The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Suprem

Yverdon-les-Bains, Switzerland

A

51-100 Employees

-

Key takeaway

The company has 30 years of expertise in developing and manufacturing high-end thermoplastic composites for demanding applications, emphasizing its commitment to innovation and tailored products that enhance customer competitiveness. Their vision focuses on collaboration to create new applications for thermoplastic composite materials.

Reference

Core business

Excellence in Thermoplastic composites

www.holy-technologies.com

Hamburg, Germany

A

1-10 Employees

2022

Key takeaway

Holy Technologies is transforming composite manufacturing with its scalable and autonomous production system, partnering with OEMs and Tier 1 suppliers to enhance the weight, stiffness, and recyclability of components. Their focus on large-series composite production aligns with the industry's lightweighting goals, making them a key player in sectors like automotive and aerospace.

Reference

Service

On-Demand Composite Manufacturing

We can help you enhance your composite components, with our innovative manufacturing technology for composites. This applies to products already made from composites or those that could be converted from metal to composites. In both cases, we can improve structural components between 20-200cm (i.e., lighter, stiffer, full recyclability, new geometries) and do so very competitively through our automation approach, helping you achieve potentially higher margins.

Toray Advanced Composites

Morgan Hill, United States

B

501-1000 Employees

-

Key takeaway

Toray Advanced Composites is a leading supplier of thermoplastic composite materials, particularly known for its Toray CFRT® brand, which emphasizes high-volume production of continuous fiber reinforced thermoplastic sheets and components. Their expertise in advanced thermoplastic composites positions them as a key player in the aerospace and defense sectors, among others.

Reference

Core business

Supplier of Toray CFRT® composite materials and solutions - Toray PMC

Toray Performance Materials Corporation focusses on the high-volume production of continuous fiber reinforced thermoplastic composite sheet material and component parts.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Complam Material Co. LTD

Taichung, Taiwan

51-100 Employees

2004

Key takeaway

The company specializes in manufacturing composite thermoplastic laminates, utilizing materials such as glass and carbon fibers, tailored to application requirements. Their focus on innovation and quality control ensures that they provide advanced reinforced thermoplastic laminates suitable for various industries including automotive, aerospace, and consumer electronics.

Reference

Core business

Reinforced Thermoplastic Laminates Expert

We provide advanced reinforced thermoplastic laminates, CFRTP GFRP and recycled Carbon Fiber Laminates. We have our own resins and are focused on research and development to meet the demands of our global customers

Advanced Composites

Sidney, United States

B

251-500 Employees

1986

Key takeaway

Advanced Composites is a leading supplier of Thermoplastic Olefins (TPOs) and Polypropylene Compounds specifically designed for the automotive industry. Their innovative products range from materials for interior trims and airbags to durable compounds for exterior components, all developed to meet the demanding needs of OEM applications.

Reference

Product

Products « Advanced Composites

CQFD Composites

Wittenheim, France

A

1-10 Employees

2006

Key takeaway

CQFD Composites specializes in thermoplastic pultrusion, offering high-performance pultruded thermoplastic composites for advanced applications. With a strong focus on R&D and innovative product development, the company positions itself as a key player in the future of thermoplastic composites, particularly for sectors like Construction, Transport, and Electrical.

Reference

Core business

Composite Pultrusion, Thermoplastic Profile Manufacturer

CQFD Composites is expert in thermoplastic pultrusion. The company delivers performance pultruded thermoplastic composites for high-end applications.

Composites One

Arlington Heights, United States

B

1-10 Employees

1999

Key takeaway

Aerovac highlights its commitment to providing high-quality reinforced thermoplastics, which are essential for high-impact and complex applications. This focus on advanced thermoplastic solutions positions the company as a key supplier in the market.

Reference

Product

Thermoplastics - Composites One | Reinforced Thermoplastics

Get high-performance reinforced thermoplastics from Composites One. Our selection of thermoplastics provide durable solutions for various industries. Browse now.

thermoPre ENGINEERING GmbH

Chemnitz, Germany

A

1-10 Employees

-

Key takeaway

The company, thermoPre ENGINEERING GmbH, positions itself as a comprehensive provider of thermoplastic composites, offering custom-fit solutions and full-service engineering to enhance product performance through lightweight structures. They emphasize their expertise in integrating innovative materials and manufacturing processes, making them a valuable partner for those looking to expand their composite component portfolio.

Reference

Core business

thermoPre ENGINEERING GmbH – Ihr Komplettanbieter für thermoplastische Composites

Construction Composites

Borough of Swale, United Kingdom

A

1-10 Employees

2005

Key takeaway

The company specializes in manufacturing thermoplastic composites, offering innovative and practical solutions tailored for the Construction, Rail, and Utilities sectors. Their expertise ensures the design and production of composite materials that combine strength and reliability with exceptional design.

Reference

Core business

- Construction Composites

A specialist composites product manufacturer delivering knowledge, innovative solutions to the Construction, Rail and Utilities sectors.

Faserplast Composites AG

Rickenbach (TG), Switzerland

A

251-500 Employees

1972

Key takeaway

Faserplast Composites specializes in the development and production of innovative composite solutions, highlighting their extensive experience and technical excellence in creating durable components for various applications, including transportation.

Reference

Service

Faserplast Composites AG: GFK Spezialist

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

On-Demand Composite Manufacturing

Go to product

Product

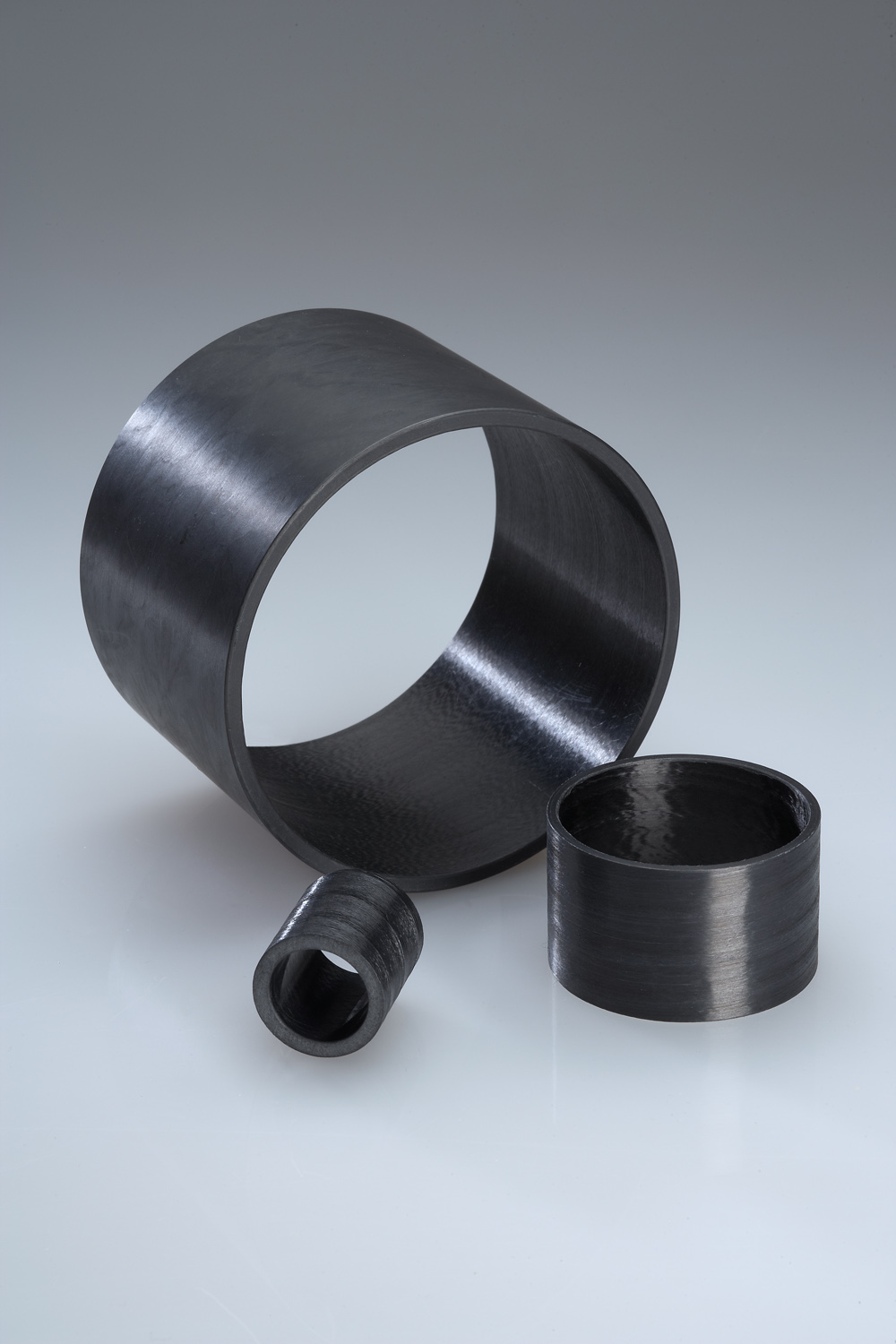

Tailored thermoplastic composites tubes and profiles

Go to product

Product

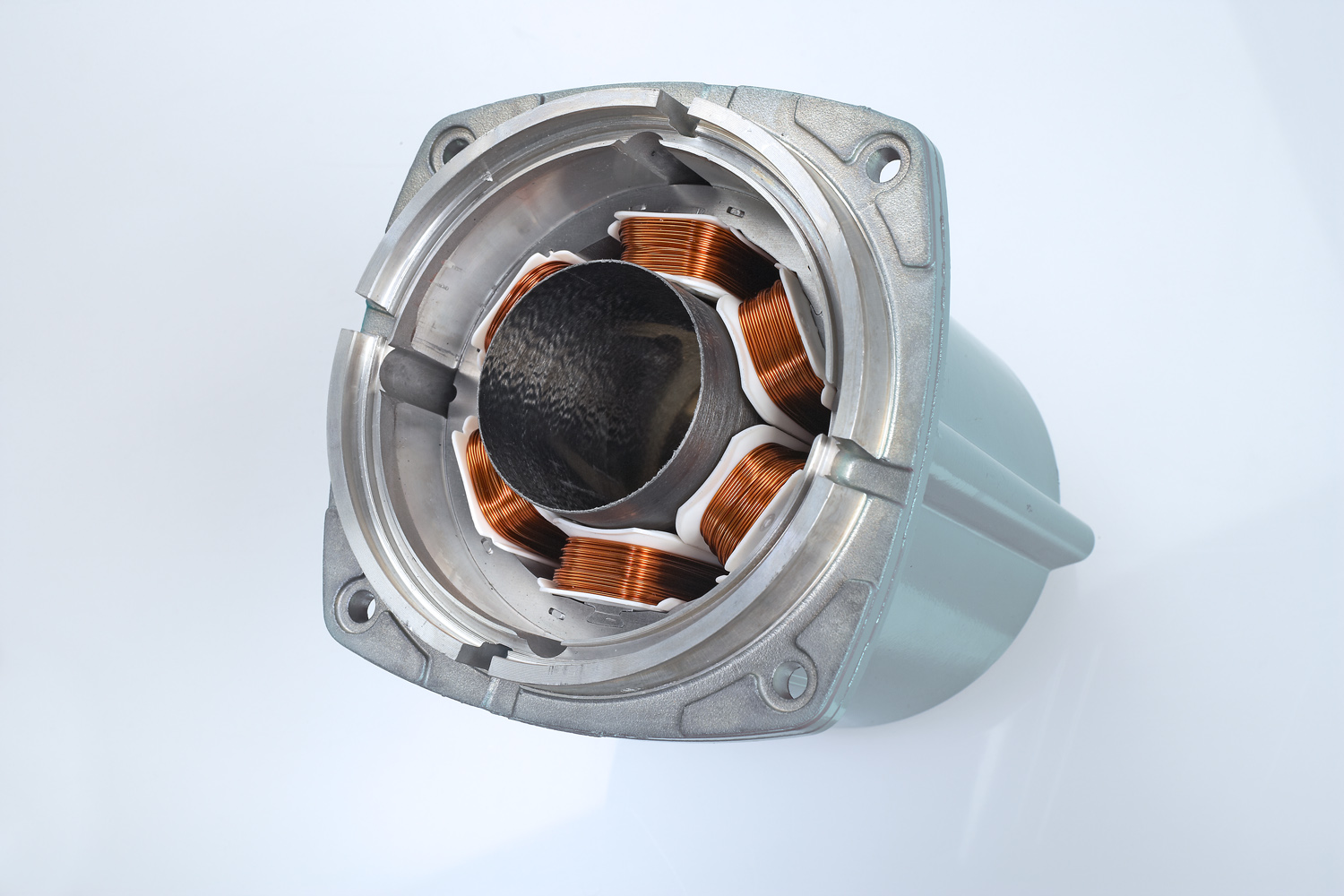

Rotor Sleeves

Go to product

Product

Stator Sleeves

Go to product

Thermoplastic composites are advanced materials made by combining thermoplastic polymers with reinforcing fibers, such as glass or carbon. These composites offer several advantages, including high strength-to-weight ratios, enhanced impact resistance, and excellent fatigue performance. The thermoplastic matrix allows for easier processing and recycling compared to traditional thermosetting composites. Additionally, they can be molded into complex shapes at elevated temperatures, making them suitable for various applications in industries like automotive, aerospace, and sports equipment.

Thermoplastic composites are increasingly utilized in the automotive industry due to their lightweight and durable nature. These materials help in reducing vehicle weight, which enhances fuel efficiency and lowers emissions. The ability to mold thermoplastic composites into complex shapes allows manufacturers to create innovative designs while maintaining structural integrity. Additionally, the recyclability of thermoplastic composites aligns with the automotive industry's push towards sustainability. Components made from these materials can be reused or repurposed, contributing to a circular economy. Their resistance to chemicals and moisture also makes them suitable for various automotive applications, including interior parts, body panels, and structural components.

1. Lightweight Properties

Thermoplastic composites are significantly lighter than traditional materials, which leads to improved fuel efficiency in automotive and aerospace applications. Their reduced weight also allows for easier handling during manufacturing and assembly processes.

2. Enhanced Durability

These materials offer excellent resistance to impact, chemicals, and moisture, making them suitable for demanding environments. Their durability ensures a longer lifespan for products, reducing the need for frequent replacements and maintenance.

3. Design Flexibility

Manufacturers benefit from the versatility of thermoplastic composites, allowing for complex shapes and designs. This adaptability can enhance product performance and aesthetics while streamlining production processes.

4. Shorter Production Times

Thermoplastic composites can be processed faster than thermosetting materials. This speed leads to shorter cycle times and higher throughput in manufacturing, providing a competitive edge in production efficiency.

5. Recyclability

These composites can be reprocessed and recycled, contributing to sustainable manufacturing practices. Their ability to be reused reduces waste and aligns with environmental regulations and consumer preferences for eco-friendly products.

Various industries are increasingly adopting thermoplastic composites due to their lightweight, strong, and durable properties. The **automotive industry** leads this trend, utilizing these materials to enhance fuel efficiency while maintaining safety and performance. The **aerospace sector** also benefits from thermoplastic composites, as they help reduce aircraft weight and improve fuel efficiency. Additionally, the **marine industry** employs these materials for building lightweight and corrosion-resistant components. Other sectors, including **consumer electronics**, **construction**, and **sports equipment**, are recognizing the advantages of thermoplastic composites, driving their integration into a multitude of applications.

Thermoplastic composites and thermoset composites differ significantly in their properties and applications. Thermoplastic composites can be reshaped upon heating, allowing for easier processing and recycling. This characteristic makes them suitable for applications requiring flexibility and durability, such as automotive parts and aerospace components. In contrast, thermoset composites undergo a chemical reaction during curing, making them rigid and heat-resistant once set. They offer superior mechanical properties and stability at high temperatures, which is advantageous for demanding applications in industries like electronics and construction. Each type serves distinct purposes based on their unique advantages and limitations.

Some interesting numbers and facts about your company results for Thermoplastic Composites

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 8871 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1972 |

| Youngest suiting company | 2022 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Thermoplastic Composites

What are related technologies to Thermoplastic Composites?

Based on our calculations related technologies to Thermoplastic Composites are Glass, Superconductors, High-Performance Materials, Raw Materials, Phase Change Materials

Who are Start-Ups in the field of Thermoplastic Composites?

Start-Ups who are working in Thermoplastic Composites are www.holy-technologies.com

Which industries are mostly working on Thermoplastic Composites?

The most represented industries which are working in Thermoplastic Composites are Plastics, Other, Manufacturing, Construction, Building Materials

How does ensun find these Thermoplastic Composites Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.