The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

FLEEP Technologies

Milan, Italy

B

1-10 Employees

2019

Key takeaway

FleepTech specializes in printing technology that facilitates the production of low-cost, flexible, and transparent electronic devices. Their innovative approach enables the integration of printed microchips into various applications, paving the way for the next generation of smart objects.

Reference

Core business

Home - FLEEP Tech

[...]Read More

FlexEnable

Cambridge, United Kingdom

A

11-50 Employees

2015

Key takeaway

FlexEnable® is a leader in flexible electronics, holding over 500 patents for organic thin-film transistors (OTFTs) and liquid crystal (LC) technologies. Their innovative manufacturing processes enable the production of ultra-thin, lightweight, and unbreakable displays and optics, making them a key player in transforming how active surfaces are utilized in various applications.

Reference

Core business

World leaders in flexible electronics | FlexEnable

The complete solution for flexible organic electronics, enabling ultra-thin, lightweight, area-scalable displays and liquid crystal optics for applications

FREEDOM ELECTRONICS LIMITED

Thatcham, United Kingdom

A

1-10 Employees

2005

Key takeaway

Freedom Electronics Ltd specializes in electronic sub-contract manufacturing and offers a comprehensive range of services, including printed circuit board assemblies (PCBA), which may encompass innovative solutions relevant to flexible electronics. The company’s commitment to quality, evidenced by its ISO9001:2015 and ISO14001:2015 certifications, ensures high standards in their production processes.

Reference

Core business

Home - Freedom Electronics

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Excel Electronics

United States

B

11-50 Employees

2006

Key takeaway

Excel Electronics positions itself as a comprehensive circuit board contract supplier, offering a wide range of integrated electronics manufacturing services. Their expertise in circuit design and commitment to quality, backed by industry certifications, ensures they can meet the needs of leading OEMs in the electronics sector.

Reference

Core business

Excel Electronics Inc.

Elcoflex

Kempele, Finland

A

1-10 Employees

-

Key takeaway

Elcoflex is a European pioneer in Roll-to-Roll production of flexible circuits, which are increasingly replacing rigid PCBs due to miniaturization trends in electronics. They manufacture various types of flexible circuits using materials like polyimide, PET, LCP, and PEN, showcasing their expertise in this innovative area.

Reference

Product

Flexible Circuits - Elcoflex

Due to the miniaturisation trend in electronics, flexible circuits are gaining ground from rigid PCBs. Polyimide, PET, LCP or PEN based flexible circuits are manufactured in roll-to-roll format.

MULTI FINELINE ELECTRONIX

Irvine, United States

B

10001+ Employees

1984

Key takeaway

MFLEX is a leading manufacturer of flexible printed circuit boards, offering advanced solutions that enhance device and user interface design. Their expertise in flexible circuits positions them as a key player in the electronics industry, addressing diverse customer challenges with integrated end-to-end solutions.

Reference

Product

Products « MFLEX

Edge Electronics

Town of Islip, United States

B

11-50 Employees

1990

Key takeaway

Edge Electronics, a leading authorized distributor of electronic components and display solutions, emphasizes its ability to source hard-to-find parts and provide specialized services, which can be crucial for the development of flexible electronics. Their extensive experience and network of manufacturers enable them to deliver tailored products and solutions that enhance customer success.

Reference

Core business

Edge Electronics - Franchised Electronic Components Distributor and Industrial LCD Flat Panel Display Solutions Provider - Diversity/Woman-Owned Small Business Supplier

SEMOUR ELECTRONICS CO. LIMITED

Shenzhen, China

D

251-500 Employees

2015

Key takeaway

Semour Electronics positions itself as a comprehensive solution provider in the electronic supply chain, emphasizing its commitment to innovation and quality through services like real-time stock and quality inspection. This focus on enhancing productivity and preventing counterfeit components is particularly relevant for those interested in flexible electronics.

Reference

Core business

Company - Electronics Supply Chain Solution Provider

Pure Electronics Limited

United Kingdom

A

11-50 Employees

-

Key takeaway

Pure PCB is a leading flexible PCB manufacturer, offering a variety of high-quality printed circuit boards, including flexible and flex-rigid options. Their dedicated engineering team ensures that each PCB is designed and manufactured to meet specific requirements, providing a reliable solution for businesses looking to enhance their product development.

Reference

Product

Leading UK Flexible PCB Manufacturer » Pure Electronics Ltd

Have your flexible PCB needs met by the UK’s leading flexible PCB manufacturer. Submit your PCB Gerber Files here and a one of our team will contact you!

jemtekkeypads.com

-

- Employees

-

Key takeaway

The company is a leading manufacturer of flexible circuitry, known for its advanced manufacturing capabilities that produce high-quality and customized solutions for various applications in flexible electronics.

Reference

Product

Top Flexible Circuitry Manufacturer

Explore the top flexible circuitry manufacturer, renowned for providing cutting-edge solutions in flexible electronics. Our advanced manufacturing capabilities enable us to produce high-quality, reliable, and customized flexible circuitry for a wide range of applications.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

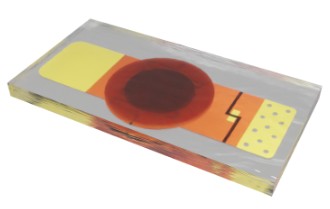

Thin film pressure sensor

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Wearable sensing

Wearable Devices, Sports Devices, Remote Monitoring

The Flex-PCB based pressure sensors can be easily integrated in wearables like insoles or gloves, sports equipment and remote monitoring equipment. Can be supplied for research or prototyping as well as for large volume manufacturing of series products. Main advantages are low-cost, high robustness and reliability under harsh conditions as well as compatibility to standard soldering processes.

Use case

Wearable sensing

Wearable Devices, Sports Devices, Remote Monitoring

The Flex-PCB based pressure sensors can be easily integrated in wearables like insoles or gloves, sports equipment and remote monitoring equipment. Can be supplied for research or prototyping as well as for large volume manufacturing of series products. Main advantages are low-cost, high robustness and reliability under harsh conditions as well as compatibility to standard soldering processes.

Flexible electronics refer to electronic devices that are built on flexible substrates, allowing them to bend and conform to various shapes. These devices incorporate components such as thin-film transistors, sensors, and displays, making them suitable for a wide range of applications, including wearable technology, flexible displays, and smart textiles. The use of materials like organic semiconductors and polymers enables lightweight and durable designs, enhancing their integration into everyday objects. This innovation is paving the way for advancements in consumer electronics, medical devices, and various industrial applications.

Flexible electronics utilize materials that can bend, stretch, and conform to various shapes while maintaining functionality. They typically employ organic semiconductors, thin-film transistors, and flexible substrates like plastic or metal foils. This design allows for the integration of electronic components, such as sensors and circuits, onto surfaces that are not rigid. The manufacturing process often involves techniques like printing and coating, which enable the production of lightweight and portable devices. Because of their adaptability, flexible electronics find applications in wearable technology, medical devices, and flexible displays, providing enhanced comfort and convenience in various settings.

Flexible electronics have a diverse range of applications across various industries.

1. Wearable Technology

These electronics are crucial in the development of wearable devices such as smartwatches, fitness trackers, and health monitoring systems. Their lightweight and flexible nature allows for comfortable integration into clothing or accessories.

2. Medical Devices

In the medical field, flexible electronics are used in biosensors and diagnostic devices. Their ability to conform to the human body enables continuous health monitoring and improved patient care.

3. Consumer Electronics

Flexible displays in smartphones and tablets enhance user experience by providing lightweight and durable screens that can bend or fold. This innovation supports the trend towards more compact and portable devices.

4. Automotive Applications

In vehicles, flexible electronics are applied in dashboards and sensor systems. These components contribute to the advancement of smart cars with enhanced functionality and design flexibility.

5. Energy Solutions

Flexible solar panels and energy harvesting devices utilize flexible electronics to create lightweight and efficient power sources. This technology enables new applications in remote and portable energy generation.

Flexible electronics utilize a variety of materials that contribute to their lightweight and bendable properties. Conductive materials, such as silver, copper, and conductive polymers, are essential for enabling electrical conductivity while maintaining flexibility. Additionally, substrates like polyethylene terephthalate (PET), polyimide, and paper are commonly used, as they provide a stable base without compromising flexibility. Dielectric materials, such as silicone and various organic compounds, are also important for insulation and ensuring proper functioning of the electronic components in varied applications.

1. Lightweight and Thin

Flexible electronics are significantly lighter and thinner than traditional rigid electronics. This property allows for integration into a variety of applications without adding substantial weight or bulk, making them ideal for wearable devices and portable technology.

2. Bendability and Conformability

The inherent flexibility of these electronics enables them to bend and conform to different shapes. This feature is essential for applications in soft robotics, medical devices, and flexible displays, allowing for innovative designs that were previously unattainable.

3. Enhanced Durability

Flexible electronics typically exhibit greater resistance to mechanical stress, which leads to improved durability. They can withstand bending, twisting, and stretching without compromising performance, making them suitable for environments where traditional electronics might fail.

4. Versatile Applications

These electronics can be utilized in a wide range of applications, from health monitoring devices to smart packaging. Their versatility opens up new possibilities for innovation across various industries, including automotive, consumer electronics, and healthcare.

5. Cost-Effective Manufacturing

The production processes for flexible electronics can be less expensive compared to traditional manufacturing methods. Techniques like roll-to-roll printing facilitate mass production, reducing material waste and lowering overall production costs.

Some interesting numbers and facts about your company results for Flexible Electronics

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 8490 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1984 |

| Youngest suiting company | 2019 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Flexible Electronics

What are related technologies to Flexible Electronics?

Based on our calculations related technologies to Flexible Electronics are Magnets, Printed Electronics, Industrial Amplifiers, Electronic Transducers, Electronic Oscillators

Which industries are mostly working on Flexible Electronics?

The most represented industries which are working in Flexible Electronics are Electronics and Electrical engineering, Other, IT, Software and Services, Semiconductor, Manufacturing

How does ensun find these Flexible Electronics Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.