The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Padmini Engineering Private Limited

Gurugram, India

D

1-10 Employees

-

Key takeaway

The company, PVNA, specializes in sustainable automotive components and has a focus on emission reduction technologies, including vacuum pumps.

Reference

Product

Vacuum Pump

Vacuum and Pressure Ltd

Leeds, United Kingdom

A

11-50 Employees

2010

Key takeaway

The company is the exclusive UK partner for PVR Vacuum, offering a wide range of high-quality vacuum pumps, including rotary vane, claw, and diaphragm pumps, as well as comprehensive support and spare parts. With over 100 years of combined engineering experience, they provide expert solutions for various industrial applications.

Reference

Product

PVR PHV10K Oil Lubricated Rotary Vane Vacuum Pump | Vacuum-Pump.co.uk

PVR PHV 10 K Oil Lubricated Rotary Vane Vacuum PumpAvailable with various motor options.Suitable for a multitude of industrial applications.Datasheet, dimensions and parts diagram available upon request.***PLEASE CALL 0113 318 9391 OR EMAIL TO ORDER***We stock a range of spare parts to suit this machine, including (where applicable) air filters, oil separators, exhaust filters, vanes, gaskets, seals, silencers, valves, couplings and bearings. We also provide on-site servicing, overhauls/repairs and rental pumps for breakdown support. We will get you back up and running, contact us to discuss your requirements.PVR Vacuum Design s.r.l. / Valmadrera 23868 Italy / Rotant / Agilent.

Vacuum Pump Support Services

United Kingdom

A

1-10 Employees

-

Key takeaway

Vacuum Pump Support Services is recognized for its cost-effective repair solutions for vacuum pumps, allowing clients to avoid scrapping old units. They offer expert advice and a comprehensive range of services, including servicing, repairing, and providing refurbished vacuum pumps and accessories.

Reference

Service

Services – Vacuum Pump Support Services Ltd

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

AIRBEST VACUUM TECHNOLOGY

Huzhou, China

D

51-100 Employees

2006

Key takeaway

AIRBEST specializes in the R&D, production, and sales of vacuum grabbing products, including vacuum pumps. Their extensive product line and innovative solutions cater to various industries, highlighting their expertise in vacuum technology.

Reference

Product

Vacuum Pumps-Airbest

Eurovacuum Products

Wychavon, United Kingdom

A

- Employees

-

Key takeaway

Eurovacuum Products is a prominent supplier of various vacuum pumps and low-pressure compressors, emphasizing quality and reliability. They offer fast delivery, comprehensive spare parts, and dedicated service and maintenance for optimal pump performance.

Reference

Core business

Eurovacuum Products – Vacuum pump and blower supplier, repairer and service provider

Vacuum Pump Spares Ltd

Sandwell, United Kingdom

A

1-10 Employees

1985

Key takeaway

With over 32 years of experience in the vacuum industry, the company offers a comprehensive inventory of industrial vacuum pump spare parts, ensuring quick and efficient service to meet customer demands. Their expertise and extensive stock enable them to address various needs related to vacuum pumps effectively.

Reference

Product

Products – Vacuum Pump Spares

SaroVee Corporation Inc

India

D

1-10 Employees

-

Key takeaway

The company specializes in industrial vacuum pumps and their components, offering a range of products including rotary vane and dry vacuum pumps, as well as vacuum pump oils and filters. They represent TenMat and provide innovative, energy-efficient solutions and accessories for various branded vacuum pumps.

Reference

Core business

ABOUT US

VACPRO - Vacuum Process Solutions

Aarhus, Denmark

A

11-50 Employees

2005

Key takeaway

VACPRO specializes in the supply and repair of vacuum pumps and related equipment, offering extensive technical knowledge and experience in vacuum processes. They provide services for various brands, including Edwards Vacuum and Vacuubrand, ensuring comprehensive support for vacuum pump maintenance and repair.

Reference

Service

Vacuum Pump Repair & Service | Vacuum Pump Solutions

We provide vacuum pump repair & service for Edwards Vacuum, Vacuubrand & more brands. From pump maintenance to leak detection, we do it all. Book today!

Vacuum Pump Supply LLC

Nazareth, United States

B

1-10 Employees

2009

Key takeaway

Vacuum Pump and Lab Supply is a leading provider of high-quality vacuum pumps and laboratory equipment, offering a wide inventory that includes remanufactured pumps to OEM specifications at competitive prices.

Reference

Core business

Vacuum Pump Supply Llc, Your Complete Source

VACAIR SUPERSTORE LIMITED

Leeds, United Kingdom

A

1-10 Employees

-

Key takeaway

VacAir Superstore is a prominent independent supplier of vacuum pumps, offering a diverse range of both original and replacement spare parts from major manufacturers. They provide various types of vacuum pumps, including their own cost-effective models, and emphasize rapid delivery and extensive expertise in the field.

Reference

Core business

Home | Vacair Superstore | Vacuum Pumps | Leeds | UK

Vacair Superstore are the largest independant supplier of vacuum pumps, pump vanes and spare parts in the UK. We have an international supply chain for 1000's of items.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

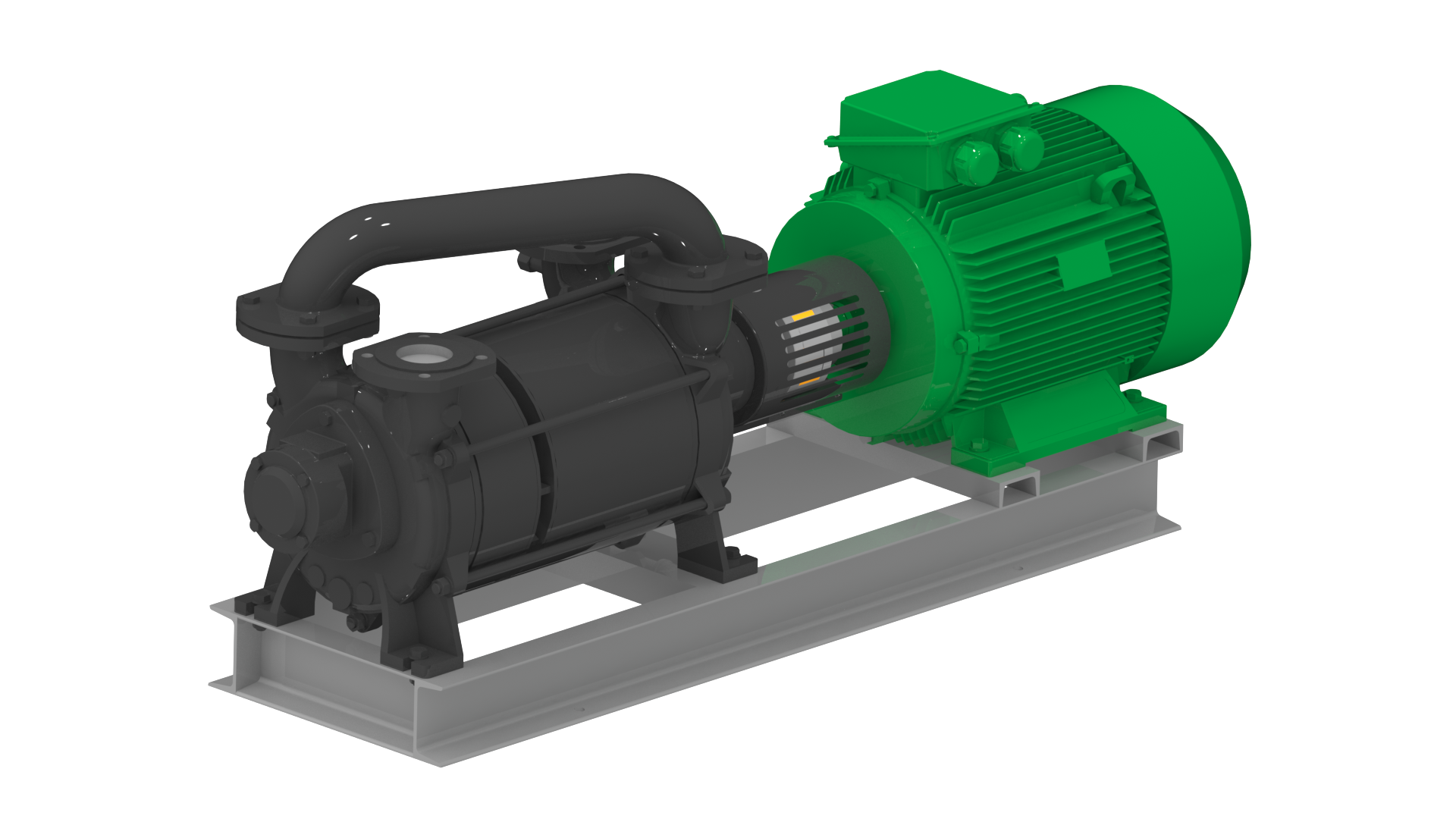

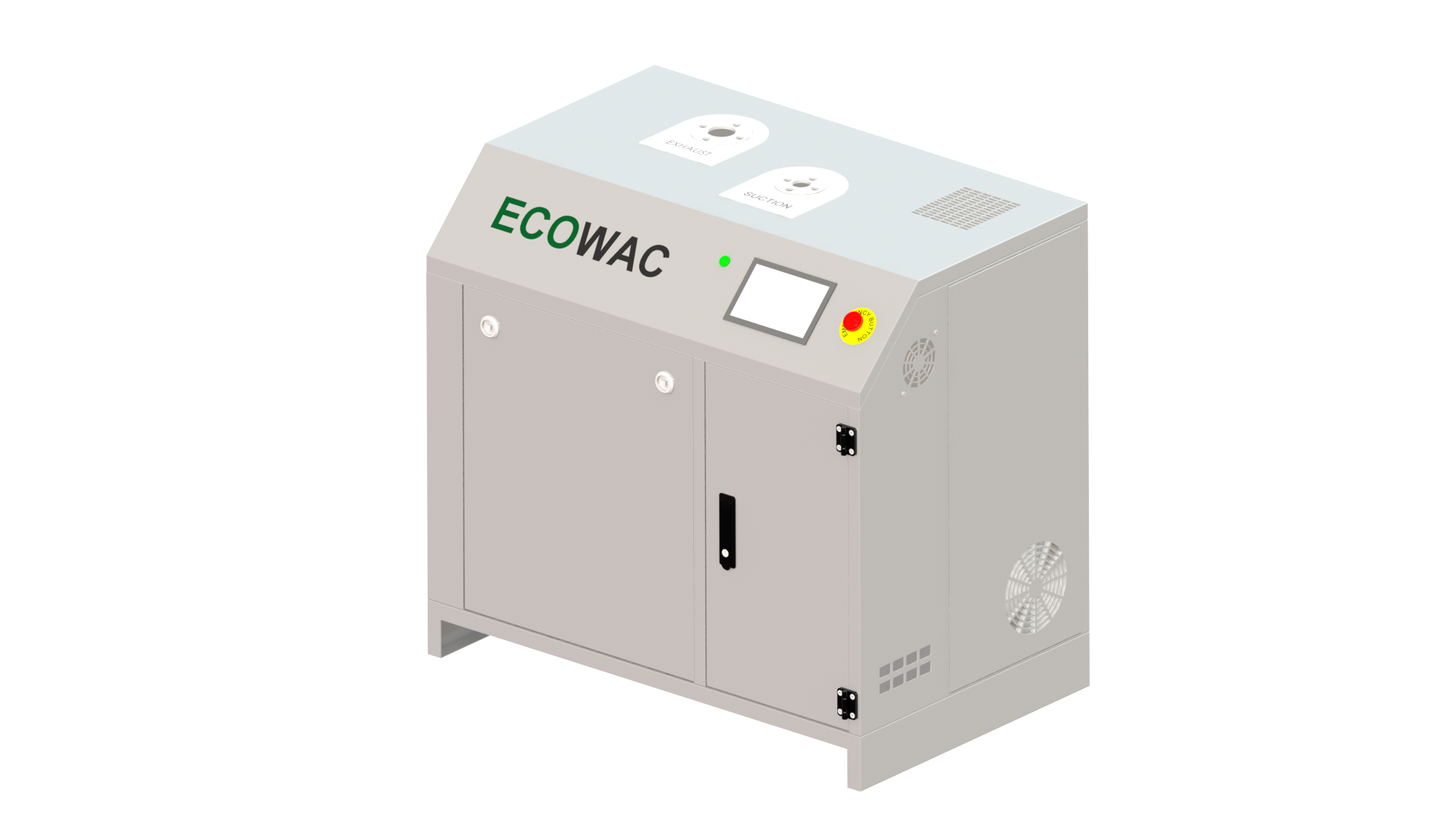

ECOWAC Liquid Ring Vacuum Solutions

Go to product

Product

Oil-Lubricated Rotary Vane Vacuum Pumps

Go to product

Product

Booster System

Go to product

Product

AI-Powered Smart Vacuum Pump Units

Go to product

A vacuum pump is a device that removes gas molecules from a sealed volume to create a vacuum. It functions by pulling air and other gases out of a space, thus lowering the pressure inside. These pumps are essential in various applications, including scientific research, manufacturing processes, and medical equipment. Different types of vacuum pumps, such as rotary vane, diaphragm, and scroll pumps, offer specific advantages for various applications. Each type operates based on different principles, making them suitable for tasks ranging from laboratory experiments to industrial processes.

A vacuum pump operates by removing air and other gases from a sealed chamber, creating a vacuum. It typically uses mechanical means to decrease the pressure within that space. As the pump runs, it captures gas molecules and draws them out, either through a piston or rotary mechanism, depending on the type of pump. The process involves two main phases: Evacuation and Compression. During evacuation, gas is drawn into the pump and transported to a collection area. In the compression phase, the gas is either expelled or compressed for storage. This continual cycle lowers the pressure inside the chamber, allowing for various applications such as enhancing chemical reactions, preserving food, or facilitating manufacturing processes.

1. Positive Displacement Pumps

These pumps operate by trapping a fixed volume of gas and then forcing it out of the system, creating a vacuum. Common examples include rotary vane and diaphragm pumps.

2. Kinetic Pumps

Kinetic vacuum pumps, such as turbo molecular and diffusion pumps, rely on high-speed rotating blades to impart momentum to gas molecules, effectively reducing pressure within the system.

3. Entrapment Pumps

These pumps capture gas molecules and hold them within a solid or liquid medium. Examples include cryopumps and getter pumps, which are often used in ultra-high vacuum applications.

4. Chemical Pumps

Chemical vacuum pumps utilize chemical reactions to remove gases from a system. They are commonly used in processes where specific gases need to be eliminated.

5. Diffusion Pumps

Diffusion pumps use a high-speed jet of vaporized oil to direct gas molecules towards the exit, creating a vacuum. They are effective for achieving high and ultra-high vacuum levels.

1. Industrial Manufacturing

Vacuum pumps are widely used in industrial manufacturing processes, such as in the production of semiconductors, where they create a vacuum environment necessary for various fabrication steps.

2. Food Packaging

In the food industry, vacuum pumps play a critical role in packaging, preserving, and extending the shelf life of products by removing air from packaging to inhibit microbial growth.

3. Medical Applications

These pumps are essential in the medical field for equipment like suction devices, where they help in the removal of fluids and gases during surgical procedures and other medical applications.

4. Laboratory Research

Laboratories utilize vacuum pumps for various experiments, including distillation and filtration processes, allowing for the efficient removal of air and volatile substances from samples.

5. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, vacuum pumps are employed to evacuate air and moisture from refrigeration systems, ensuring optimal performance and efficiency.

When selecting a vacuum pump, several factors play a crucial role in ensuring optimal performance and reliability.

1. Application Requirements

Understanding the specific application for which the vacuum pump will be used is essential. Different processes, such as laboratory work, industrial applications, or food packaging, may require distinct types of vacuum pumps that operate under varying pressure ranges and capacities.

2. Pump Type

The choice between different types of vacuum pumps, such as rotary vane, diaphragm, or scroll pumps, significantly impacts efficiency and maintenance needs. Each type has its advantages and limitations based on the intended use and the level of vacuum required.

3. Performance Specifications

Consider the pump's ultimate vacuum level, pumping speed, and flow rate. These specifications determine how effectively the pump can achieve and maintain the desired vacuum level in the system.

4. Maintenance and Service

Evaluate the maintenance requirements and availability of service support for the vacuum pump. A pump with easy access to parts and a straightforward maintenance routine can lead to lower downtime and operational costs.

5. Energy Efficiency

Energy consumption is another significant factor. Selecting a vacuum pump that operates efficiently can reduce operational costs and environmental impact.

6. Budget

Lastly, the initial purchase price and ongoing operational costs should align with your budget without compromising on quality and performance. Investing in a reliable vacuum pump can lead to better long-term savings.

Some interesting numbers and facts about your company results for Vacuum Pump

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 5334 |

| Amount of suitable service providers | 4324 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 1985 |

| Youngest suiting company | 2010 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Vacuum Pump

What are related technologies to Vacuum Pump?

Based on our calculations related technologies to Vacuum Pump are Heat Exchangers, Hydraulic & Pneumatic Systems, Industrial Reactors, Industrial Packaging, Industrial Filters

Which industries are mostly working on Vacuum Pump?

The most represented industries which are working in Vacuum Pump are Manufacturing, Machinery Manufacturing, Other, Oil, Energy and Gas, Automation

How does ensun find these Vacuum Pump Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.