The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Carbon Fibre Tubes Ltd

Fareham, United Kingdom

A

11-50 Employees

2003

Key takeaway

Carbon Fibre Tubes Ltd specializes in the design and manufacture of custom carbon fiber tubes, offering solutions tailored to specific applications. They provide a wide range of tubing options, from diameters of 5mm to 500mm and lengths up to 5m, utilizing advanced in-house profiling and finishing techniques.

Reference

Core business

Carbon Fibre Tubes Ltd - Composite Tube Design & Manufacture

Complete composite tube design and manufacturing. Carbon fibre tube supplier and bespoke manufacture, composite part manufacture & machining and assembly.

Donggua XieChuang Composite Materail Co. Ltd(xccomposite)

Dongguan, China

D

51-100 Employees

2008

Key takeaway

Xccarbon specializes in the production of carbon fiber tubes, offering advanced manufacturing solutions for various applications, including precision parts for automotive and UAV components. With a focus on innovation and customization, they provide OEM and ODM services to meet the needs of global brands.

Reference

Product

Carbon Tube|Carbon Tube|carbon fiber tube

We Are The Best Carbon Fiber Products Manufacturer,We are always ready to provide advanced manufacturing solutions suitable for your products.

JIASHI DE Nanjing Toy products Co. ltd.

Nanjing City, China

D

251-500 Employees

-

Key takeaway

Wuxi Carbon Fiber Tubes Co., Ltd is a leading manufacturer and exporter of carbon fiber products, including carbon fiber tubes. Their commitment to high quality and exceptional performance has garnered positive feedback from customers worldwide.

Reference

Core business

Wuxi Carbon Fiber Tubes Co.,Ltd

Wuxi Carbon Fiber Tubes Co.,Ltd

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Shenzhen Jinjiuyi Electronic & Technology Co. Ltd

Shenzhen, China

D

11-50 Employees

2012

Key takeaway

Jinjiuyi is a leading manufacturer and supplier of high-quality carbon fiber products, including carbon fiber tubes. The company's mission is to promote carbon fiber as a primary composite building material, helping businesses enhance their performance through premium offerings.

Reference

Core business

Carbon fiber sheets and tubes supplier in China

CARBON FIBRE PROFILES LTD

London, United Kingdom

A

- Employees

-

Key takeaway

The company, a specialist UK manufacturer and supplier, offers a wide range of high-quality carbon fiber tubes, rods, and profiles, emphasizing their expertise and commitment to durability and reliability. With over 40 years of experience and ISO 9001 approval, they ensure that their products meet the highest standards for various applications.

Reference

Core business

Carbon Fibre Tubes, Rods & More From Carbon Fibre Profiles – Carbon Fibre Profiles Ltd

Browse our range of fibreglass and carbon fibre tubes, rods, bars, angles and more. Manufactured to the highest standard at our factory in the UK, with over 40 years experience.

WT Carbon Fiber Technology Co. Ltd

Huizhou, China

D

11-50 Employees

2013

Key takeaway

WT Carbon Fiber Technology Co., Ltd specializes in carbon fiber products, prominently featuring a variety of carbon fiber tubes used in applications like tents, tripods, and ski poles. As a leading manufacturer in China, the company emphasizes quality and timely delivery, ensuring a comprehensive service for customers seeking carbon fiber solutions.

Reference

Core business

WT Carbon Fiber Technology Co., Ltd - China carbon fiber parts Manufacturer,carbon fiber tube Supplier,composite Factory

Acen carbon fiber

Shenzhen, China

D

51-100 Employees

-

Key takeaway

Acen International Company Limited specializes in manufacturing high-quality carbon fiber products, including a variety of carbon fiber tubes in different shapes such as round, square, rectangular, and tapered.

Reference

Product

Carbon Fiber Products | Acen carbon fiber

Professional manufacturer of carbon fiber sheet,tubes,rods,custom made parts and fiberglass rods,tubes,strips,profiles.

Zibo zhongdu trade Co. ltd (sinoflyelephant)

Zibo, China

D

1-10 Employees

2015

Key takeaway

SINO is a wholesale provider of high-quality carbon fiber products, including a diverse range of carbon fiber tubes and pipes. They offer custom solutions, such as 20m telescopic water-fed window cleaning poles and various weaves and finishes, catering to different industry needs.

Reference

Product

CARBON FIBER TUBE Archives - Sino Carbon Fiber

Protech Composites

Vancouver, United States

B

11-50 Employees

2008

Key takeaway

Protech Composites specializes in developing custom carbon fiber parts, including high-quality dash panels and interior surfaces for innovative boat builders. Their commitment to exceptional quality and innovative materials positions them as a key resource for diverse applications in the carbon fiber sector.

Reference

Core business

Carbon Fiber Supplier & Manufacturer | Protech Composites | Protech Composites

Protech Composites manufactures carbon fiber sheets and parts for diverse applications — with zero porosity and zero cosmetic defects, guaranteed.

carbon fibre tubes & rods

Zibo, China

D

1-10 Employees

-

Key takeaway

Zibo Xinnuo Commercial & Trading Co., Ltd specializes in supplying a wide range of carbon fiber products, including carbon fiber tubes and rods, tailored to various applications such as surveying and the oil industry. Their extensive experience and commitment to quality make them a reliable source for both standard and custom carbon fiber tubing solutions.

Reference

Core business

Professional carbon fiber and glass fiber products Supplier

Zibo Xinnuo Commercial & Trading Co.,Ltd ,The trading branch of our factory in China.We can supply carbon fiber tubes, carbon fiber sheets,carbon fiber telescopic pole,carbon fiber window cleaning pole, carbon fiber extension pole, glass fiber tube/pole/rod according to clients request.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

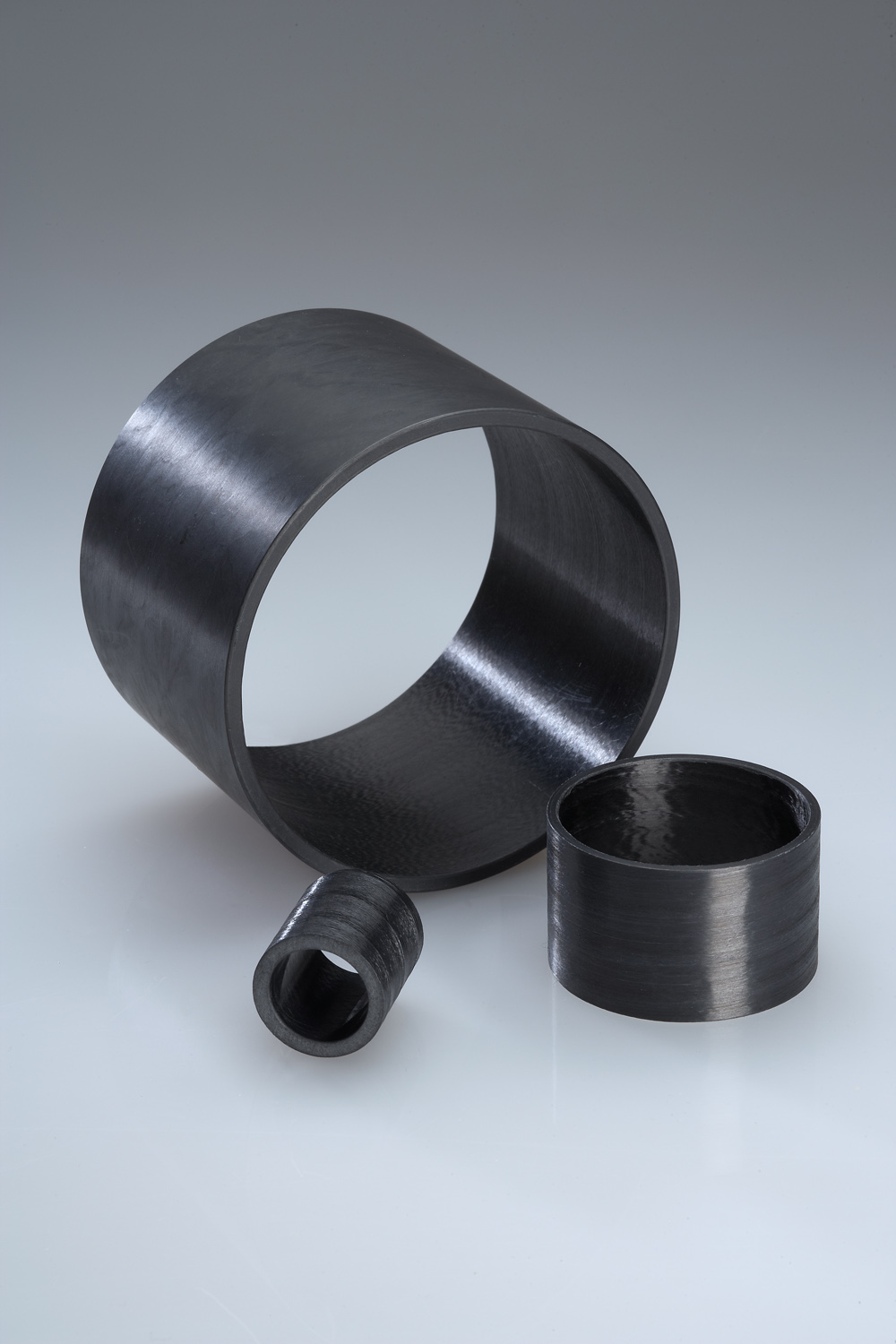

Tailored thermoplastic composites tubes and profiles

Go to product

Product

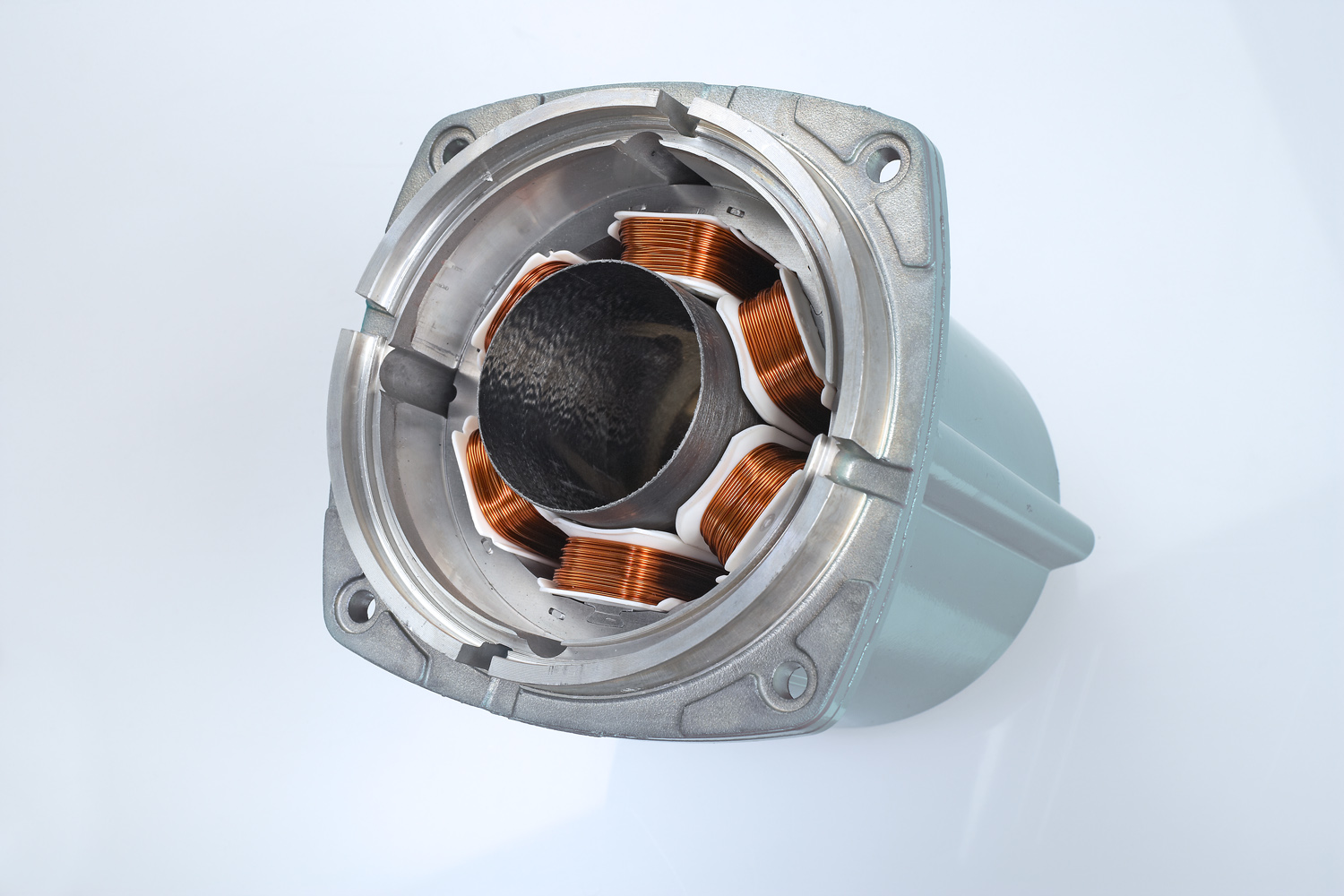

Rotor Sleeves

Go to product

Product

Stator Sleeves

Go to product

A carbon fiber tube is a cylindrical structure made from carbon fiber reinforced polymer (CFRP). This material is known for its high strength-to-weight ratio, flexibility, and resistance to corrosion. Carbon fiber tubes are lightweight yet extremely durable, making them ideal for various applications in industries such as aerospace, automotive, sports equipment, and construction. The manufacturing process typically involves layering carbon fiber fabrics with resin and curing them to create a solid, rigid structure. These tubes can be produced in different diameters and lengths, catering to specific needs. Their superior mechanical properties allow for the design of components that can withstand significant stress while maintaining a low overall weight.

1. Aerospace Industry

Carbon fiber tubes are widely used in the aerospace sector due to their lightweight and high-strength characteristics. They help reduce the overall weight of aircraft components, which contributes to improved fuel efficiency and performance.

2. Sporting Goods

In the realm of sporting goods, carbon fiber tubes are employed in equipment such as bicycles, tennis rackets, and fishing rods. Their rigidity and low weight enhance performance while providing durability under varying conditions.

3. Automotive Applications

The automotive industry utilizes carbon fiber tubes in high-performance vehicles to improve speed and fuel efficiency. They are commonly found in chassis and other structural components, offering the necessary strength without the added weight of traditional materials.

4. Medical Devices

Carbon fiber tubes are increasingly used in the medical field for devices like prosthetics and orthopedic equipment. Their biocompatibility and strength make them ideal for applications requiring both durability and lightweight design.

5. Industrial Applications

In industrial settings, carbon fiber tubes serve various roles, from robotic arms to scaffolding. Their resilience and lightweight nature provide significant advantages in manufacturing and construction processes.

The manufacturing process of a carbon fiber tube typically involves several key steps. Initially, raw material preparation takes place, where carbon fibers are combined with a resin, usually an epoxy, to create a composite material. This mixture is then laid out in specific patterns, often using a technique called filament winding or pultrusion, where the resin-impregnated fibers are wound around a mandrel or pulled through a die to form the tube shape. After the tube is formed, curing is necessary to harden the resin. This is done by applying heat and pressure, which allows the resin to cure and bond the fibers together, resulting in a strong and lightweight structure. Once cured, the tube may undergo finishing processes, such as cutting to size and surface treatment, ensuring it meets the required specifications and quality standards.

1. Lightweight

Carbon fiber tubes are significantly lighter than traditional materials such as steel or aluminum. This reduced weight translates to improved performance in applications where weight savings are critical, such as in aerospace, automotive, and sporting goods.

2. High Strength

Despite being lightweight, carbon fiber tubes possess exceptional tensile strength. They can withstand high levels of stress without deforming, making them ideal for structures and components that require durability and resilience.

3. Corrosion Resistance

Carbon fiber is inherently resistant to corrosion, unlike metals that can rust or degrade over time. This property ensures a longer lifespan and lower maintenance costs for products made from carbon fiber tubes, especially in harsh environments.

4. Design Flexibility

The manufacturing process of carbon fiber allows for intricate designs and custom shapes. This flexibility enables engineers and designers to create tailored solutions that meet specific performance and aesthetic requirements.

5. Damping Properties

Carbon fiber tubes exhibit excellent vibration-damping characteristics. This quality reduces unwanted vibrations in applications such as musical instruments and high-performance vehicles, enhancing overall user experience and performance.

When selecting a carbon fiber tube, several factors play a crucial role in ensuring you choose the right product for your application. First, Material Quality is essential; high-quality carbon fibers provide superior strength and durability. Consider the tube's Dimensions, including outer diameter and wall thickness, as these affect both performance and fit for your specific needs. Another important aspect is Manufacturing Process; tubes produced using advanced techniques often exhibit better mechanical properties. Additionally, evaluate the Weight of the tube, especially if it's intended for applications where weight savings are critical. Lastly, take into account the Supplier Reputation; a reliable provider can ensure consistent quality and support throughout your purchasing process.

Some interesting numbers and facts about your company results for Carbon Fiber Tube

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6672 |

| Amount of suitable service providers | 5091 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 2003 |

| Youngest suiting company | 2015 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Carbon Fiber Tube

What are related technologies to Carbon Fiber Tube?

Based on our calculations related technologies to Carbon Fiber Tube are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Which industries are mostly working on Carbon Fiber Tube?

The most represented industries which are working in Carbon Fiber Tube are Other, Manufacturing, Plastics, Mining, Construction

How does ensun find these Carbon Fiber Tube Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.