The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Creative IC3D

Israel

B

1-10 Employees

2015

Key takeaway

Creative IC3D specializes in Additive Manufacturing for the Printed Electronics industry, offering a Semi-Additive Process that enables rapid production of high-quality Copper-based electronic components, such as those used in IoT, sensors, and more. Their technology allows for quick turnaround from design to finished product, making it ideal for various applications.

Reference

Core business

Printed Electronics | Creative IC3D | South District

Creative IC3D is an innovative start-up company in the field of Additive Manufacturing for the Printed Electronics industry.

Neotech AMT GmbH

Nuremberg, Germany

A

11-50 Employees

2001

Key takeaway

Neotech AMT GmbH is a prominent developer of systems for 3D Printed Electronics, integrating hardware and software to enable the production of complex circuitry on various 3D surfaces. Their advancements have led to the first commercial installations for mass production of printed 3D antennas.

Reference

Core business

Home | Neotech AMT - Advanced Manufacturing Technologies for 3D Printed Electronics

FLEEP Technologies

Milan, Italy

B

1-10 Employees

2019

Key takeaway

The company utilizes innovative printing technology to create low-cost, flexible, and ultra-thin electronic devices, enabling high production volumes and easy integration into standard processes. Their PrintIC platform offers a comprehensive library of fully printed integrated systems, including sensors and displays, which allows for the development of novel electronic applications.

Reference

Product

Technology - FLEEP Tech

[...]Read More

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Nano Dimension

Ness Ziona, Israel

B

51-100 Employees

2012

Key takeaway

Nano Dimension is transforming the electronics production industry through its pioneering work in additively manufactured electronics (AME) and industrial 3D printing. Their advanced platform not only enhances production efficiency but also significantly reduces environmental impact.

Reference

Core business

Industrial 3D Printing of Electronics for Manufacturing and AME

Nano Dimension is revolutionizing the industry as the pioneer of Industrial 3D Printing of Electronics for Manufacturing and AME.

Voltera

Kitchener, Canada

A

1-10 Employees

2013

Key takeaway

Voltera is revolutionizing the 3D printed electronics landscape by providing rapid prototyping platforms that facilitate the creation of traditional circuit boards and advanced flexible, stretchable, and biocompatible electronics. Their additive technology promotes material freedom and opens up new applications in various fields, including wearable electronics and printed sensors.

Reference

Core business

Home - The Future of Additive Electronics | Voltera

Voltera is driving change in the additive electronics industry. Our printers enable rapid prototyping of PCBs, flexible and stretchable electronics, and more.

EEPROTO.EU

Timișoara, Romania

B

1-10 Employees

-

Key takeaway

EE Proto specializes in 3D printing parts, catering to both functional and creative needs, and offers PCB assembly services that can support the development of 3D printed electronics from prototype to production.

Reference

Service

3D Printing - EEProto

Sculpteo

Villejuif, France

A

51-100 Employees

2009

Key takeaway

Sculpteo specializes in 3D printing for the electronics industry, highlighting how additive manufacturing can enhance electronics projects by scaling production and creating customized devices. They also offer a free sample kit to help customers explore these innovations.

Reference

Service

3D Printing for the Electronics Industry

Discover how 3D printing can help you grow your electronics business. Scale your production and create perfectly adapted devices for your electronic projects.

3D LOGICS

Hillsboro, United States

B

1-10 Employees

2017

Key takeaway

3D Logics specializes in 3D printing and offers advanced manufacturing solutions that can help businesses transform their ideas into high-value parts. With a focus on quality and industry-leading technology, they are well-equipped to support various additive manufacturing needs.

Reference

Core business

3D Logics - Advanced Manufacturing Solutions

Advanced Manufacturing Solutions

www.surfacescan.co.uk

-

- Employees

-

Key takeaway

The company offers professional 3D printing services, which could be relevant for those interested in 3D printed electronics.

Reference

Service

3D Printing

Professional 3D printing for all your manufacturing needs. Choose from a wide array of colours and materials, and either FDM or SLS technology. Serving industries such as aerospace, automotive, healthcare, and product development. Rapid delivery available to customers across the United Kingdom. Exceptional customer service.

Electronic Specifier Ltd

Maidstone, United Kingdom

A

11-50 Employees

2005

Key takeaway

The company highlights the latest developments in 3D printed electronics, showcasing innovations that are transforming the industry.

Reference

Product

3D Printing news from electronic specifier

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

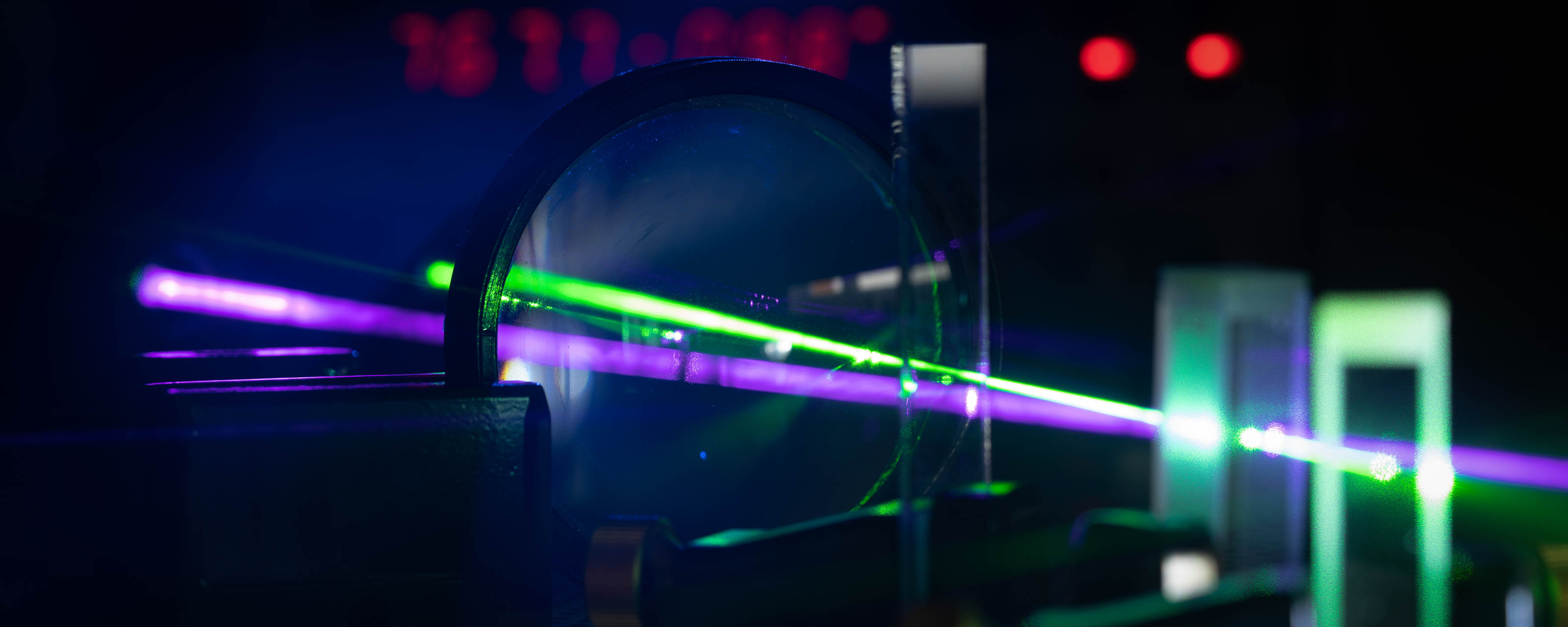

Product

Laser Material Processing solutions

Go to product

3D printed electronics refers to the innovative process of creating electronic components and devices using additive manufacturing techniques. This technology allows for the integration of conductive materials into three-dimensional structures, enabling the production of complex circuit designs that can be embedded directly within various substrates. The advantages of this approach include greater design flexibility, reduced production times, and the ability to create customized electronic solutions that traditional manufacturing methods may not easily achieve. As a result, 3D printed electronics are increasingly being used in industries such as automotive, consumer electronics, and healthcare, where tailored solutions are essential for advancement and efficiency.

3D printed electronics integrate traditional 3D printing techniques with electronic components, enabling the creation of functional devices in a single manufacturing process. The technique involves using conductive inks made from materials like silver or copper, which are printed onto various substrates. These inks allow the creation of intricate circuit pathways alongside structural elements, such as housings or support structures, all in one step. This method permits rapid prototyping and customization, leading to innovative designs that are often lightweight and compact. By layering materials, manufacturers can embed sensors, antennas, and other electronic components directly into the printed structure, enhancing performance and expanding application possibilities across industries such as consumer electronics, medical devices, and automotive.

The applications of 3D printed electronics are vast and varied, impacting multiple industries. One significant area is in the production of custom electronic devices, where components can be designed and printed to fit specific requirements, leading to faster prototyping and reduced production costs. Another prominent application is in wearable technology, where 3D printed electronics enable the integration of sensors and circuits into flexible materials, enhancing user comfort and functionality. Additionally, this technology is utilized in the automotive and aerospace sectors for lightweight, compact components that improve overall performance and energy efficiency. The ability to create complex geometries also allows for innovative designs in consumer electronics, medical devices, and smart packaging solutions.

1. Customization

3D printed electronics allow for high levels of customization, enabling designs to be tailored to specific applications. This flexibility can lead to innovative product development and rapid prototyping, as manufacturers can easily modify designs to meet unique requirements.

2. Reduced Waste

The additive manufacturing process used in 3D printing minimizes material waste compared to traditional subtractive manufacturing methods. This efficiency not only lowers production costs but also contributes to more sustainable manufacturing practices, making it an environmentally friendly option.

In 3D printed electronics, various materials are utilized to create functional components. Conductive inks are essential, typically made from materials like silver, copper, or graphene, enabling the creation of conductive pathways. Additionally, dielectric materials, such as certain polymers, serve as insulators and support the electronic structure. Another category includes flexible materials, which allow for the development of bendable circuits and devices. Furthermore, embedding materials like epoxy resins can enhance the durability and performance of printed components. These diverse materials work together to support the innovative capabilities of 3D printed electronics, enabling the production of complex and compact electronic systems.

Some interesting numbers and facts about your company results for 3D Printed Electronics

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 2001 |

| Youngest suiting company | 2019 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for 3D Printed Electronics

What are related technologies to 3D Printed Electronics?

Based on our calculations related technologies to 3D Printed Electronics are Magnets, Printed Electronics, Industrial Amplifiers, Electronic Transducers, Electronic Oscillators

Which industries are mostly working on 3D Printed Electronics?

The most represented industries which are working in 3D Printed Electronics are Electronics and Electrical engineering, Other, Manufacturing, IT, Software and Services, Printing

How does ensun find these 3D Printed Electronics Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.