The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

www.surfacescan.co.uk

-

- Employees

-

Key takeaway

The company specializes in 3D printing services, offering solutions for both one-off prints and batch production across various sectors. Their expertise in 3D scanning, reverse engineering, and additive manufacturing enables clients to significantly reduce development time.

Reference

Service

3D Printing

Professional 3D printing for all your manufacturing needs. Choose from a wide array of colours and materials, and either FDM or SLS technology. Serving industries such as aerospace, automotive, healthcare, and product development. Rapid delivery available to customers across the United Kingdom. Exceptional customer service.

Quality Printing 3D

Ewenny, United Kingdom

A

1-10 Employees

2018

Key takeaway

Quality Printing 3D specializes in 3D printing, providing prototypes and finished products for various industries such as jewellery, engineering, and automotive. With over 6 years of experience and a wide range of modern equipment, they ensure high-quality service tailored to client needs.

Reference

Core business

3D Printing – Quality Printing 3D

Strategic 3D Solutions Inc.

Raleigh, United States

B

1-10 Employees

2014

Key takeaway

The company specializes in providing a variety of 3D printing solutions, including printers, scanners, and printing services, emphasizing their commitment to value and customer satisfaction. They offer products from leading brands and state-of-the-art technology for diverse 3D printing needs.

Reference

Core business

3D Printers, 3D Scanners, 3D Printing - Strategic 3D Solutions

Leading 3D printers by Markforged, EnvisionTEC, MakerBot, Fusion3, Airwolf, and Mcor. High end 3D Scanners by Geomagic, Shining 3D, and more.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

D3D Printing Services

-

11-50 Employees

-

Key takeaway

The company offers an industrial 3D printing service that guarantees accuracy and repeatability, allowing for the production of highly precise parts, functional prototypes, and complex designs in as little as one day. Their online platform provides a convenient way to upload 3D models and receive top-quality prints with precision and durability.

Reference

Core business

Home - d3dprintingxyz.com

3D printing service on demand files accepted: stl, obj, zip, step, stp, iges, igs, 3ds, wrl 3D Print Made Easy ONLINE 3D PRINTING Our online 3D printing services provide a convenient way to bring your designs to life. Upload your designs and have them printed remotely, without investing in your own 3D printer. Get A […]

Sculp 3D

Vadodara, India

D

1-10 Employees

2018

Key takeaway

Sculp 3D specializes in high-quality 3D printing and design solutions, catering to a wide range of clients from engineers to corporates. Their services include various 3D printing technologies, ensuring they can meet diverse manufacturing needs efficiently.

Reference

Core business

Sculp 3D | Additive Manufacturing Company

Sculp 3D provides high quality 3D Printing and CAD/3D Designing solutions for Engineering and Industrial Applications. Our manufacturing service includes FDM 3D Printing, DLP 3D Printing, SLA 3D Printing, SLS 3D Printing and DMLS/Metal 3D Printing.

UNIFIED GLOBAL 3D SOLUTION

Hyderabad, India

D

1-10 Employees

2018

Key takeaway

The company is a leading 3D printing service provider, offering fully customizable solutions and a fast, seamless experience from concept to 3D printable file. With expertise in various 3D printing technologies, they support diverse industries, ensuring efficient product development and mass production capabilities.

Reference

Core business

UG3DS | Best 3D Design & Printing Service Provider | On Demand Manufacturing

3D Print Direct

Aylesbury, United Kingdom

A

1-10 Employees

2015

Key takeaway

3DPrintDirect.co.uk, soon transitioning to Graphite-am.co.uk, is an online automated 3D printing company that offers affordable and high-quality printing using premium materials on industrial machines. They provide a user-friendly online ordering portal and a built-in file checker, making it easy to order both one-off models and production runs.

Reference

Core business

3D Print Direct | Fast & Easy 3D Printing

Excellent quality at competitive prices. Over 100 5-star Google Reviews. For one-off models or production runs.

3D PRINTING SOLUTIONS

Greece

B

1-10 Employees

-

Key takeaway

The company specializes in providing high-quality 3D printing services, ensuring a quick turnaround and support throughout the entire process, from modeling to post-processing. They emphasize the ability of 3D printed models to identify design flaws early, highlighting the transformative potential of additive manufacturing across various industries.

Reference

Service

Services - 3d-printing.solutions

3D Printing Solutions - Discover the benefits and limitless potential of 3D printing

3Deometry Innovations

India

D

1-10 Employees

2016

Key takeaway

The company offers a comprehensive 3D printing service, supporting the entire product cycle from initial sketches to mass manufacturing. They specialize in FFF, SLS, and metal 3D printed parts, emphasizing the benefits of integrating advanced 3D printing technology to enhance workflows and improve ROI.

Reference

Product

Portfolio » 3Deometry Innovations

3D Maker Shop

Lebanon

D

1-10 Employees

2018

Key takeaway

3D Maker Shop is dedicated to leading the 3D printing revolution in the MENA region by offering top-quality 3D printers and materials, along with comprehensive engineering services. Their mission is to make 3D printing accessible to all, providing a full range of solutions from design to prototyping and product development.

Reference

Service

3D Printing Solutions & Services | 3D Maker Shop

We developed a full range of 3D printing solutions from designing and prototyping to reverse engineering and product development. Our services meet our customers needs and provide them end-to-end solutions.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

3D Printing

Go to product

Product

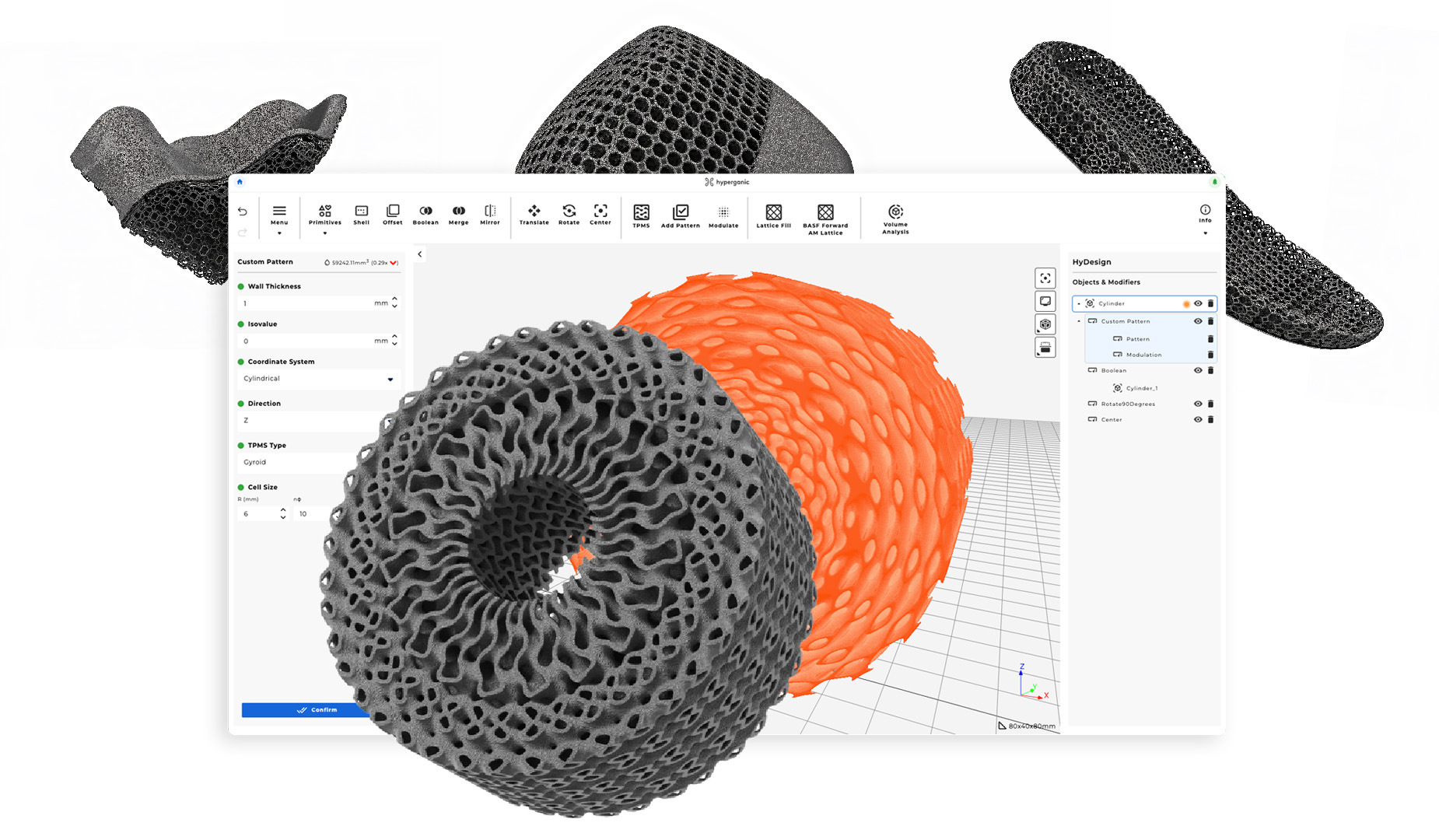

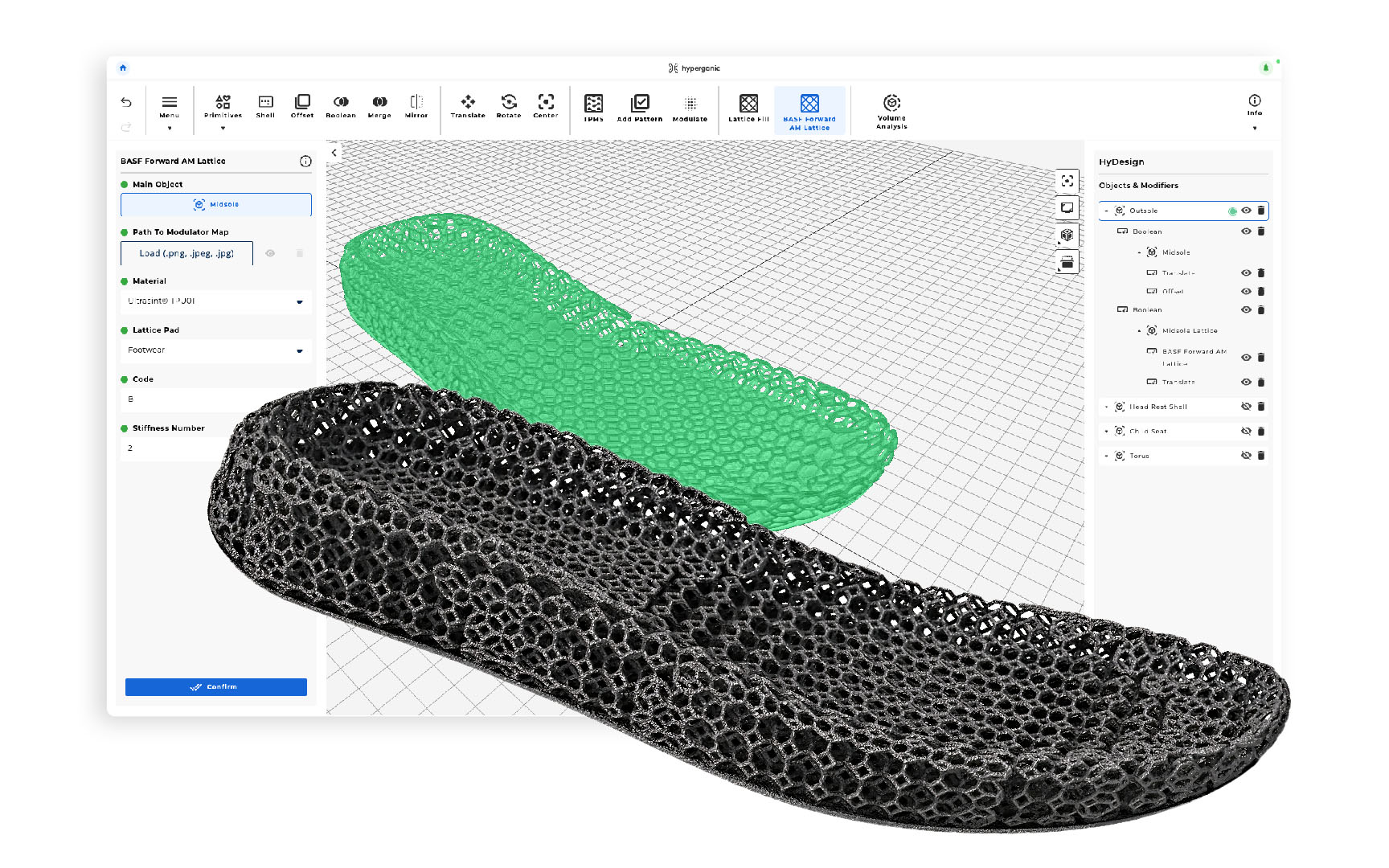

HyDesign

Go to product

Product

3DPBOSS Max

Go to product

Product

3DPBOSS Standard

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Air Ducts

Industrial

Manufacture industrial parts like air ducts for cars or other air ventilation systems. Sturdy materials that withstand long-term daily use. We can customise the parts to your exact requirements, and even adjust the design in CAD if you need to make slight changes to the product. We can produce any quantity.

Use case

Foam Replacement with Additive Manufacturing

Automotive, Consumer Goods, Sportwear, Fashion, Sporting Goods, Orthotics, Medical

Mass Customization with HyDesign: HyDesign allows manufacturers to replace conventional, inflexible production methods with highly adaptable and scalable additive manufacturing techniques. This enables the production of custom-fit products ranging from automotive parts to personalized medical devices. By integrating customer-specific data, such as body scans or usage patterns, directly into the design process, HyDesign ensures each product is uniquely tailored to meet individual specifications. Foam Replacement in Manufacturing: Foam components are ubiquitous in products requiring cushioning, insulation, or lightweight structures. However, traditional foam can be limited in terms of structural optimization and environmental impact. HyDesign addresses these issues by enabling the design of lattice structures that can mimic or even surpass the properties of foam. These structures are not only lighter and stronger but also more sustainable, as they can be manufactured from recyclable materials without the waste associated with traditional foam cutting. Customization with 2D Bitmaps: A standout feature of HyDesign is its ability to modulate the thickness of lattice beams using 2D bitmap images. This technology is ideal for industries where customization is key, such as: Healthcare: Creating patient-specific implants and prosthetics. Sports Equipment: Developing customized protective gear and performance-enhancing apparatus. Furniture and Ergonomics: Producing custom seating solutions and ergonomic tools.

Use case

3d printing business management software

3d printing, 3d printing business, 3d printer farms

Save time. Grow sales, production, and stay on schedule. Control materials and spare parts stock and usage. Reduce repairs, and expand 3d printers’ lifespan. Manage orders, jobs, finances, team, contractors, files, and docs. Leverage analytics to scale your small-to-mid 3D printing business, modify the system easily, and more... + BONUSES

Use case

Transport Woom 3

3D Print, Qeridoo, Familie

Kinderfahrrad Halterung: Genießen Sie sorgenfreie Radtouren mit Ihrem Kind! Lieben Sie es, gemeinsam mit Ihrem Kind Fahrrad zu fahren? Seitdem unsere Große selbstständig radeln kann, brechen wir zu längeren Ausflügen auf. Doch was tun, wenn die kleinen Beine müde werden und das Fahrrad nicht mehr bewegt werden möchte? Unsere Kinderfahrrad Halterung ist die Lösung für unbeschwerte Ausflüge. Früher mussten wir das Fahrrad mühsam auf dem Dach des Fahrradanhängers befestigen, nur um es fünf Minuten später wieder abzunehmen, weil das Kind doch lieber selbst fahren möchte… Nach intensiven Recherchen im Netz haben wir für den Qeridoo Qupa 2 keine Zubehörteile gefunden, die dieses Problem lösen können. Da ich die Möglichkeit habe, Bauteile im CAD zu entwerfen und sie anschließend im SLS, SLA und FDM 3D-Druck herzustellen, lag es nahe, eine Lösung zu entwickeln.

Use case

Air Ducts

Industrial

Manufacture industrial parts like air ducts for cars or other air ventilation systems. Sturdy materials that withstand long-term daily use. We can customise the parts to your exact requirements, and even adjust the design in CAD if you need to make slight changes to the product. We can produce any quantity.

3D printing is a revolutionary manufacturing process that creates three-dimensional objects from a digital file. This technology builds items layer by layer, using materials such as plastic, metal, or resin. The precision involved allows for complex shapes and designs that are difficult or impossible to achieve with traditional manufacturing methods. The applications of 3D printing span various industries, including automotive, aerospace, healthcare, and consumer products. By enabling rapid prototyping and customization, it has transformed product development and production efficiency. Additionally, 3D printing reduces waste and can lower costs, making it an attractive option for many businesses.

3D printing operates through an additive manufacturing process, where objects are created layer by layer from a digital model. The process begins with a 3D design, typically created using computer-aided design (CAD) software. Once the design is finalized, the 3D printer reads the file and starts building the object by depositing material, such as plastic, metal, or resin, layer by layer. Each layer is fused together, creating a solid structure as the build progresses. Various techniques are used in 3D printing, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), among others. These methods differ in how they manipulate materials, but they all share the fundamental principle of adding material rather than subtracting it, which is a hallmark of traditional manufacturing processes. This technology allows for intricate designs and rapid prototyping, making it valuable across various industries.

Various materials are utilized in 3D printing, each offering unique properties suited for different applications. One of the most common materials is PLA (Polylactic Acid), a biodegradable thermoplastic derived from renewable resources like corn starch. It is user-friendly and ideal for beginners due to its ease of use. Another widely used material is ABS (Acrylonitrile Butadiene Styrene), known for its strength and durability. ABS is suitable for functional prototypes and items requiring impact resistance. Nylon is also prevalent, recognized for its flexibility and toughness, making it perfect for parts that must endure stress. Additionally, resins are used in stereolithography (SLA) printing, offering high detail and smooth finishes. Each material has specific characteristics that cater to various 3D printing needs, allowing for versatility in design and production.

1. Prototyping

3D printing is widely used for rapid prototyping, allowing designers and engineers to create physical models of their concepts quickly. This technology enables the testing of designs for functionality and aesthetics before moving to full-scale production.

2. Manufacturing

In manufacturing, 3D printing streamlines production processes by enabling the creation of complex geometries that traditional methods cannot achieve. It is utilized for producing custom parts, tools, and components tailored to specific requirements, enhancing efficiency and reducing waste.

3. Healthcare

Healthcare applications include the production of patient-specific implants, prosthetics, and even bioprinting tissues and organs. This personalization improves surgical outcomes and patient comfort, demonstrating the technology's transformative potential in the medical field.

4. Aerospace

The aerospace industry leverages 3D printing for lightweight components, contributing to fuel efficiency in aircraft. The ability to create intricate parts with reduced weight supports advancements in aircraft design and performance.

5. Automotive

In the automotive sector, 3D printing is used for prototyping, tooling, and even producing end-use parts. This technology helps manufacturers innovate faster and reduce costs associated with traditional manufacturing methods.

6. Education

Educational institutions utilize 3D printing to enhance learning experiences. Students can engage in hands-on projects, creating physical models that foster creativity and improve understanding of complex concepts in various subjects.

7. Art and Design

Artists and designers use 3D printing to bring their visions to life, creating unique sculptures and functional art pieces. This technology expands creative possibilities and allows for intricate designs that would be challenging to achieve by hand.

1. Customization

3D printing allows for high levels of customization in product design. This technology enables the creation of unique items tailored to specific needs, which is particularly beneficial in industries such as healthcare for creating prosthetics or dental implants.

2. Reduced Waste

Traditional manufacturing methods often produce significant waste. In contrast, 3D printing generates less scrap material since objects are built layer by layer. This not only conserves resources but also reduces overall production costs and environmental impact.

3. Rapid Prototyping

With 3D printing, businesses can quickly create prototypes and iterate designs. This accelerates the product development process, allowing companies to bring innovations to market faster and respond to changing consumer demands more effectively.

4. Cost-Effectiveness

3D printing can lower manufacturing costs, especially for small production runs. It eliminates the need for expensive molds or tooling, making it an attractive option for startups and small businesses looking to minimize initial investments.

Some interesting numbers and facts about your company results for 3D Printing

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6299 |

| Amount of suitable service providers | 8145 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 2014 |

| Youngest suiting company | 2018 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for 3D Printing

What are related technologies to 3D Printing?

Based on our calculations related technologies to 3D Printing are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Which industries are mostly working on 3D Printing?

The most represented industries which are working in 3D Printing are Printing, Marketing Services, Other, IT, Software and Services, Manufacturing

How does ensun find these 3D Printing Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.