The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

www.graebener.com

Netphen, Germany

A

51-100 Employees

1921

Key takeaway

The company offers a dedicated approach to analyzing and optimizing the design of bipolar plates for manufacturability, ensuring that necessary features for economical mass production are considered. Their production laboratory can quickly verify the manufacturability of your bipolar plate design, providing efficient and cost-effective initial results.

Reference

Product

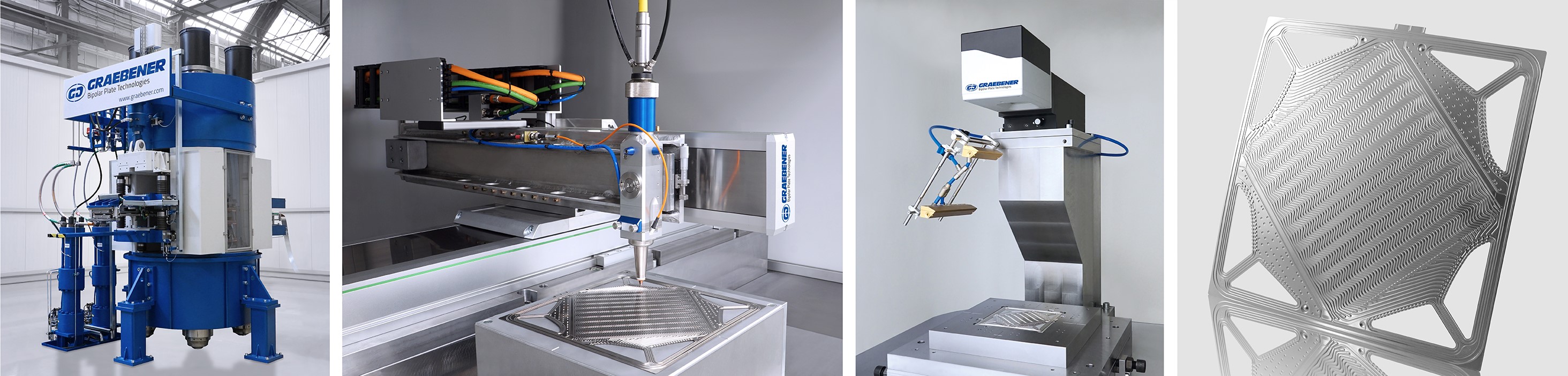

Graebener Production Laboratory

In our production laboratory, we are able to verify the manufacturability of your bipolar plate design using a selected area as test geometry – this way you obtain initial results quickly and cost-effectively. This also applies to the design optimizations we work out. With the continuously optimized and patented Graebener® technology used in the laboratory, we are able to produce smallest lot sizes and small series of your plate design – and later transfer the production parameters one-to-one to your own Graebener® production line.

Entegris

Billerica, United States

B

1001-5000 Employees

1966

Key takeaway

Entegris specializes in providing innovative solutions, including premium graphite components such as bipolar plates, essential for advanced technologies in the semiconductor industry. Their commitment to collaboration and R&D ensures they address complex process challenges effectively.

Reference

Product

Bipolar Plates | Premium Graphite Components | USD | Entegris

CellImpact

Karlskoga, Sweden

A

11-50 Employees

1999

Key takeaway

The company is a leading manufacturer of customized bipolar flow plates specifically for hydrogen fuel cells, highlighting its expertise and capability to improve plate design and support high-volume production. With a focus on advanced testing and measurement, they are well-equipped to meet the needs of the hydrogen industry.

Reference

Core business

Scaling up hydrogen– Cell Impact

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Hyfindr

Stuttgart, Germany

A

1-10 Employees

2021

Key takeaway

Hyfindr.com specializes in the hydrogen economy and offers services related to bipolar plate design, analyzing and developing modifications for manufacturability. They also provide prototyping capabilities, making them a valuable resource for those in need of expert support in this area.

Reference

Service

Bipolar Plate Design | Hyfindr.com

We analyse your bipolar plate design regarding manufacturability and work with you to develop modifications so that your plate can be successfully manufactured – also with regard to the necessary features for an economic series production. You do not have a design yet? We would be pleased to implement your idea as a CAD model for you.

Elcon, Inc.

San Jose, United States

B

11-50 Employees

1967

Key takeaway

Elcon Precision specializes in the manufacturing of custom bipolar plates, utilizing advanced photochemical etching techniques that provide significant advantages for fuel cell and electrolyzer plate engineers. Their expertise in precision components and commitment to high-quality, cost-effective solutions make them a key player in the production of mission-critical applications.

Reference

Product

Custom Bipolar Plates - Elcon Precision LLC

Elcon's photochemical etching offers fuel cell and electrolyzer plate engineers many advantages to combat their design, time, and cost challenges.

Guangdong zhuanjing automobile parts manufacturing co.Ltd

Dongguan, China

D

51-100 Employees

2016

Key takeaway

Tongjin Technology specializes in precision-etched metal components through an innovative chemical etching service. They specifically mention the production of high-purity graphite bipolar plates for fuel cells, highlighting their capability to create components that meet exacting specifications.

Reference

Product

Fuel cell graphite bipolar plate by chemical etching process – Tongjin Technology

This Fuel cell graphite bipolar plate high pure graphite anode plate electrode was Produced by Photochemical Machining Process. Please kindly inform us these information below: 1.The CAD Profile of the Component Drawing; 2.The Components Raw Material; 3.Sheet metals size and thickness; 4.The Custom Quantity;

ZBT

Duisburg, Germany

A

101-250 Employees

2001

Key takeaway

The company, ZBT, is actively engaged in developing future technologies related to hydrogen, fuel cells, and batteries. Their expertise includes research and services focused on bipolar plates and seals, which are essential components in fuel cell technology.

Reference

Product

Bipolarplatten und Dichtungen

IRD Fuel Cells A/S

Denmark

A

11-50 Employees

1996

Key takeaway

The company, IRD Fuel Cells, specializes in the research, development, and production of fuel cell components, including flow plates for PEM and DMFC fuel cells. Their focus on improving product performance and reducing costs aligns with their vision of providing innovative energy solutions.

Reference

Product

Products - IRD Fuel Cells

At IRD Fuel Cells, we are devoted to the research, development, and production of fuel cell components.

Gerling GmbH

Halle (Saale), Germany

A

- Employees

1984

Key takeaway

The company, Alleima, specializes in the development and manufacturing of advanced stainless steels and special alloys, highlighting its innovative approach to producing bipolar plates for fuel cells. Their smarter coatings concept significantly streamlines the production process, reducing costs and transforming the value chain by eliminating the need to coat individual plates.

Reference

Product

The faster way from raw material to bipolar plate — Alleima

With a coated steel strip ready to be pressed into bipolar plates for fuel cells, the Alleima smarter coatings concept drastically shortens the production process. By removing the need and cost of coating individual plates, your entire value chain is transformed overnight.

Eisenhuth GmbH & Co. KG

Germany

A

11-50 Employees

1945

Key takeaway

Eisenhuth specializes in the manufacturing of bipolar plates for fuel cells, utilizing plastic/graphite composites and has been producing graphite bipolar plates since 2007. Their expertise also extends to components for electrolysers, highlighting their significant role in hydrogen technology.

Reference

Product

Produkte - Eisenhuth GmbH & Co. KG

Wasserstoff WasserstofftechnologieMade in Germany Als Komponentenlieferant für Bauteile von Brennstoffzellen-Stacks und in der Wasserstoffherstellung von Elektrolyse-Stacks haben wir viel Fachwissen. Unsere Hauptkomponenten sind dabei Graphit-Bipolarplatten und Dichtungen. Seit 2007 fertigen wir Graphit-Bipolarplatten für unterschiedliche Anwendungen im Bereich Brennstoffzellen und Redox-Flow-Batterien. Für Elektrolyseanwendungen fertigen wir auch Titan- und Nickel-Kompositplatten. Für kleinere Losgrößen setzen wir auf unsere … Produkte Weiterlesen »

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Graebener Production Laboratory

Go to product

Product

Graebener Production Lines

Go to product

A bipolar plate is a critical component in fuel cells, particularly in polymer electrolyte membrane (PEM) fuel cells. It serves multiple functions, including the distribution of reactant gases, conducting electricity, and providing structural support to the cell. Typically made from materials like graphite or metal, these plates feature channels that allow for the efficient flow of gases such as hydrogen and oxygen. By facilitating the electrochemical reactions that occur within the fuel cell, bipolar plates play a vital role in energy conversion processes, directly impacting the overall efficiency and performance of the system. Their design and material composition are essential for optimizing conductivity and minimizing weight, which are crucial for applications in automotive and portable power sectors.

Bipolar plates play a crucial role in fuel cells by acting as conductive components that facilitate the flow of reactants and products. They serve as a separator between individual cells in a fuel cell stack, allowing for efficient distribution of hydrogen and oxygen while also collecting and conducting electrical current generated during the electrochemical reaction. The design of bipolar plates includes channels that direct the flow of gases, ensuring optimal contact with the electrodes. This design enhances the overall efficiency and performance of fuel cells. Additionally, materials used for bipolar plates are selected for their conductivity, corrosion resistance, and mechanical strength, contributing to the longevity and reliability of the fuel cell system.

Various materials are utilized for the fabrication of bipolar plates, each offering distinct properties suited for fuel cell applications. Graphite is widely used due to its excellent conductivity and corrosion resistance. Metal bipolar plates, often made from stainless steel or aluminum, provide higher mechanical strength and durability, though they may require coatings to enhance corrosion resistance. Additionally, composite materials are gaining traction, as they can combine the advantages of metals and polymers while reducing weight. Polymer coatings are also applied to enhance performance and longevity. Each material choice impacts the efficiency, cost, and longevity of the fuel cells, making it crucial for providers to carefully select the appropriate type.

1. High Electrical Conductivity

Metal bipolar plates offer superior electrical conductivity compared to alternatives, ensuring efficient current distribution across the fuel cell.

2. Mechanical Strength

These plates possess excellent mechanical strength, allowing them to withstand high pressures and temperatures, which enhances the durability of the fuel cell system.

3. Corrosion Resistance

Many metals used in bipolar plates are treated or coated to resist corrosion, prolonging the lifespan of the components in harsh operating environments.

4. Thermal Management

Metal bipolar plates provide effective thermal conductivity, which helps in the efficient management of heat within the fuel cell, optimizing performance.

5. Improved Gas Flow

The design of metal bipolar plates can facilitate better gas flow distribution, enhancing the overall efficiency of the fuel cell operation.

The efficiency of a fuel cell is significantly influenced by the design and material of the bipolar plate. These plates serve a dual purpose: they act as separators between individual cells while also conducting current. A well-designed bipolar plate minimizes the resistance to electron flow and ensures optimal gas distribution, which is crucial for maintaining the electrochemical reactions within the cell. Additionally, the thermal management capabilities of bipolar plates play a vital role in maintaining the ideal operating temperature. Effective heat distribution helps prevent hotspots that can degrade performance. Therefore, high-quality materials and innovative designs in bipolar plates directly contribute to improved fuel cell performance, leading to enhanced overall efficiency.

Some interesting numbers and facts about your company results for Bipolar Plate

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 8429 |

| Amount of suitable service providers | 6136 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1921 |

| Youngest suiting company | 2021 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Bipolar Plate

What are related technologies to Bipolar Plate?

Based on our calculations related technologies to Bipolar Plate are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Who are Start-Ups in the field of Bipolar Plate?

Start-Ups who are working in Bipolar Plate are Hyfindr

Which industries are mostly working on Bipolar Plate?

The most represented industries which are working in Bipolar Plate are Other, Oil, Energy and Gas, Electronics and Electrical engineering, Manufacturing, Machinery Manufacturing

How does ensun find these Bipolar Plate Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.