ✔ Completed in-depth DFM analysis, tooling, and T1 samples within 3 weeks. ✔ Manufactured a total of 5 tools to support 8 designs. ✔ Precision laser-cut and black anodized 200 sets of sheet metal speaker meshes and rear covers. ✔ Delivered 4k+ parts (200 sets of speakers) in time for Kombo’s Demo and Launch Event in Copenhagen.

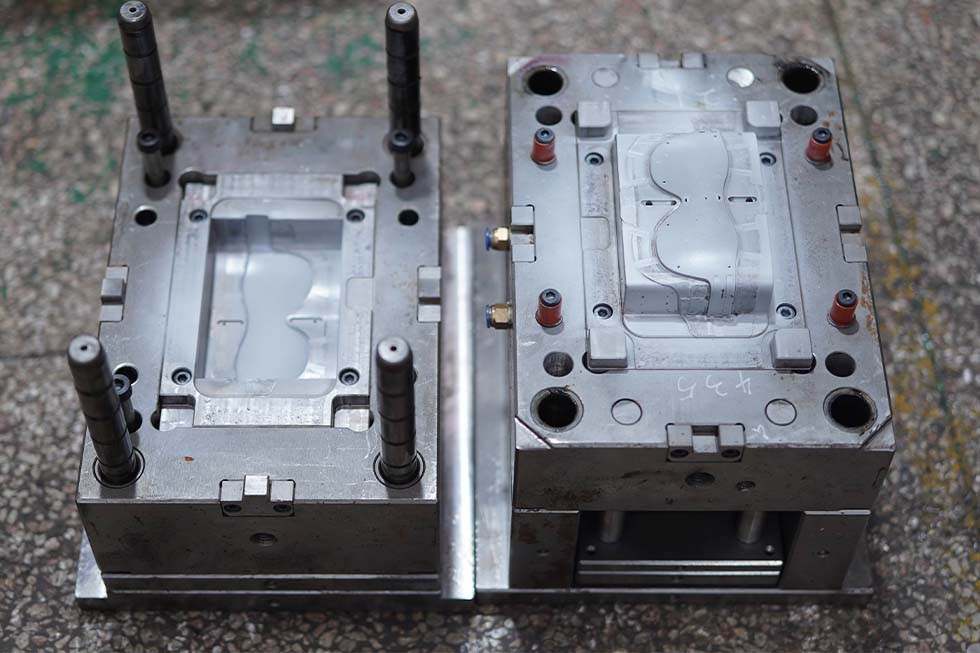

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. This method is commonly employed for creating plastic components, though it can also work with metals and glass. The process begins with heating the material until it becomes fluid, which is then forced into a pre-made mold cavity under high pressure. Once the material cools and solidifies, the mold is opened to reveal the finished part. This technique is highly efficient for mass production, offering consistent quality and reduced material waste. The versatility of injection molding allows for complex shapes and intricate designs, making it a favored choice in industries such as automotive, consumer goods, and electronics.

Injection molding is a manufacturing process that involves injecting molten material into a mold to create various parts and products. Initially, plastic pellets or other raw materials are heated until they become liquid. This molten material is then injected under high pressure into a precisely designed mold cavity, which shapes the material as it cools and solidifies. As the material cools, it takes the form of the mold, creating a finished part. Once the part has cooled sufficiently, the mold opens, and the finished product is ejected. This process allows for high-volume production of complex shapes with excellent precision and repeatability, making it a preferred method in various industries, including automotive, consumer goods, and medical devices.

A variety of materials are utilized in injection molding, with thermoplastics being the most common choice. Polypropylene is favored for its versatility, impact resistance, and low cost, making it suitable for a wide range of applications. Additionally, ABS (Acrylonitrile Butadiene Styrene) is popular due to its strength and durability, often used for consumer products and automotive parts. Polyethylene offers excellent chemical resistance and is frequently used in packaging. Other materials include polycarbonate, known for its transparency and toughness, and thermosetting plastics, which provide enhanced heat resistance and structural integrity for specialized applications.

Several industries commonly utilize injection molding due to its efficiency and versatility in producing plastic parts.

1. Automotive

This industry relies on injection molding for manufacturing components such as dashboards, bumpers, and interior parts, allowing for lightweight and durable solutions.

2. Consumer Goods

Manufacturers of household items, toys, and packaging often use injection molding to create a wide range of products that require precision and high-volume output.

3. Medical

Injection molding is critical in the medical field for producing syringes, surgical tools, and diagnostic equipment, ensuring sterility and accuracy.

4. Electronics

This sector benefits from injection molding for creating housings, connectors, and various components that require intricate designs and reliable performance.

5. Industrial

In industrial applications, injection molding is used for making machinery parts, tools, and fixtures that need to withstand heavy use while maintaining dimensional precision.

1. Cost-Effectiveness

Injection molding is highly efficient for mass production, which significantly reduces the cost per unit. The initial investment in molds may be high, but the long-term savings through large-scale production make it economically advantageous.

2. Design Flexibility

This manufacturing process allows for intricate designs and complex geometries that would be difficult or impossible to achieve with other methods. The ability to use multiple materials and colors in a single mold enhances design possibilities.

3. High Precision and Consistency

Injection molding offers exceptional precision, ensuring that parts are produced with tight tolerances. This consistency leads to high-quality products with minimal variation, essential for industries requiring exact specifications.

4. Rapid Production

The speed of injection molding is unmatched, as it can produce thousands of parts in a short time frame. This rapid turnaround is ideal for businesses needing quick delivery to meet market demands.

5. Minimal Waste

Since the process uses only the necessary amount of material, waste generation is significantly lower compared to other manufacturing methods. This eco-friendly aspect contributes to sustainability goals for many companies.

Some interesting numbers and facts about your company results for Injection Molding

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1972 |

| Youngest suiting company | 2009 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Injection Molding

What are related technologies to Injection Molding?

Based on our calculations related technologies to Injection Molding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Injection Molding?

The most represented industries which are working in Injection Molding are Other, Plastics, Manufacturing, Machinery Manufacturing, Packaging

How does ensun find these Injection Molding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.