The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

United Aluminum Corporation

North Haven, United States

B

101-250 Employees

1891

Key takeaway

United Aluminum specializes in manufacturing and supplying Custom Rolled® aluminum coils tailored to meet specific requirements, making it a leading supplier in the industry for over a century. With a commitment to on-time shipments and the ability to process orders of any size and exact gauge, they ensure faster and more profitable production for their customers.

Reference

Core business

Custom Rolled Aluminum Coil | Aluminum Coil Strip |

Custom Rolled® aluminum coil slit & annealed to your specifications. Exact gauge, any sized order, shipped on time. Get your quote.

Henan Sigma Industry Co.Ltd

Zhengzhou, China

D

501-1000 Employees

1997

Key takeaway

The company provides detailed information on aluminum coils, including price trends and industry news. Their product range includes various series of aluminum coils, which have versatile applications across multiple sectors such as aerospace, construction, and packaging.

Reference

Product

Products - Aluminum Coil

Aluminum Coils

Avon, United States

B

- Employees

1988

Key takeaway

ACI specializes in providing painted aluminum coil and mill finish aluminum in various quantities, catering to the building products industry. With a focus on the 3105 alloy, ACI offers competitive pricing and a range of options to meet customer needs.

Reference

Core business

Welcome to Aluminum Coils

Aluminum Coils has the alloys, gauges, tempers and colors you need. With four slitters and two embossing lines at our Cleveland, Ohio and Tampa, Florida locations.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Aluminum Coil Anodizing Corporation

Streamwood, United States

B

11-50 Employees

1961

Key takeaway

ACA is a global technology leader in continuous aluminum coil anodizing, providing cost-effective solutions and alternatives to meet clients' needs.

Reference

Core business

ACA – Aluminum Coil Anodizing

Vanco

China

D

- Employees

-

Key takeaway

The company specializes in aluminum composite panel products, including fireproof aluminum composite panels and metal composite panels. With over 20 years of experience and a dedicated team, they ensure high-quality production and compliance with international standards, making them a reliable source for aluminum materials.

Reference

Product

Aluminum Coil Manufacturers in China - Aluminium Composite Panel

Min-Aluminum Co. Ltd

Nanping City, China

D

5001-10000 Employees

-

Key takeaway

Min-aluminum specializes in a wide range of customized aluminum products, including aluminum coils, which are essential for various applications in the aerospace and automotive industries. Their expertise in producing high-quality aluminum semi-products supports manufacturers in creating lighter and more efficient vehicles.

Reference

Core business

Aluminum CoilAluminum Foil,Aluminum Strip,Aluminum Tread Plate,Coated Aluminum Coil,Min Aluminum Co., Ltd

SO-LUCKY STEEL

Huangpu District, China

D

- Employees

-

Key takeaway

So-Lucky Steel International CO., LTD is a professional supplier of aluminum coils, offering a range of products including 5s and 6s aluminum coils specifically for the metal manufacturing, processing, and distribution industry. Their expertise in aluminum coil production and classification supports various applications, particularly in the automotive sector.

Reference

Product

Aluminum Coil - Solucky Steel

So-Lucky Steel International CO., LTD is a professional aluminum coil suppliers from China. For more than ten years, we have been a supplier of aluminum materials with 5s Aluminum coil and 6s Aluminum coil in the metal manufacturing, processing and distribution industry.

Zhaoqing DingFeng Building Materials Co. Ltd.

Zhaoqing City, China

D

251-500 Employees

2011

Key takeaway

Dingfeng is a leading manufacturer of color-coated aluminum coils, specializing in high-quality prepainted aluminum strip coils for various applications, including interior and exterior decoration. They offer a range of coatings and finishes, ensuring durability and aesthetic versatility, making their products ideal for uses such as roofing and wall cladding.

Reference

Product

Color Coated Aluminum Coil,Painted Aluminium Coil - DingFeng

Haomei Aluminum

Zhengzhou, China

D

51-100 Employees

1998

Key takeaway

Haomei Aluminum is a prominent aluminum processing enterprise that specializes in a variety of aluminum products, including aluminum coils. Their offerings encompass different series of aluminum alloys, highlighting their capability to meet diverse industry needs.

Reference

Product

1100 Aluminum Coil,Aluminum Alloy Coil

YOCON Aluminum

-

- Employees

-

Key takeaway

China is a leading manufacturer of aluminum coils, including high precision aluminum alloy products like the 1080 Aluminum Coil, which is highlighted by YOCON Aluminum as a trusted supplier.

Reference

Product

1080 Aluminum Coil - Aluminum Products Supplier in China | YOCON Aluminum

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

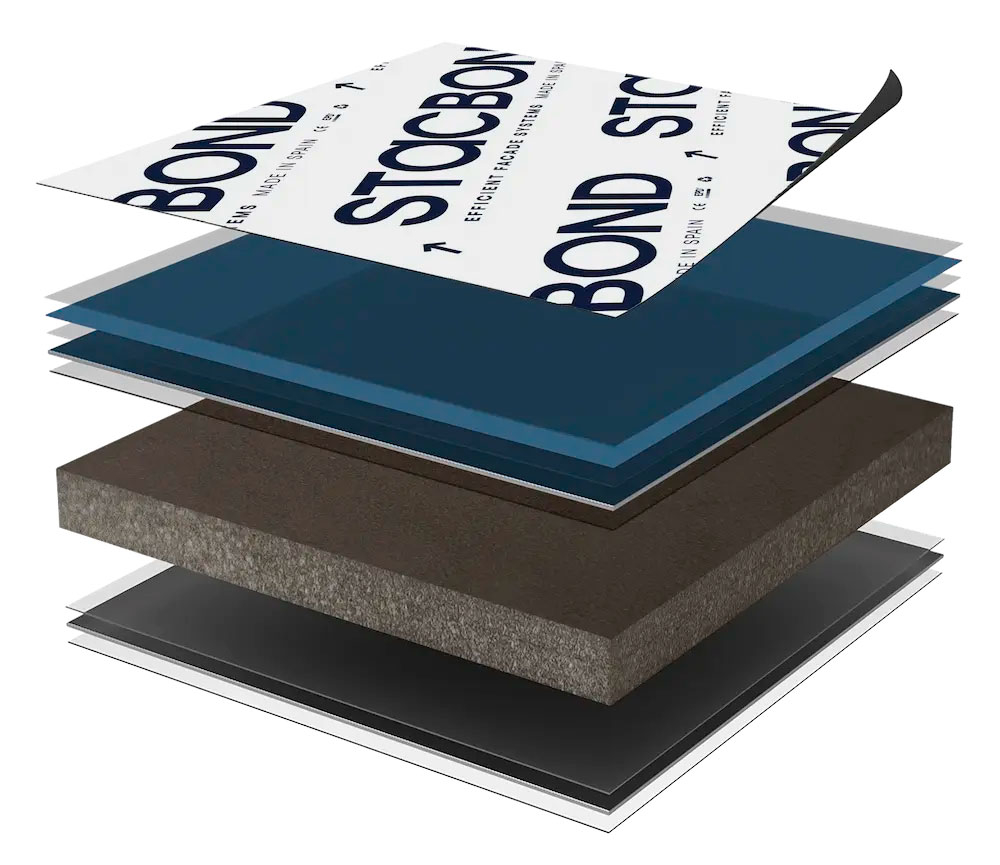

STACBOND composite panels

Go to product

Product

Assembly systems of ventilated façades

Go to product

Product

Aluminium coils

Go to product

Service

Transformation and machining processes for composite panels:

Go to product

Aluminum coil is a rolled form of aluminum that is produced by processing aluminum sheets into a coiled format. This material is lightweight, corrosion-resistant, and has excellent thermal and electrical conductivity, making it ideal for various applications. It is commonly used in the construction industry for roofing, siding, and insulation. Additionally, aluminum coil is utilized in manufacturing processes for creating products such as automotive parts, packaging materials, and electrical components. The versatility and durability of aluminum coil contribute to its widespread use across multiple industries.

1. Construction

Aluminum coils are widely used in the construction industry for roofing, siding, and window frames due to their lightweight nature and resistance to corrosion. They provide durability and aesthetic appeal in both residential and commercial buildings.

2. Automotive

In the automotive sector, aluminum coils are utilized for manufacturing various components. Their lightweight properties contribute to fuel efficiency, making them ideal for parts like heat exchangers, body panels, and structural components.

3. Electrical

Electrical applications also benefit from aluminum coils, particularly in the production of electrical conductors and wiring. Aluminum's excellent conductivity and lightweight characteristics make it a popular choice for these uses.

4. Packaging

In packaging, aluminum coils are often transformed into foil for food and beverage containers. Their ability to preserve freshness and provide a barrier against light and moisture makes them an essential material in the food industry.

Aluminum coil manufacturing involves several key processes to transform raw aluminum into thin, continuous sheets. Initially, aluminum ingots are heated and then passed through a series of rollers in a process called hot rolling. This reduces the thickness and increases the length of the aluminum. Once the desired thickness is achieved, the aluminum is cooled and then subjected to cold rolling, which further refines the material and enhances its strength. After rolling, the aluminum coil undergoes annealing, a heat treatment process that relieves internal stresses and improves workability. The final steps include surface finishing treatments, such as cleaning and coating, which enhance durability and aesthetics. The result is a versatile aluminum coil widely used in various industries, including construction, automotive, and packaging.

1. Lightweight

Aluminum coil is significantly lighter than other metals, making it easier to handle and transport. This lightweight nature reduces the overall load on structural elements, which can lead to savings in both materials and labor during construction.

2. Corrosion Resistance

Aluminum has excellent resistance to corrosion, which enhances the longevity of construction projects. This attribute allows structures to maintain their integrity and appearance over time, reducing maintenance costs and extending the lifespan of the building.

3. Versatility

The material can be easily formed into various shapes and sizes, providing designers and engineers with flexibility in their projects. This adaptability makes aluminum coil suitable for a wide range of applications, from roofing to siding and interior finishes.

4. Energy Efficiency

Aluminum coil can be coated with reflective materials that help in improving energy efficiency. This feature reduces heat absorption, leading to lower energy costs for heating and cooling within buildings.

5. Recyclability

Aluminum is highly recyclable, making it an environmentally friendly option for construction. Using aluminum coil contributes to sustainability efforts, as recycled aluminum requires significantly less energy to process compared to new aluminum production.

Aluminum coils are available in a wide range of sizes and thicknesses to suit various applications. Common thicknesses typically range from 0.008 inches to 0.250 inches, catering to both lightweight and heavier industrial needs. In terms of width, aluminum coils can be found in sizes from 30 inches to 60 inches, although custom widths may also be available depending on the supplier. These variations ensure that aluminum coils can meet the specific requirements of different projects, including construction, automotive, and manufacturing.

Some interesting numbers and facts about your company results for Aluminum Coil

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6839 |

| Amount of suitable service providers | 5696 |

| Average amount of employees | 5001-10000 |

| Oldest suiting company | 1891 |

| Youngest suiting company | 2011 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Aluminum Coil

What are related technologies to Aluminum Coil?

Based on our calculations related technologies to Aluminum Coil are Glass, Superconductors, High-Performance Materials, Raw Materials, Phase Change Materials

Which industries are mostly working on Aluminum Coil?

The most represented industries which are working in Aluminum Coil are Other, Construction, Mining, Building Materials, Manufacturing

How does ensun find these Aluminum Coil Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.