The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Conveyor Units

Wyre Forest, United Kingdom

A

1-10 Employees

-

Key takeaway

Conveyor Units, the largest conveyor roller manufacturer in the UK, produces over 30,000 high-quality conveyor rollers each week, utilizing in-house manufacturing processes that adhere to strict quality standards. With more than 60 years of experience, the company ensures quick dispatch and a diverse product range used across various industries.

Reference

Core business

About Us - Conveyor Rollers

Conveyor Rollers Inc

Arlington Heights, United States

B

11-50 Employees

-

Key takeaway

With over 27 years of experience, the company offers a wide range of innovative and cost-effective conveyor roller solutions, including heavy-duty and custom options tailored for various industries such as food handling and manufacturing. Their expertise ensures that clients can find the perfect conveyor roller to meet their specific needs.

Reference

Core business

Conveyor Rollers | Replacement Conveyor Rollers | Custom Conveyor Rollers

Conveyor Rollers of ConveyorRollers.com are custom made. Use our online roller builder for new or replacement conveyor rollers 866-976-5537

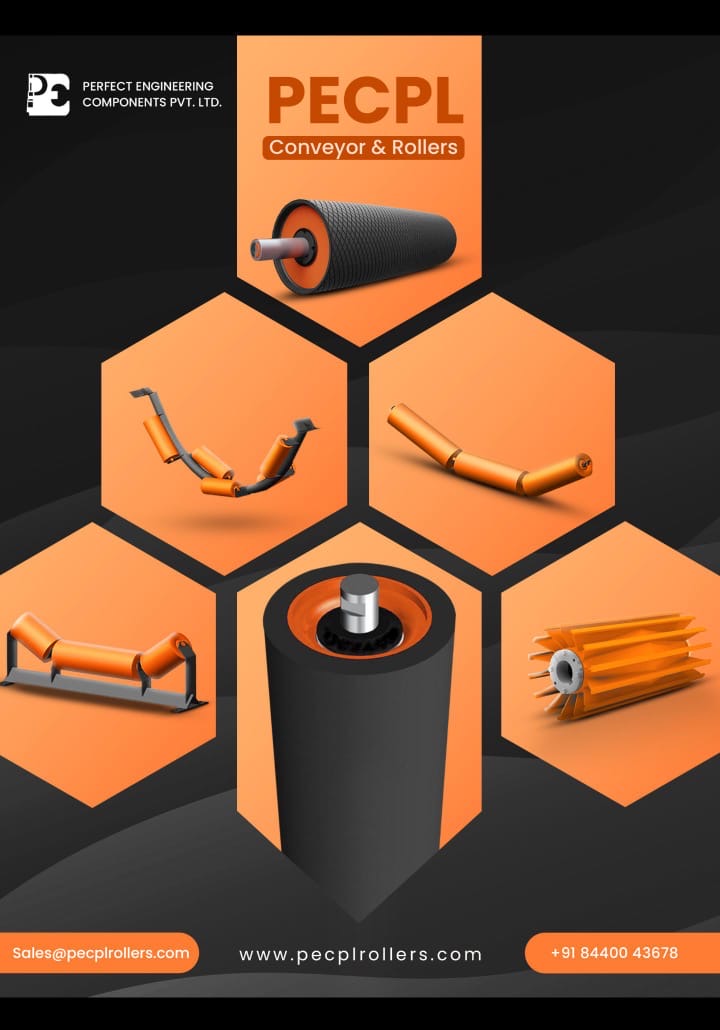

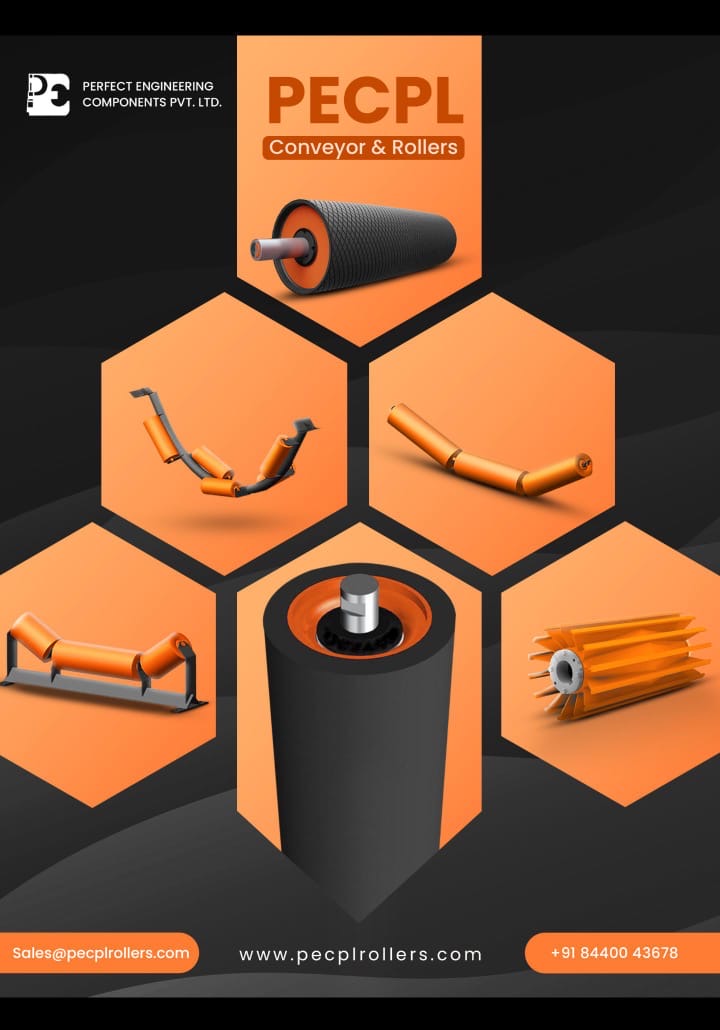

PECPL Conveyors & Rollers

Karoli, India

D

101-250 Employees

1989

Key takeaway

PECPL is a leading manufacturer of high-quality conveyor rollers, emphasizing innovation and durability while adhering to global standards. Their state-of-the-art production ensures exceptional performance, making them a preferred choice for various industries.

Reference

Product

Conveyor Roller

PECPL is India’s top manufacturer of high-quality conveyor rollers, crafted using fully automatic production lines for unmatched precision and efficiency. Designed for bulk material handling, these rollers feature robust construction, precision bearings, and corrosion-resistant coatings. Built to endure heavy loads and harsh conditions, they ensure smooth, low-maintenance operation, making them ideal for industries like mining, construction, and manufacturing.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

CONVERO SOLUTIONS

Ahmedabad, India

D

11-50 Employees

1986

Key takeaway

CONVERO SOLUTIONS is a leading manufacturer of conveyor rollers and idlers in Gujarat, with a focus on high quality and innovative design. They offer a wide range of conveyor accessories and have a fully automated manufacturing plant, ensuring durability and flexibility in conveyor design.

Reference

Core business

Conveyor Roller Manufacturer | CONVERO SOLUTIONS | Gujarat

CONVERO SOLUTIONS are conveyor idler manufacturer, Fully automated idler manufacturing plant, first in gujarat 76 mm D. to 152 mm D. 200 mm L. to 2600 mm L.

Conveline Systems

Ahmedabad, India

D

11-50 Employees

2013

Key takeaway

Conveline is a leading manufacturer of conveyor rollers, offering a wide range of innovative solutions for various industries such as food distribution, logistics, and manufacturing. With a production capacity of 350,000 rollers per year, they also specialize in 24V DC roller motors, making them a key player in the motor-driven roller conveyor market.

Reference

Product

Roller Conveyor :: Conveline - Inspired by Excellence

Conveline Systems is one of the biggest Manufacturers and Suppliers of different types of Rollers Conveyors in Ahmedabad, India.

LASER CUTTING AT FASTRAX

Corby, United Kingdom

A

11-50 Employees

2005

Key takeaway

Fastrax specializes in manufacturing a diverse range of high-quality conveyor rollers, utilizing materials such as stainless steel and PVC, with diameters ranging from 20mm to 102mm. They emphasize customization, allowing for production tailored to specific widths and requirements, ensuring customer satisfaction and a focus on stringent quality standards throughout the manufacturing process.

Reference

Core business

Conveyor Rollers - Fastrax Conveyor Rollers

Airoll - Conveyor Rollers - www.airoll.in

India

D

11-50 Employees

2003

Key takeaway

Airoll is a leading supplier of conveyor rollers in India, emphasizing high-quality manufacturing for various industries. They are also the largest exporter of conveyor rollers to several countries, highlighting their expertise and commitment to enhancing organizational productivity through efficient conveyor systems.

Reference

Product

Conveyor Roller System Manufacturers/Suppliers in India | Airoll

ROLL-EZY LIMITED

United Kingdom

A

1-10 Employees

-

Key takeaway

Roll Ezy is a specialist in conveyor rollers, boasting over 20 years of manufacturing experience and a comprehensive range of quality products. They are ready to assist with any conveyor roller enquiry, offering everything from a single roller to larger quantities.

Reference

Core business

Home - Roll-Ezy Limited

Celebrating over 20 Years Experience in Rollers! DISCOVER MORE CONVEYOR ROLLER EXPERTS Welcome to Roll Ezy where we are experts in rollers for conveyors. We have been manufacturing conveyor rollers for over 20 years and supporting industry and suppliers with a comprehensive range of quality rollers which we manufacture at our purpose built facilities in […]

Rollers UK

Fenland District, United Kingdom

A

- Employees

-

Key takeaway

Mundell Engineering Limited, through its division Rollers UK, specializes in providing a wide range of conveyor rollers, including welded drums and polypropylene rollers, designed to meet diverse requirements. Additionally, they offer support products like side frames and brackets, ensuring comprehensive solutions for mechanical handling needs.

Reference

Core business

Leading Manufacturer in Bespoke Conveyor Rollers | Rollers UK

Rollers UK offer solutions to meet the requirements & variations that conveyor rollers bring. We also offer side frames,brackets and much more.

AED Rollers Ltd

Dudley, United Kingdom

A

11-50 Employees

1996

Key takeaway

AED Rollers specializes in designing and manufacturing high-quality conveyor rollers, ensuring a perfect fit for your conveyor system with quick lead times. Their commitment to advanced technology and quality materials since 1996 positions them as a reliable source for custom conveyor solutions.

Reference

Core business

Conveyor Rollers | Conveyors For Sale - AED Rollers

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Conveyor Roller

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Heavy-Duty Conveyor Roller

Mining, Ports, Boilers, SugarPowe, Steel, Mineral processing , Crushing & Screening

PECPL is India’s leading manufacturer of high-quality conveyor rollers, renowned for their exceptional durability and superior performance. With state-of-the-art, fully automatic production lines, PECPL delivers precision-engineered rollers designed to provide the highest service life, even in the most demanding conditions. Trusted across industries such as mining, construction, steel, cement, and ports, PECPL sets the benchmark for reliability, efficiency, and innovation in bulk material handling solutions. Our commitment to quality and customer satisfaction makes us the top choice for conveyor rollers in India.

Use case

Heavy-Duty Conveyor Roller

Mining, Ports, Boilers, SugarPowe, Steel, Mineral processing , Crushing & Screening

PECPL is India’s leading manufacturer of high-quality conveyor rollers, renowned for their exceptional durability and superior performance. With state-of-the-art, fully automatic production lines, PECPL delivers precision-engineered rollers designed to provide the highest service life, even in the most demanding conditions. Trusted across industries such as mining, construction, steel, cement, and ports, PECPL sets the benchmark for reliability, efficiency, and innovation in bulk material handling solutions. Our commitment to quality and customer satisfaction makes us the top choice for conveyor rollers in India.

A conveyor roller is a cylindrical component used in material handling systems to facilitate the movement of goods along a conveyor belt. These rollers are typically mounted horizontally and can be powered or gravity-driven, depending on the design of the conveyor system. They are essential for the smooth and efficient transport of items, reducing friction and wear on the conveyor belt. Conveyor rollers are available in various materials, such as steel, plastic, or rubber, and they come in different sizes and configurations to suit specific applications, including manufacturing, warehousing, and distribution centers.

A conveyor roller operates by providing a surface on which materials can move. The rollers are typically cylindrical and positioned in a series along a conveyor system. When items are placed on top of the rollers, gravity helps them slide down the incline or the motion of the conveyor belt drives them forward. The rollers are usually mounted on bearings, allowing them to spin freely and reduce friction. This design facilitates the smooth transportation of goods, making it easier to move heavy or bulky items across distances. Additionally, the spacing and diameter of the rollers can be adjusted based on the needs of the application, ensuring efficiency and reliability in material handling.

Conveyor rollers are primarily made from a few key materials that cater to specific applications and environments.

1. Steel

Steel is commonly used due to its strength and durability, making it ideal for heavy-duty applications. It can withstand significant loads and has a long lifespan, especially when coated with protective finishes to resist corrosion.

2. Plastic

Plastic rollers are lightweight and resistant to corrosion. They are often used in environments where moisture or chemicals are present, as they do not rust and are easier to maintain.

3. Aluminum

Aluminum offers a balance between weight and strength, making it suitable for applications where weight savings are important. It is also resistant to corrosion and provides a good aesthetic finish.

These materials ensure that conveyor rollers can effectively support various industrial processes while maintaining efficiency and longevity.

1. Steel Rollers

Steel rollers are commonly used in heavy-duty applications. They provide strength and durability, making them ideal for transporting heavy materials and handling abrasive products.

2. Plastic Rollers

Plastic rollers are lightweight and resistant to corrosion. They are suitable for environments where moisture or chemicals may be present, and they help reduce noise during operation.

3. Rubber Rollers

Rubber rollers offer excellent grip and shock absorption. They are often utilized in applications requiring a gentle handling of products, such as packaging and food processing.

4. Impact Rollers

Impact rollers are designed to withstand heavy loads and shock impacts. They are typically installed at points where materials are dropped onto the conveyor system, minimizing damage and wear.

5. Return Rollers

Return rollers support the return side of the conveyor belt. They help maintain belt alignment and reduce friction, thus enhancing the overall efficiency of the conveyor system.

1. Regular Inspection

Routine inspections are crucial for maintaining conveyor rollers. Check for signs of wear, damage, or misalignment. Ensure that the rollers rotate freely and do not exhibit excessive noise during operation.

2. Lubrication

Proper lubrication is essential for reducing friction and wear. Apply lubricant to bearings according to the manufacturer's recommendations. This helps to enhance performance and prolong the life of the rollers.

3. Cleaning

Keep the conveyor rollers clean from debris and contaminants. Accumulated dirt can affect the roller's performance and lead to premature failure. Use appropriate cleaning methods that do not damage the rollers.

4. Alignment

Ensure that the conveyor rollers are correctly aligned within the system. Misalignment can cause uneven wear and lead to operational issues. Adjust the alignment as needed to maintain optimal function.

5. Replacement

When a roller shows significant wear or damage, it may be time for replacement. Addressing issues promptly can prevent further damage to the conveyor system and maintain operational efficiency.

Some interesting numbers and facts about your company results for Conveyor Roller

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6233 |

| Amount of suitable service providers | 5490 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1986 |

| Youngest suiting company | 2013 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Conveyor Roller

What are related technologies to Conveyor Roller?

Based on our calculations related technologies to Conveyor Roller are Heat Exchangers, Hydraulic & Pneumatic Systems, Industrial Reactors, Industrial Packaging, Industrial Filters

Which industries are mostly working on Conveyor Roller?

The most represented industries which are working in Conveyor Roller are Other, Logistics, Supply Chain and Transportation, Manufacturing, Machinery Manufacturing, Automation

How does ensun find these Conveyor Roller Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.