The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

A-Tech Authority

Chino, United States

B

1-10 Employees

1979

Key takeaway

The company offers rotary encoders that provide speed and position measurement with sub-arc second accuracy, enhancing the precision and efficiency of automated manufacturing processes. Their commitment to high standards and customer relationships ensures exceptional service and support for these advanced technologies.

Reference

Product

A Tech Authority - Rotary Encoders

Encoder Products Company

Sagle, United States

B

101-250 Employees

1969

Key takeaway

Encoder Products Company (EPC) specializes in manufacturing high-quality rotary encoders, offering both incremental and absolute types. Their newest 36 mm absolute encoder provides compact versatility and high accuracy, making it an excellent choice for various motion control applications.

Reference

Core business

Encoder Manufacturer | Rotary Incremental & Absolute Encoders Company

For more than 50 years, Encoder Products Company (EPC) has provided top-quality motion feedback devices, with exceptional customer service and reliable delivery.

Netzer Precision Motion Sensors

Misgav Regional Council, Israel

B

- Employees

1998

Key takeaway

Netzer Precision Position Sensors specializes in high-end absolute rotary encoders, utilizing their unique Electric Encoder™ technology. Their product portfolio includes encoders designed for diverse applications, including industrial automation, robotics, and aerospace.

Reference

Core business

Rotary Encoders | Position Sensors |Electric Encoder | Netzer

Netzer designs manufactures, and supplies high-end absolute position rotary encoders, for harsh environment, industrial automation and space applications.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Tomson Electronics Private Limited

Kochi, India

D

11-50 Employees

1988

Key takeaway

The company, Tomson Electronics, offers a 360 Degree Rotary Encoder Module, which is an essential component for robotics applications. This device indicates both the amount and direction of rotation, making it a valuable tool for enhancing DIY projects and robotics in Kochi, Kerala.

Reference

Product

360 Degree Rotary Encoder Module – TOMSON ELECTRONICS

DESCRIPTION The 360 Degree rotary encoder,from Tomson Electronics,Kochi, Kerala, India, is a rotary input device (as in knob) that provides an indication of how much the knob has been rotated AND what direction it is rotating in. It’s a great device for you robotics applications can easily be integrated with your Ardui

protosupplies

Lake Stevens, United States

B

- Employees

-

Key takeaway

The company offers a Rotary Encoder Module, which is a continuously variable position sensor that reports relative position and direction of rotation. They emphasize thorough testing and comprehensive specifications for their products, ensuring high quality before shipment.

Reference

Product

Rotary Encoder Module - ProtoSupplies

The Rotary Encoder Module is a continuously variable position sensor that reports relative position and direction of rotation of the shaft.

Everight Position

Lower Merion Township, United States

B

1-10 Employees

2008

Key takeaway

The company specializes in providing a range of sensors, including incremental and absolute rotary encoders. Their MR348 MRI-Safe Rotary Incremental Encoder is specifically designed for use in MRI applications, offering minimal latency and eliminating the need for homing.

Reference

Product

MR348 MRI-Safe Rotary Incremental Encoder - Everight Position

The MR348 series Fiber Optic Incremental Sensor is a non-metallic and designed for use in Magnetic Resonance Imaging (MRI) applications.

RLS

Komenda, Slovenia

A

- Employees

1989

Key takeaway

RLS specializes in position encoders and metrology solutions, with a strong focus on magnetic encoder technology. They offer a variety of rotary absolute encoders, which are crucial for precise speed and position control in various applications.

Reference

Product

Rotary absolute encoders

Quantum Devices, Inc.

Barneveld, United States

B

11-50 Employees

1989

Key takeaway

Quantum Devices specializes in manufacturing high-performance incremental optical rotary encoders, offering various configurations to meet the diverse needs of the motion control industry. Their expertise in photodiode fabrication and integrated manufacturing ensures high quality and performance for their encoder products.

Reference

Product

Incremental Optical Rotary Encoders made in USA | Quantum Devices

High-performance encoders ideal for a wide variety of industries. Custom line count, commutation, bore sizes available + free samples for qualified projects.

The Pi Hut

West Suffolk, United Kingdom

A

1-10 Employees

2012

Key takeaway

The company offers a Grove module that is an incremental rotary encoder, which encodes rotation signals and outputs them as electronic pulses. This product is ideal for Raspberry Pi projects, providing essential components for both beginners and experienced makers.

Reference

Product

Grove - Encoder | The Pi Hut

This Grove module is an incremental rotary encoder. It encodes the rotation signal from the axis and outputs the signal via electronic pulse. The Grove – Encoder is one of the many Grove series modules and uses a standard Grove interface. Combine with the Grove Circular LED for LED feedback from your encoder! Note: Usu

WILTRONICS RESEARCH PTY LTD

Ballarat, Australia

A

11-50 Employees

1974

Key takeaway

Wiltronics offers an Arduino compatible Rotary Encoder module, priced at $4.95, which provides feedback on the amount of rotation and the direction of a knob. This product is part of their extensive range, catering to various electronic and educational needs.

Reference

Product

Rotary Encoder Module (Arduino Compatible) | Wiltronics

Arduino compatible Rotary Encoder module provides an indication of how much the knob has been rotated and the direction of rotation.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Encoder ESC17 mini

Go to product

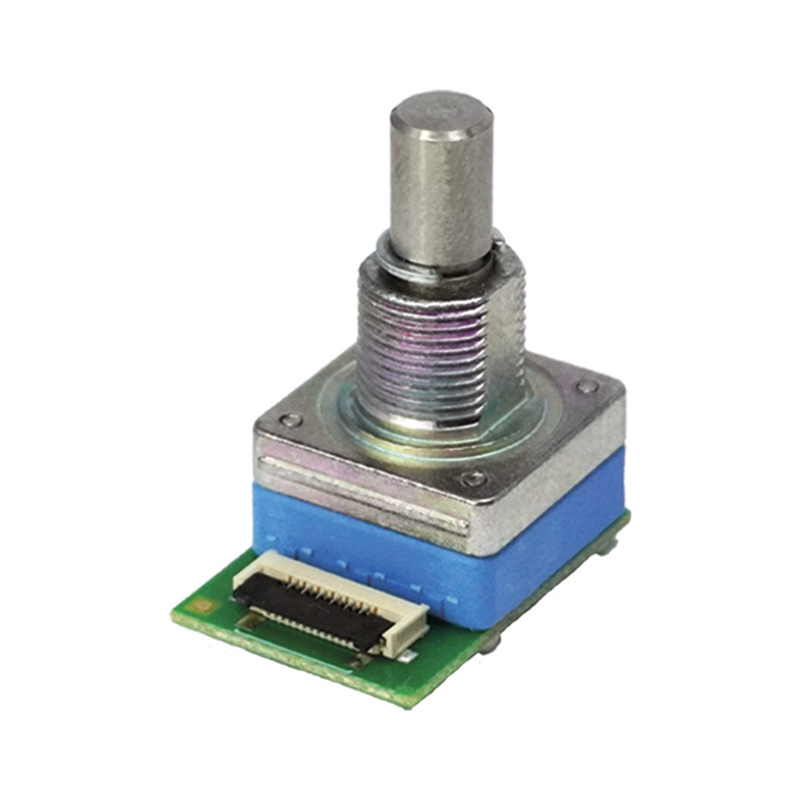

A rotary encoder is a device that converts the angular position or motion of a shaft into an electrical signal. This signal can be utilized to determine the position, speed, and direction of rotation. Rotary encoders are essential components in various applications, including robotics, industrial machinery, and automation systems. They come in two main types: incremental and absolute encoders, each serving specific purposes in different environments. Incremental encoders provide position changes relative to a reference point, while absolute encoders maintain a unique position value throughout the entire rotation.

A rotary encoder is a device that converts the angular position or motion of a shaft into an electrical signal. It typically consists of a rotating disk with patterns or tracks and a sensor that detects these patterns as the disk turns. When the shaft rotates, the encoder generates a series of pulses that correspond to the movement. These pulses can be either incremental, indicating changes in position, or absolute, providing the exact position at any given time. By interpreting these signals, machines and systems can determine the shaft's movement direction, speed, and position, making rotary encoders essential in automation and control applications.

1. Industrial Automation

Rotary encoders are widely utilized in industrial automation for position sensing and control in machinery. They provide feedback for motor position, allowing for precise control of robotic arms, conveyor systems, and CNC machines.

2. Consumer Electronics

In consumer electronics, rotary encoders are found in devices such as audio equipment and gaming controllers. They enable users to adjust settings like volume or navigate menus with ease, enhancing user interaction and experience.

3. Automotive Applications

Automotive systems use rotary encoders to monitor wheel position, throttle position, and other critical functions. This feedback is essential for improving vehicle safety and performance in various driving conditions.

4. Robotics

Robots depend on rotary encoders for accurate movement and positioning. They help in determining the exact angle of joints and limbs, which is crucial for tasks requiring precision, such as assembly or material handling.

5. Medical Equipment

In the medical field, rotary encoders are employed in imaging systems and surgical instruments. They ensure accurate positioning and control, which is vital for procedures that require high precision.

1. Precision

Rotary encoders provide high precision in position feedback. They can detect even the smallest angular movements, making them ideal for applications requiring accurate control, such as robotics and CNC machinery.

2. Versatility

These devices come in various types, including incremental and absolute encoders, allowing for flexibility in different applications. This versatility enables their use across multiple industries, from automotive to aerospace.

3. Durability

Rotary encoders are designed to withstand harsh environments. Many models are built with rugged enclosures to protect against dust, moisture, and temperature variations, ensuring reliable performance over time.

4. Real-time feedback

They offer real-time feedback on position and speed, enabling systems to make instantaneous adjustments. This capability is crucial for automation and control systems that require immediate response to changes in position.

5. Compact design

Most rotary encoders are compact, allowing for easy integration into tight spaces within machinery and equipment. Their small size does not compromise performance, making them efficient in space-constrained applications.

Choosing the right rotary encoder involves several key considerations. Type Understanding the type of rotary encoder needed for your application is crucial. Rotary encoders can be incremental or absolute, and the choice between them depends on whether you need relative position feedback or absolute position data. Resolution The resolution of the encoder is another important factor. Higher resolution encoders provide finer position feedback, which is essential for applications requiring precise control. Environmental Conditions Consider the environmental conditions such as temperature, humidity, and exposure to dust or moisture. Ensuring that the encoder is rated for your specific environment will enhance its reliability and longevity. Connection Type Lastly, the connection type should match your system's requirements. Different encoders offer various output formats, such as quadrature or serial, so it’s essential to select one that is compatible with your existing equipment.

Some interesting numbers and facts about your company results for Rotary Encoder

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 4896 |

| Amount of suitable service providers | 3387 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1969 |

| Youngest suiting company | 2012 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Rotary Encoder

What are related technologies to Rotary Encoder?

Based on our calculations related technologies to Rotary Encoder are Magnets, Printed Electronics, Industrial Amplifiers, Electronic Transducers, Electronic Oscillators

Which industries are mostly working on Rotary Encoder?

The most represented industries which are working in Rotary Encoder are Electronics and Electrical engineering, Other, Automation, Manufacturing, IT, Software and Services

How does ensun find these Rotary Encoder Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.