The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Duresco

Wilderswil, Switzerland

A

- Employees

2003

Key takeaway

The company specializes in developing and producing high-performance thermoset epoxy molding compounds, which are essential for driving innovation in various applications.

Reference

Product

HIGH-PERFORMANCE PLASTICS - Duresco

Sumitomo Bakelite Europe N.V.

Novi, United States

B

101-250 Employees

1967

Key takeaway

SBHPP, a business unit of Sumitomo Bakelite Co., Ltd, is a global leader in high-performance plastics solutions, emphasizing its expertise in phenolic technology developed over more than 100 years. They are committed to innovation and environmental protection, continuously developing new technologies to enhance various applications, particularly in smart devices.

Reference

Core business

Home

Power Plastics Corp.

Portland, United States

B

11-50 Employees

1992

Key takeaway

Power Plastics is a prominent distributor of high-performance plastics, including UHMW, Nylon, Acetal, PTFE, and Phenolic. They also manufacture a variety of industrial plastic components, ensuring quick delivery and competitive pricing.

Reference

Core business

Power Plastics, HD-PE. Polypropylene. Nyoil, UHMW-PE, Nylon, Acetal, Delrin, PTFE, Teflon, Kynar, Phenolic

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

PBY Plastics Inc.

Ontario, United States

B

11-50 Employees

1995

Key takeaway

PBY Plastics specializes in producing high-performance plastics, offering a range of compression-molded shapes like tubes, rods, and sheets, tailored for demanding applications. Their commitment to quality is underscored by certifications such as AS9100D and ISO 9001:2015, ensuring that they meet stringent industry standards.

Reference

Core business

Plastic Molding Manufacturing – Performance Plastics | PBY

PBY Plastics manufacturers high-performance plastics for a variety of applications and industries. Learn more and get in touch with us today!

Engineering Plastics Ltd

Cookstown, United Kingdom

A

1-10 Employees

-

Key takeaway

Engineering Plastics Ltd specializes in high-performance engineering solutions, offering a variety of advanced materials such as nylon and polyethylene, which are crucial for enhancing the durability and efficiency of machinery in sectors like mining and food processing. Their expertise in high-performance plastics can help reduce maintenance costs and improve production processes.

Reference

Product

High Performance Polyethylenes - Engineering Plastics Ltd

ElringKlinger Engineered Plastics North America, Inc.

Buford, United States

B

501-1000 Employees

2013

Key takeaway

The company specializes in developing and producing high-performance plastics, including a range of thermoplastic materials such as PTFE, PFA, and PEEK, making it a strong partner for various applications. Their innovative products, like the award-winning ThermoGeniusTM water heat exchanger, highlight their commitment to market-driven solutions.

Reference

Product

Products - ElringKlinger Engineered Plastics

HONYPLASTICS

Shenzhen, China

D

51-100 Employees

2008

Key takeaway

HONY Engineering Plastics Co., Ltd is a high-technology enterprise that specializes in the R&D and production of a wide range of engineering plastics, offering products in semi-finished formats and precise machined parts. Their extensive experience and value-added services, such as CNC milling and injection molding, cater to various industries including aerospace, medical equipment, and semiconductor manufacturing.

Reference

Product

Engineering Plastics - Hony Plastics - Engineering Plastics

General Polymers Thermoplastic Materials

Rochester Hills, United States

B

11-50 Employees

2016

Key takeaway

The company offers a wide variety of engineered resins from reputable suppliers, highlighting its expertise in thermoplastic materials and resin distribution, which is directly relevant to high-performance plastics.

Reference

Core business

General Polymers Thermoplastic Materials

Thermoplastic Resin Distribution

GINAR TECHNOLOGY CO., LTD.

Taoyuan City, Taiwan

101-250 Employees

1982

Key takeaway

Ginar Technology Co., Ltd. is a leading player in engineering thermoplastics, offering compounded polymer materials that provide high mechanical strength and serve as alternatives to metal across various industries. Their commitment to rigorous quality control and the development of environmentally friendly products further enhances their service to customers.

Reference

Core business

Engineering Plastics 工程塑料 - Ginar Technology 晉倫科技

Ginar Technology Co., Ltd.,Taiwanese company,engineering plastic in Taiwan

Polyplastics Industries India Pvt Ltd

India

D

1001-5000 Employees

1970

Key takeaway

Polyplastics Group is dedicated to high precision and quality in its products, which aligns with the requirements for high-performance plastics. With over 50 years of experience and a commitment to innovation, the company aims to be a global manufacturer of automotive components.

Reference

Service

IMD - Polyplastics Group

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

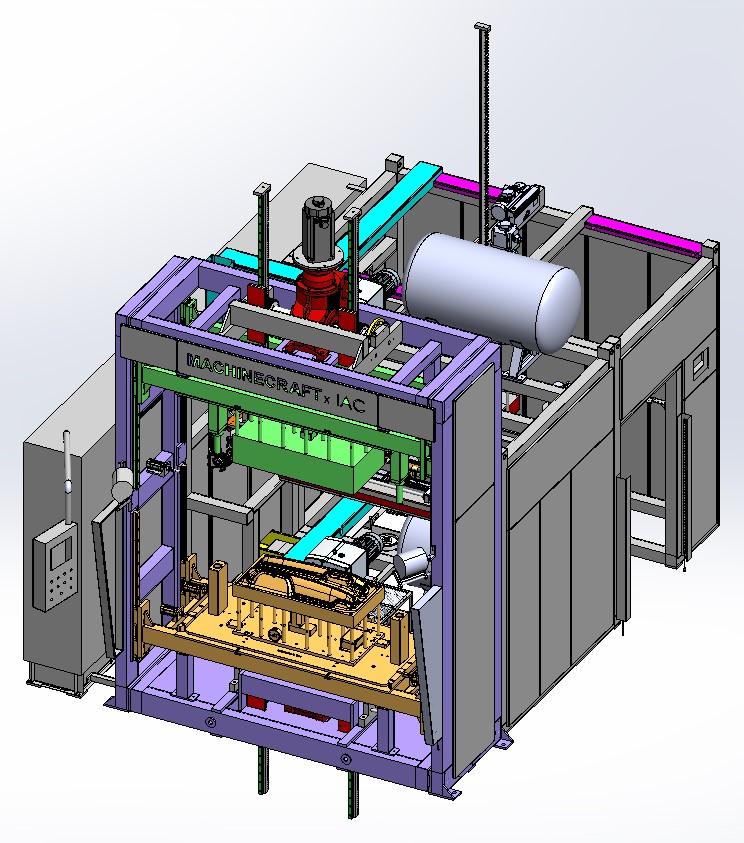

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

High-performance plastics are advanced polymer materials designed to withstand extreme conditions, including high temperatures, corrosive environments, and significant mechanical stress. These materials exhibit superior properties such as excellent chemical resistance, dimensional stability, and low flammability, making them suitable for demanding applications in industries like aerospace, automotive, and electronics. The unique molecular structure of high-performance plastics allows them to maintain their strength and integrity under challenging conditions. Their versatility enables manufacturers to use them for components like bearings, seals, and insulation, where conventional plastics would fail. As a result, high-performance plastics are crucial in enhancing the reliability and efficiency of various technical applications.

1. Exceptional Durability

High-performance plastics are known for their superior strength and resistance to wear, making them ideal for demanding applications. They can withstand extreme temperatures and harsh chemicals, which significantly extends the lifespan of products manufactured with these materials.

2. Lightweight Characteristics

These materials offer a significant weight advantage over metals, which can enhance fuel efficiency in transportation applications. This lightweight nature also allows for easier handling and reduces overall production costs, making high-performance plastics a versatile choice in various industries.

High-performance plastics are engineered to withstand extreme conditions and provide superior mechanical, thermal, and chemical resistance compared to standard plastics. They are often used in demanding applications where durability is critical, such as aerospace, automotive, and medical industries. These advanced materials exhibit enhanced properties, such as higher temperature tolerance, better dimensional stability, and lower friction coefficients, making them suitable for specialized applications. In contrast, standard plastics may suffice for everyday uses but typically fall short in performance when exposed to harsh environments or specific stressors.

High-performance plastics are integral to various industries due to their exceptional properties, such as heat resistance, chemical stability, and mechanical strength.

1. Aerospace

In the aerospace sector, these plastics are utilized in components that must withstand extreme environments and reduce weight without sacrificing performance.

2. Automotive

The automotive industry employs high-performance plastics for parts like fuel systems and electrical components, enhancing durability and efficiency.

3. Electronics

Electronics manufacturers rely on these materials for insulation and housings, ensuring safety and reliability in their products.

4. Medical

In the medical field, high-performance plastics are used in devices and equipment, meeting stringent regulatory standards while maintaining biocompatibility.

5. Oil and Gas

The oil and gas industry benefits from these plastics in applications exposed to harsh chemicals and high temperatures, ensuring longevity and performance.

The environmental impacts of high-performance plastics can be significant. These materials often have a longer lifecycle compared to traditional plastics, which can reduce waste in the long term. However, the production process of high-performance plastics typically involves energy-intensive methods and the use of chemicals that may be harmful to the environment. Additionally, while some high-performance plastics are designed to withstand extreme temperatures and conditions, their disposal can be problematic. Many of these materials are not biodegradable and can contribute to plastic pollution if not properly recycled. Efforts to improve recycling technologies and develop bio-based alternatives are ongoing to mitigate these environmental concerns.

Some interesting numbers and facts about your company results for High-Performance Plastics

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 8121 |

| Average amount of employees | 101-250 |

| Oldest suiting company | 1967 |

| Youngest suiting company | 2016 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for High-Performance Plastics

What are related technologies to High-Performance Plastics?

Based on our calculations related technologies to High-Performance Plastics are Glass, Superconductors, High-Performance Materials, Raw Materials, Phase Change Materials

Which industries are mostly working on High-Performance Plastics?

The most represented industries which are working in High-Performance Plastics are Plastics, Other, Manufacturing, Chemicals, Packaging

How does ensun find these High-Performance Plastics Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.