The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Tube Fins Ltd

North Kesteven, United Kingdom

A

51-100 Employees

1978

Key takeaway

Tube Fins Limited is a specialized manufacturer of finned tubes, boasting over 50 years of experience in enhancing tube surfaces for various industries, including power cooling and petrochemicals. They offer a diverse range of finned tubes, including bespoke options, ensuring high-quality products and technical support from their ISO 9001 approved facilities.

Reference

Core business

Manufacturer of Finned Tube and Turbulator Tube Inserts.

Fin Tube Products Inc.

-

11-50 Employees

1993

Key takeaway

The company specializes in various fin to tube attachment methods, with a focus on helically wound brazed finned tubes. Their FINBRAZE® tubing is particularly suitable for high-temperature applications, highlighting their expertise in custom-made fin tube products.

Reference

Product

Products | Fin Tube Products, Inc.

Explore Fin Tube Products products including Finbraze, Cladfin, Mini-Fin, Edge Tension, Soldered, Stamped / Plate Fine, "L" foot, & coils & bending products.

Energy Transfer - Finned Tube

Minerva, United States

B

51-100 Employees

1984

Key takeaway

Durafintube specializes in manufacturing fin tubes and customized heat exchanger products designed to enhance heat exchange efficiency in HVAC systems. Their innovative solutions aim to improve heating and cooling efficiency while complying with government standards, ultimately preventing system failures and overheating.

Reference

Core business

Manufacturing Capabilities – Durafin Tube

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Vulcan Finned Tubes L.P.

Tomball, United States

B

11-50 Employees

1999

Key takeaway

The company is a leading global supplier of high-quality finned tubes and finned pipes, essential for heat transfer applications, catering to both OEMs and the aftermarket.

Reference

Core business

Vulcan Finned Tubes

TEX-FIN INC

Houston, United States

B

11-50 Employees

1964

Key takeaway

Tex-Fin specializes in the production of various finned tubes, including high-frequency helical serrated and non-serrated options, as well as longitudinal finned pipes and tubes. With a commitment to custom design and service, Tex-Fin ensures maximum heat transfer performance for its clients.

Reference

Product

Welded Finned Pipes - Tex Fin

Tek-Fins Inc.

Tulsa, United States

B

51-100 Employees

1989

Key takeaway

TEK-FINS is a leading manufacturer of air cooled heat exchangers and a major supplier of finned tubes, emphasizing their expertise in this area.

Reference

Core business

HOME | Tek-Fins

Airco-Fin Group

Netherlands

A

51-100 Employees

1979

Key takeaway

Airco·Fin BV specializes in providing high and low finned tubes (fintubes), making it a key supplier for refineries and manufacturers of air-cooled heat exchangers.

Reference

Core business

Finned tubes supplier and aluminium louvers | AircoFin

World wide suplier high and low finned tubes (fintubes) and aluminium louvers. Airco·Fin is established in 1979 and fully independent.

Aerofin Corporation

Lynchburg, United States

B

51-100 Employees

1923

Key takeaway

Aerofin is a prominent manufacturer of finned tube heat exchanger coils, offering a wide range of products and accessories designed for various industries, including HVAC and power generation. Their expertise in custom designs and compliance with ASME standards ensures that they can meet diverse heat transfer needs effectively.

Reference

Product

Custom - Aerofin | Heat Transfer Products

Salem Tube International

Prudhoe, United Kingdom

A

11-50 Employees

1992

Key takeaway

Salem Tube International is a leading manufacturer of finned tubes, offering high-quality products that ensure reliability and timely delivery. Their integrated value chain allows them to provide comprehensive solutions for heat exchangers and boilers.

Reference

Product

Finned Tubes – Salem Tube International

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Fidelity Radcore Heat

Petaling Jaya, Malaysia

C

- Employees

-

Key takeaway

FRHE specializes in the design and manufacturing of heat exchangers, including finned tube heat exchangers, and offers comprehensive thermal process design and evaluation services. With years of experience and a commitment to quality, FRHE is a reliable source for efficient heat transfer solutions in the engineering industry.

Reference

Product

Finned Tube Heat Exchanger, Finned Tube Malaysia, Air preheater Malaysia - Heat Exchanger Malaysia, Heat Exchanger Manufacturer

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

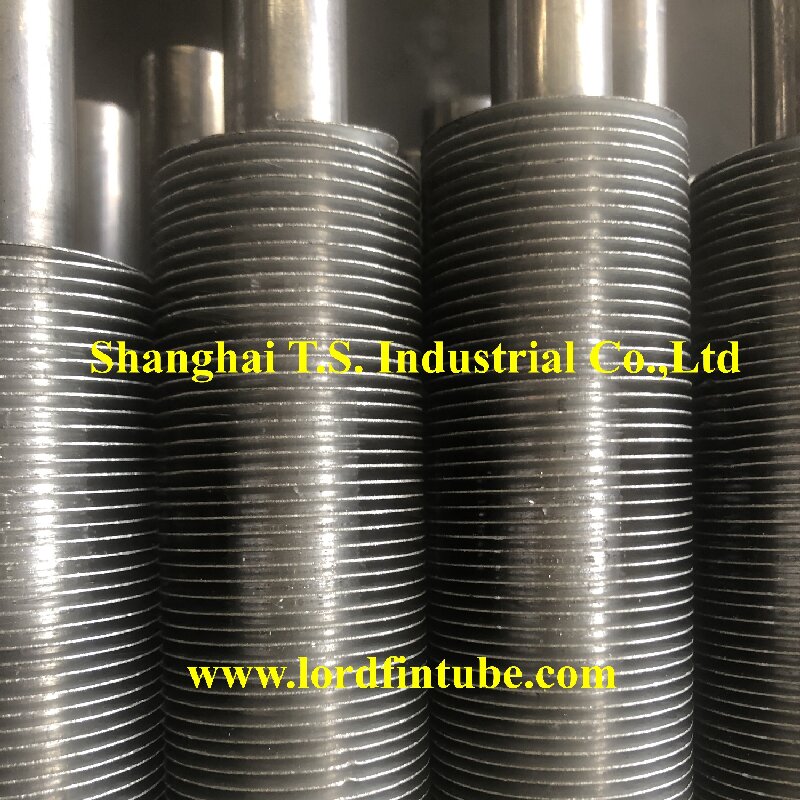

Aluminum Extruded Finned Tube

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

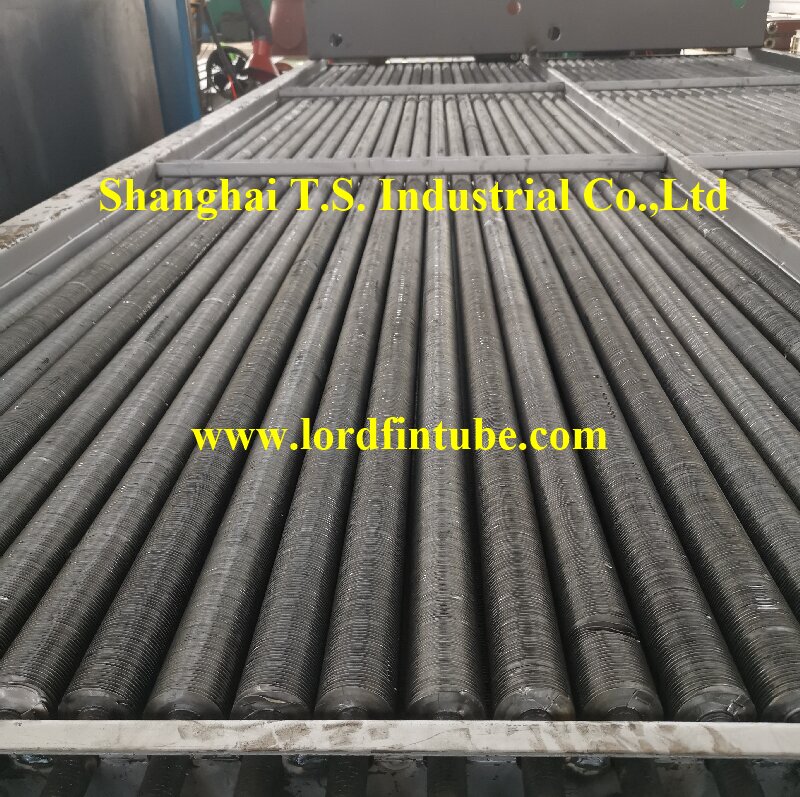

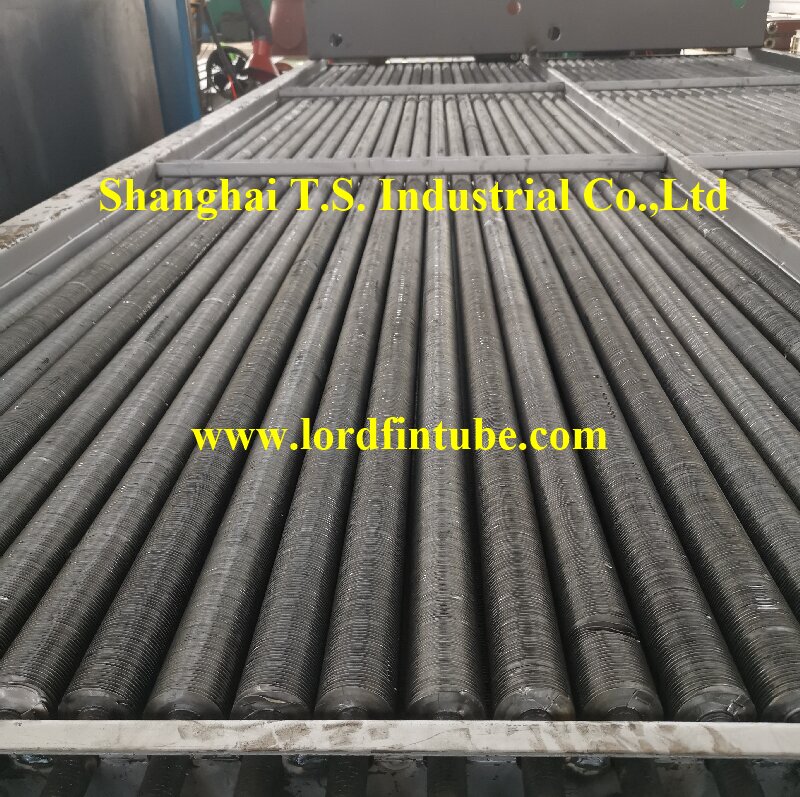

Fin tube for Heat Exchanger

petrochemical, power plant, oil refinery

Finned tube heat exchanger is one of the earliest and most successful discoveries in the process of improving tubular heat exchange. This method is still the most widely used method of enhancing heat transfer on all kinds of tubular heat exchange surfaces. It is not only suitable for single finned tube heat exchangers, but also widely used in power, chemical, petrochemical, air conditioning engineering and refrigeration engineering.

Use case

Fin tube for Heat Exchanger

petrochemical, power plant, oil refinery

Finned tube heat exchanger is one of the earliest and most successful discoveries in the process of improving tubular heat exchange. This method is still the most widely used method of enhancing heat transfer on all kinds of tubular heat exchange surfaces. It is not only suitable for single finned tube heat exchangers, but also widely used in power, chemical, petrochemical, air conditioning engineering and refrigeration engineering.

Fin tubes are specialized heat exchangers that enhance thermal conductivity by incorporating extended surfaces or fins. These fins increase the surface area available for heat transfer, making fin tubes highly efficient in applications where heat dissipation or absorption is critical. Typically constructed from materials like copper or aluminum, they are widely used in various industries, including HVAC systems, refrigeration, and power generation, to improve energy efficiency and reduce operational costs. The design can vary, with different fin configurations tailored to specific operational requirements, ensuring optimal performance in diverse environments.

Fin tubes enhance heat transfer efficiency through their unique design, which incorporates extended surfaces. The fins increase the surface area available for heat exchange, allowing for more effective transfer of heat between the fluid inside the tube and the surrounding environment. By promoting turbulent flow around the fins, these tubes also facilitate better mixing of the fluid, further improving heat transfer rates. The combination of increased surface area and enhanced fluid dynamics results in a significant boost in thermal performance, making fin tubes an essential component in various heating and cooling applications.

In the construction of fin tubes, various materials are commonly utilized to enhance performance and durability. Carbon Steel is frequently chosen for its strength and cost-effectiveness, making it suitable for a wide range of applications. Stainless Steel is another popular option due to its corrosion resistance, which is essential in environments exposed to moisture or chemicals. Additionally, Copper and Aluminum are often used for their excellent thermal conductivity, allowing for efficient heat transfer in applications such as heat exchangers. Each material offers unique benefits, catering to specific operational requirements and environmental conditions.

Fin tubes are typically used in various industrial applications where efficient heat exchange is critical. They are commonly found in heat exchangers, boilers, and condensers, facilitating improved thermal performance by increasing the surface area for heat transfer. Industries such as power generation, petrochemical, HVAC (Heating, Ventilation, and Air Conditioning), and refrigeration frequently utilize fin tubes to enhance energy efficiency and optimize thermal management in their systems. The design of fin tubes allows them to perform well in both high and low-temperature environments, making them versatile for different operational conditions.

Fin Tube systems require regular inspections to ensure optimal performance and longevity. Cleaning is essential, as dust and debris can accumulate on the fins, reducing heat transfer efficiency. Periodic washing with appropriate cleaning solutions helps maintain efficiency. Leak Checks are also critical. Regularly inspect for any signs of leaks or corrosion, especially at connection points. Early detection of issues can prevent significant damage and costly repairs. Additionally, monitoring the operating pressure and temperature can help identify potential problems before they escalate.

Some interesting numbers and facts about your company results for Fin Tube

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 7298 |

| Amount of suitable service providers | 5639 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1923 |

| Youngest suiting company | 1999 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Fin Tube

What are related technologies to Fin Tube?

Based on our calculations related technologies to Fin Tube are Heat Exchangers, Hydraulic & Pneumatic Systems, Industrial Reactors, Industrial Packaging, Industrial Filters

Which industries are mostly working on Fin Tube?

The most represented industries which are working in Fin Tube are Other, Manufacturing, Construction, Oil, Energy and Gas, Machinery Manufacturing

How does ensun find these Fin Tube Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.