The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Weld Action Company

United States

B

51-100 Employees

-

Key takeaway

Weld-Action specializes in custom-designed robotic and standard arc welding cells, offering a comprehensive engineering solution that includes design, build, testing, and installation. Their commitment to providing essential peripheral equipment and tooling enhances the overall effectiveness of welding applications.

Reference

Product

WeldingEquipment - Weld Action

Arc Solutions Inc.

Hicksville, United States

B

11-50 Employees

2001

Key takeaway

Arc Solutions, Inc. is a specialized supplier of welding products and services, highlighting their expertise in providing solutions for arc welding. They offer a range of products designed to enhance productivity and safety, including the Swivel Arc, a flexible welding boom that ensures precise wire delivery for various materials.

Reference

Core business

Arc Solutions | Welding Product Supply & Machine Service Company

Arc Solutions, Inc. is your go-to expert for welding products, plasma cutting, automation, machine repair & sales of equipment & consumables.

Arc Training Solutions

Ireland

A

1-10 Employees

-

Key takeaway

Arc Training Solutions in Carlow specializes in professional welder training, offering courses that cover everything from introductory techniques to advanced skills, including Manual Metal Arc Welding. Their programs are designed to equip participants with the necessary competencies and certifications for coded pipe welding.

Reference

Core business

About Us | Arc Training Solutions

Arc Training Solutions, Carlow was established in 2011 to provide professional welder training in Ireland at all levels. Training is provided at our dedicated training facility in Carlow where each trainee is allocated his/her own work bay which is fully … Read More

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Welders

Aalst, Belgium

A

11-50 Employees

1948

Key takeaway

Welders N.V. has extensive experience with various welding techniques, including Flux Cored Arc Welding, Gas Metal Arc Welding, and Gas Tungsten Arc Welding, making it a key player in the industry since 1948. Their commitment to advanced welding methods and quality management, evidenced by ISO:9001 and ASME U-Stamp certifications, underscores their expertise in custom-built equipment for the hydrocarbon and chemical processing sectors.

Reference

Product

Products | Welders

RENTARC LIMITED

Portsmouth, United Kingdom

A

1-10 Employees

-

Key takeaway

RentArc specializes in hiring welding equipment, offering a wide range of products including plasma cutters, MIG and TIG packages, and MMA stick welding tools. Their commitment to reliability and strong client relationships ensures that they can provide the right machinery and support for any welding project, particularly in the South of the UK.

Reference

Core business

Welding Machine Hire Specialists in Hampshire | RentArc

RentArc are welding equipment hire specialists based in Hampshire, UK. Hire welding equipment for every application and industry sector. Call us on +44 (0)23 80 867 789

Welding & Welder

Plymouth, United Kingdom

A

1-10 Employees

2010

Key takeaway

Welding and Welder offers a comprehensive selection of high-quality welding equipment and supplies, including solutions for MIG, TIG, and MMA welding. With a focus on precision and dedication, the company ensures that professionals and hobbyists alike have access to the products they need for successful welding projects.

Reference

Core business

Welding & Welder: Welding Equipment & Supplies

Welding equipment for MIG, TIG & MMA welding. Vast range of welding machines, cutting equipment, safety equipment and fume extraction. Welding suppliers online.

ARO Welding Technologies

Montval-sur-Loir, France

A

101-250 Employees

1949

Key takeaway

ARO Welding Technologies SAS has been a leader in resistance welding technology since 1949, providing innovative solutions for various welding methods, including spot, projection, seam, and butt welding.

Reference

Service

Service | ARO Welding Technologies

Weltechs

Antwerp, Belgium

A

1-10 Employees

-

Key takeaway

The company offers specialized welding services, including Tungsten Inert Gas (TIG) or Gas Tungsten Arc Welding, ensuring they meet and exceed client expectations through customization and exceptional customer service.

Reference

Core business

Welder | Weltechs

Advanced Welding Projects

Coatbridge, United Kingdom

A

1-10 Employees

-

Key takeaway

Advanced Welding Projects is a certified welding company that offers a range of services, including welding, fabrication, and design works, particularly in structural pipe work and bespoke fabrications.

Reference

Service

Services – Advanced Welding Projects

betterWeld

United Kingdom

A

1-10 Employees

-

Key takeaway

betterWeld specializes in training, consultancy, and fabrication, with a strong focus on welding. They offer a comprehensive range of qualifications, from introductory courses to advanced coded welder training, and supply various welding equipment and consumables.

Reference

Product

ArcTrode - E7018-1 Electrodes (4.0mm) 5kg – BetterWeld Group

Here at betterWeld we specialise in the supply of welding equipment & consumables. We offer adult appretices from Level 2 Performing Manufacturing Operationf to Level 4 responsible welding co-ordinator courses. We are able to implement welding procdures & carry our air quality checks.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

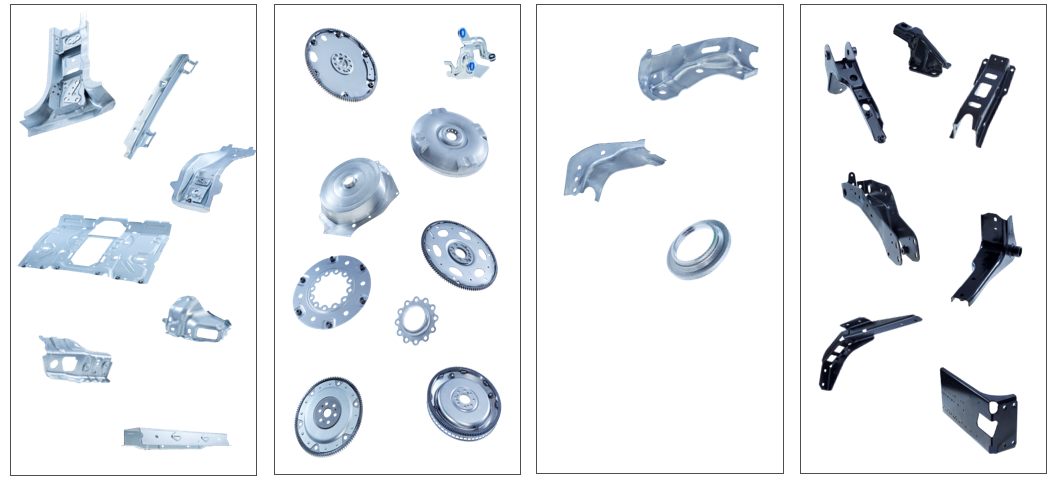

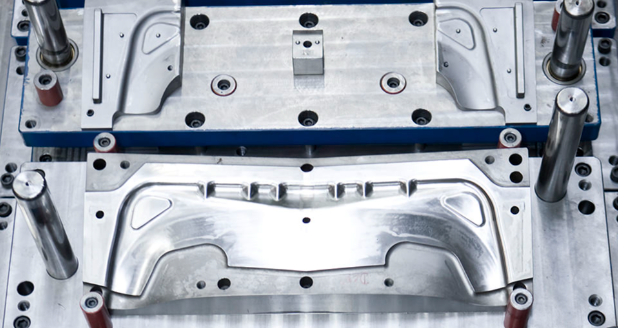

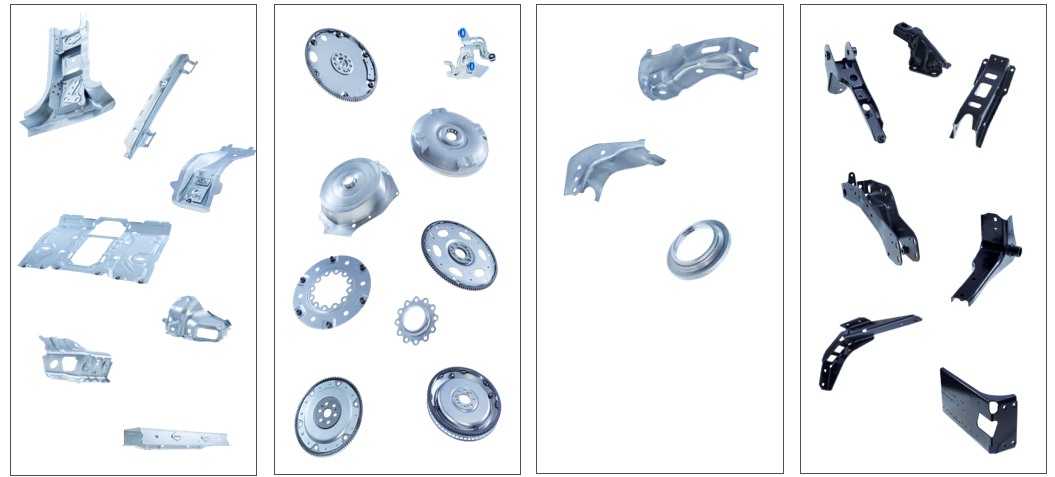

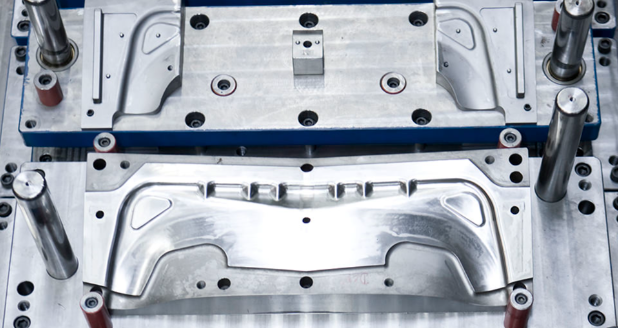

Sheet Metal Parts and Components

Go to product

Service

Relocation Projects

Go to product

Product

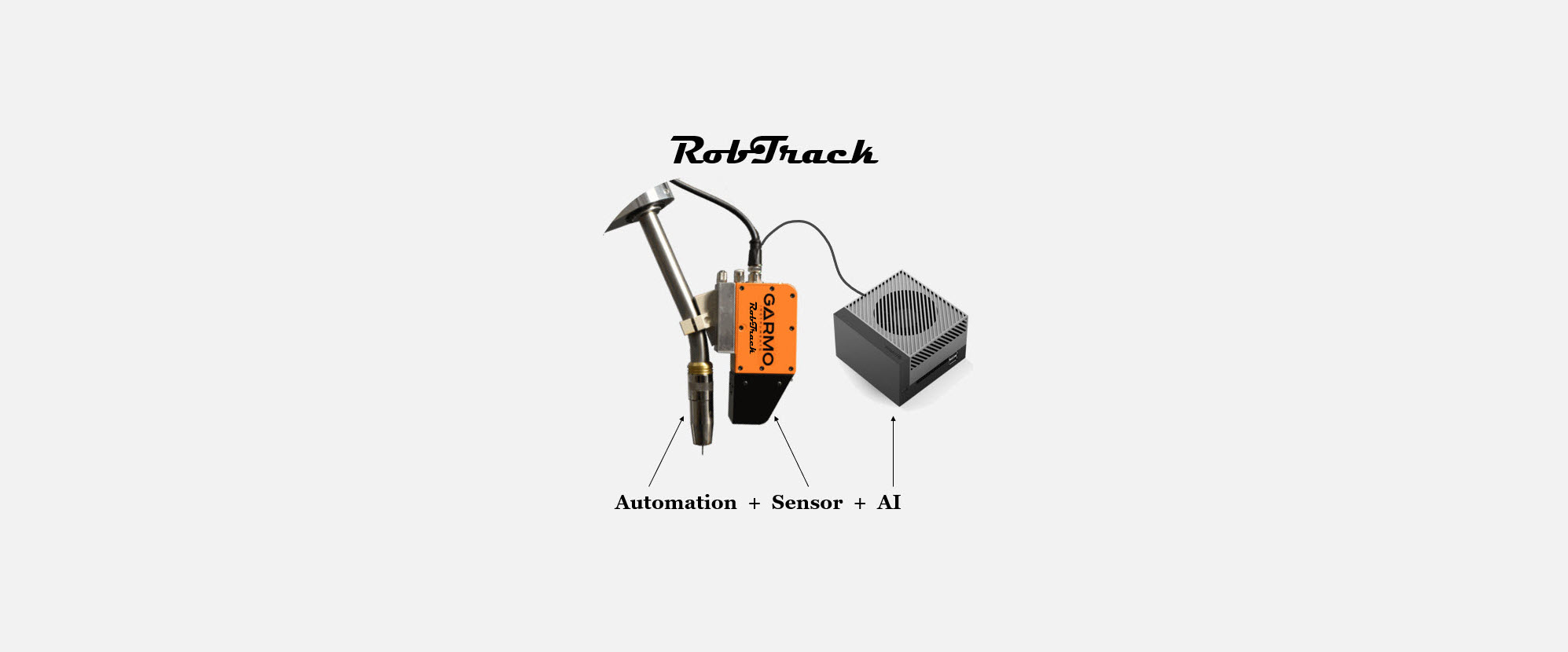

RobTrack

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

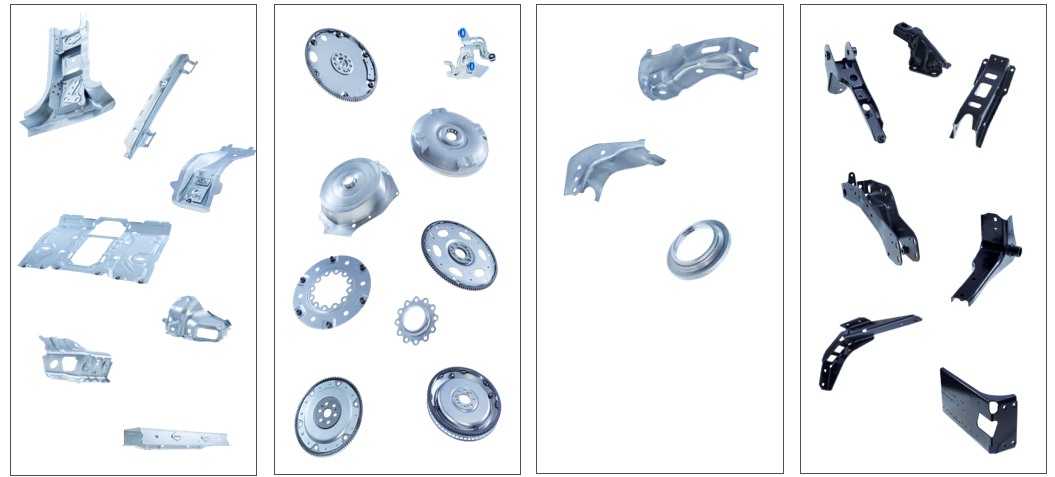

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

Use case

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

Car Body in White

Automotive, Industry

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

ARC welding is a process that uses an electric arc to create heat, melting the base metals and filler material to form a weld. This technique is widely employed in various industries due to its versatility and effectiveness in joining metals. The arc is established between an electrode and the workpiece, producing temperatures that can exceed 6,500°F (3,600°C). Different types of ARC welding, such as Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW), utilize specific electrodes and shielding gases to protect the weld pool from contamination. The process is favored for its ability to produce strong, high-quality joints in a variety of applications, ranging from construction to automotive manufacturing.

ARC welding operates by creating an electric arc between an electrode and the workpiece. This arc generates intense heat, melting both the electrode and the base material, allowing them to fuse together. The process typically involves a consumable electrode, which melts and contributes to the weld pool while also shielding it from contaminants in the air. The welder maneuvers the electrode along the joint, maintaining a consistent arc length to ensure a strong bond. As the molten metal cools, it solidifies, resulting in a durable welded joint. Various techniques and equipment can be used in ARC welding, including different electrode types and current settings, to achieve desired results for various applications.

1. Versatility

ARC welding can be employed across various materials, including steel, aluminum, and cast iron. This adaptability makes it suitable for numerous applications in manufacturing, construction, and repair.

2. Cost-Effectiveness

The equipment and materials used in ARC welding are generally less expensive compared to other welding methods. This affordability can lead to significant savings for businesses, especially in high-volume production environments.

3. Strong Welds

Welds produced through ARC welding are known for their strength and durability. The process creates deep, penetrating welds that are often stronger than the base materials, ensuring long-lasting results.

4. Ease of Use

ARC welding techniques are relatively easy to learn, making them accessible for both beginners and experienced welders. The simplicity of the process allows for quick setup and execution, increasing productivity.

5. Portability

Many ARC welding machines are portable, allowing for use in various locations. This mobility is particularly beneficial for on-site repairs and projects that require flexibility in work environments.

To perform ARC welding, several essential pieces of equipment are required to ensure efficiency and safety. A welding machine is the primary tool, providing the necessary electrical current to create the arc. Additionally, welding electrodes are crucial, as they melt to fuse the materials being joined. Protective gear is also vital; this includes a welding helmet to shield the eyes and face from bright light and sparks, along with gloves and protective clothing to safeguard the skin. Lastly, a workpiece holder or clamping device can help stabilize the materials during the welding process, ensuring precision and control.

Safety precautions for ARC welding are crucial to protect both the welder and those nearby. First, it is essential to wear proper personal protective equipment (PPE), which includes a welding helmet with appropriate shading to protect the eyes from intense light and harmful UV radiation. Additionally, gloves, long-sleeved clothing, and steel-toed boots should be worn to shield the skin and feet from sparks and heat. Proper ventilation in the workspace is also necessary to reduce the risk of inhaling harmful fumes. It is important to ensure that the work area is free of flammable materials to prevent fire hazards. Furthermore, maintaining a safe distance from electrical sources and using insulated equipment can help avoid electric shock. Regularly inspecting tools and equipment for wear and tear adds another layer of safety, ensuring that all components function correctly and safely.

Some interesting numbers and facts about your company results for ARC Welding

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 5973 |

| Amount of suitable service providers | 8959 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 1948 |

| Youngest suiting company | 2010 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for ARC Welding

What are related technologies to ARC Welding?

Based on our calculations related technologies to ARC Welding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on ARC Welding?

The most represented industries which are working in ARC Welding are Other, Construction, Manufacturing, Machinery Manufacturing, Oil, Energy and Gas

How does ensun find these ARC Welding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.