The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Cambridge Numerical Control

Huntingdonshire, United Kingdom

A

1-10 Employees

1981

Key takeaway

Cambridge Numerical Control specializes in providing comprehensive DNC and MDC solutions for CNC machine tools, highlighting their expertise and experience in the engineering industry since 1981. They are recognized by major machine tool companies for their capability in DNC installations, making them a reliable partner for CNC solutions.

Reference

Core business

CNC

CNC Machine Services

Washington, United States

B

11-50 Employees

1988

Key takeaway

CNC Machine Services, Inc. specializes in providing advanced manufacturing solutions, including a focus on CNC machines and tools. With a commitment to innovation and automation, they offer a range of high-quality products and services to support the manufacturing industry.

Reference

Core business

Machine Tools, Services, Software, Accessories

At CNC, we offer the highest quality products, services supported by an exceptional staff that defines customer service. CNC is your single source for machine tool sales, service, software, parts and accessories. We take pride in doing 110 business with honesty and integrity. Contact us today!

Total Machine Support Ltd

Tamworth, United Kingdom

A

1-10 Employees

-

Key takeaway

The company specializes in CNC machine diagnostics and calibration, offering total support and repair services for a wide range of CNC machines.

Reference

Core business

Total Machine Support - CNC Repair in Tamworth UK

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Advance Technology Consortium Ltd.(ATCL)

Dhaka, Bangladesh

E

51-100 Employees

1999

Key takeaway

The company, ATCL (Advance Technology Consortium Ltd.), is a prominent supplier of various types of equipment, including CNC machinery, for sectors such as engineering education, industry, and research. They emphasize their commitment to providing world-class products and support, enhancing their reputation as a leading provider in this field.

Reference

Product

CNC Machinery

CNC PROFESSIONAL MACHINE ANE ENGINEERING

South Africa

C

11-50 Employees

2013

Key takeaway

CNC Professional Machines positions itself as a key player in the South African market, offering high-tech and high-quality CNC products that are increasingly replacing imported alternatives. Their commitment to efficiency and timely provision of parts ensures that production processes in industries like advertising, molding, and woodworking can continue smoothly.

Reference

Core business

Welcome

CNC Professional Machines promotes high-tech high-quality products, engaging in sales of CNC products in the advertising, molding, woodworking...

CNC Digital Inc

LaGrange, United States

B

1-10 Employees

2004

Key takeaway

CNC Digital, Inc. offers a range of quality CNC machines, from simple drill presses to advanced multi-axes Turn/Mill lathes, along with expert service and spare parts. They also provide refurbishment services for older CNC machines, enhancing their performance at a lower cost than new equipment.

Reference

Product

Equipment | CNC Digital, Inc. - CNC Digital, Inc.

CNC Digital, Inc. is committed to bringing you quality CNC machine tool sales, service and spare parts. Whether you are buying a simple drill press or a complicated mult…

PCMS

High Wycombe, United Kingdom

A

1-10 Employees

-

Key takeaway

PCMS offers a comprehensive range of CNC services, including 3-axis and 5-axis programming, ensuring timely delivery of complex programs for milling and routing needs.

Reference

Service

CNC Machining - PCMS

Campat Machine Tool Inc. (800)-450-4120

Plano, United States

B

11-50 Employees

1988

Key takeaway

CAMPAT Machine Tool, Inc. is a CNC machinery importer, distributor, and reseller, highlighting its expertise in the field. The company also offers GibbsCam training, further enhancing its service offerings related to CNC technology.

Reference

Core business

CNC Machinery importer, distributor, and reseller

CNC Machines

Sanford, United States

B

11-50 Employees

2010

Key takeaway

The company offers a wide selection of used CNC machines, including CNC mills and lathes from top brands like Haas and Mazak. Their expertise in the CNC industry ensures that they can help buyers find the right equipment to meet their specific machining needs.

Reference

Core business

CNC Machines: Sell & Buy Used CNC Machines & Equipment

CNC Manufacturing Inc.

Coatesville, United States

B

51-100 Employees

1997

Key takeaway

CNC Manufacturing has been a key player in American manufacturing since 1997, offering high-quality and reliable machining services. They specialize in efficiently producing exotic materials and close tolerance parts, making them well-equipped to meet the demands of CNC machining.

Reference

Core business

About Us – CNC Manufacturing

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

CNC300 Software

Go to product

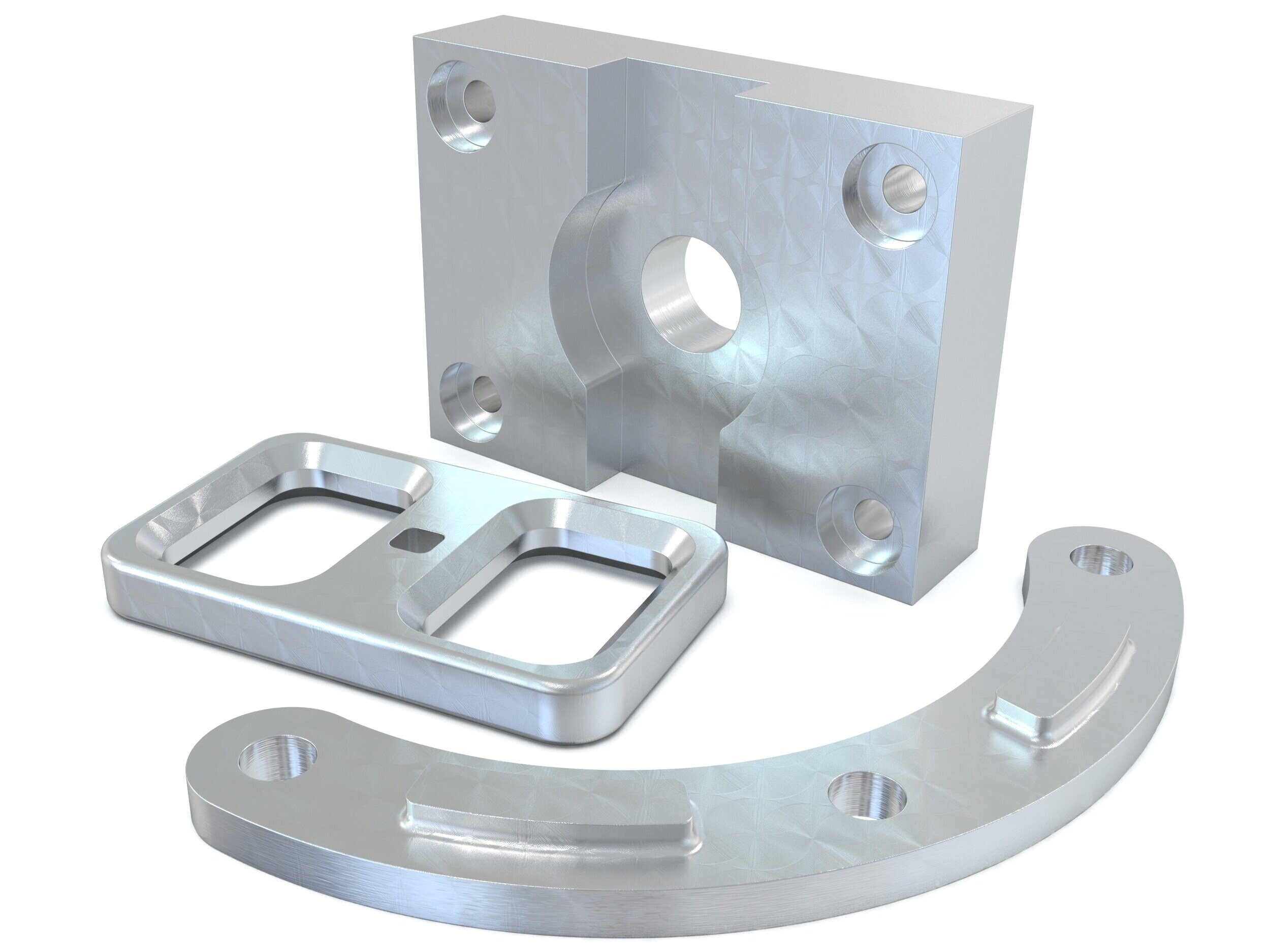

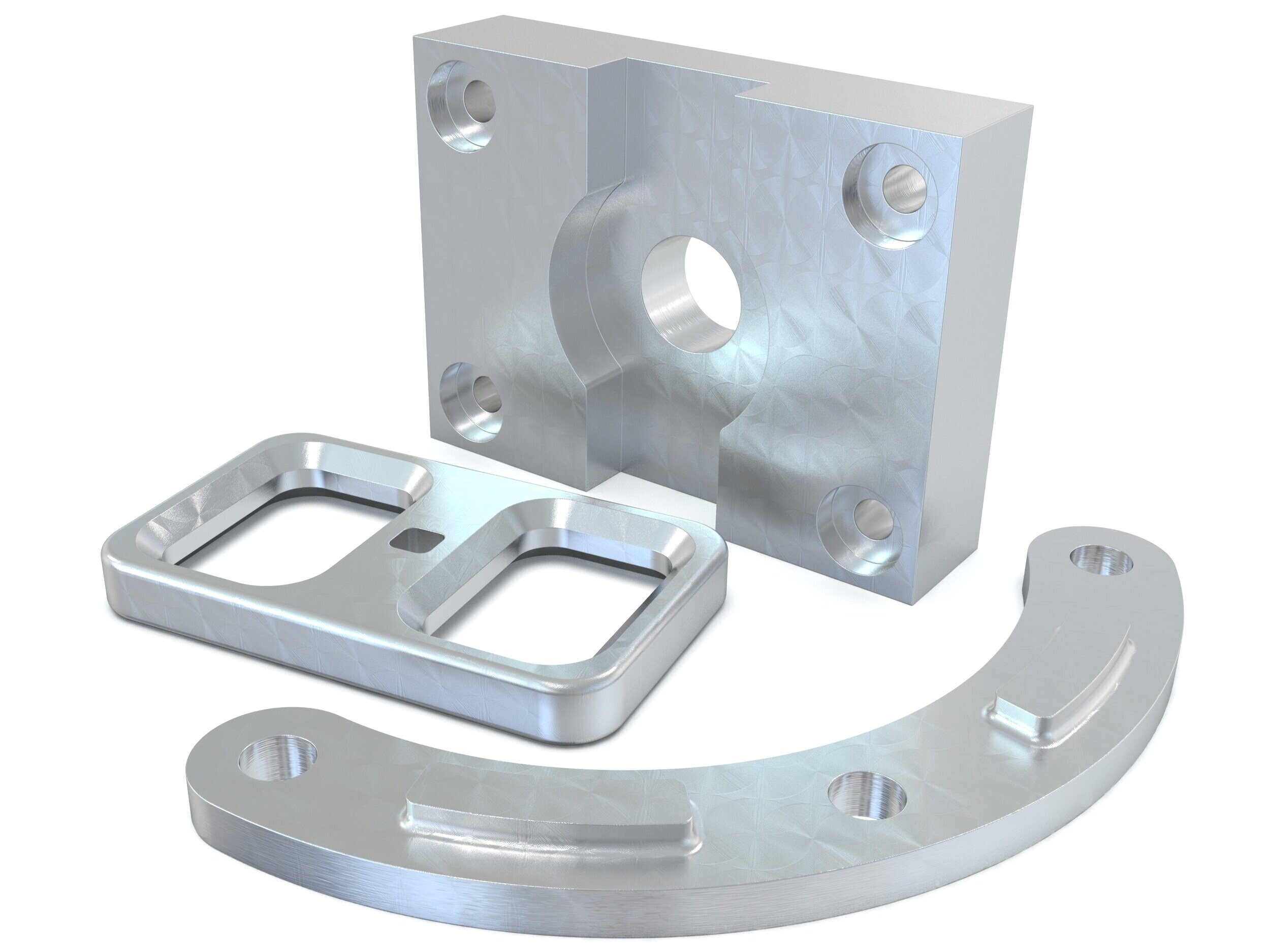

Product

CNC Machining

Go to product

Product

CNC Milling

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

CNC Machining Parts for Machinery

Machinery, Automotive, Medical

CNC machining (Computer Numerical Control machining) is a manufacturing process in which pre-programmed computer software manages the movement of tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Use case

CNC Milling Parts

machinery, automotive, electronics, construction machinery, heavy equipment, farming equipment, construction

CNC Milling process is highly versatile and capable of producing flat or curved profiles and intricate shapes with a high degree of accuracy and excellent surface finish. Milling machines are a fundamental component in modern machine shops due to their efficiency and capability in shaping a wide range of materials into precise parts and components.

Use case

CNC Machining Parts for Machinery

Machinery, Automotive, Medical

CNC machining (Computer Numerical Control machining) is a manufacturing process in which pre-programmed computer software manages the movement of tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

A CNC machine, or Computer Numerical Control machine, is a highly advanced tool used in manufacturing processes. It automates the control of machining tools such as drills, lathes, and milling machines through computer programming. This technology allows for precise and intricate designs to be created with minimal human intervention, enhancing efficiency and accuracy in production. Through the use of Computer-Aided Design (CAD) software, operators can input detailed specifications that the CNC machine follows to produce components with exact dimensions and tolerances. As a result, CNC machines are essential in various industries, including aerospace, automotive, and electronics, where precision engineering is crucial.

A CNC machine operates through a combination of computer programming and mechanical processes. The core component is the Computer Numerical Control (CNC) system, which interprets a digital design file, often created using CAD (Computer-Aided Design) software. This file is translated into a set of instructions that control the movement of the machine's cutting tools or other components. Once the program is loaded, the CNC machine follows precise coordinates to perform tasks like cutting, milling, drilling, or engraving. It utilizes motors and actuators to move the tools along multiple axes, ensuring high accuracy and repeatability in production. The automation provided by CNC technology enhances efficiency, reduces human error, and allows for complex shapes and designs to be manufactured with minimal manual intervention.

1. Precision and Accuracy

CNC machines operate with high precision, allowing for intricate designs and consistent production quality. This level of accuracy significantly reduces human error, ensuring that each piece produced meets exact specifications.

2. Efficiency and Speed

The automation of CNC machines enhances production speed, enabling manufacturers to complete tasks much faster than manual processes. This efficiency leads to higher output and the ability to meet tight deadlines.

3. Versatility

CNC machines can work with a wide range of materials, including metals, plastics, and wood. Their adaptability makes them suitable for various applications across different industries, from aerospace to automotive.

4. Reduced Waste

With precise cutting and shaping, CNC machines minimize material waste. This not only lowers production costs but also contributes to more sustainable manufacturing practices.

5. Safety

CNC machines are designed to operate with minimal human intervention, reducing the risk of accidents associated with manual machining. This enhances workplace safety while allowing operators to focus on monitoring and quality control.

CNC machines are widely utilized across various industries due to their precision and efficiency.

1. Aerospace

This industry relies on CNC machines for manufacturing intricate components that meet stringent safety and performance standards.

2. Automotive

CNC technology is essential in producing parts for vehicles, ensuring accuracy and repeatability in high-volume production.

3. Medical

In the medical field, CNC machines manufacture specialized instruments and implants, adhering to exact specifications to ensure patient safety.

4. Electronics

The electronics industry uses CNC machines for creating circuit boards and enclosures, allowing for detailed designs and high precision.

5. Furniture

CNC machining is prevalent in furniture production, enabling the creation of complex shapes and designs efficiently.

6. Metalworking

Metal fabrication often employs CNC machines for cutting, drilling, and shaping metal parts, enhancing productivity and reducing waste.

7. Construction

CNC technology assists in producing custom components for buildings, improving the speed and accuracy of construction projects.

Regular maintenance is crucial for ensuring the longevity and precision of a CNC machine. Key requirements include routine cleaning of the machine's components, especially the rails and ball screws, to prevent debris buildup that can affect performance. Lubrication of moving parts is essential to minimize friction and wear, ensuring smooth operation. Additionally, periodic checks on the electrical and mechanical systems help identify any potential issues before they escalate. This includes inspecting wiring, connectors, and coolant systems. Lastly, software updates and calibration should be performed regularly to maintain accuracy and efficiency in machining processes.

Some interesting numbers and facts about your company results for CNC Machine

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 8154 |

| Amount of suitable service providers | 9362 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1981 |

| Youngest suiting company | 2013 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for CNC Machine

What are related technologies to CNC Machine?

Based on our calculations related technologies to CNC Machine are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on CNC Machine?

The most represented industries which are working in CNC Machine are Machinery Manufacturing, Manufacturing, Other, Automation, IT, Software and Services

How does ensun find these CNC Machine Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.