The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

EA Aluminum Welding

Santa Ana, United States

B

- Employees

-

Key takeaway

EA Aluminum Welding has over 40 years of experience in aluminum welding and multiple certifications, highlighting their expertise and capability to handle various welding needs, including repairs and fabrication. Their mobile services allow them to conveniently assist with projects on-site.

Reference

Service

Welding Services | EA Aluminum Welding

WELDING ALLOYS LTD

Nairobi, Kenya

D

51-100 Employees

1977

Key takeaway

Welding Alloys Limited has extensive experience in manufacturing a variety of electrodes, including those suitable for different welding applications. Their product range and established partnerships position them as a comprehensive resource for welding needs, which may include aluminium welding solutions.

Reference

Service

Welding Alloys Ltd

Weldtool Technologies Inc

United States

B

1-10 Employees

2007

Key takeaway

Weldtool Technologies specializes in supplying hard-to-find filler metals and rods, including those for aluminum welding. They provide quick quotations and emphasize fast and comprehensive service, making them a reliable source for aluminum welding materials.

Reference

Product

Aluminum Welding Filler Metals – Weldtool Technologies

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Arcalloys

Dudley, United Kingdom

A

1-10 Employees

-

Key takeaway

Arc Alloys specializes in welding and fabrication, offering comprehensive aluminium welding services that cater to various industries. With over 30 years of experience and a commitment to customer service, they are well-equipped to meet the needs for aluminium welding and fabrication.

Reference

Product

Aluminium Welding Services - Welding & Fabrication | Arc Alloys

Welding and Fabrication have been at the core of Arc Alloys business since 1998. Check out our Aluminium Welding Services here and contact us today.

Indalco Alloys Inc.

Mississauga, Canada

A

- Employees

2001

Key takeaway

Indalco® Alloys, a division of the Lincoln Electric Company of Canada LP, specializes in providing comprehensive aluminum welding solutions, offering high-quality MIG and TIG products designed for demanding applications. With over 25 years of experience and unique in-house capabilities, Indalco ensures a full range of alloys and exceptional technical support.

Reference

Core business

News | Indalco | Superior Aluminum Welding Performance

LINK ENGINEERING AND WELDING LTD

Llanfair Dyffryn Clwyd, United Kingdom

A

1-10 Employees

-

Key takeaway

Link Engineering and Welding specializes in engineering and fabrication services, which may include aluminium welding. The company's commitment to quality ensures that customers receive top-notch products and services.

Reference

Service

Aluminium-welding - Link Engineering Wrexham

WB ALLOY WELDING PRODUCTS LIMITED

Aberdeen City, United Kingdom

A

- Employees

1998

Key takeaway

WB Alloys is a manufacturer of various welding consumables, including high-quality filler wires for MiG, TIG, MMA, SAW, and Flux welding processes. They also offer comprehensive technical support and a range of services related to welding engineering and equipment.

Reference

Core business

Welding Supplies and Equipment | WB Alloys

WB Alloys Direct welding supplies & equipment, Aberdeen, Glasgow, Stockton and Tavistock. Full range of solutions from Welding wire, Welding Machines, Fume Extraction Systems, Plasma Cutters, Gas Cutting Equipment, Safety Equipment, Pipe Bevelling Machines, Pipe stands for welding and Data Logging weld monitors and Gas Analysis...

HYPA ALUMINIUM EXTRUSIONS LTD

Birmingham, United Kingdom

A

11-50 Employees

2009

Key takeaway

Hypa Aluminium specializes in aluminium welding, offering TiG and MiG welding services that adhere to stringent quality standards. Their commitment to flexibility and fast turnaround ensures that they can meet diverse production demands while maintaining high-quality welding processes.

Reference

Service

TiG & MiG Welding – Hypa Aluminium

Angell Welding & Fabrications

London, United Kingdom

A

11-50 Employees

1978

Key takeaway

Angell Welding is a professional welding company that specializes in aluminium welding and fabrication, offering services such as aluminium casting repairs and the creation of bespoke structures. With extensive experience since 1978, they cater to various industries, including specialized work for the Formula One sector.

Reference

Core business

HOME - Angell Welding

Based in South London, Est.1978 we're experts in Metal Fabrication, Welding & Engineering for all industries including architectural & building services.

Fabweld Metalworks

Dover, United Kingdom

A

1-10 Employees

-

Key takeaway

Fabweld Metalworks specializes in aluminium welding, providing full TIG and MIG welding facilities capable of handling materials ranging from 0.9mm to 25mm thick. Their experienced team has been delivering engineering services since 1987, making them well-equipped for various projects.

Reference

Service

Aluminium | Fabweld Metalworks

We are specialists in the handling of Aluminium, offering a full Tig and Mig welding facility, with dedicated machines for this process, welding anything from 0.9mm to 25mm thick. We can work this …

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

SpeedGun

Go to product

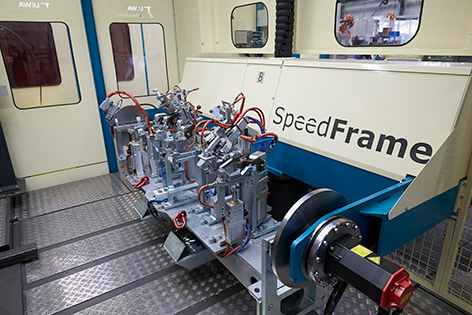

Product

SpeedFrame

Go to product

Product

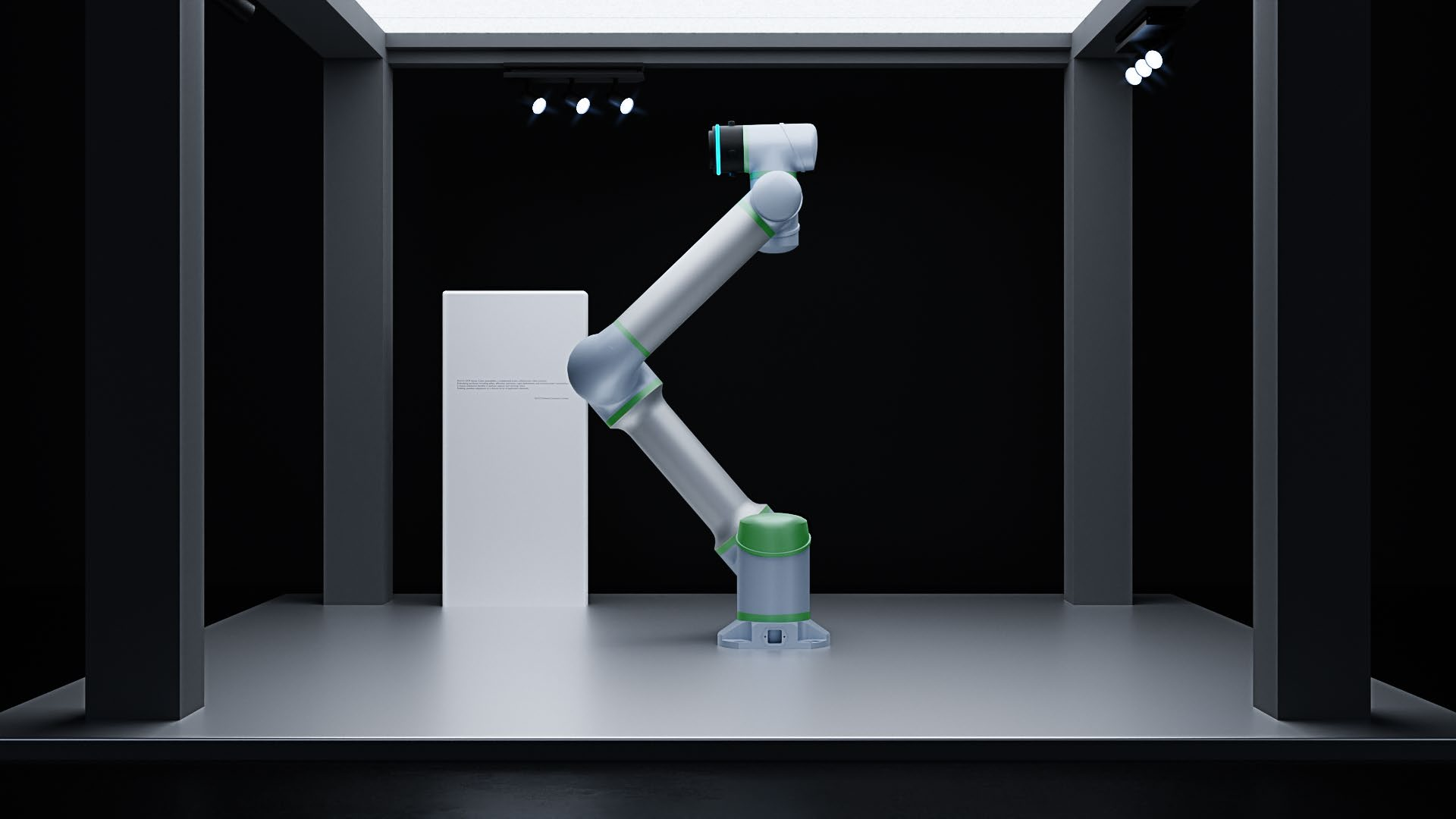

Collaborative Robot

Go to product

Service

Welding

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

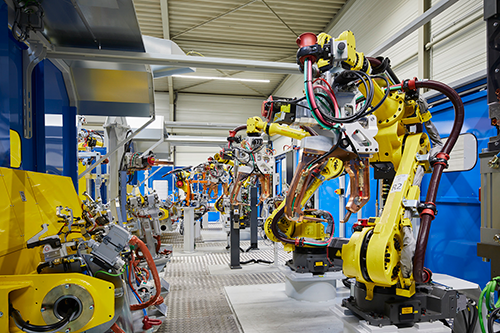

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Use case

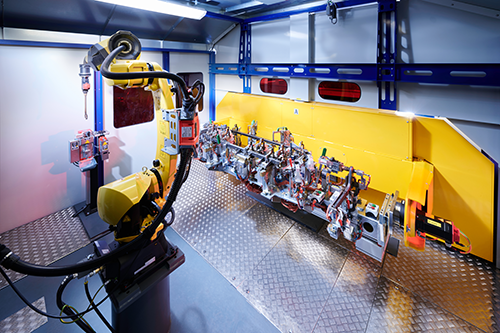

Production system for MIG welding of a seat assembly

automotive

esign of a production system for MIG welding of a complex, heavy duty vehicle seat assembly consisting of backrest (60% and 40%) and seat bench. The goal is 30,000 units per year in a maximum of 616 seconds per seat assembly. The production system is to be manned by one operator. We developed a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.

Use case

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Aluminium welding refers to the process of joining aluminium materials through the application of heat and pressure. This method is essential in various industries, such as automotive, aerospace, and construction, due to aluminium's lightweight and corrosion-resistant properties. Different techniques, including Gas Metal Arc Welding (GMAW) and Tungsten Inert Gas (TIG) welding, are commonly employed for aluminium welding. Each technique has its advantages, enabling precision and strength in the welds. Proper selection of filler materials and welding techniques is crucial to ensure strong, durable joints that can withstand the demands of their intended applications.

1. Gas Metal Arc Welding (GMAW)

This technique, also known as MIG welding, uses a continuous wire feed and a shielding gas to protect the weld pool from contamination. GMAW is favored for its speed and versatility, making it suitable for various aluminium thicknesses.

2. Tungsten Inert Gas Welding (TIG)

TIG welding employs a non-consumable tungsten electrode and requires the welder to manually feed a filler rod into the weld pool. This method allows for precise control and is ideal for thin aluminium sections, producing high-quality, clean welds.

3. Plasma Arc Welding (PAW)

In PAW, an electric arc is formed between a tungsten electrode and the workpiece, creating a plasma beam that melts the metal. This technique offers greater control over the heat input, making it suitable for intricate designs and high-purity welds.

4. Shielded Metal Arc Welding (SMAW)

SMAW, or stick welding, uses a consumable electrode coated in flux to create the weld. While less common for aluminium compared to other methods, it is still used for certain applications due to its simplicity and portability.

5. Friction Stir Welding (FSW)

This solid-state process involves using a rotating tool to create frictional heat, softening the aluminium and allowing it to be stirred together without melting. FSW is particularly effective for joining thick sections and can produce strong, defect-free welds.

Aluminium welding differs significantly from steel welding due to the unique properties of aluminium. Thermal conductivity is a major factor; aluminium has a higher thermal conductivity, which requires different heat input and control during the welding process. This results in a tendency for distortion and warping if not managed properly. Another key difference is oxidation. Aluminium forms a tough oxide layer that must be removed for effective welding. This contrasts with steel, which can rust but does not have the same oxide challenge. Additionally, aluminium welding often involves different techniques, such as TIG or MIG welding, which are more suitable for this lightweight metal compared to traditional steel welding methods.

The essential equipment for aluminium welding includes a welding machine that can handle the specific requirements of aluminium, such as AC TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding systems. Additionally, welding electrodes or filler rods specifically designed for aluminium are necessary to ensure a strong bond. Protection gear, including a welding helmet, gloves, and protective clothing, is crucial for safety during the process. Lastly, proper gas supply for shielding, typically argon for TIG and a mix for MIG, is needed to prevent contamination of the weld.

Aluminium welding presents several challenges that require specialized knowledge and techniques. One significant issue is the high thermal conductivity of aluminium, which can lead to rapid heat dissipation. This characteristic makes it difficult to achieve the necessary temperatures for proper fusion without causing distortion in the material. Another challenge is the formation of oxide layers on aluminium surfaces. These oxide films can hinder the welding process by preventing proper adhesion between the weld metal and the base material. It is crucial to clean the surfaces thoroughly before welding to ensure a strong bond. Additionally, the risk of porosity is higher in aluminium welds, which can occur due to trapped gases during the welding process. Proper techniques and equipment are essential to mitigate these challenges and achieve high-quality welds.

Some interesting numbers and facts about your company results for Aluminium Welding

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 6625 |

| Amount of suitable service providers | 8547 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1977 |

| Youngest suiting company | 2009 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Aluminium Welding

What are related technologies to Aluminium Welding?

Based on our calculations related technologies to Aluminium Welding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Aluminium Welding?

The most represented industries which are working in Aluminium Welding are Other, Manufacturing, Construction, Mining, Machinery Manufacturing

How does ensun find these Aluminium Welding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.