The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

ZHAOHAN VACUUM PUMP CO.LTD

Zibo, China

D

51-100 Employees

1998

Key takeaway

Zibo Zhaohan Vacuum Pump Co., Ltd. specializes in providing liquid ring vacuum pumps and complete vacuum systems, making them a reliable choice for various demanding process applications across multiple industries. They also offer replacement pumps for well-known brands, ensuring compatibility and performance for OEMs and engineering contractors.

Reference

Core business

Liquid Ring Vacuum Pump, Vacuum Compressor Manufacturers, Suppliers - Zibo Zhaohan Vacuum Pump Co.,Ltd

Zibo Zhaohan Vacuum Pump Co.,Ltd offer liquid ring vacuum pumps and complete vacuum systems as reliable solution for most demanding process, for OEM and Engineering-Contractors.

Plant Equipment

Bangkok, Thailand

C

11-50 Employees

-

Key takeaway

Plant Equipment specializes in providing solutions for various industrial products, including Liquid Ring Vacuum Pumps. With a dedicated team of engineers and a focus on quality and customer service, they ensure effective and reliable vacuum pump solutions.

Reference

Product

Liquid Ring Vacuum Pumps - Plant Equipment

DEVELOPMENT VACUUM EQUIPMENT CO. LTD

Taizhou, China

D

51-100 Employees

2000

Key takeaway

The company specializes in manufacturing water (liquid) ring vacuum pumps, highlighting their expertise and capability to develop custom products for various applications in industries such as pharmaceuticals, chemical, and aerospace.

Reference

Product

Water (Liquid) Ring Vacuum Pumps Manufacturers, Suppliers

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Process Vacuum

Midvaal Local Municipality, South Africa

C

11-50 Employees

-

Key takeaway

Process Vacuum specializes in manufacturing high-quality conical ported liquid ring vacuum pumps and has a strong commitment to maintaining ISO 9001:2015 standards. Their liquid ring vacuum pumps are designed to operate at vacuum levels up to 33-44 mbara, offering high reliability and efficiency, especially for gas mixtures containing condensable vapors.

Reference

Product

Liquid Ring Vacuum Pumps - Process Vacuum

Liquid ring vacuum pumps are used for operating vacuum levels up to 33-44 mbara, depending on liquid ring temperature. Moreover, it is fairly cheap. They provide high reliability because of their simplicity. These types of pumps are normally used to handle gas mixtures which contain condensable vapors. When the vacuum pump impeller rotates, the centraputal

Zepher UK Ltd

Stoke-on-Trent, United Kingdom

A

11-50 Employees

2001

Key takeaway

The company specializes in the supply and repair of Liquid Ring Vacuum Pumps, highlighting their long life, high reliability, and efficiency. With a commitment to quality and competitive pricing, they serve various industries, ensuring customers have access to top-tier vacuum pump products and support.

Reference

Product

Liquid Ring | Zepher UK

VN-Pumpen GmbH & CO. KG

Bremen, Germany

A

1-10 Employees

1968

Key takeaway

The company specializes in providing customized pumping solutions, including Liquid Ring Vacuum Pumps. With a strong engineering background and partnerships with leading manufacturers, they offer a wide selection of pump types and end-to-end services.

Reference

Product

Centrifugal Pumps | Vacuum Pump

AVTPUMP LIMITED

-

11-50 Employees

2003

Key takeaway

AVTPUMP specializes in the supply, service, and repair of liquid ring vacuum pumps, offering high-quality support and maintenance to ensure optimal performance. Their team of trained engineers provides 24/7 technical assistance and pump upgrades, making them a reliable partner for various industry sectors.

Reference

Product

Liquid Ring Pumps | AVTPUMP - Supply, Service and Repair

Zorn Compressor & Equipment (Industrial Compressed Air Solutions)

City of Pewaukee, United States

B

51-100 Employees

1965

Key takeaway

Zorn Compressor & Equipment specializes in distributing a wide variety of compressed air equipment, including liquid ring vacuum pumps. They offer sales, rentals, and repair services for this type of equipment, making them a valuable resource for those in need of vacuum pump solutions.

Reference

Product

Liquid Ring Vacuum Pump Equipment | Zorn Compressor & Equipment

Vacuum pump supplier & distributor. Explore our vacuum pumps, including liquid ring vacuum pumps. Contact us to buy, rent, or repair equipment today.

Flowserve

Irving, United States

B

10001+ Employees

1997

Key takeaway

Flowserve specializes in fluid motion control solutions and has enhanced its portfolio by acquiring SIHI Group, which adds vacuum and fluid pump capabilities, including liquid ring vacuum pumps.

Reference

Product

Industrial Liquid Ring Vacuum Pumps Products | Flowserve

Edwards Vacuum

Crawley, United Kingdom

A

1001-5000 Employees

1919

Key takeaway

Edwards is a global leader in vacuum and abatement solutions, offering innovative Liquid Ring Vacuum Pumps that provide optimum performance and maximum uptime.

Reference

Product

Liquid Ring Pumps - Edwards Vacuum

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

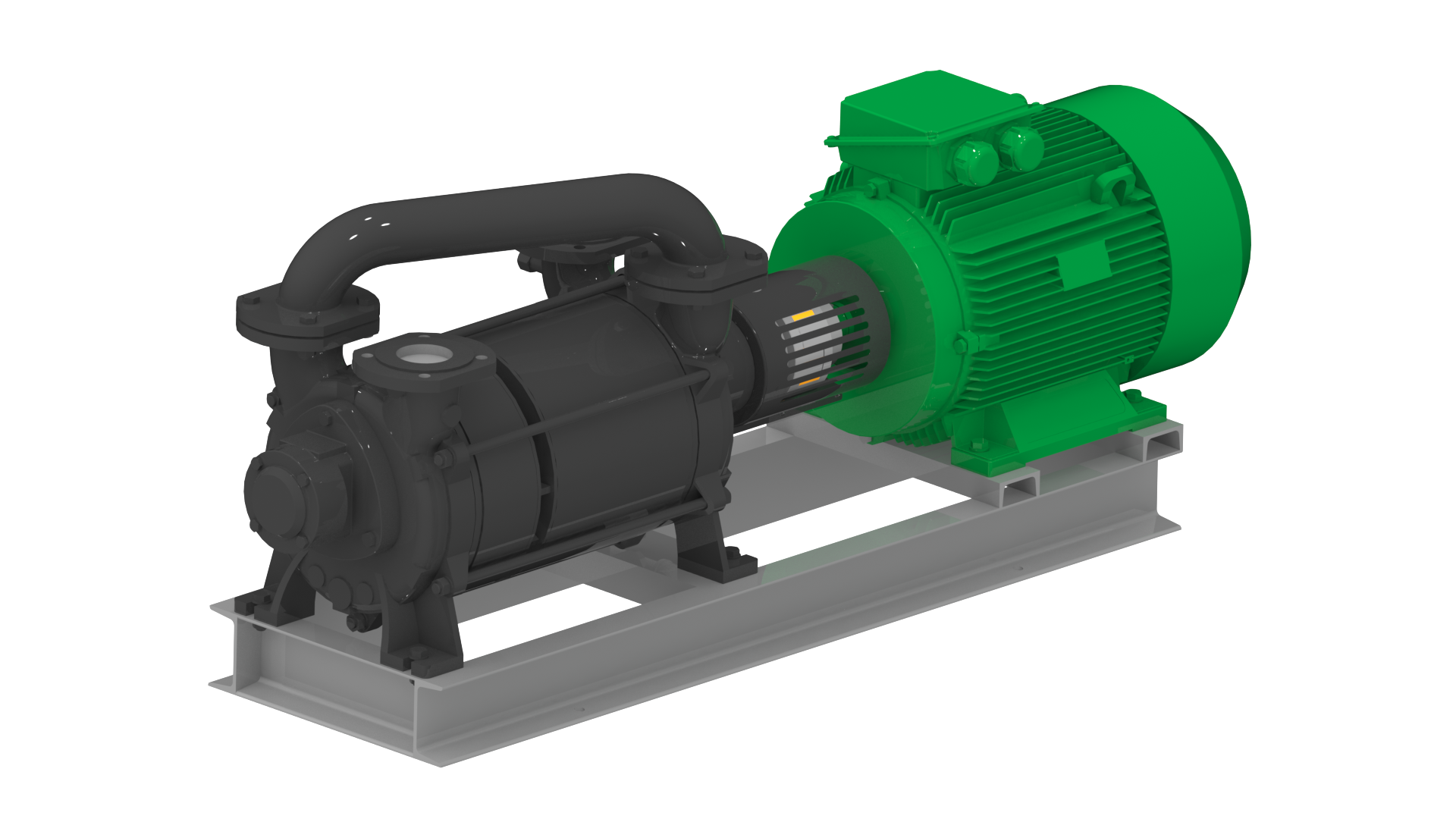

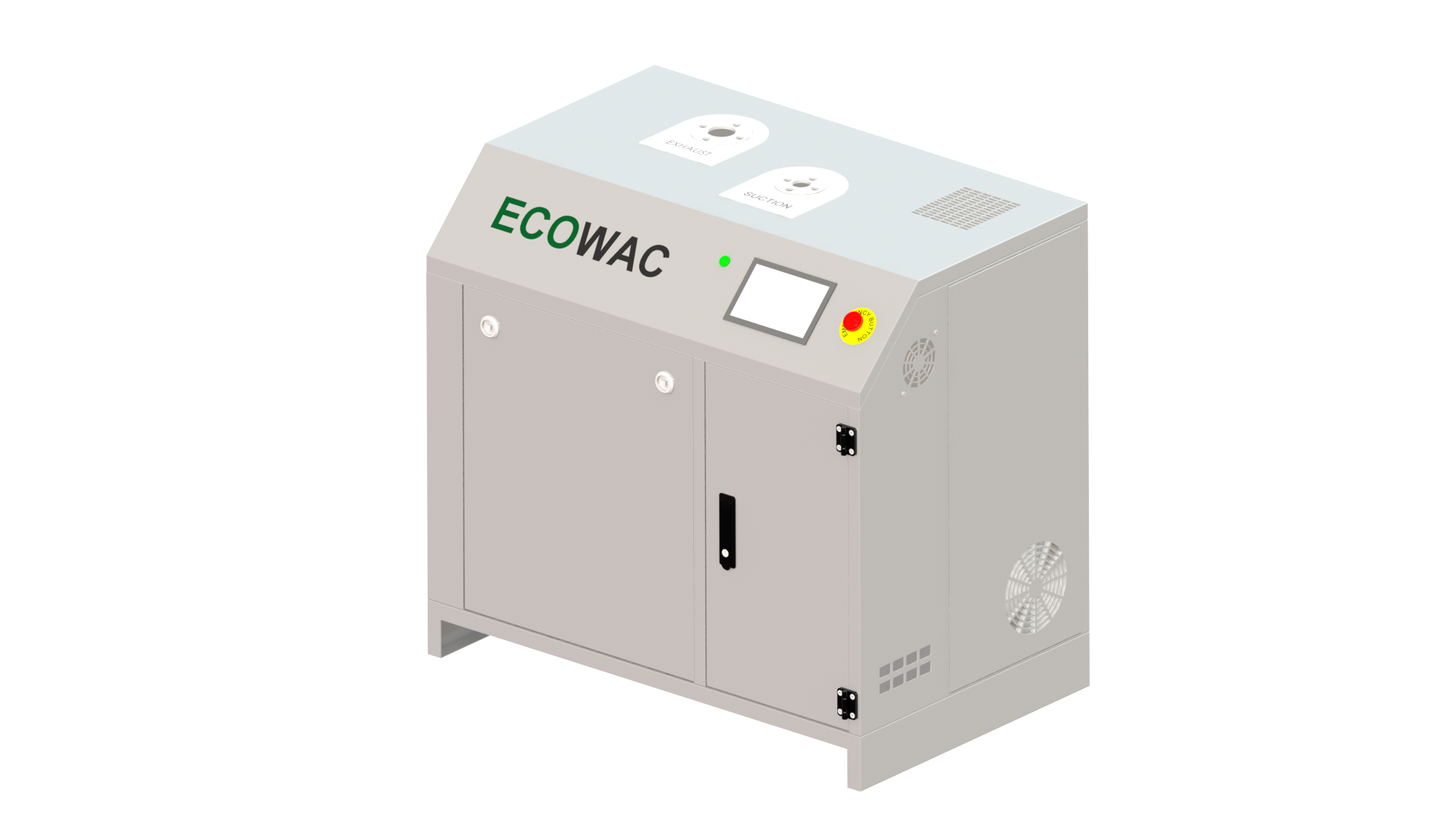

ECOWAC Liquid Ring Vacuum Solutions

Go to product

Product

Booster System

Go to product

Product

AI-Powered Smart Vacuum Pump Units

Go to product

Product

Monoblock vacuum pump

Go to product

A liquid ring vacuum pump is a type of positive displacement pump that utilizes a liquid, typically water or oil, to create a vacuum. The pump operates by rotating an impeller inside a cylindrical casing, which causes the liquid to form a ring along the inner wall of the casing. As the impeller spins, it traps a volume of gas between the blades and the liquid ring. This action compresses the gas and displaces it toward the discharge port, effectively generating a vacuum in the process. These pumps are known for their durability and ability to handle wet or corrosive gases, making them suitable for various industrial applications. They are especially effective in processes where a continuous flow of gas is required, such as in the chemical and petrochemical industries. The simplicity of their design allows for easy maintenance, and the ability to use different liquids makes them versatile for different operational environments.

A Liquid Ring Vacuum Pump operates by creating a vacuum through the use of a rotating impeller that generates a liquid ring. As the impeller spins, it draws in liquid, typically water or oil, which forms a ring along the inner wall of the pump casing. This liquid ring creates a series of pockets that fluctuate in volume as the impeller rotates. The process starts when gas enters the pump, filling the expanding pockets formed by the rotating liquid ring. As the impeller continues to turn, these pockets reduce in volume, compressing the gas and forcing it out of the discharge port. The continuous circulation of the liquid maintains the vacuum and ensures efficient gas removal, making this type of pump ideal for various industrial applications where a reliable vacuum is essential.

Liquid Ring Vacuum Pumps are widely used across various industries due to their efficient operation and ability to handle wet and corrosive gases.

1. Chemical Processing

These pumps are essential in the chemical industry for applications such as distillation, evaporation, and drying processes, where maintaining a vacuum is crucial for product quality and efficiency.

2. Food and Beverage Industry

In the food sector, Liquid Ring Vacuum Pumps are utilized for packaging, freeze-drying, and in processes that require the removal of air without altering the product's integrity.

3. Pharmaceutical Manufacturing

These pumps play a vital role in the pharmaceutical industry, particularly in processes that require precise vacuum levels for drying and concentration of active ingredients.

4. Wastewater Treatment

In wastewater treatment facilities, Liquid Ring Vacuum Pumps are employed to create a vacuum for conveying sludge and other materials, making the process more efficient and effective.

5. Pulp and Paper Industry

They are also used in the pulp and paper industry for applications such as dewatering and drying, helping to enhance productivity and reduce energy consumption.

1. Efficient Operation

Liquid ring vacuum pumps operate efficiently across a wide range of pressures. They can handle varying flow rates while maintaining consistent performance, making them suitable for diverse industrial applications.

2. Low Maintenance Requirements

These pumps have fewer moving parts compared to other types of vacuum pumps, which translates to reduced maintenance needs. The simple design allows for easy servicing and less downtime in industrial processes.

3. Compatibility with Vapors and Liquids

Liquid ring vacuum pumps can effectively handle both vapors and liquids without risk of damage. This versatility is essential for applications in industries such as food processing, pharmaceuticals, and chemical manufacturing.

4. Environmentally Friendly

They operate using a liquid (usually water) as the working medium, which minimizes the emission of harmful gases. This feature makes them a more environmentally friendly option compared to other vacuum systems.

5. Stable Vacuum Levels

These pumps provide stable vacuum levels, which is crucial for processes that require consistent pressure. This stability helps improve product quality and efficiency in manufacturing operations.

1. Regular Inspection

Routine inspections are crucial for identifying potential issues early. Check the pump for leaks, unusual noises, or vibrations. Ensuring that the seals and gaskets are intact will prevent loss of vacuum and reduce operational inefficiencies.

2. Fluid Management

Maintaining the proper fluid level is vital for optimal operation. Regularly check the liquid ring fluid for contamination and replace it as needed. Monitoring the temperature of the fluid can also help in preventing overheating and ensuring efficiency.

3. Cleaning and Maintenance

Periodically clean the pump components to remove any build-up of debris or contaminants. This includes the impeller and casing. Following the manufacturer's guidelines for maintenance schedules will extend the lifespan of the pump and enhance its performance.

4. Bearing Lubrication

Ensure that the bearings are properly lubricated to minimize friction and wear. Using the recommended lubricant and maintaining appropriate lubrication intervals will help keep the pump running smoothly.

5. Monitor Performance

Regularly monitor the performance metrics of the pump, such as the vacuum level and energy consumption. Any significant deviations from normal operational parameters should be investigated promptly to avoid further issues.

Some interesting numbers and facts about your company results for Liquid Ring Vacuum Pump

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6537 |

| Amount of suitable service providers | 4965 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1919 |

| Youngest suiting company | 2003 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Liquid Ring Vacuum Pump

What are related technologies to Liquid Ring Vacuum Pump?

Based on our calculations related technologies to Liquid Ring Vacuum Pump are Heat Exchangers, Hydraulic & Pneumatic Systems, Industrial Reactors, Industrial Packaging, Industrial Filters

Which industries are mostly working on Liquid Ring Vacuum Pump?

The most represented industries which are working in Liquid Ring Vacuum Pump are Manufacturing, Machinery Manufacturing, Other, Oil, Energy and Gas, Automation

How does ensun find these Liquid Ring Vacuum Pump Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.