The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

SENTI Hydraulics

Balingen, Germany

A

1-10 Employees

-

Key takeaway

The company's in-house developed gear design mathematics significantly enhances gear performance, achieving up to 7 times the tooth engagement, which results in higher torque transmission and improved noise and vibration behavior. Their technology also offers scalability and material versatility, including applications with plastic.

Reference

Product

Gear Technology

Boston Gear

Charlotte, United States

B

51-100 Employees

1877

Key takeaway

Boston Gear provides a wide range of gearing solutions, including standard enclosed gear drives and custom speed reducers, making it a key player in the industry. Their products are essential in various applications, particularly in material handling.

Reference

Product

Change Gears

The Robot MarketPlace LLC

Bradenton, United States

B

1-10 Employees

2002

Key takeaway

The company, known for building combat robots for various events, emphasizes its commitment to offering a diverse range of products, including gears, in a marketplace that supports small businesses.

Reference

Product

Gears

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

MINI-GEARS(STOCKPORT)LIMITED

Stockport, United Kingdom

A

51-100 Employees

1966

Key takeaway

Mini Gears specializes in manufacturing a wide range of high precision gears and racks, tailored to customer specifications. With a focus on quality and innovation, they have expanded their capabilities to serve various high-end markets, making them a key player in the gear manufacturing industry.

Reference

Service

se_ass_gearbox - Mini Gears

ESA Eppinger GmbH

Denkendorf, Germany

A

251-500 Employees

1925

Key takeaway

The Eppinger Group specializes in the development and production of precision gears, offering innovative and customized solutions for various applications in robotics and machine engineering. Their gear technology is noted for its quality, precision, and performance, making it a key focus of their extensive product range.

Reference

Product

Gears - Eppinger - Group

Gateshead Bearings

Gateshead, United Kingdom

A

1-10 Employees

-

Key takeaway

Gateshead Bearings Group is a leading supplier of professional-grade bearings and related products, including gears. They provide a wide range of quality products from top manufacturers, ensuring that they can meet diverse needs in transmission and motion-related applications.

Reference

Product

TRANSMISSION: Gears

Warrior, Inc

Tualatin, United States

B

11-50 Employees

1992

Key takeaway

Warrior Products specializes in manufacturing high-quality accessories for Jeep, Toyota, and 4x4 vehicles, ensuring that all products are 100% US made. Their commitment to quality and customer service positions them as a reliable source for automotive aftermarket gear and accessories.

Reference

Product

Gear + Accessories - Product

MGS Gears

Rho, Italy

B

11-50 Employees

2016

Key takeaway

MGS Gears specializes in designing and manufacturing a wide range of gearboxes and mechanical power transmission components, leveraging over 30 years of experience to enhance production processes and extend the lifespan of industrial equipment. Their expertise makes them a key player in sectors requiring efficient gear solutions.

Reference

Core business

Reducers | Rho | MGS GEARS

MGS GEARS S.r.L. is a leader in all industrial sectors in which parts for the mechanical power transmission are employed.

REVERSE GEAR Inc.

Victoria, Canada

A

1-10 Employees

2008

Key takeaway

REVERSE GEAR Inc. specializes in custom clothing for recumbent riders, emphasizing sustainability by creating products from upcycled bike parts. Their commitment to reducing waste and extending the lifespan of materials aligns with the values of efficient and eco-friendly practices.

Reference

Core business

Home | Reverse Gear

Nuttall Gear L L C

City of Niagara Falls, United States

B

51-100 Employees

1887

Key takeaway

Nuttall Gear, established in 1887, is a leading manufacturer of custom gearing solutions, including helical gears, speed reducers, and gearmotors. Their expertise extends to designing gear drives for rail car propulsion systems and moveable bridges, highlighting their significant contributions to gear engineering.

Reference

Product

Loose Gearing & Gear Sets

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

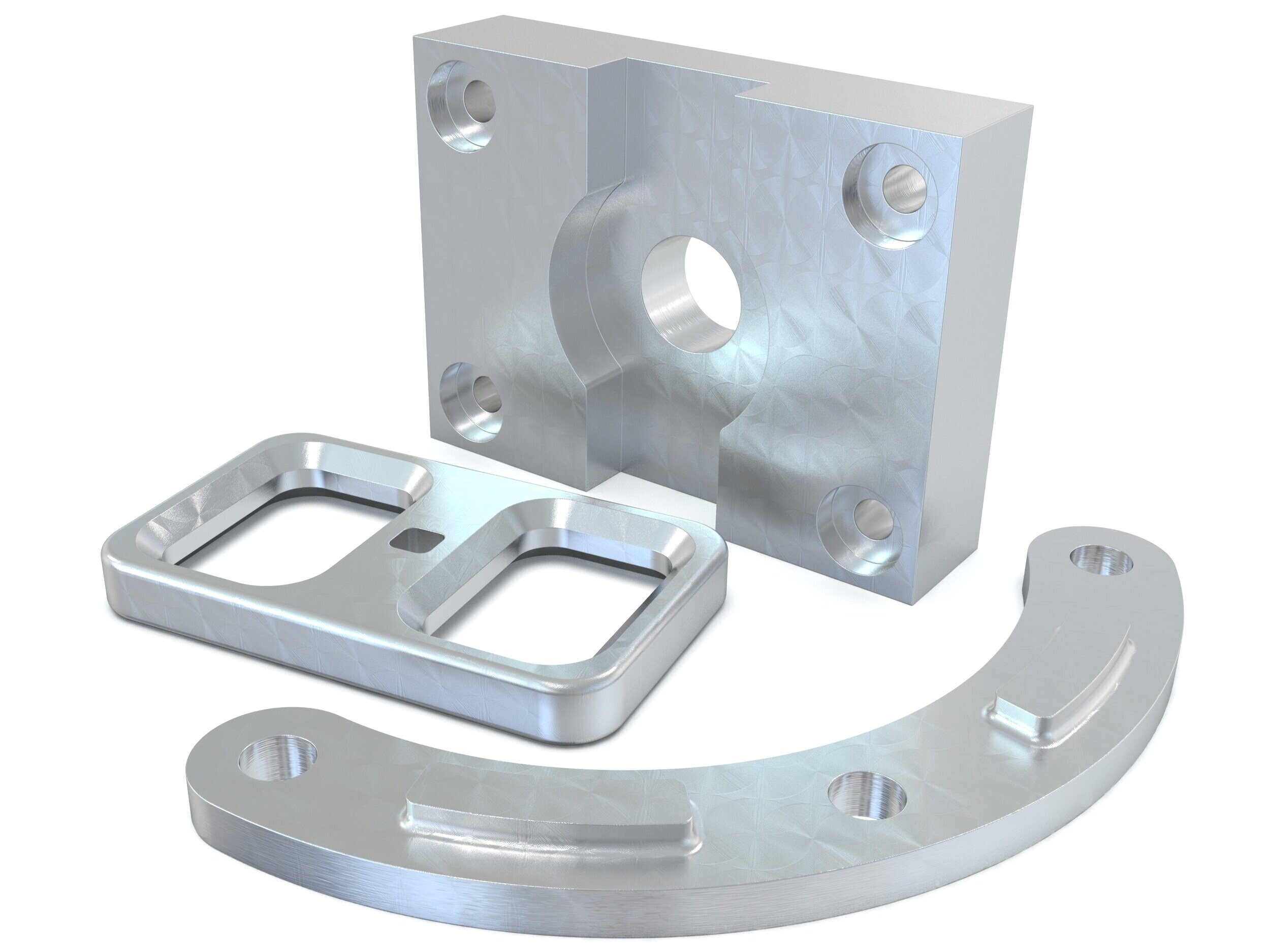

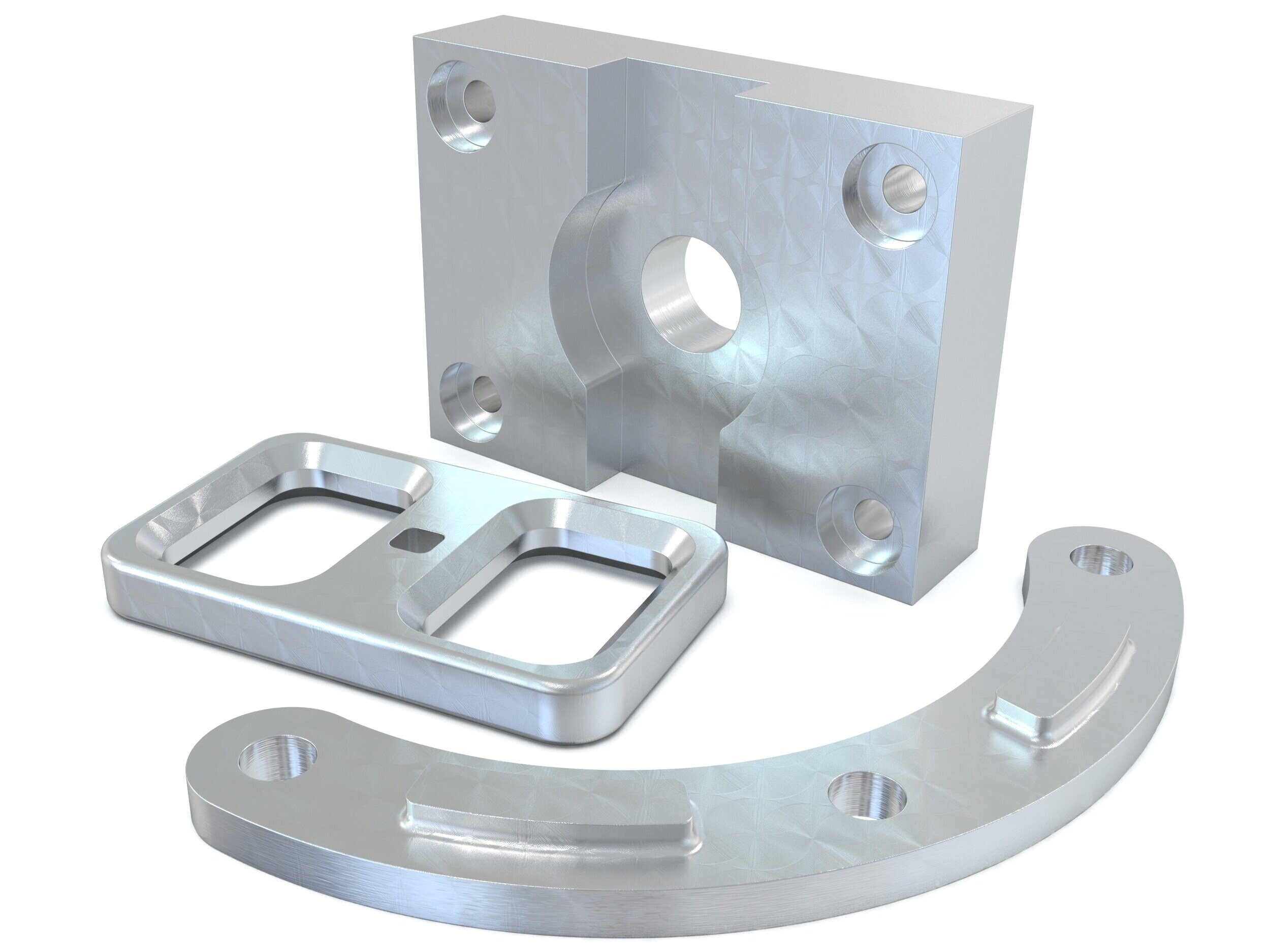

Product

CNC Machining

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

CNC Machining Parts for Machinery

Machinery, Automotive, Medical

CNC machining (Computer Numerical Control machining) is a manufacturing process in which pre-programmed computer software manages the movement of tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Use case

CNC Machining Parts for Machinery

Machinery, Automotive, Medical

CNC machining (Computer Numerical Control machining) is a manufacturing process in which pre-programmed computer software manages the movement of tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Gear refers to equipment or tools utilized in various industries, including sports, outdoor activities, and technical fields. It encompasses a wide range of items, from protective clothing and accessories to specialized instruments and machinery. The right gear enhances performance, ensures safety, and optimizes efficiency, making it essential for professionals and enthusiasts alike. The selection of quality gear can significantly impact the overall experience and outcomes in any endeavor.

Gear in technology refers to the various mechanical devices or components that facilitate movement and control in machines and systems. These components work by transferring motion and force, allowing machines to perform specific tasks efficiently. For instance, gears can change the direction of motion, increase torque, or adjust the speed of rotation. In many technological applications, gears are used in conjunction with motors and other mechanisms to optimize performance. Their design and material selection are crucial, as they affect durability, efficiency, and overall functionality. Properly functioning gears ensure smooth operation in everything from simple toys to complex machinery in manufacturing processes.

1. Automotive Industry

Gears are essential in vehicles for transmitting power from the engine to different components, enabling efficient movement and control.

2. Industrial Machinery

In industrial settings, gears facilitate the functioning of various machines, enhancing the performance of conveyor systems, drilling equipment, and manufacturing tools.

3. Robotics

Gears play a critical role in robotics, allowing for precise movement and positioning in robotic arms and other automated systems.

4. Appliances

Household appliances, such as washing machines and mixers, utilize gears to improve efficiency and performance by controlling motor speed and torque.

5. Aerospace

In aerospace applications, gears are vital for controlling the operation of various systems, including landing gear and flight control mechanisms.

1. Improved Efficiency

Using gear systems in machinery significantly enhances efficiency by optimizing the transfer of power and motion. Gears enable precise control over speed and torque, allowing machines to operate at their ideal performance levels.

2. Increased Durability

Gears are designed to withstand high levels of stress and wear, ensuring longevity in machinery. Their robust construction minimizes the risk of failure, leading to reduced maintenance costs and extended operational life of equipment.

Gear plays a crucial role in enhancing the performance of devices by optimizing the power transmission and mechanical efficiency. When high-quality gear systems are integrated, they ensure that energy is transferred smoothly, reducing friction and wear. This leads to less energy loss, allowing devices to operate more efficiently and effectively. Furthermore, well-designed gear ratios can enhance torque and speed, tailoring the performance to specific applications. This adaptability not only improves the overall functionality of machines but also extends their lifespan, as gears reduce the strain on other components.

Some interesting numbers and facts about your company results for Gear

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 2225 |

| Amount of suitable service providers | 1598 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1877 |

| Youngest suiting company | 2016 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Gear

What are related technologies to Gear?

Based on our calculations related technologies to Gear are Heat Exchangers, Hydraulic & Pneumatic Systems, Industrial Reactors, Industrial Packaging, Industrial Filters

Which industries are mostly working on Gear?

The most represented industries which are working in Gear are Other, Manufacturing, Automotive, Machinery Manufacturing, Retail

How does ensun find these Gear Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.