The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

WeldiT Mobile Welding & Fabrication

Houston, United States

B

251-500 Employees

2018

Key takeaway

WELDIT is a prominent provider of welding and fabrication services, specializing in metal welding to meet diverse manufacturing and engineering needs. With a commitment to quality and customer satisfaction, they offer customized solutions across various industries, ensuring timely delivery and innovative approaches to every project.

Reference

Service

WeldIt

WELDMAN LTD

London, United Kingdom

A

1-10 Employees

-

Key takeaway

Weldman Welding Industries Pte Ltd specializes in the design and manufacturing of inverter welding equipment, making it a key player in the metal welding industry in Singapore. With over 30 years of experience through its parent company, Weldman is well-equipped to meet the needs of sectors like shipbuilding and construction.

Reference

Service

Services - Weldman

WELD-TECH LTD

United Kingdom

A

1-10 Employees

-

Key takeaway

Weld Tech Welders in Bolton specializes in the design, manufacture, and installation of various metalwork products, including wrought iron gates and railings. With over 20 years of experience, they are known for high-quality workmanship and offer a complete service from design to installation.

Reference

Service

Services | Weld Tech

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

COMPLETE WELDING SERVICES INTERNATIONAL PTY. LTD.

Melbourne, Australia

A

11-50 Employees

1991

Key takeaway

Complete Welding Services is a prominent player in the welding sector, particularly known for its expertise in pipe fabrication for the Fire Protection industry. With over 35 years of experience, the company offers a wide range of welding solutions that emphasize speed, quality, and productivity.

Reference

Core business

Complete Welding Services

Commercial Welding LLC

Commerce City, United States

B

11-50 Employees

2021

Key takeaway

The company offers high-quality welding services, including pipe fabrication and welding for industrial applications, showcasing their extensive experience and readiness to tackle new challenges.

Reference

Service

Capabilities — Commercial Welding LLC

Rio Welding Ltd

Vaughan, Canada

A

1-10 Employees

-

Key takeaway

Rio Welding Ltd. provides a comprehensive range of welding services, including metal fabrication, repair, and mobile welding, all delivered with a commitment to high quality standards.

Reference

Core business

Rio Welding Ltd. - CWB Certified Welding, Mobile Welding, Repairs and Custom Metal Fabriction

MK Welding & Fabrication

Waynesville, United States

B

1-10 Employees

1989

Key takeaway

MK Welding & Fabrication has over 30 years of experience in industrial fabrication and repairs, highlighting their expertise in metal welding and related services.

Reference

Service

Services | MK Welding

Welders

Aalst, Belgium

A

11-50 Employees

1948

Key takeaway

Welders N.V. has extensive experience in various welding techniques, including Flux Cored Arc Welding, Gas Metal Arc Welding, and Gas Tungsten Arc Welding, making it a key player in the industry. The company's commitment to quality is underscored by its ISO:9001 and ASME U-Stamp certifications, ensuring high standards in their welding processes.

Reference

Product

Products | Welders

Barkers Welding Inc

Superior, United States

B

1-10 Employees

1984

Key takeaway

BWI offers extensive metal welding and fabrication services, including MIG and TIG welding, for steel, aluminum, and stainless steel. With decades of experience and AWS certified welders, they handle everything from repairs to custom tank manufacturing and industrial products.

Reference

Core business

Welding and Metal Fabrication Services - Steel and Aluminum

Steel, aluminum, and stainless steel welding and fabrication services. CAD services, prototyping, industrial fabrication to small repairs

West Country Welding Supplies Ltd

Bristol, United Kingdom

A

11-50 Employees

1986

Key takeaway

The company specializes in providing high-quality welding products and services, including aluminum MIG welding from an engine-driven welder. They also offer servicing, repairs, and safety checks for various welding and cutting equipment, ensuring that customers have access to reliable and technical welding solutions.

Reference

Service

Services - West Country Welding Supplies

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

SpeedGun

Go to product

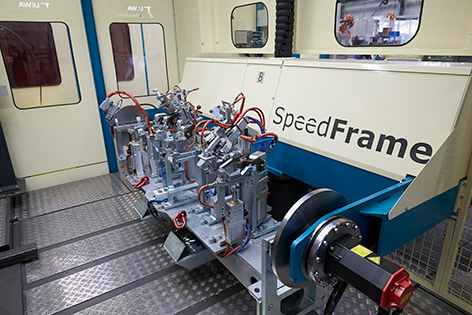

Product

SpeedFrame

Go to product

Product

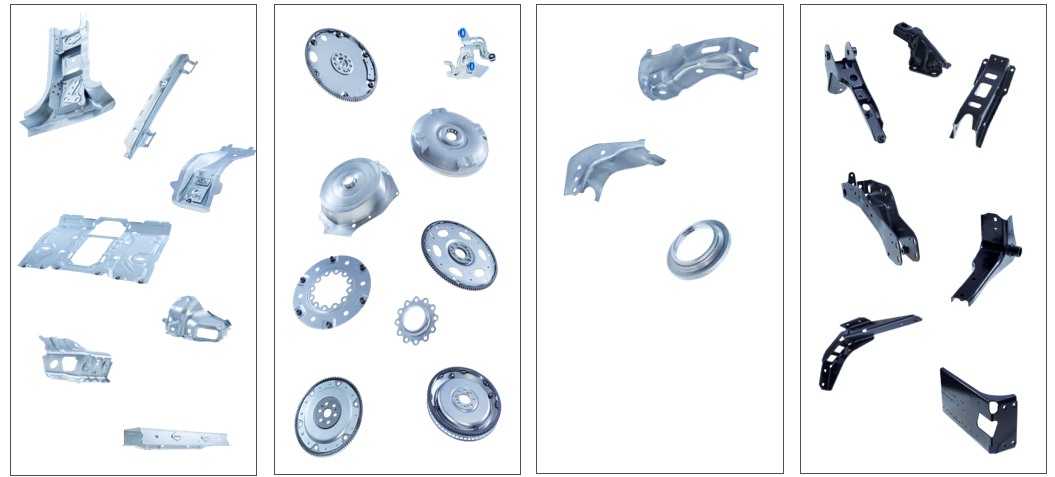

Metal Fabrication Parts

Go to product

Service

Sheet Metal Parts and Components

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

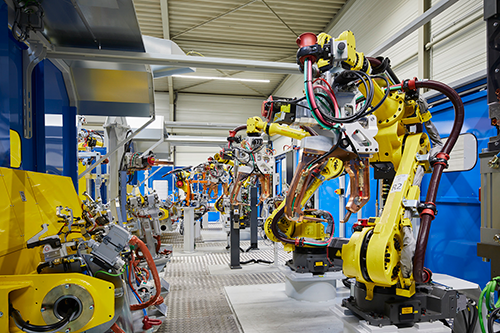

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

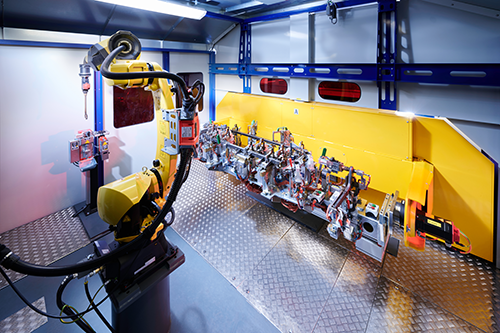

Use case

Production system for MIG welding of a seat assembly

automotive

esign of a production system for MIG welding of a complex, heavy duty vehicle seat assembly consisting of backrest (60% and 40%) and seat bench. The goal is 30,000 units per year in a maximum of 616 seconds per seat assembly. The production system is to be manned by one operator. We developed a flexible production concept, which ensures future expansion and integration of other products in the event of volume fluctuations or design modifications according to the ReUse principle.

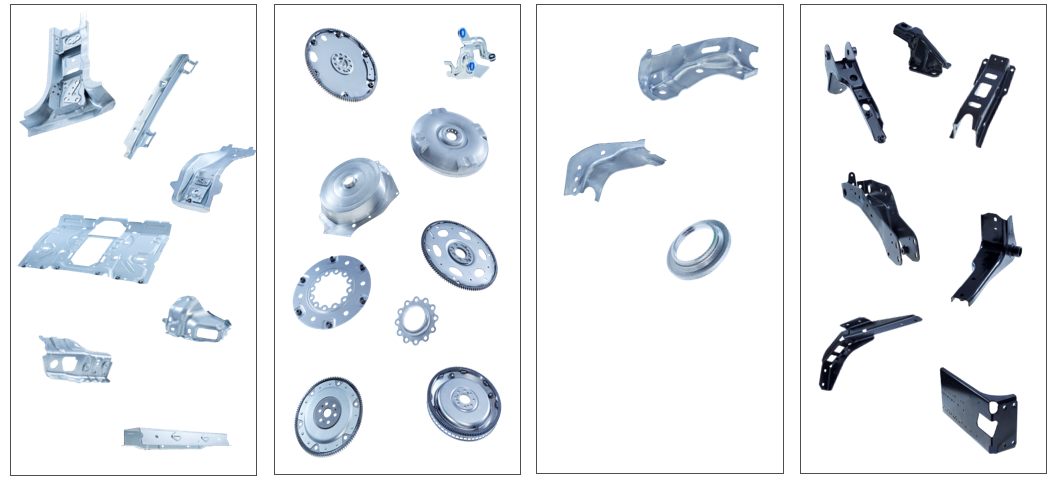

Use case

Car Body in White

Automotive, Industry

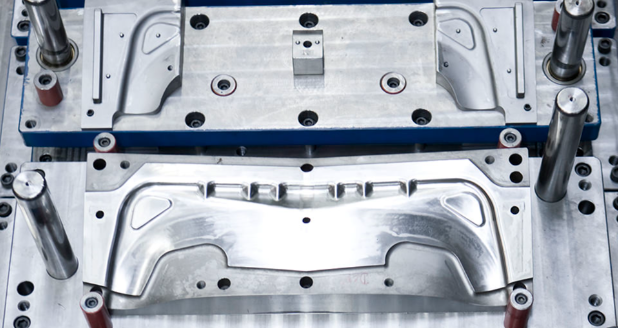

Our know how ranges over various fields of business. We develop and produce various forming, welding and joining components in differing combinations in conjunction with our partners. In the category body work, this includes crossmembers, reinforcements, consoles as well as various safety related products such as safety belt and axle mounting parts. In addition, our products are necessary as an example, to attach power trains or pumps to the vehicle body. Our mounting parts are also necessary for further functions such as protection of the aggregates against damage, vibration or heat impact. Mühlhoff produces various parts for motor and power train. For example, we develop and produce mounts for gearshift cables for fixation of the outer gearshift, mounts to retain electronic components in the vehicle inner, as well as motor and gear carrier for cars and commercial vehicles. We prove professional know how since over 25 years in the field of development and production of drive plates, which are applied between the converter and gear mechanism. They are responsible for the starting sequence and for the impulse of the entire engine management system. In addition, they balance out the axial forces between engine and gearing mechanism. Our products are used in all areas of cars and vans for e.g., the front end, the undercarriage, the roof, the rear end as well as in the framework and drivers cab of lorries. In addition, we also supply to trailer manufacturers and non-automotive customers.

Use case

Relocation projects

Automotive, Industry

Seamless Relocation Projects in Forming and Joining Technology—Powered by Mühlhoff When it comes to relocating your production lines, Mühlhoff is your expert partner. We specialize in executing complex relocation projects in forming and joining technology, ensuring minimal downtime and maximum efficiency. With our comprehensive service, we handle everything—from planning and dismantling to reassembly and optimization at the new site. Our experienced team works closely with you, providing tailor-made solutions that meet your specific needs while ensuring that your production is up and running as quickly as possible. Why trust Mühlhoff with your relocation project? End-to-End Service: We manage every aspect of the relocation process, so you don’t have to. Expertise in Forming and Joining: Decades of experience in these specialized technologies mean your equipment is in safe hands. Minimal Downtime: Efficient planning and execution to reduce disruptions and keep your production moving. Customized Solutions: We tailor our approach to fit your unique production requirements and goals. Relocating doesn’t have to be a headache. With Mühlhoff’s proven expertise, your forming and joining equipment will be relocated smoothly, safely, and on schedule. Get in touch with us today, and let’s make your next relocation project a success!

Use case

A fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components.

automotive

Example of a fully automated “Lights out” joining system for automotive patch plates with LEWA-SpeedLine components: SpeedGun, SpeedCell as well as camera technology. For our automotive customers we develop highly automated and "workerless" joining systems for the welding of patch plates for the production of door sills, B-pillars, A-pillars, etc.

Metal welding is a fabrication process that joins materials, typically metals or thermoplastics, by using high heat to melt the parts together. This method creates a strong bond once the molten material cools and solidifies, resulting in a durable connection. Various techniques, such as arc welding, MIG welding, and TIG welding, are employed depending on the materials and desired strength of the weld. In addition to strength, metal welding can enhance the overall integrity of structures, making it a crucial process in industries ranging from automotive to construction. The precision and skill involved in metal welding require trained professionals who understand the specifics of different welding techniques and material properties.

1. MIG Welding

MIG (Metal Inert Gas) welding utilizes a continuous solid wire electrode fed through a welding gun. This process creates an electric arc between the wire and the workpiece, melting the wire and joining the metals. It is known for its speed and versatility, making it ideal for a variety of materials.

2. TIG Welding

TIG (Tungsten Inert Gas) welding employs a non-consumable tungsten electrode to produce the weld. A filler material can be used, but it is often not necessary. This method offers greater control over the welding process and is excellent for thin materials and precise applications.

3. Stick Welding

Stick welding, or Shielded Metal Arc Welding (SMAW), involves a consumable electrode coated in flux. The arc forms between the electrode and the workpiece, melting both to create a weld. This process is widely used for outdoor applications and in situations where portability is essential.

4. Flux-Cored Arc Welding

Flux-cored arc welding (FCAW) is similar to MIG welding but uses a tubular wire filled with flux. This allows for welding in various positions and environments without the need for shielding gas. It is effective for thicker materials and is often used in construction and heavy manufacturing.

5. Laser Welding

Laser welding employs a focused beam of light to melt and join materials. This process offers high precision and minimal heat-affected zones. It is commonly used in industries requiring intricate designs, such as automotive and aerospace applications.

6. Electron Beam Welding

Electron beam welding uses a high-velocity beam of electrons to melt materials in a vacuum environment. It provides deep penetration and is highly efficient for welding thick sections of metal. This method is often used in specialized applications, including aerospace and nuclear industries.

Metal welding significantly influences material strength through the process of fusion. When metals are welded together, the heat applied causes the base materials to melt and intermix, which can create a strong bond once cooled. This fusion can enhance the overall structural integrity of the welded joint, making it capable of withstanding various stresses. Additionally, the cooling rate and welding technique employed can affect the properties of the material. For instance, rapid cooling can lead to hardening, while slower cooling might allow for more ductility. Therefore, the choice of welding method, such as MIG or TIG, and the subsequent heat treatment can either strengthen or weaken the final product, impacting its performance in real-world applications.

Ensuring safety during metal welding is crucial to prevent accidents and injuries. First, wearing proper personal protective equipment (PPE) is essential. This includes a welding helmet with a suitable filter lens to protect the eyes from bright light and sparks, flame-resistant gloves, and protective clothing to shield the skin from burns and hazardous materials. Additionally, maintaining a well-ventilated workspace is vital to avoid inhaling harmful fumes. Keeping flammable materials away from the welding area helps prevent fires. It's also important to ensure that all equipment is in good working condition and that operators are trained in proper welding techniques and safety protocols. Regular safety checks and awareness of surroundings can further mitigate risks associated with metal welding.

1. Welding Machine

A reliable welding machine is crucial for metal welding. This equipment can vary based on the welding technique, such as MIG, TIG, or Stick. Each machine is designed to deliver the appropriate power and control needed for different applications.

2. Protective Gear

Welders must use protective gear, including helmets, gloves, and aprons. This equipment safeguards against sparks, heat, and harmful UV radiation emitted during the welding process, ensuring the safety of the operator.

3. Welding Accessories

Essential accessories include clamps, welding rods, and wire for MIG welding. These tools support the welding process and contribute to achieving precise and strong welds. Proper accessories enhance efficiency and effectiveness in various welding tasks.

4. Fume Extraction System

A fume extraction system is important for maintaining a safe working environment. It removes hazardous fumes and gases produced during welding, ensuring air quality remains safe for the welder and others nearby.

Some interesting numbers and facts about your company results for Metal Welding

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6680 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1948 |

| Youngest suiting company | 2021 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Metal Welding

What are related technologies to Metal Welding?

Based on our calculations related technologies to Metal Welding are Industrial Electroplating, Industrial Filtration, Industrial Sintering, Industrial Extrusion, Industrial Handling

Who are Start-Ups in the field of Metal Welding?

Start-Ups who are working in Metal Welding are Commercial Welding LLC

Which industries are mostly working on Metal Welding?

The most represented industries which are working in Metal Welding are Other, Manufacturing, Construction, Mining, Machinery Manufacturing

How does ensun find these Metal Welding Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.