The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Microfluidics International Corporation

Westwood, United States

B

51-100 Employees

1982

Key takeaway

Microfluidics International Corporation specializes in high shear fluid processors, particularly their Microfluidizer® technology, which is essential for producing micro- and nano-scale materials across various industries, including pharmaceuticals and biotech. Their expertise and commitment to customer support ensure that clients can effectively leverage this technology to enhance product development and process efficiency.

Reference

Core business

Microfluidics International Corporation - high shear fluid processors

Microfluidics, manufacturer of Microfluidizer® high shear fluid processors is a leader in the design and production of lab and commercial equipment

Micronit Microfluidics

Enschede, Netherlands

A

51-100 Employees

1999

Key takeaway

The company is a global leader in microfluidic product development and specializes in the manufacturing of lab-on-a-chip consumables, offering a comprehensive design-to-manufacturing service for microfluidic diagnostic tests. They emphasize collaboration with clients to drive innovation and quickly provide ready-to-use products.

Reference

Core business

Micronit DE | Micronit | Enabling microfluidic products

Microfluidic Valley

Paris, France

A

51-100 Employees

2011

Key takeaway

The Microfluidic Valley provides comprehensive expertise for microfluidic projects, including scientific counseling, chip design and fabrication, and system validation. Their team is dedicated to helping you plan and execute your microfluidic setup.

Reference

Core business

Microfluidic Valley – All about microfluidics

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

UFLUIDIX INC

Canada

A

11-50 Employees

2010

Key takeaway

uFluidix is a leading company in the custom fabrication of microfluidic devices, specializing in PDMS and thermoplastics. With advanced manufacturing equipment and proprietary processes, they offer high-fidelity production of microfluidic chips and serve as a full-service development partner for microfluidic solutions.

Reference

Core business

Microfluidics Fabrication Leader | Custom Microfluidics Fabrication

uFluidix is the industry leader in Custom Microfluidics Fabrication and PDMS microfluidic chips. We mean Microfluidics!

Rapid Fluidics Ltd

Newcastle upon Tyne, United Kingdom

A

1-10 Employees

2020

Key takeaway

Rapid Fluidics is a specialized microfluidics consultancy that offers design and rapid prototyping services for custom microfluidic devices. Their expertise and cutting-edge technology enable the quick transition from design concepts to testable prototypes, making them a valuable resource for microfluidic development.

Reference

Core business

Microfluidic Prototyping | Rapid Fluidics Ltd

Rapid Fluidics Ltd provides prototyping and manufacture of 3D printed microfluidic chips. Offering microfluidic design consultancy and prototyping.

LiveDrop

Liège, Belgium

A

1-10 Employees

2022

Key takeaway

LiveDrop is a specialized droplet microfluidics company with over 10 years of experience, dedicated to enhancing cell biology and microbiology research through innovative integrated flow cytometers like the ModaFlow™. Their expertise in microfluidics aims to streamline and optimize experimental processes for scientists and researchers.

Reference

Core business

LiveDrop | Droplet microfluidics company

LiveDrop is a droplet microfluidics company developing all-in-one integrated flow cytometers to boost your cell biology and microbiology studies

microfluidic ChipShop

Jena, Germany

A

11-50 Employees

2002

Key takeaway

Microfluidic ChipShop specializes in lab-on-a-chip systems, providing tailor-made microfluidic solutions that enhance laboratory efficiency. With a focus on precision manufacturing and a commitment to integrating innovative technologies into everyday lab practices, they offer both standard and customized microfluidic products.

Reference

Service

Fluidic Platforms for Custom Design - microfluidic ChipShop

NextGenMicrofluidics

Graz, Austria

A

51-100 Employees

2020

Key takeaway

The company specializes in the development and production of customized microfluidic lab-on-a-foil systems, catering to a range of clients from startups to large-scale industries. Their expertise is supported by a collaboration of 21 organizations and funding from the European Union’s HORIZON 2020 program.

Reference

Core business

NextGenMicrofluidics - Microfluidic lab-on-a-foil systems

✅ We develop customized microfluidic lab-on-a-foil systems & offer services for the development and production of these systems for companies.

Fluigent

Le Kremlin-Bicêtre, France

A

11-50 Employees

2005

Key takeaway

Fluigent specializes in advanced fluid control systems for microfluidics, addressing the need for precise and stable technology in applications like droplets and cell biology. Their innovative solutions, including a self-learning flow rate control algorithm and non-intrusive flow sensing, enhance the performance of fluid handling at the microscale.

Reference

Product

OEM Microfluidic Technologies - Fluigent

DFC, "self-learning" flow rate control algorithm Non-intrusive flow sensing technology Compact all-in-one pressure supply & pressure/flow control Liquid stirring solutions Microfluidic temperature control

Protron Mikrotechnik Gmbh

Bremen, Germany

A

1-10 Employees

-

Key takeaway

Protron Mikrotechnik specializes in developing micro-electro-mechanical systems (MEMS) and has a focus on microfluidics, offering customer-specific manufacturing concepts that cater to both small and high-volume production needs.

Reference

Product

Microfluidics

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

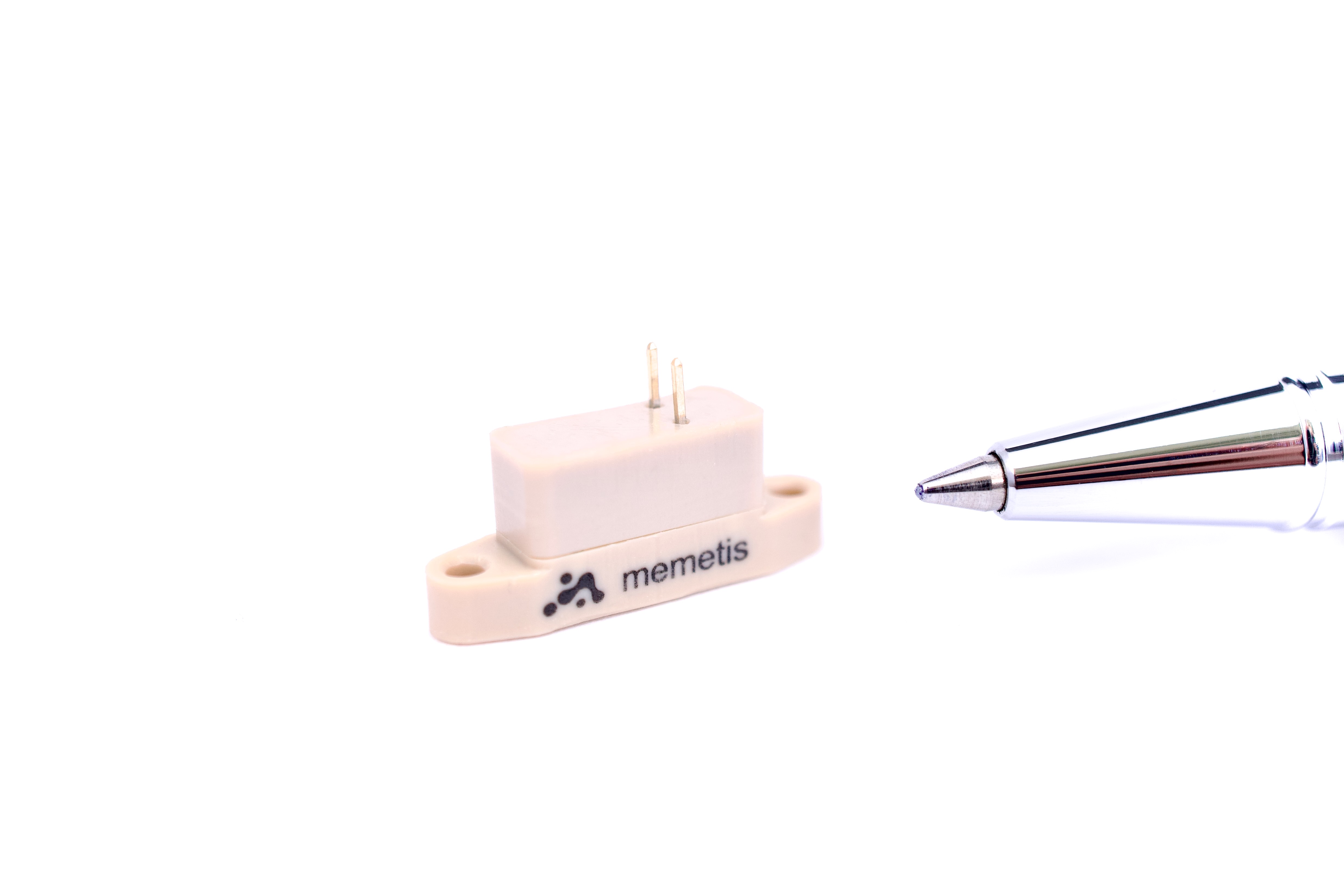

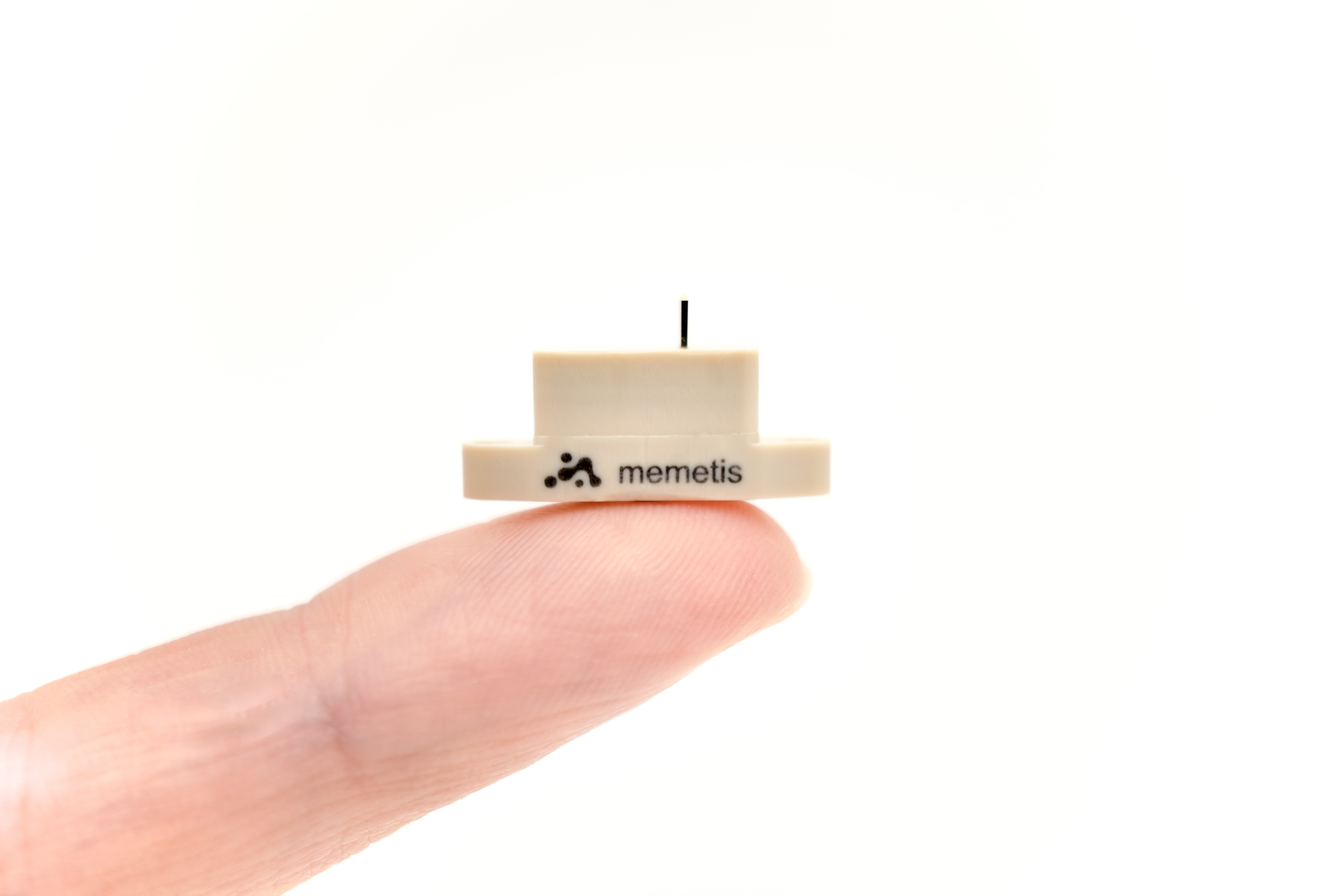

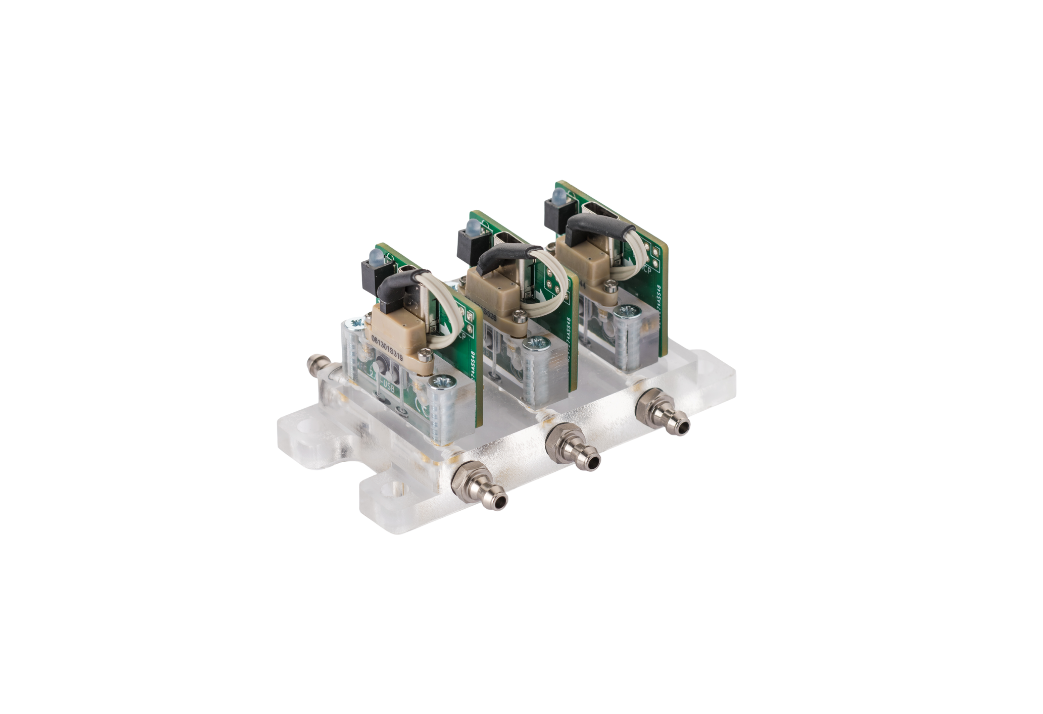

Product

Normally-Closed Microvalve: Classic

Go to product

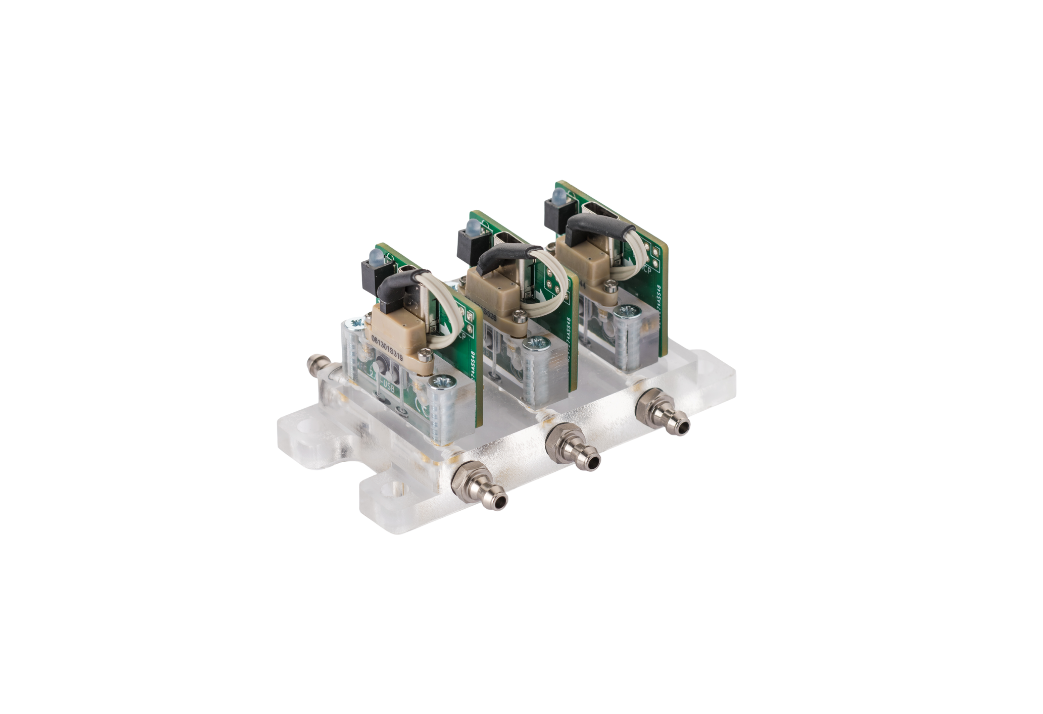

Product

Normally-Closed Microvalve: Negative Pressure

Go to product

Service

Microfluidic Control Systems

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Smallest Mass Flow Controller for Precise Gas Quantification

Gas Analysis, Bioreactors, Respirometry, Mass Flow Control

This memetis Valve Use Case describes design of the Mass Flow Controller (MFC) EMF 100 built by ECHO Instruments. The purpose of creating the MFC was to enable multiple plastic biodegradability measurements in a compact space with flow ranges up to 100 sml/min. Having done this, ECHO Instruments can build respirometers with smaller control units, while reducing production costs and becoming independent from external mass flow control device suppliers.

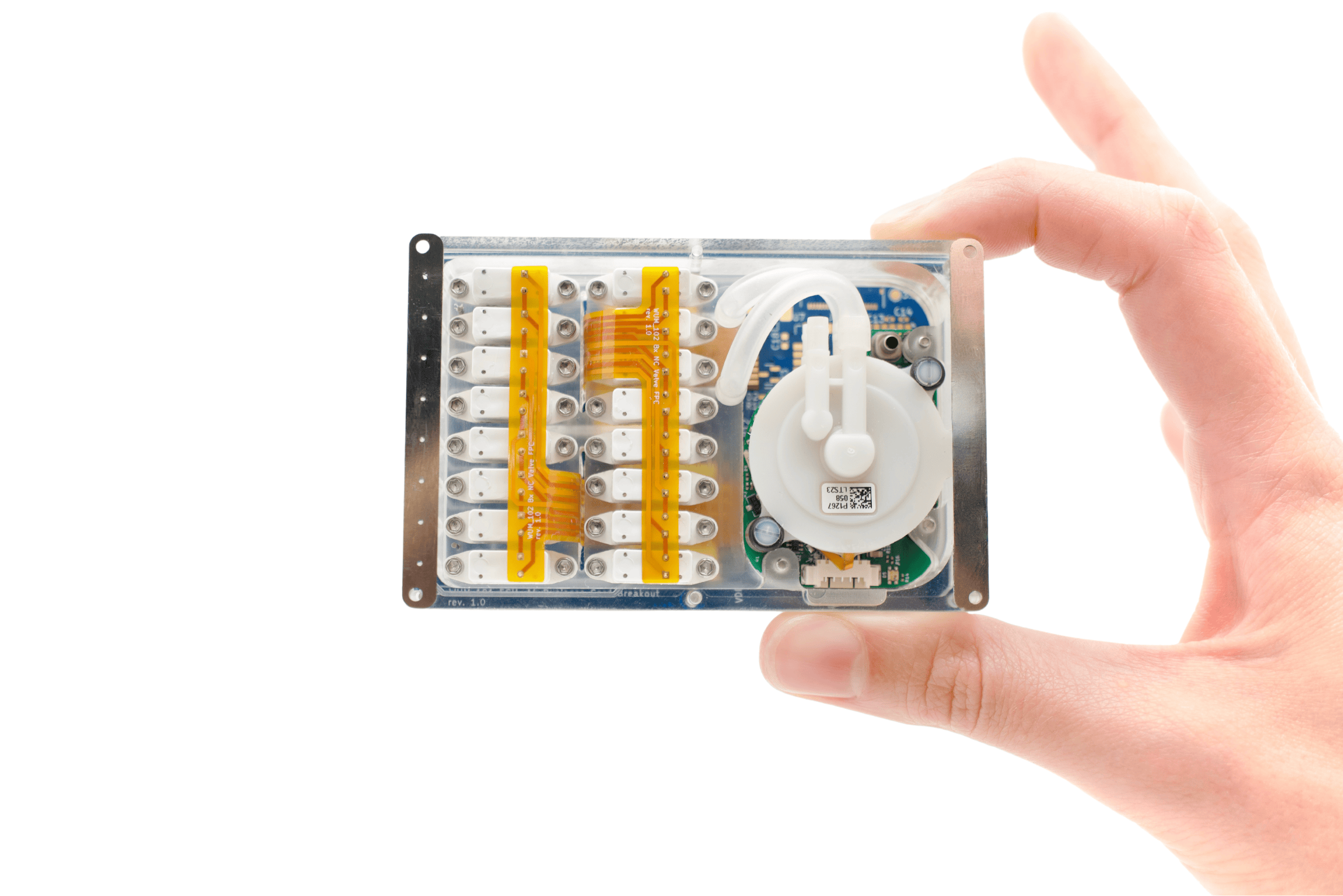

Use case

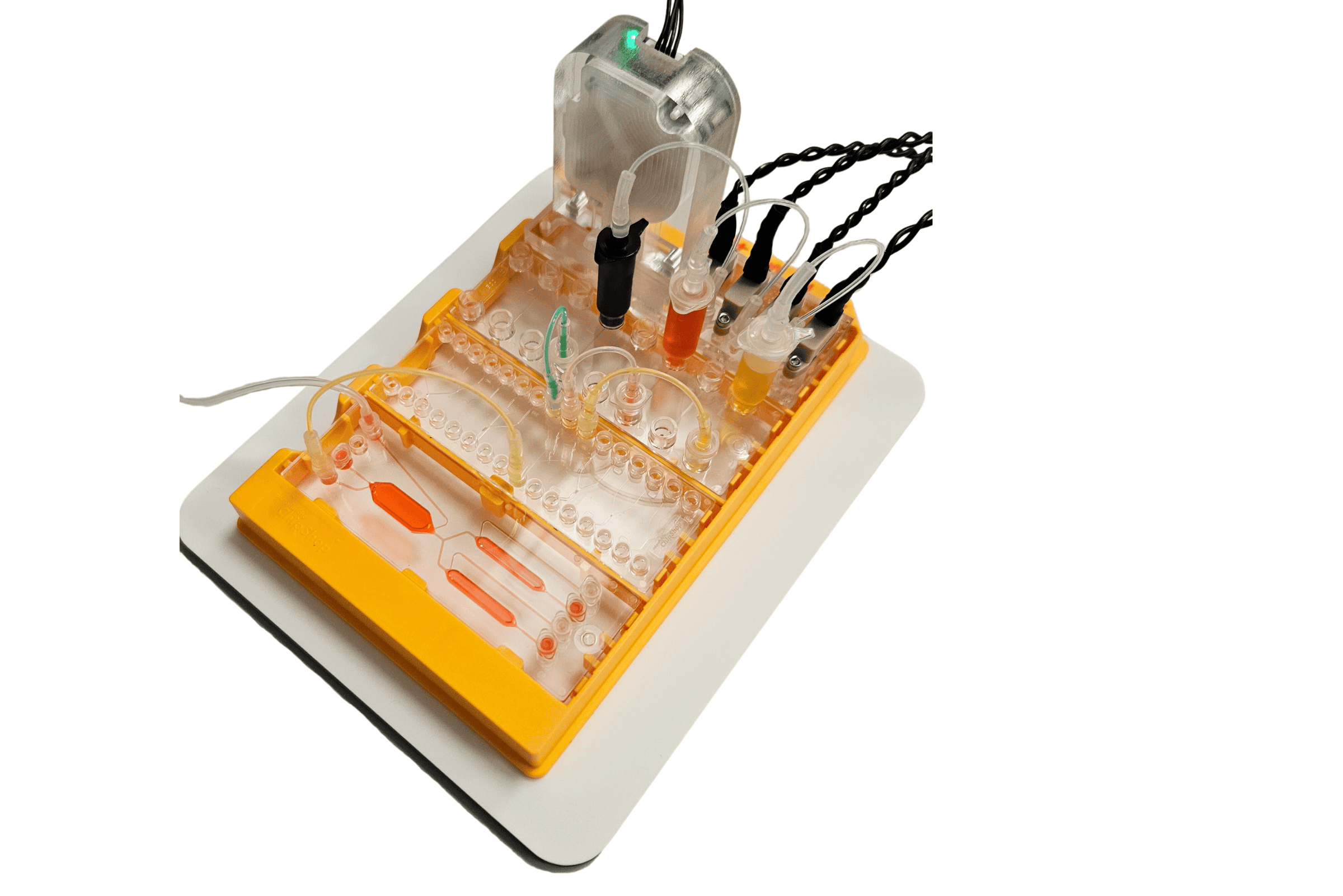

Modular Lab-on-a-Chip System for Automated Cell Culture and Staining

Microfluidics, Lab-on-chip, Organ-on-chip, Automated cell culture, Automated perfusion system

microfluidic ChipShop has used the custom-made pump-valve module by memetis to create their modular lab-on-a-chip system that enables full automation of long-term cell culture and various in vitro experiments. The flow control module fits the footprint of a microscopy slide and comes with a basic Python script to facilitate setting up the first automated assays.

Use case

Smallest Mass Flow Controller for Precise Gas Quantification

Gas Analysis, Bioreactors, Respirometry, Mass Flow Control

This memetis Valve Use Case describes design of the Mass Flow Controller (MFC) EMF 100 built by ECHO Instruments. The purpose of creating the MFC was to enable multiple plastic biodegradability measurements in a compact space with flow ranges up to 100 sml/min. Having done this, ECHO Instruments can build respirometers with smaller control units, while reducing production costs and becoming independent from external mass flow control device suppliers.

Microfluidics involves the manipulation of fluids at a microscopic scale, typically in channels with dimensions ranging from tens to hundreds of micrometers. This technology allows for precise control over small volumes of liquids, enabling numerous applications in areas such as biomedical diagnostics, drug delivery, and chemical analysis. The integration of microfluidic systems can lead to faster analysis times, reduced reagent consumption, and enhanced sensitivity, making it a vital component in modern laboratory-on-a-chip devices and point-of-care testing solutions.

Microfluidics play a crucial role in medical diagnostics by enabling precise manipulation of small volumes of fluids, typically in the microliter range. This technology allows for the development of highly sensitive and rapid diagnostic devices that can analyze samples for various biomarkers, pathogens, and genetic material. In practice, microfluidic systems facilitate processes such as sample preparation, mixing, and reaction control, all within a compact platform. This miniaturization not only reduces the amount of reagents needed but also enhances the speed of analysis, making it possible to obtain results quickly. Furthermore, the integration of microfluidics with advanced detection techniques, such as fluorescence or electrochemical sensors, significantly improves the accuracy and reliability of diagnostic tests in fields like infectious disease detection and personalized medicine.

1. Enhanced Precision

Microfluidics allows for precise control over small fluid volumes, enabling researchers to perform experiments with greater accuracy. This level of precision is essential for applications such as biomedical research, where small variations can significantly impact results.

2. Cost Efficiency

The miniaturization of processes reduces the amount of reagents and materials needed, leading to significant cost savings in research. Smaller sample sizes also mean that researchers can conduct experiments with less waste, making microfluidics an environmentally friendly option in R&D.

3. High Throughput

Microfluidic systems can facilitate the simultaneous processing of multiple experiments, increasing throughput. This capability accelerates research timelines and enhances the ability to conduct large-scale studies efficiently.

4. Integration of Multiple Functions

Microfluidics enables the integration of various laboratory functions on a single chip. This versatility simplifies workflows and reduces the need for multiple, bulky pieces of equipment, streamlining the research process.

5. Improved Reaction Kinetics

The small scale of microfluidic devices enhances mass transfer and heat transfer rates, leading to faster reaction kinetics. This advantage is particularly beneficial for chemical synthesis and biological assays, where rapid results are often required.

In microfluidics devices, various materials are utilized to optimize performance and functionality. Polydimethylsiloxane (PDMS) is one of the most popular materials due to its flexibility, optical clarity, and ease of fabrication. It allows for rapid prototyping and is often used in soft lithography techniques. Another commonly used material is glass, known for its excellent chemical resistance and optical properties. Glass microfluidic devices provide high precision and are suitable for applications requiring minimal contamination. Additionally, thermoplastics like polymethyl methacrylate (PMMA) and polycarbonate (PC) are also used, offering durability and ease of manufacturing. Each material serves specific needs based on the required application, ensuring the effectiveness of microfluidic systems.

Microfluidics play a pivotal role in the development of lab-on-a-chip technology by enabling the manipulation of small volumes of fluids at the microscale. This technology allows for precise control over chemical reactions and biological processes, making it possible to conduct complex analyses in a compact format. Through the integration of microchannels, valves, and pumps, microfluidic systems facilitate rapid sample processing and high-throughput screening. These systems enhance sensitivity and reduce the amount of sample and reagents needed, which is critical for applications in diagnostics, drug development, and environmental monitoring. The miniaturization inherent in microfluidics not only decreases costs but also improves the overall efficiency of laboratory procedures.

Some interesting numbers and facts about your company results for Microfluidics

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 8455 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1982 |

| Youngest suiting company | 2022 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Microfluidics

What are related technologies to Microfluidics?

Based on our calculations related technologies to Microfluidics are Aromatics, Desiccants, Refrigerants, Resins, Green Chemistry

Who are Start-Ups in the field of Microfluidics?

Start-Ups who are working in Microfluidics are LiveDrop

Which industries are mostly working on Microfluidics?

The most represented industries which are working in Microfluidics are Biotechnology, Other, Medical, Manufacturing, IT, Software and Services

How does ensun find these Microfluidics Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.