The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Laser Prototypes Europe

Belfast, United Kingdom

A

11-50 Employees

1991

Key takeaway

The company specializes in additive manufacturing technologies, including Selective Laser Sintering (SLS), and is committed to delivering high-quality prototypes and low-volume production. With a focus on innovation and a skilled workforce, they aim to meet diverse project needs and maintain strong customer relationships.

Reference

Service

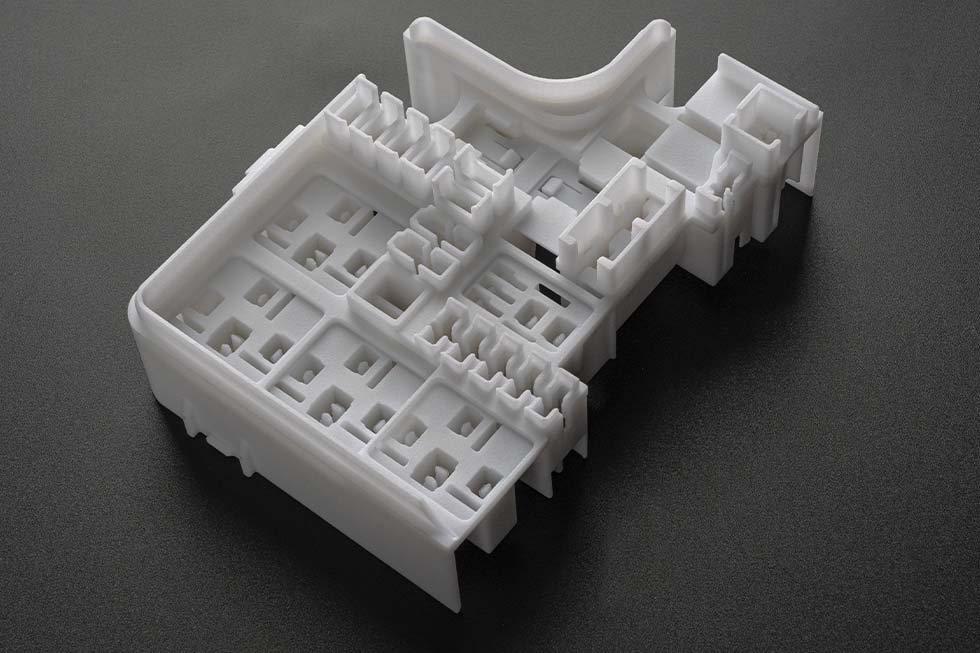

Selective Laser Sintering | Laser Prototype

Interpro Models

Deep River, United States

B

11-50 Employees

1996

Key takeaway

TriMech offers Selective Laser Sintering (SLS) 3D printing services that produce parts with excellent long-term stability and chemical resistance, making them ideal for tooling, fixtures, and low-volume production. Their expertise ensures the creation of fully functional prototypes with strong mechanical properties and good thermal resistance.

Reference

Service

Selective Laser Sintering (SLS) 3D Printing Service TriMech

TriMech Selective Laser Sintering Service provides fully functional prototypes with strong mechanical properties and good thermal resistance.

FastParts

Ruvo di Puglia, Italy

B

1-10 Employees

2019

Key takeaway

The company offers professional services for Additive Manufacturing, including Selective Laser Sintering (SLS), which involves using a laser to sinter polymer or composite powder particles to create parts.

Reference

Product

SLS - Fast Parts

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

GoProto

San Diego, United States

B

11-50 Employees

2016

Key takeaway

UPTIVE, formed by the collaboration of RE3DTECH and GoProto, emphasizes its commitment to innovative digital manufacturing solutions, which includes Selective Laser Sintering (SLS).

Reference

Product

Selective Laser Sintering (SLS) | - Uptive

Axis Prototypes

Montreal, Canada

A

11-50 Employees

2005

Key takeaway

Axis Prototypes specializes in additive manufacturing and highlights Selective Laser Sintering (SLS) as a versatile 3D printing process capable of creating highly complex parts, making it ideal for prototyping. Their expertise ensures optimal build orientation and surface finishing, enhancing dimensional accuracy and the overall quality of prototypes.

Reference

Product

Selective Laser Sintering: Discover 3D Printing with the SLS process

3D Printing with SLS technology is one of the most versatile prototyping processes and allows for highly complex parts. Jigs and Fixtures, Rapid Manufacturing and many more.

SLM Solutions Group AG

Lübeck, Germany

A

11-50 Employees

2006

Key takeaway

SLM Solutions highlights the capabilities of their selective laser melting technology, which is suitable for both rapid prototyping and mass production. They emphasize working with advanced materials to ensure high quality and productivity, positioning their technology as a transformative solution for supply chains.

Reference

Core business

Indian service provider 3D Product Development orders SLM® machine | SLM Solutions

MakeTime

Lexington, United States

B

51-100 Employees

2014

Key takeaway

The company, Xometry, offers a Selective Laser Sintering (SLS) 3D Printing Service, providing quick quotes and fast shipping for SLS parts. Their expertise in additive manufacturing allows for the development of practical prototypes and production parts.

Reference

Service

Selective Laser Sintering (SLS) 3D Printing Service - Additive Manufacturing

Upload your CAD file to get instant quotes on SLS parts. Parts ship in days. Free shipping on all US orders.

FKM Sintertechnik

Biedenkopf, Germany

A

11-50 Employees

1994

Key takeaway

FKM is a pioneering 3D printing service provider specializing in Selective Laser Sintering (SLS) and Selective Laser Melting (SLM) in Germany and Europe. With over 25 years of experience, they offer certified series quality for functional prototypes, spare parts, and small series production directly from 3D data.

Reference

Product

Lasersintern in Deutschlands größtem SLS-Maschinenpark | FKM

Selektives Lasersintern (SLS) - 41 Maschinen für Rapid Prototyping, Ersatzteile und Kleinserien. ➨ Jetzt informieren und anfragen! 25 Jahre Erfahrung ✓

AME-3D

Sheffield, United Kingdom

A

11-50 Employees

1996

Key takeaway

AME-3D specializes in Selective Laser Sintering (SLS) 3D printing, offering high-quality, rapid prototyping services with quick lead times and cost-effective production of low-volume parts. Their expertise and advanced technologies make them a trusted partner for additive manufacturing solutions.

Reference

Product

Selective Laser Sintering | SLS 3D Printing | Technologies | AME-3D

High quality, fast turnaround UK-based SLS 3D Printing services. Selective laser sintering services for rapid prototyping. Request a quote.

Additive Manufacturing Germany GmbH & Co. KG

Hanover, Germany

A

1-10 Employees

2019

Key takeaway

The company specializes in the professional use of additive manufacturing, particularly Selective Laser Sintering (SLS), for the development and production of complex plastic components. They offer a range of SLS 3D printers suitable for industry, research, and education, highlighting their advantages for prototyping and small-scale production of high-quality parts.

Reference

Product

SLS Industriesysteme - SLS 3D

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

SLS 3D Printing

Go to product

Selective Laser Sintering (SLS) is an advanced 3D printing technology that utilizes a laser to selectively fuse powdered materials, typically polymers, into solid structures. This process involves spreading a thin layer of powder onto a build platform, where a high-powered laser scans the surface, melting the particles together according to a digital model. Once the laser completes a layer, the platform lowers, and a new layer of powder is applied, repeating the process until the entire object is formed. SLS is known for its ability to create complex geometries, making it ideal for prototyping and manufacturing functional parts. The absence of support structures allows for the creation of intricate designs. Additionally, SLS offers excellent mechanical properties and is suitable for producing durable components that can withstand various applications across industries such as aerospace, automotive, and medical.

Selective Laser Sintering (SLS) works by using a high-powered laser to fuse small particles of polymer, metal, or ceramic powder into a solid structure. The process begins with a thin layer of powder being spread across the build platform. The laser then scans the surface, selectively heating and fusing the particles together according to the 3D model's specifications. After the laser completes one layer, the build platform lowers slightly, and another layer of powder is applied. This layering continues until the entire object is formed. The un-sintered powder remains in the build chamber, providing support and allowing for complex geometries to be created without the need for additional support structures. This method is known for its ability to produce strong, functional parts with intricate designs.

Selective Laser Sintering (SLS) is compatible with a variety of materials that enhance its versatility in manufacturing. The most commonly used material is nylon, particularly nylon 12, which offers excellent mechanical properties and is widely favored for its strength and flexibility. Additionally, polystyrene and polycarbonate are also utilized, providing unique benefits such as impact resistance and durability. Metal powders, including aluminum and titanium, are gaining traction for applications requiring enhanced strength and thermal properties. Furthermore, ceramics can be employed in SLS, allowing for high-temperature applications and specialized uses in various industries.

1. High Precision and Detail

Selective Laser Sintering (SLS) technology allows for the creation of highly detailed and intricate parts. The process utilizes a laser to fuse powdered materials layer by layer, resulting in complex geometries that traditional manufacturing methods may struggle to achieve.

2. Material Versatility

SLS supports a wide range of materials, including various plastics and metals. This flexibility enables manufacturers to choose the optimal material for their specific application, enhancing functionality and performance.

3. Reduced Waste

The additive nature of SLS minimizes material waste compared to subtractive manufacturing processes. Unused powder can often be recycled and reused, making it a more sustainable option.

4. Rapid Prototyping

With SLS, prototypes can be produced quickly. This speed allows for efficient design iterations and faster time-to-market for new products, giving companies a competitive edge.

5. Strong Mechanical Properties

Parts produced through SLS exhibit excellent mechanical strength and durability. These attributes make SLS an ideal choice for producing functional end-use parts, not just prototypes.

Selective Laser Sintering is widely utilized in several industries due to its unique capabilities in additive manufacturing.

1. Aerospace

This industry leverages Selective Laser Sintering for producing lightweight components that are crucial for improving fuel efficiency and performance in aircraft.

2. Automotive

Manufacturers in the automotive sector use this technology for rapid prototyping and creating complex parts that would be difficult or expensive to produce using traditional methods.

3. Medical

In the medical field, Selective Laser Sintering is employed to create custom implants and prosthetics tailored to individual patient needs, enhancing both fit and comfort.

4. Consumer Goods

This technology allows for the production of intricate designs in consumer products, enabling companies to innovate and respond quickly to market demands.

5. Education and Research

Educational institutions and research organizations often utilize Selective Laser Sintering for experimenting with new materials and processes, advancing the field of additive manufacturing.

Some interesting numbers and facts about your company results for Selective Laser Sintering

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 9189 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1991 |

| Youngest suiting company | 2019 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Selective Laser Sintering

What are related technologies to Selective Laser Sintering?

Based on our calculations related technologies to Selective Laser Sintering are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on Selective Laser Sintering?

The most represented industries which are working in Selective Laser Sintering are Other, Manufacturing, Machinery Manufacturing, Plastics, IT, Software and Services

How does ensun find these Selective Laser Sintering Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.