The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Techtrans Engineers

New Delhi, India

D

1-10 Employees

2009

Key takeaway

Techtrans Engineers is a leading provider of Plate Heat Exchangers, offering various types such as Gasketed, Brazed, Semi-Welded, and Welded models, tailored for industries like chemical processing, pharmaceuticals, and food production. Their commitment to high-quality, efficient heat transfer solutions since 2009 ensures reliable performance and longevity of equipment.

Reference

Service

Brazed Plate Heat Exchanger

The Brazed Plate Heat Exchanger by Techtrans Engineers offers a compact, efficient solution for high-performance heat transfer in demanding environments. Ideal for industries with space constraints, this exchanger features robust, stainless steel plates that are permanently joined through brazing, eliminating the need for gaskets and making it highly resistant to high pressures and temperatures. This design enhances thermal efficiency while minimizing maintenance requirements, ensuring dependable performance in sectors like HVAC, refrigeration, and process engineering. Techtrans Engineers’ Brazed Plate Heat Exchanger is engineered to optimize heat transfer with minimal energy loss, enabling efficient operation in applications requiring continuous and reliable temperature control. With expert support and tailored solutions, Techtrans Engineers provides top-tier products to meet rigorous industry demands, helping companies achieve sustainable, cost-effective operations.

Qingdao Ruipute Heat Exchange Equipment Manufacturing Co.Ltd

Qingdao, China

D

51-100 Employees

-

Key takeaway

Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd. specializes in high-efficiency energy-saving heat exchangers, including plate heat exchangers. The company has developed advanced welding techniques, ensuring their products meet high-quality standards comparable to global brands like Alfa Laval and GEA.

Reference

Product

plate heat exchanger-REAPTER

Tianjin Jinfan Mould Co.ltd.

Jinnan District, China

D

51-100 Employees

2003

Key takeaway

The company, Jinfan, specializes in the production of plate heat exchangers, offering a wide range of models and spare parts to meet industrial needs. With a commitment to sustainable development and innovative heat exchange solutions, Jinfan positions itself as a leading manufacturer in this field.

Reference

Core business

Plate Heat Exchanger Manufacturer in China

JINFANMOJU is a Chinese manufacturer & supplier of high quality heat transfer products. Our products include plate heat exchangers, heat exchanger plates, heat exchanger gaskets, plate and shell heat exchangers, welded plate heat exchangers, evaporator & condenser.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Grandeh Dished Ends Pvt Ltd

India

D

11-50 Employees

-

Key takeaway

GRANDEH DISHED ENDS PVT LTD specializes in providing a range of energy-saving products, including plate type heat exchangers (PHE), which are essential for efficient heating and cooling processes. Their commitment to sustainable technologies and solutions positions them as a key player in helping industries transition to more environmentally friendly operations.

Reference

Product

Plate type heat exchanger - Steam coil air preheater, Air cooled condenser manufacturer

SonFlow A/S

Kolding, Denmark

A

11-50 Employees

-

Key takeaway

SonFlow offers a diverse selection of plate heat exchangers that are energy-efficient and designed for optimal heat transfer in various industrial applications. Their products are AHRI-Certified®, ensuring quality and reliability, and they provide a variety of high-quality plate materials to enhance corrosion resistance.

Reference

Core business

Pumps & Plate Heat Exchangers

Fidelity Radcore Heat

Petaling Jaya, Malaysia

C

- Employees

-

Key takeaway

FRHE specializes in the design and manufacturing of plate heat exchangers, leveraging advanced thermal and mechanical design methods to ensure high efficiency and durability. With years of experience, FRHE also offers comprehensive heat transfer calculations and thermal process design services, making it a reliable source for premium heat exchanger solutions in the engineering industry.

Reference

Product

Plate Heat Exchanger, PHE Gaskets, Plate heat exchanger plates, Fully welded plate heat exchanger - Heat Exchanger Malaysia, Heat Exchanger Manufacturer

Process Equipment Solutions

Louisville, United States

B

1-10 Employees

2008

Key takeaway

Process Equipment Solutions offers a range of customized products and parts, including Plate Heat Exchangers, tailored to meet the specific production needs of various industrial sectors. Their commitment to excellent customer service and extensive product knowledge positions them as a key provider for equipment and service solutions.

Reference

Product

Plate Heat Exchangers - Process Equipment Solutions

PACKAGED HEAT

Salford, United Kingdom

A

1-10 Employees

2018

Key takeaway

Packaged Heat Ltd is the UK’s leading manufacturer of Plate Heat Exchangers, offering a wide range of products designed to meet diverse hot water needs in commercial and industrial settings. With over 50 years of experience, the company ensures reliable and long-lasting solutions for various applications, including NHS facilities, prisons, leisure centers, schools, and hotels.

Reference

Core business

About Us - packagedheat.uk

ABOUT PACKAGED HEAT Packaged Heat Ltd is the UK’s leading manufacturer of Plate Heat Exchangers with over 50 years of experience in designing and manufacturing of Heat ExchangersWe provide a vast range of heat exchangers that will fulfil all of your hot water requirements in both commercial and industrial applications.We have the knowledge expertise and

Shanghai Empire Mechanical Engineering Co. Ltd

Huangpu District, China

D

51-100 Employees

2005

Key takeaway

Shanghai Empire specializes in designing and manufacturing plate heat exchangers, including plate and shell heat exchangers, gaskets, and plates. With a strong focus on R&D and innovation, the company offers optimized heat transfer solutions and holds multiple patents in the field.

Reference

Core business

Plate Heat Exchanger | PHE Gaskets and Plates | Plate and Shell Heat Exchanger | Shanghai Empire

Shanghai Empire provides plate heat exchanger, plate and shell heat exchanger,gasketes and plates, plate evaporator, plate condenser, hydraulic press.

Zhejiang Forwon Plate Heat Exchanger Co., Ltd

Jiaxing, China

D

1001-5000 Employees

2008

Key takeaway

Zhejiang Forwon Heat Exchanger Co., Ltd. is a leading provider of energy-efficient heat exchanger solutions, offering a wide range of products, including water-to-water brazed plate heat exchangers. The company emphasizes model selection and technical reports to ensure accuracy and provide the most suitable solutions for various working conditions.

Reference

Product

Water To Water Brazed Plate Heat Exchangers Suppliers, Company

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Gasketed Plate Heat Exchanger

Go to product

Service

PHE Spare Parts

Go to product

Service

Semi-Welded Plate Heat Exchanger

Go to product

Service

Welded Plate Heat Exchanger

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Shell and Tube Heat Exchanger in Oil Refining

Gas, Oil

An oil refining company faces the challenge of efficiently managing the heat transfer during the distillation process, where crude oil is separated into various components using heat. The process involves high temperatures and aggressive chemical reactions, requiring a robust and reliable heat exchanger to maximize energy recovery and minimize operational costs. Solution: Techtrans Engineers provides a Shell and Tube Heat Exchanger, designed to handle the high pressures and temperatures of the refining process. The heat exchanger is custom-engineered to allow the hot flue gases from the furnace to flow through the shell while the crude oil flows through the internal tubes. As the two fluids pass each other, heat is efficiently transferred, reducing the need for additional fuel and lowering energy costs. Benefits: High Capacity: Capable of managing large fluid volumes and high temperatures without compromising efficiency. Durability: The robust construction ensures long-term performance in the challenging conditions of an oil refinery. Energy Efficiency: By recovering heat from the exhaust gases, the exchanger improves energy efficiency and reduces overall operating costs. Customization: Tailored to the specific heat load and fluid properties of the refining process, ensuring optimal performance. This application of the Shell and Tube Heat Exchanger helps the oil refining company achieve a more efficient, cost-effective process while ensuring reliable operation and energy conservation.

Use case

Shell and Tube Heat Exchanger in Oil Refining

Gas, Oil

An oil refining company faces the challenge of efficiently managing the heat transfer during the distillation process, where crude oil is separated into various components using heat. The process involves high temperatures and aggressive chemical reactions, requiring a robust and reliable heat exchanger to maximize energy recovery and minimize operational costs. Solution: Techtrans Engineers provides a Shell and Tube Heat Exchanger, designed to handle the high pressures and temperatures of the refining process. The heat exchanger is custom-engineered to allow the hot flue gases from the furnace to flow through the shell while the crude oil flows through the internal tubes. As the two fluids pass each other, heat is efficiently transferred, reducing the need for additional fuel and lowering energy costs. Benefits: High Capacity: Capable of managing large fluid volumes and high temperatures without compromising efficiency. Durability: The robust construction ensures long-term performance in the challenging conditions of an oil refinery. Energy Efficiency: By recovering heat from the exhaust gases, the exchanger improves energy efficiency and reduces overall operating costs. Customization: Tailored to the specific heat load and fluid properties of the refining process, ensuring optimal performance. This application of the Shell and Tube Heat Exchanger helps the oil refining company achieve a more efficient, cost-effective process while ensuring reliable operation and energy conservation.

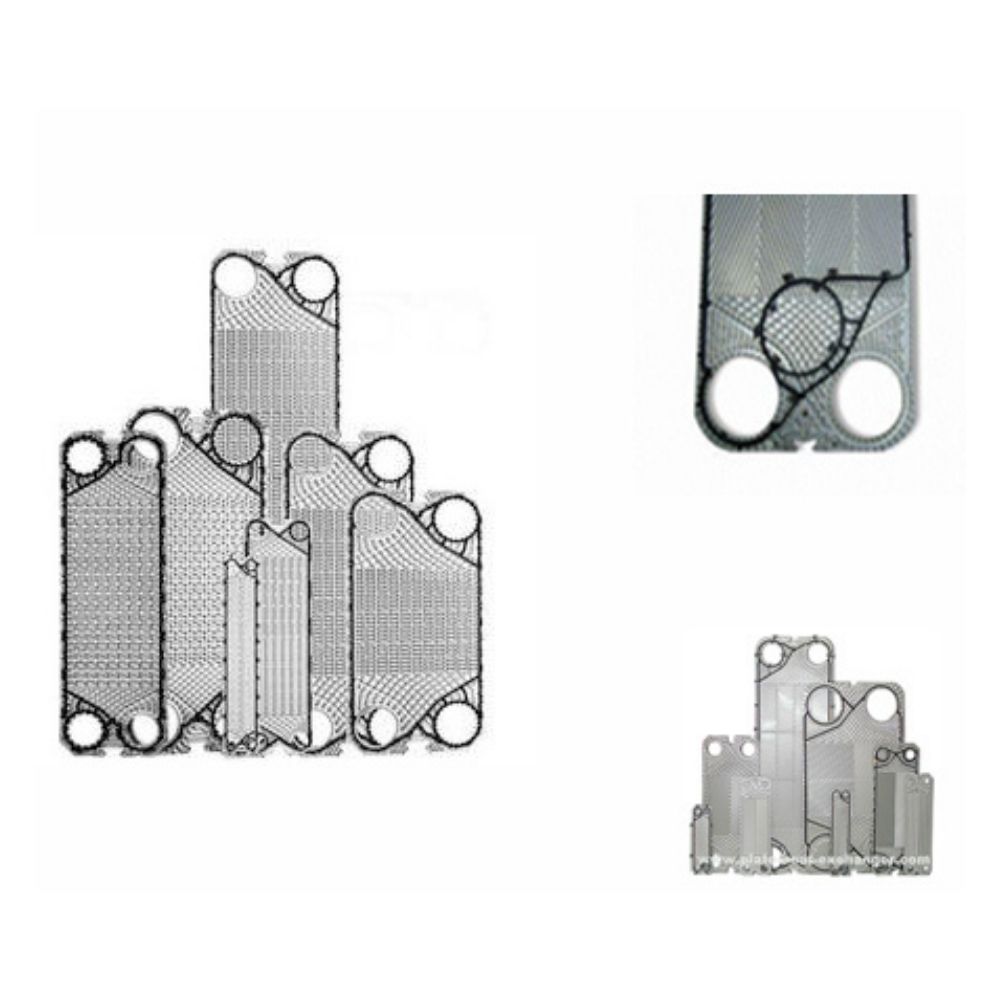

A plate heat exchanger is a type of heat exchanger that utilizes multiple thin plates to transfer heat between two fluids. The design consists of a series of plates stacked together, creating channels for the fluids to flow through. This structure enhances the surface area for heat transfer, making plate heat exchangers highly efficient compared to traditional shell-and-tube heat exchangers. These devices are widely used in various industries, including food processing, chemical manufacturing, and HVAC systems due to their compact size and effectiveness in heat transfer. The ability to easily disassemble for cleaning and maintenance further contributes to their popularity among providers and facility operators.

A plate heat exchanger operates by transferring heat between two fluids through a series of thin, corrugated plates. The fluids flow in alternating channels created by the plates, allowing for efficient heat transfer due to the large surface area provided by the plates. As one fluid enters the heat exchanger, it releases heat to the plates, which in turn warms the adjacent fluid flowing in the opposite direction. This counterflow design maximizes the temperature difference between the two fluids, enhancing thermal efficiency. The plates are typically made of stainless steel or other materials resistant to corrosion, ensuring durability and longevity. This technology is widely used in various applications, including HVAC systems, food processing, and chemical industries, due to its compact size and high efficiency.

1. High Efficiency

Plate heat exchangers are designed to maximize heat transfer efficiency. Their large surface area compared to their volume allows for effective thermal exchange, which can lead to significant energy savings in various applications.

2. Compact Design

These heat exchangers are compact and lightweight. Their design requires less space compared to traditional shell-and-tube heat exchangers, making them ideal for facilities with limited installation space.

3. Easy Maintenance

Maintenance is straightforward due to the modular design. The plates can be easily accessed, cleaned, or replaced, ensuring that the system remains efficient and operational with minimal downtime.

4. Versatility

Plate heat exchangers can handle a wide range of fluids and temperatures. This versatility makes them suitable for various industries, including food and beverage, chemical processing, and HVAC systems.

5. Cost-Effectiveness

Over time, the operational savings from energy efficiency and reduced maintenance costs contribute to the overall cost-effectiveness of plate heat exchangers compared to other heat exchanger types.

Regular maintenance of a Plate Heat Exchanger is crucial for optimal performance and longevity. Cleaning is one of the primary tasks, as fouling can significantly reduce heat transfer efficiency. Depending on the fluid characteristics, cleaning may be required periodically to remove deposits. Another important aspect is inspection. Routine checks for leaks, corrosion, and physical wear are essential. This includes monitoring the tightness of the bolts and the condition of the gaskets. Ensuring that the unit is operating within specified parameters helps prevent operational issues. Regular maintenance not only extends the lifespan of the equipment but also enhances its efficiency.

1. Determine the Application Requirements

Understanding the specific heating or cooling requirements of your application is crucial. Consider factors such as fluid types, temperature ranges, and pressure drops. This information will guide you in selecting the right materials and design specifications for the heat exchanger.

2. Evaluate Performance Specifications

Look at the thermal performance, including heat transfer efficiency and overall heat transfer coefficient. Ensure that the selected plate heat exchanger can handle the expected flow rates and achieve the desired temperature exchange while maintaining energy efficiency.

3. Consider Space and Installation Constraints

Assess the available space for installation and the layout of your system. Plate heat exchangers can vary significantly in size and configuration, so a model that fits within your space while providing optimal performance is essential.

4. Review Maintenance and Cleaning Needs

Choose a design that allows for easy access and cleaning. Some applications may require frequent maintenance, so it’s important to select a plate heat exchanger that simplifies this process, ensuring longevity and consistent performance.

Some interesting numbers and facts about your company results for Plate Heat Exchanger

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 7806 |

| Amount of suitable service providers | 7513 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 2003 |

| Youngest suiting company | 2018 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Plate Heat Exchanger

What are related technologies to Plate Heat Exchanger?

Based on our calculations related technologies to Plate Heat Exchanger are Heat Exchangers, Hydraulic & Pneumatic Systems, Industrial Reactors, Industrial Packaging, Industrial Filters

Which industries are mostly working on Plate Heat Exchanger?

The most represented industries which are working in Plate Heat Exchanger are Other, Manufacturing, Construction, Oil, Energy and Gas, Machinery Manufacturing

How does ensun find these Plate Heat Exchanger Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.