The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Stable Drilling Fluids

Turkey

C

11-50 Employees

2016

Key takeaway

Stable Drilling Fluids is a prominent drilling fluids company in Turkey, boasting over 30 years of experience in the oil, gas, and geothermal industries. They specialize in providing high-quality API grade drilling fluids and mud consultancy, aimed at enhancing the safety and cost-effectiveness of the drilling process.

Reference

Service

Stable Drilling Fluids | Services

Professional Fluid Services LLC

United States

B

1-10 Employees

2003

Key takeaway

Professional Fluid Services specializes in innovative drilling fluids technology, having collaborated with operators and technology providers since 1999 to develop tailored solutions for various applications. Their commitment to advancing drilling fluid technologies positions them as a leader in the oil and gas industry.

Reference

Core business

Drilling Fluid | Professional Fluid Services, LLC.

Innovating drilling fluid technologies since 1999, Professional Fluid Services sets the standard throughout the oil and gas industry. Contact us today.

Global Drilling Fluids & Chemicals Limited

Faridabad, India

D

1-10 Employees

1990

Key takeaway

Global Drilling Fluids & Chemicals Limited (GDFCL) is a leading manufacturer of specialty drilling fluids and mud chemicals in India, supplying a diverse range of drilling fluids and additives. They also offer testing solutions for mud service companies and drilling contractors, ensuring high quality and safety standards across their production facilities.

Reference

Core business

Drilling Chemicals, Drilling Fluids, Oilfield Chemicals, Mud Chemicals, Cement Additive, Oil Drilling Fluids

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Drilling Fluid Solutions, L.L.C.

Rayne, United States

B

11-50 Employees

2014

Key takeaway

Drilling Fluid Solutions LLC is dedicated to exceeding safety, economic, and environmental requirements while effectively maintaining drilling fluid properties. Their commitment to proficient solids control operations and comprehensive reporting ensures that projects are managed safely and efficiently.

Reference

Core business

Home | Drilling Fluid Solutions

Drilling Fluid Solutions LLC was formed to provide our customers with the “Best in Class” Equipment and Personnel. Our goal is to exceed your safety, economic, and environmental requirements while maintaining drilling fluid properties effectively.

Global Drilling Fluids and Chemicals Limited

Faridabad, India

D

51-100 Employees

1988

Key takeaway

The company offers a comprehensive range of drilling fluids specifically designed for oil and gas wells, including mud chemicals and completion fluids. With fully automated, ISO-certified manufacturing facilities and a focus on quality and innovation, they ensure fast delivery and the ability to customize products to meet customer requirements.

Reference

Core business

Drilling Fluids,Drilling Mud Chemicals,Oil Drilling Chemicals

SINO MUD GROUP-Be A Better Mud Company

Puyang, China

D

51-100 Employees

1997

Key takeaway

The company aims to be a leading manufacturer of drilling fluids, offering a comprehensive range of products that enhance efficiency and reduce costs for drilling operations. Their SINO MUD products, including various polymers and lubricants, are designed to optimize drilling performance.

Reference

Product

Oil & Gas - Your One-stop Drilling Fluids Source

Drilling Fluids Technology

Booker, United States

B

11-50 Employees

1985

Key takeaway

DFT offers specialized drilling fluids technology, emphasizing strong technical expertise and a comprehensive range of products and services designed to meet customer needs. They prioritize safety and cost-effective application techniques, ensuring compliance with strict safety standards.

Reference

Service

Services – Drilling Fluids Technology

A1 Drilling Fluids

United States

B

11-50 Employees

2007

Key takeaway

A1 Drilling Fluids focuses on leveraging innovative technologies and data analytics to enhance drilling performance while reducing costs and environmental impacts, making it well-equipped to service various producing basins.

Reference

Product

Products – A1 Drilling Fluids, Inc.

The Fluids Specialists

Malaysia

C

1-10 Employees

2017

Key takeaway

TFS, The Fluids Specialists, specializes in optimizing the performance of drilling fluids and related services, offering a comprehensive range of technical and business management services throughout a project's lifecycle. With a focus on enhancing both technical and commercial performance, TFS ensures that drilling fluids are effectively managed to align with project goals and deliver maximum value.

Reference

Core business

Home template - The Fluids Specialists

Citadel Energy Resources Limited

Port-Harcourt, Nigeria

E

11-50 Employees

2012

Key takeaway

The company specializes in drilling and completion fluids, offering laboratory services, technical consulting, and field support, all of which are essential for effective drilling operations. They emphasize innovation and technical expertise, providing a wide range of products and services tailored to the oil and gas industry.

Reference

Core business

Citadel Mud School™

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

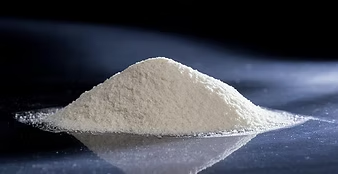

Texan Xanthan Gum

Go to product

Drilling fluids, also known as drilling muds, are specialized liquids used in the drilling process of boreholes to extract oil and gas. These fluids serve multiple critical functions, including cooling and lubricating the drill bit, transporting cuttings to the surface, and maintaining wellbore stability. Typically, drilling fluids can be classified into two main categories: water-based and oil-based fluids. Water-based drilling fluids consist primarily of water mixed with various additives, while oil-based fluids use oil as a base, providing better lubrication and stability in certain geological conditions. The selection of drilling fluids is crucial, as it directly impacts the efficiency and safety of the drilling operation.

Drilling fluids play a crucial role in enhancing drilling efficiency by performing multiple functions that facilitate the drilling process. First, they help in cooling and lubricating the drill bit, which reduces wear and tear and allows for smoother drilling operations. This leads to increased penetration rates and decreased overall drilling time. Additionally, drilling fluids provide hydrostatic pressure to counteract the formation pressure, preventing blowouts and ensuring a safer working environment. They also aid in transporting cuttings from the borehole to the surface, which keeps the wellbore clear and minimizes the risk of stuck pipe incidents. By optimizing these aspects, drilling fluids significantly improve operational efficiency and reduce costs associated with drilling activities.

The environmental impacts of drilling fluids can be significant if not managed properly. These fluids, used in the drilling process to lubricate and cool the drill bit, can contain various chemicals that may pose risks to ecosystems. When drilling fluids are improperly disposed of, they can contaminate soil and groundwater, leading to potential harm to plant and animal life. Moreover, spills or leaks during drilling operations can result in the release of harmful substances into surrounding environments, affecting aquatic ecosystems and terrestrial habitats. The choice of drilling fluids, therefore, is crucial, with biodegradable and non-toxic options increasingly being favored to minimize ecological impact. Implementing proper waste management and treatment practices can help mitigate these environmental risks.

1. Water-Based Fluids

These fluids primarily consist of water as the base, mixed with various additives to enhance performance and control properties. They are widely used due to their environmental friendliness and cost-effectiveness, making them suitable for many drilling applications.

2. Oil-Based Fluids

Utilizing oil or synthetic oil as the base, these fluids offer excellent lubrication, stability, and wellbore support. They are particularly effective in high-temperature and high-pressure environments, although they are more costly and may pose environmental concerns.

3. Synthetic-Based Fluids

These fluids are formulated from synthetic oils, providing a balance between the advantages of oil-based and water-based fluids. They deliver superior performance with lower environmental impact, making them increasingly popular in complex drilling operations.

4. Foam-Based Fluids

Foam-based drilling fluids consist of gas and liquid, creating a stable foam. They are effective in reducing hydrostatic pressure and enhancing drilling efficiency, particularly in challenging geological formations.

The performance of drilling fluids is measured through several key parameters. Viscosity is a critical factor, as it influences the fluid's ability to carry cuttings to the surface. A higher viscosity can indicate better lifting capacity but may also lead to increased pressure losses. Another important metric is density, which must be carefully controlled to prevent wellbore instability and to counteract formation pressures. Additionally, the fluid's filtration properties are assessed to determine how well it can form a filter cake, thus minimizing fluid loss into the formation. Finally, the stability and compatibility of the drilling fluid with the geological formations being drilled play a significant role in its overall performance, affecting both efficiency and safety during drilling operations.

Some interesting numbers and facts about your company results for Drilling Fluids

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1985 |

| Youngest suiting company | 2017 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Drilling Fluids

What are related technologies to Drilling Fluids?

Based on our calculations related technologies to Drilling Fluids are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Which industries are mostly working on Drilling Fluids?

The most represented industries which are working in Drilling Fluids are Oil, Energy and Gas, Other, Construction, Manufacturing, Environment, Disposal and Recycling

How does ensun find these Drilling Fluids Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.