The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

WB Pipeline LLC

Houston, United States

B

501-1000 Employees

2017

Key takeaway

WB Pipeline is a specialized oil and gas construction company that focuses on pipeline construction and integrity management, ensuring safe and efficient services that benefit both customers and the environment.

Reference

Service

Pipeline Construction | Oil & Gas Construction Services

Pipework & Welding

Hungerford, United Kingdom

A

1-10 Employees

-

Key takeaway

Pipework and Welding Contracting Services (PWCS) specializes in pipework fabrication and installation, highlighting their expertise in composite reinforcement systems and extensive experience in the pipeline field. Their comprehensive services include locating defects, conducting tests, and carrying out remedial works, making them a key player in pipeline welding and maintenance.

Reference

Core business

Pipework and Welding Contracting Services | United Kingdom

With over 50 years of industry experience, Pipework and Welding Contracting Services (PWCS) are leaders in pipework fabrication and installation, testing, rehabilitation, and composite reinforcement.

Task Welding

Winchester, United Kingdom

A

11-50 Employees

1979

Key takeaway

Task Welding is a specialist facility that offers advanced welding processes, including pipe welding with Helix M85, serving industries such as Oil & Gas and petro-chem. They provide full site services for pipe welding across the UK, operating 24/7.

Reference

Core business

Pipe welding with Helix M85 in Ecuador - Task Welding UK

Pipe welding with Helix M85 in Ecuador

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Rohrmatic GmbH

Mülheim-Kärlich, Germany

A

1-10 Employees

-

Key takeaway

The company is a specialized welding expert with a strong commitment to quality, certified in ISO 9001:2008 and SCC 2011, making them a reliable partner for industrial pipelaying work. Their qualified workforce can provide skilled personnel for pipeline construction projects on short notice.

Reference

Service

Services

MP Weld

Rychnov nad Kněžnou, Czechia

A

1-10 Employees

-

Key takeaway

ESAB is a leading global manufacturer of welding and cutting equipment, and MP Weld offers a wide range of products for welding and grinding, including specialized solutions for pipe welding.

Reference

Service

Pipe Welding – mp-weld

COMPLETE WELDING SERVICES INTERNATIONAL PTY. LTD.

Melbourne, Australia

A

11-50 Employees

1991

Key takeaway

Complete Welding Services is a prominent pipe fabricator for the Fire Protection industry, boasting over 35 years of experience in diverse fabrication and welding projects.

Reference

Core business

Complete Welding Services

WeldFit Corporation

Houston, United States

B

11-50 Employees

1968

Key takeaway

WeldFit specializes in engineered products and services that enhance pipeline productivity while ensuring safety and efficiency. With over 50 years of experience, they offer solutions like automated pigging systems and line intervention, making them a key player in the pipeline welding industry.

Reference

Core business

We're Making Pipelines More Productive Hot Tap Line Stop… | WeldFit

WeldFit specializes in automated pipeline pigging systems, traditional pig launchers/receivers, quick opening closures and pig passage indicators

WeldiT Mobile Welding & Fabrication

Houston, United States

B

251-500 Employees

2018

Key takeaway

WELDIT is a prominent provider of welding and fabrication services, offering customized solutions that cater to various industries, including construction. Their commitment to high-quality work and outstanding service positions them as a valuable resource for pipeline welding needs.

Reference

Service

WeldIt

Pt Pipe Fabrications Ltd

Chelmsford, United Kingdom

A

1-10 Employees

-

Key takeaway

PT Pipe Fabrications Ltd specializes in pipework fabrication, offering high-quality services in various materials, including stainless steel and carbon steel. With over 150 years of experience, their expert team ensures timely delivery for all types of pipework projects.

Reference

Service

Our Work - PT Pipes

[vc_row r_bg_color=”bkg-red” half_section=”0″ r_parallax=”0″ css=”.vc_custom_1506005226156{margin-bottom: 30px !important;}”][vc_column c_align=”center” c_align_mobile=”center” c_animation=”0″ c_eq_height=”1″ c_margin_bottom=”1″][vc_custom_heading text=”Prefabrication from sketches or on-site measuring” font_container=”tag:h1|font_size:38px|text_align:center|color:%23ffffff|line_height:42px” use_theme_fonts=”yes” css=”.vc_custom_1506439424371{padding-top: 10px !important;padding-bottom: 1px !important;}”][/vc_column][/vc_row][vc_row r_width_type=”boxed” half_section=”0″ r_parallax=”0″ css=”.vc_custom_1506178954460{margin-top: 30px !important;margin-bottom: 30px !important;}”][vc_column c_align=”center” c_align_mobile=”center” c_animation=”0″ c_eq_height=”1″ c_margin_bottom=”1″][vc_column_text]PT Pipe Fabrications Ltd are specialist pipework fabricators, fabricating pipework to the highest standards, compliant to BS-EN-ISO-15614 part […]

Pro-pipework

Wakefield, United Kingdom

A

1-10 Employees

-

Key takeaway

Pro-Pipework Ltd is a professional pipework and welding service provider in the UK, specializing in all aspects of pipework in the commercial sector.

Reference

Core business

Pro-pipework LTD

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

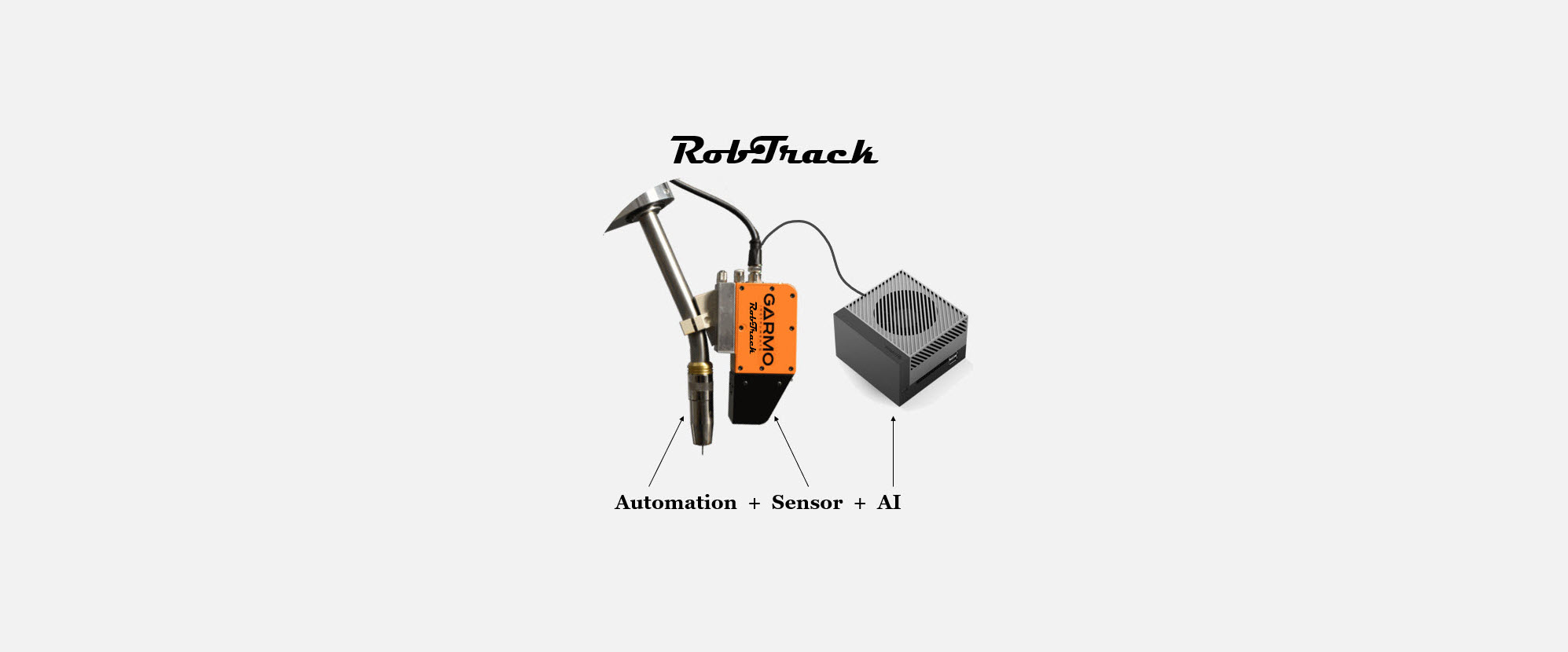

RobTrack

Go to product

Pipeline welding refers to the specialized process of joining sections of pipe, typically used in the transportation of fluids and gases across various industries. This method ensures the integrity and durability of pipelines, which are critical for infrastructure such as oil and gas distribution, water supply systems, and chemical transport networks. Skilled welders utilize techniques such as shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and others to create strong, leak-resistant joints. Proper pipeline welding is essential for maintaining safety standards and efficient operation in these vital systems.

Various equipment is essential for effective pipeline welding. A welding machine is crucial, typically a multi-process welder that can handle different welding methods, such as MIG, TIG, or stick welding. Additionally, welding consumables, such as electrodes and filler materials, are needed to ensure strong and durable welds. Safety gear, including helmets, gloves, and protective clothing, is vital to protect welders from hazards. Welding positioners and clamps help secure the pipes in place, while grinders and cutting tools are often used for preparation and finishing of the welds.

Safety measures in pipeline welding are crucial to ensure the well-being of workers and the integrity of the pipeline. First, personal protective equipment (PPE) plays a vital role. Welders should wear helmets with appropriate face shields, gloves, fire-resistant clothing, and steel-toed boots to protect against burns and injuries. Additionally, adequate ventilation is necessary to prevent the accumulation of harmful fumes and gases. Ensuring that the work area is well-ventilated reduces the risk of inhalation hazards. Furthermore, fire safety protocols must be in place, including having fire extinguishers readily available and establishing a clear evacuation plan. Regular training on these safety measures helps to maintain a culture of safety on the job site.

Pipeline welding is distinct from other welding techniques primarily due to its specific applications and requirements in the construction and maintenance of pipelines. This method often involves welding pipes that transport liquids and gases, which necessitates adherence to stringent industry standards and regulations. The process typically requires specialized skills and equipment to ensure the integrity and safety of the welds, as any failure could lead to significant environmental and safety hazards. Additionally, pipeline welding often occurs in challenging environments, such as remote locations or under extreme weather conditions, which further sets it apart from more standard welding practices used in various manufacturing settings.

1. Welding Techniques

Pipeline welders must be proficient in various welding techniques, including SMAW (Shielded Metal Arc Welding), GTAW (Gas Tungsten Arc Welding), and GMAW (Gas Metal Arc Welding). Each technique has its specific applications and requires different skills to ensure strong and reliable welds.

2. Blueprint Interpretation

Understanding blueprints and technical drawings is essential for pipeline welders. This skill enables them to accurately interpret specifications and dimensions, ensuring that all welding work aligns with project requirements and industry standards.

3. Safety Practices

Knowledge of safety protocols and practices is critical in pipeline welding due to the hazardous environment. Welders must be familiar with personal protective equipment (PPE) and safety regulations, reducing the risk of accidents and injuries on the job.

4. Equipment Proficiency

Pipeline welders must be skilled in operating welding equipment and tools. This includes setting up machines, adjusting parameters, and performing routine maintenance to ensure optimal performance during welding operations.

5. Inspection Skills

The ability to conduct inspections and assess the quality of welds is crucial. Welders should be knowledgeable in non-destructive testing methods to ensure that their work meets the required standards for strength and durability.

Some interesting numbers and facts about your company results for Pipeline Welding

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6846 |

| Amount of suitable service providers | 9324 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1968 |

| Youngest suiting company | 2018 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Pipeline Welding

What are related technologies to Pipeline Welding?

Based on our calculations related technologies to Pipeline Welding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Pipeline Welding?

The most represented industries which are working in Pipeline Welding are Other, Construction, Oil, Energy and Gas, Manufacturing, Machinery Manufacturing

How does ensun find these Pipeline Welding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.