The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Captive Power Limited

Cape Town, South Africa

C

1-10 Employees

-

Key takeaway

Captive Power is an Energy-as-a-Service company that provides power solutions for Commercial and Industrial clients in Africa, emphasizing the reduction of their Levelized Cost of Energy.

Reference

Core business

Solar | Captive Power

Captive Power Captive Power is an Energy-as-a-Service company. Offering power solutions for Commercial and Industrial (“C&I”) clients in Africa, with a focus on reducing their Levelized Cost of Energy (“LCOE”).

PowerCap Limited

Nigeria

E

11-50 Employees

2005

Key takeaway

PowerCap offers comprehensive consultancy services for power projects, supporting them from scoping to commissioning. Their expertise in the power and energy sectors, coupled with a commitment to innovative solutions, positions them as a valuable partner for those interested in efficient electricity management.

Reference

Service

powercaplimited | Services

Revenue Cycle Management, Power Business Advisory, Power Sector Capacity Building, Engineering Design/Construction, Owners' Engineer Services

POWERPLANT LIMITED

United Kingdom

A

1-10 Employees

-

Key takeaway

Powerplant Ltd specializes in providing customized generator solutions, which are essential for establishing a reliable captive power plant. Their dedicated team handles everything from design to commissioning, ensuring that unique power needs are met efficiently.

Reference

Core business

About - Powerplant Ltd - Generator Solutions

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Cenpower Generation Company

Accra, Ghana

D

51-100 Employees

2003

Key takeaway

Cenpower Generation Ltd is focused on developing the Kpone Independent Power Plant, which aims to provide reliable and environmentally sustainable electricity to the Electricity Company of Ghana. Their mission aligns with the objectives of a captive power plant, emphasizing economic viability and efficient energy production.

Reference

Core business

CSR

Operational Energy Group India Ltd

Chennai, India

D

1001-5000 Employees

2002

Key takeaway

The company, with a strong focus on the captive power producer (CPP) market, has been providing comprehensive services since 2002, positioning itself as a key player in enhancing the performance of captive power plants like Bhola CCPP in Bangladesh. Their collaboration with top technology partners ensures the delivery of high-quality products and services tailored to client needs.

Reference

Product

Nabha Power – Operational Energy Group India Limited

Cogeneration Consultants

Walled Lake, United States

B

1-10 Employees

1991

Key takeaway

Cogeneration Consultants offers extensive expertise in renewable power source projects, which is highly relevant for understanding the context of captive power plants.

Reference

Core business

Cogeneration Consultants - Industry Leader in Renewable Power Source Programs

Aperion Energy Group

Cibolo, United States

B

1-10 Employees

2016

Key takeaway

Aperion Energy Group specializes in the design, development, and deployment of various power plant technologies, emphasizing instant-on thermal solutions. Their expertise in power asset lifecycle management and site selection services supports the development of reliable, continuous electrical power, which is essential for modern businesses.

Reference

Core business

Power First - Aperion Energy Group

Continuous, affordable electrical power is the backbone of every modern business. Without power, nothing happens. Demand is rising across industries […]

Capstone Power Solutions Ltd

-

- Employees

-

Key takeaway

Capstone Power Solutions specializes in designing, installing, and maintaining Capstone Turbine equipment, offering innovative solutions for on-site power generation. Their microturbines, such as the environmentally friendly CR65 and methane-fueled CR200, provide significant energy savings and support sustainable practices in various applications, including combined heat and power (CHP) for industries and wastewater treatment.

Reference

Service

Services :: Capstone Power Solutions

Kapil Power & Infra (P) Ltd.

Hyderabad, India

D

251-500 Employees

2014

Key takeaway

Kapil Power specializes in the design, construction, and maintenance of both on-grid and off-grid solar power systems, making it a key player in the solar energy sector in India. Their expertise in comprehensive EPC services and turnkey solutions highlights their capability to support various applications, including domestic and industrial needs.

Reference

Core business

Kapil Power - Best Solar Energy Company | Solar Power Company In India

Kapil Power is a leading solar energy company in India. It undertakes the design, construction,and maintenance of ON-GRID and OFF-GRID solar power systems.

Powergen Development Group

New York, United States

B

11-50 Employees

2012

Key takeaway

PowerGen Development Group, LLC specializes in alternative energy solutions, including the installation and operation of Combined Heat and Power (CHP) Systems. With over 5 megawatts of power-generating capacity and a commitment to sustainable energy projects, the company focuses on enhancing operational cash flow for commercial and industrial facilities while improving environmental impact.

Reference

Core business

Powergen Development Group

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

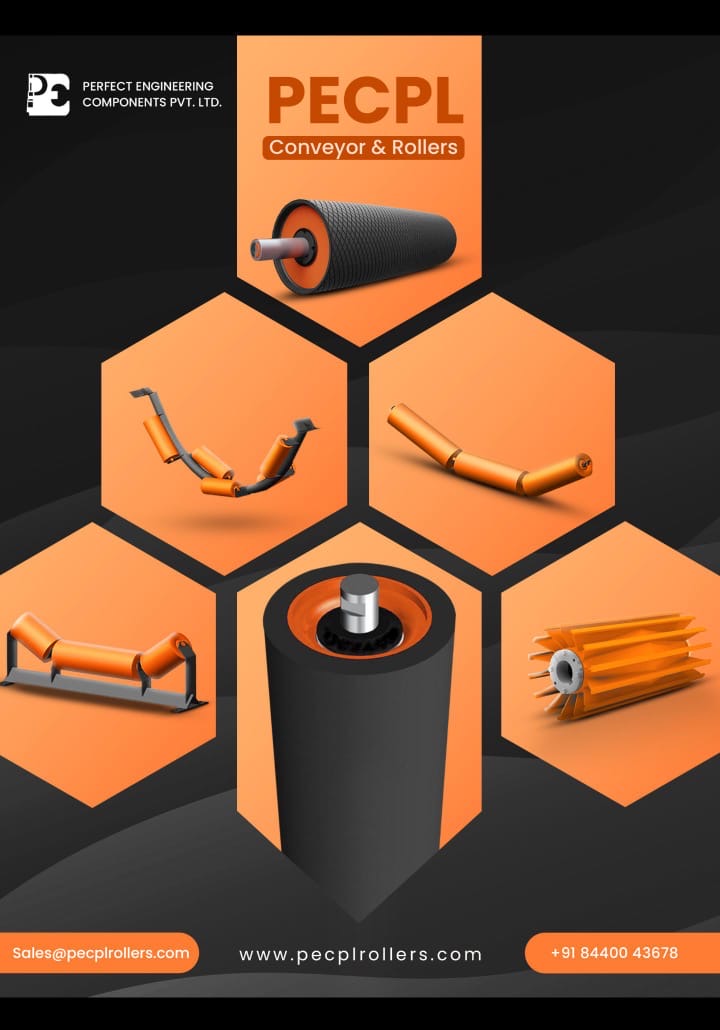

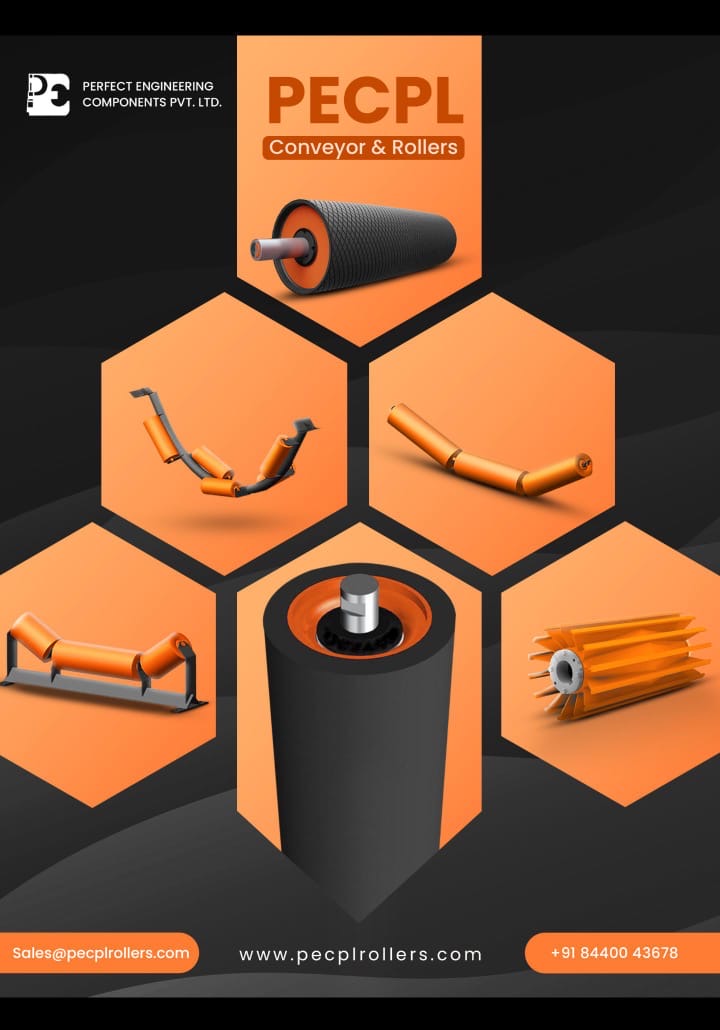

Product

Conveyor Roller

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Heavy-Duty Conveyor Roller

Mining, Ports, Boilers, SugarPowe, Steel, Mineral processing , Crushing & Screening

PECPL is India’s leading manufacturer of high-quality conveyor rollers, renowned for their exceptional durability and superior performance. With state-of-the-art, fully automatic production lines, PECPL delivers precision-engineered rollers designed to provide the highest service life, even in the most demanding conditions. Trusted across industries such as mining, construction, steel, cement, and ports, PECPL sets the benchmark for reliability, efficiency, and innovation in bulk material handling solutions. Our commitment to quality and customer satisfaction makes us the top choice for conveyor rollers in India.

Use case

Heavy-Duty Conveyor Roller

Mining, Ports, Boilers, SugarPowe, Steel, Mineral processing , Crushing & Screening

PECPL is India’s leading manufacturer of high-quality conveyor rollers, renowned for their exceptional durability and superior performance. With state-of-the-art, fully automatic production lines, PECPL delivers precision-engineered rollers designed to provide the highest service life, even in the most demanding conditions. Trusted across industries such as mining, construction, steel, cement, and ports, PECPL sets the benchmark for reliability, efficiency, and innovation in bulk material handling solutions. Our commitment to quality and customer satisfaction makes us the top choice for conveyor rollers in India.

A Captive Power Plant refers to a facility that generates electricity primarily for its own use rather than for sale to the general public. This type of power generation is typically established by large industrial units or commercial entities to ensure a reliable and cost-effective power supply. Captive power plants can utilize various energy sources, including fossil fuels, biomass, and renewable energy, allowing businesses to reduce dependence on the grid and manage energy costs more effectively. By having their own power generation capability, companies can also enhance operational efficiency and maintain continuity in power supply even during grid outages.

A Captive Power Plant operates by generating electricity primarily for the energy needs of a specific facility or group of facilities. It typically uses conventional fuels like natural gas, coal, or renewable sources such as biomass and solar energy. The process begins with the conversion of fuel into energy through combustion or other means. This energy drives turbines connected to generators, producing electricity. The generated power is used on-site, reducing reliance on the grid and often resulting in cost savings. These plants can also operate independently or in conjunction with the main grid, providing flexibility and reliability in energy supply. Additionally, advancements in technology enable these plants to optimize efficiency, minimize emissions, and maintain operational control.

1. Energy Security

A Captive Power Plant ensures a reliable and uninterrupted power supply for industries. By generating their own electricity, businesses can mitigate the risks associated with grid failures and fluctuating energy prices.

2. Cost Efficiency

These plants can significantly reduce energy costs in the long run. With lower operational and maintenance expenses compared to purchasing power from the grid, organizations can achieve substantial savings on their energy bills.

3. Environmental Benefits

Captive Power Plants often utilize cleaner technologies and renewable energy sources, contributing to reduced carbon emissions. This aligns with sustainability goals and can improve a company's overall environmental footprint.

4. Tailored Energy Solutions

Organizations can customize their power generation to meet specific operational needs. This flexibility allows for the optimization of energy production based on demand, ensuring efficiency and reliability.

5. Enhanced Control

With a Captive Power Plant, businesses maintain control over their energy generation process. This autonomy enables better management of power resources, leading to improved operational efficiency and reduced reliance on external suppliers.

Various industries commonly utilize captive power plants to meet their energy needs.

1. Manufacturing

Manufacturing facilities often rely on captive power plants to ensure a consistent and reliable power supply, which is critical for uninterrupted production processes.

2. Mining

The mining sector frequently adopts captive power plants due to the remote locations of operations, where access to grid electricity can be limited or unreliable.

3. Textiles

Textile industries benefit from captive power plants to maintain high energy demands for machinery and processes, thereby enhancing productivity and reducing operational costs.

4. Chemicals

Chemical manufacturing plants utilize captive power to support energy-intensive processes, ensuring stability and efficiency in production.

5. Food and Beverage

In the food and beverage sector, captive power plants help maintain stringent quality control and consistent production schedules, minimizing downtime caused by power outages.

Setting up a Captive Power Plant involves several cost implications that organizations need to consider. The initial investment can be substantial, as it includes expenses for equipment, installation, and infrastructure development. Additionally, ongoing operational costs such as fuel, maintenance, and labor must be factored into the overall budget. Moreover, regulatory compliance and environmental assessments may incur further costs. However, the long-term benefits, such as reduced electricity bills and increased energy security, often justify the initial financial outlay. Organizations may also benefit from potential tax incentives and subsidies that can alleviate some of the upfront expenditures.

Some interesting numbers and facts about your company results for Captive Power Plant

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 9830 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1991 |

| Youngest suiting company | 2016 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Captive Power Plant

What are related technologies to Captive Power Plant?

Based on our calculations related technologies to Captive Power Plant are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Which industries are mostly working on Captive Power Plant?

The most represented industries which are working in Captive Power Plant are Oil, Energy and Gas, Other, Electronics and Electrical engineering, Construction, Utilities

How does ensun find these Captive Power Plant Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.