The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Texas Hydraulics

Temple, United States

B

251-500 Employees

1968

Key takeaway

The company is a leading manufacturer of custom welded hydraulic cylinders, offering engineering solutions that address challenges related to cylinder operation, such as cushion problems and contamination. With over 60 years of experience, they ensure timely production and shipping of quality hydraulic cylinder products.

Reference

Service

Hydraulic Cylinder Engineering Solutions | Prototype Designs & Support

Texas Hydraulics engineering solutions have addressed many of the challenges related to cylinder operation including cushion problems, contamination, pressure trapping and friction.

PB Machine Tech

The Municipal District of Muinebeag, Ireland

A

51-100 Employees

1988

Key takeaway

PB Machine Tech Ltd is a hydraulic cylinder manufacturer that produces a wide range of single acting, double acting, and displacement cylinders tailored to precise customer requirements. Their purpose-built factory ensures superior product quality and control throughout the manufacturing process.

Reference

Core business

PB Machine Tech Ltd - Hydraulic Cylinder Manufacturer

PB Machine Tech Showcase

The Municipal District of Muinebeag, Ireland

A

51-100 Employees

1988

Key takeaway

PB Machine Tech Ltd is a hydraulic cylinder manufacturer that produces a wide range of single acting, double acting, and displacement cylinders tailored to precise customer requirements. Their purpose-built factory ensures superior product quality and control throughout the manufacturing process.

Reference

Core business

PB Machine Tech Ltd - Hydraulic Cylinder Manufacturer

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Hydroline

Hankasalmi, Finland

A

251-500 Employees

1962

Key takeaway

Hydroline is a leading manufacturer of high-quality hydraulic cylinders, known for its expertise and problem-solving capabilities in the field. With a strong history since 1962, the company emphasizes meticulous assembly and offers resources for sourcing hydraulic cylinders.

Reference

Product

Hydraulic cylinder manufacturing | Hydroline

Air-Hydraulic Systems

Chanhassen, United States

B

11-50 Employees

-

Key takeaway

Air-Hydraulic Systems is a key supplier of hydraulic cylinders, emphasizing their commitment to improving fluid conveyance for enhanced productivity. With a team of fluid power experts, they are well-equipped to assist with various application challenges.

Reference

Product

Your Source for Hydraulic Cylinders, Piston Motors

Precision Hydraulic Cylinders

Wilmington, United States

B

51-100 Employees

2000

Key takeaway

Precision Hydraulic Cylinders, a Leggett & Platt company, is a leading manufacturer of hydraulic cylinders, offering a wide range of designs including single acting, double acting, telescopic, and tie-rod cylinders, tailored to various mobile equipment applications. With a focus on quality control, innovation, and strong customer collaboration, they ensure that their hydraulic cylinder products meet rigorous specifications and support OEMs throughout the development process.

Reference

Product

Hydraulic Cylinder Design | Precision Hydraulic Cylinders, Inc.

Aggressive Hydraulics

Oak Grove, United States

B

101-250 Employees

2002

Key takeaway

Aggressive Hydraulics specializes in the design and manufacturing of high-performance, custom hydraulic cylinders, ensuring quality construction and reliability. Their commitment to ISO 9001:2015 standards and a wide range of design features allows them to meet diverse customer requirements effectively.

Reference

Core business

Hydraulic Cylinder Manufacturer | Custom Hydraulic Cylinders

Aggressive Hydraulics specializes in the design and manufacturing of superior, custom hydraulic cylinders. We are committed to providing our customers with the highest quality custom hydraulic cylinder solutions. Our customers receive prompt courteous service from our staff which has both the experience and technical insight to deliver consistently. Our facility is equipped top of the line machines and staffed with seasoned and qualified machinists, welders and hydraulic technicians. Quality is not just a department, it’s a company-wide commitment.

BVA Hydraulics - EMEA

Etten-Leur, Netherlands

A

251-500 Employees

1972

Key takeaway

The company offers a comprehensive range of hydraulic cylinders designed for various applications and industries, emphasizing their commitment to quality and customer service.

Reference

Product

Products | BVA Hydraulics

Hydraulic Cylinders Inc

United States

B

11-50 Employees

-

Key takeaway

Hydraulic Cylinders Inc. specializes in hydraulic cylinders, offering a wide range of in-stock and custom options for both industrial and mobile applications. With a team of experienced professionals, they provide solutions for manufacturers, end users, and resellers, ensuring quick access to quality replacement cylinders and innovative designs to meet diverse industry needs.

Reference

Core business

Replacement Hydraulic Cylinders | Custom Hydraulic Cylinders

HCI offers in-stock and custom hydraulic cylinders and component parts for mobile and industrial equipment. Shop our USA-made, ready-to-ship cylinders!

CYLINDERS & VALVES INC

Strongsville, United States

B

1-10 Employees

1958

Key takeaway

Cylinders & Valves, Inc. specializes in manufacturing hydraulic cylinders and offers customization to meet specific requirements. Their commitment to reliability and serviceability ensures that their cylinders perform well and have a longer lifespan compared to many competitors.

Reference

Core business

Hydraulic Cylinder Manufacturer

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

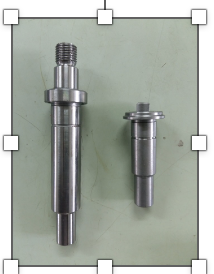

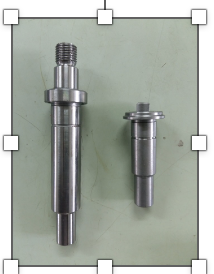

Product

Forged & CNC turned shafts

Go to product

Product

Hollow head shaft

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Hydraulic pump shafts

In automobile / Tractor power steering applications

Commercial vehicles & tractors are fitted with power steering for easy manoeuvrability. This is a hydraulic system which reduces the effort required to steer vehicles, by hydraulic assistance. This product forged by us is a part used in the hydraulic pumps in the power steering system. The pump is also used in other hydraulic industries for fluid movement.

Use case

Hydraulic pump shafts

In automobile / Tractor power steering applications

Commercial vehicles & tractors are fitted with power steering for easy manoeuvrability. This is a hydraulic system which reduces the effort required to steer vehicles, by hydraulic assistance. This product forged by us is a part used in the hydraulic pumps in the power steering system. The pump is also used in other hydraulic industries for fluid movement.

A hydraulic cylinder is a mechanical device that converts hydraulic energy into linear motion. It consists of a cylindrical barrel, a piston, and hydraulic fluid. When pressurized fluid enters the cylinder, it pushes the piston, creating movement. This mechanism is widely used in various applications, such as construction equipment, manufacturing machinery, and automotive systems, due to its efficiency and ability to exert significant force. The design and construction of hydraulic cylinders can vary, allowing for customization based on specific operational needs and pressure requirements.

A hydraulic cylinder operates by using pressurized hydraulic fluid to create linear motion. Inside the cylinder, a piston is positioned, which divides the cylinder into two chambers. When hydraulic fluid is introduced into one chamber, it pushes the piston in the opposite direction, resulting in movement. The pressure generated by the fluid is what enables the cylinder to lift heavy loads or apply significant force. The flow of hydraulic fluid is controlled through valves, allowing for precision in movement and speed. As the fluid exits one chamber, it returns to a reservoir or is redirected, completing the hydraulic circuit. This mechanism is widely used in various applications, including construction equipment, manufacturing machinery, and automotive systems, due to its ability to generate substantial force in a compact design.

A hydraulic cylinder consists of several key components that work together to convert hydraulic energy into mechanical force.

1. Cylinder Barrel

The cylinder barrel is the main body of the hydraulic cylinder, providing structure and housing for the internal components.

2. Piston

The piston is a crucial part that moves back and forth within the cylinder barrel, driven by hydraulic pressure.

3. Piston Rod

Attached to the piston, the piston rod extends outside the cylinder, transmitting the force generated by the hydraulic fluid to perform work.

4. Seals

Seals are essential for preventing hydraulic fluid from leaking out of the cylinder and ensuring efficient operation.

5. End Caps

End caps close off the ends of the cylinder barrel, providing structural integrity and housing the seals for the piston rod.

Each of these components plays a vital role in the functionality and efficiency of hydraulic cylinders in various applications.

Hydraulic cylinders are utilized in various industrial applications due to their ability to generate significant force and precise control. One common use is in construction equipment, where they power excavators, bulldozers, and cranes, allowing for the lifting and moving of heavy materials. Additionally, hydraulic cylinders play a crucial role in manufacturing processes, such as in metal forming and assembly lines, where they assist in pressing, bending, and shaping materials. They are also found in agricultural machinery, enabling tasks like plowing and harvesting, which require substantial force and reliability.

1. Regular Inspection

Routine inspections are crucial for identifying any signs of wear, corrosion, or leaks. Checking the seals, hoses, and connections helps ensure the hydraulic cylinder operates efficiently.

2. Lubrication

Applying the appropriate lubricant on moving parts minimizes friction and wear. It’s essential to use the manufacturer-recommended lubricant to prevent damage and maintain functionality.

3. Cleanliness

Maintaining cleanliness is vital to avoid contamination. Ensure that hydraulic cylinders are free from dirt and debris, which can compromise performance and longevity.

4. System Pressure Checks

Monitoring the hydraulic system pressure prevents excessive strain on the cylinder. Regularly testing the pressure settings helps maintain optimal performance.

5. Prompt Repairs

Addressing issues immediately, such as leaks or unusual noises, helps avoid more significant problems. Swift repairs can extend the lifespan of the hydraulic cylinder and ensure reliable operation.

Some interesting numbers and facts about your company results for Hydraulic Cylinder

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6702 |

| Amount of suitable service providers | 5928 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1958 |

| Youngest suiting company | 2002 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Hydraulic Cylinder

What are related technologies to Hydraulic Cylinder?

Based on our calculations related technologies to Hydraulic Cylinder are Heat Exchangers, Hydraulic & Pneumatic Systems, Industrial Reactors, Industrial Packaging, Industrial Filters

Which industries are mostly working on Hydraulic Cylinder?

The most represented industries which are working in Hydraulic Cylinder are Manufacturing, Other, Machinery Manufacturing, Oil, Energy and Gas, Construction

How does ensun find these Hydraulic Cylinder Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.