The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Vacuum and Pressure Ltd

Leeds, United Kingdom

A

11-50 Employees

2010

Key takeaway

The company is the exclusive UK partner for PVR Vacuum, offering a wide range of vacuum pumps, including rotary vane pumps. With over 100 years of combined engineering experience, they provide solutions and support for various industrial applications.

Reference

Product

DVP LC 205 KZERO Oil Lubricated Rotary Vane Vacuum Pump | Vacuum-Pump.co.uk

DVP LC205 KZERO Oil Lubricated Rotary Vane Vacuum PumpAvailable with various motor options.Suitable for a multitude of industrial applications.Datasheet, dimensions and parts diagram available upon request.***PLEASE CALL 0113 318 9391 OR EMAIL TO ORDER***We stock a range of spare parts to suit this machine, including (where applicable) air filters, oil separators, exhaust filters, vanes, gaskets, seals, silencers, valves, couplings and bearings. We also provide on-site servicing, overhauls/repairs and rental pumps for breakdown support. We will get you back up and running, contact us to discuss your requirements.D.V.P Vacuum Technology / Bologna 40018 Italy.

DEVELOPMENT VACUUM EQUIPMENT CO. LTD

Taizhou, China

D

51-100 Employees

2000

Key takeaway

The company offers a range of vacuum pumps, including rotary piston vacuum pumps, which are essential in various applications like vacuum coating and metallurgy. They emphasize their strong R&D capabilities, allowing for the development of custom solutions based on customer specifications.

Reference

Product

Custom Oil Diffusion Vacuum Pumps Manufacturers, Suppliers

COOLINK Vacuum Equipment Co.Ltd.

Taizhou, China

D

51-100 Employees

2007

Key takeaway

The company, Coolink, is a leading manufacturer of HVAC refrigeration vacuum pumps, emphasizing their extensive experience and commitment to innovation and quality since 2007. They offer a range of superior vacuum pumps, including oil-sealed rotary piston models, which may be relevant to your interest in dry, oilless vacuum pumps.

Reference

Product

Industrial Oil-Sealed Rotary Piston Vacuum Pump | COOLINK

Professional, Cost-effective and High Performance Oil Sealed Rotary Piston Vacuum Pump H-150G for Harsh Industrial Applications

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Oxytec Solutions Inc.

Cebu City, Philippines

D

11-50 Employees

2017

Key takeaway

Oxytec Solutions specializes in medical gas pipeline systems and onsite oxygen generator systems, highlighting their expertise in industrial instrumentation and medical devices. They provide a range of high-performing products, including suction and oxygen therapy solutions.

Reference

Product

medgas-oilless-rotary-claw-vacuum -

Fluid Technology

Lakewood, United States

B

11-50 Employees

1978

Key takeaway

Airtech's dry rotary vane vacuum pumps eliminate the need for oil and are virtually maintenance-free, making them a leading choice for dry oilless vacuum solutions.

Reference

Product

Dry Rotary Vane Pumps – fluid-technology

Airtech's dry rotary vane pumps eliminate the need for oil and are virtually maintenance free. Learn more about Airtech's ORION series pumps & request a quote today.

Conquest Inc

Gardnerville, United States

B

1-10 Employees

1992

Key takeaway

The company positions itself as a leading source for various vacuum pump oils, indicating a strong expertise in this area.

Reference

Core business

Conquest West – WE ARE YOUR BEST SOURCE FOR ALL YOUR VACUUM PUMP OIL NEEDS

Ash Air

Upper Harbour, New Zealand

A

51-100 Employees

1979

Key takeaway

The company specializes in vacuum pumps and offers a range of dry rotary vane pumps, which are robust, affordable, and easy to maintain. Their products are designed for various applications, including skin packaging and thermoforming, highlighting their expertise in energy-efficient, oil-free vacuum solutions.

Reference

Product

Ash Air - Vacuum Pumps - Rotary Vane Pumps

Dry and oil-sealed vane vacuum pumps are robust, affordable and easy in maintenance. You can use DVP vane pumps for wide range of application, for skin packaging, holding, lifting, thermoforming.

Trillium US

United States

B

101-250 Employees

2002

Key takeaway

Trillium specializes in dry vacuum pumps, offering a range of products and services that include dry, rotary piston, and turbo pumps, which are particularly beneficial in applications like semiconductor manufacturing. With decades of expertise and an ISO 9001 certified quality system, Trillium ensures high-quality solutions to meet specific business needs.

Reference

Product

Dry Pumps – Trillium

First introduced in the early 1980s, dry vacuum pumps have gradually supplanted oil sealed rotary vane and rotary piston pumps in a number of applications, but most prevalently in semiconductor manufacturing. The oil free pumping mechanism of a dry pump provides benefits both to the inherent vacuum process, but also in terms of waste stream …

AIRBEST VACUUM TECHNOLOGY

Huzhou, China

D

51-100 Employees

2006

Key takeaway

AIRBEST specializes in the R&D, production, and sales of vacuum grabbing products, which may include dry oilless vacuum pumps within their extensive range of over 3000 SKUs. Their innovative solutions cater to various industries, highlighting their commitment to quality and customer-specific needs.

Reference

Product

Vacuum Pumps-Airbest

DVP Pumps UK

Leeds, United Kingdom

A

1-10 Employees

-

Key takeaway

DVP Vacuum Technology specializes in manufacturing vacuum pumps, including the LC40 and LC60 models, which feature a compact design and low noise levels. These lubricated rotary vane vacuum pumps are designed to prevent oil vapors at the outlet and ensure efficient operation, making them suitable for various industrial applications.

Reference

Product

LC40 /LC60 - DVP UK

Compact design, low noise level, ease of oil check and refill and simplified maintenance operation, are the main features of LC 40 and LC 60 lubricated rotary vane vacuum pumps. The damping and recovery system, equipped with a by-pass, together with the new float type oil recovery valve, ensures the absence of oil vapors at the outlet. Moreover, a sealing device prevents the oil from being sucked back should the pump stops under vacuum. Only hazardous parts have been housed in order to improve both the cooling and the appearance of the pumps. Nominal capacity: 40 – 72 m3/h 28.3 – 42.4 CFM Nominal capacity m3/h 50Hz/60Hz Max water vapour pumping rate kg/h Total final pressure mBar (ass) Motor power Kw50Hz/60Hz LC40 40/48 0.5 0.1 1.1/1.35 LC60 60/72 0.7 0.1 1.5/1.8

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Product

Oil-Lubricated Rotary Vane Vacuum Pumps

Go to product

Product

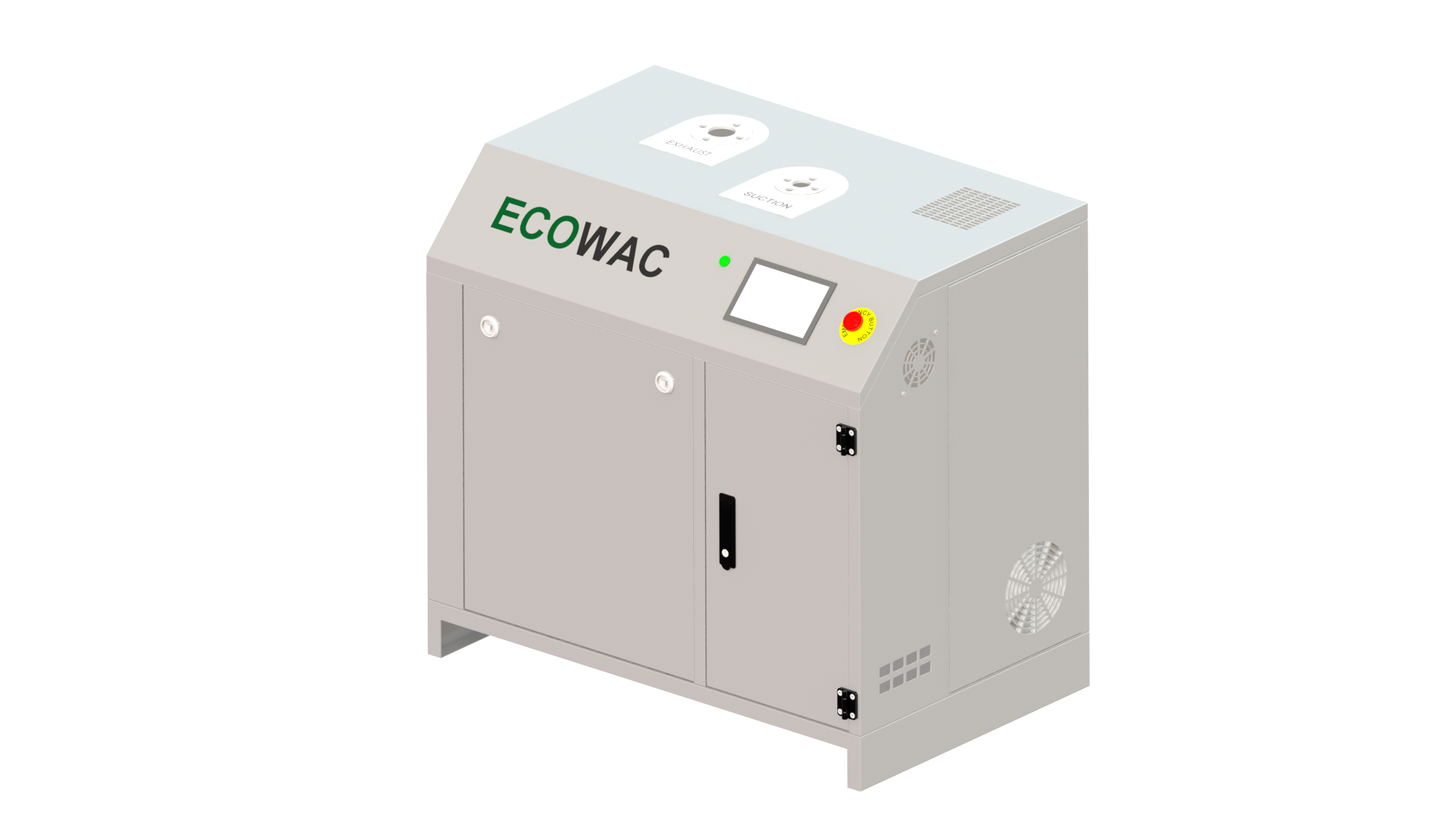

AI-Powered Smart Vacuum Pump Units

Go to product

A dry oilless vacuum pump is a type of vacuum pump designed to create a vacuum without the use of oil in its operation. This technology relies on mechanisms such as rotary vane or diaphragm pumps to achieve the desired vacuum levels. The absence of oil eliminates the risk of oil contamination in the process, making these pumps suitable for applications in the food, pharmaceutical, and semiconductor industries where cleanliness is paramount. These pumps are known for their reliability and efficiency. They typically have lower maintenance requirements compared to oil-lubricated pumps, thus reducing operational costs. Additionally, dry oilless vacuum pumps operate quietly and produce minimal emissions, contributing to a more environmentally friendly solution in vacuum applications.

A dry oilless vacuum pump operates through a mechanism that removes air and other gases from a sealed environment without the use of oil for lubrication or sealing. Instead, these pumps utilize specially designed materials and components to create a vacuum. The main working principle involves the movement of rotor blades within a stator, which compresses the gas and expels it through an exhaust port. These pumps maintain a clean operation by avoiding contamination that oil can introduce, making them ideal for sensitive applications. Their design allows for efficient gas removal while ensuring that the vacuum remains consistent, thus providing reliable performance in various industrial and laboratory settings.

1. Environmentally Friendly

Dry oilless vacuum pumps operate without the use of oil, which reduces the risk of environmental contamination. This makes them a sustainable choice for various applications, especially in industries where emissions and waste management are critical.

2. Low Maintenance

These pumps require less maintenance compared to traditional oil-based pumps. Without oil to change or manage, operational downtime is minimized, leading to increased efficiency and reduced operating costs over time.

3. High Efficiency

Dry oilless vacuum pumps are designed to provide consistent performance with high efficiency. They can achieve low pressures quickly, making them ideal for applications that require rapid vacuum generation.

4. Clean Operation

The absence of oil means that the risk of contamination from oil mist is eliminated. This is particularly important in industries such as food processing, pharmaceuticals, and electronics, where product purity is paramount.

5. Versatility

These pumps are versatile and can be used in a wide range of applications, including laboratory work, packaging, and semiconductor manufacturing. Their adaptability makes them suitable for both small-scale and industrial processes.

1. Pharmaceuticals

Dry oilless vacuum pumps are widely used in the pharmaceutical industry for processes like freeze-drying and solvent recovery. Their oil-free design prevents contamination, making them ideal for applications that require high purity.

2. Food Processing

These pumps are suitable for food packaging and vacuum sealing. Using dry oilless vacuum pumps ensures that no oil comes into contact with food products, maintaining hygiene and safety.

3. Semiconductor Manufacturing

In semiconductor manufacturing, dry oilless vacuum pumps play a crucial role in creating clean vacuum environments for processes like chemical vapor deposition and etching. Their design minimizes particle generation, essential for maintaining product quality.

4. Laboratory Applications

Laboratories utilize dry oilless vacuum pumps for various applications, including vacuum filtration and distillation. Their reliability and low maintenance needs make them a preferred choice in research settings.

To maintain a Dry Oilless Vacuum Pump, regular inspection and cleaning are essential. Start by checking the pump for any signs of wear or damage. Ensure that all seals and gaskets are in good condition to prevent leaks. Additionally, clean the inlet filter as needed to avoid blockages that can affect performance. Monitor the pump’s performance parameters, such as pressure and flow rate, to identify any irregularities early. Properly store the pump when not in use to protect it from environmental factors that could lead to deterioration.

Some interesting numbers and facts about your company results for Dry Oilless Vacuum Pump

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6207 |

| Amount of suitable service providers | 4503 |

| Average amount of employees | 51-100 |

| Oldest suiting company | 1978 |

| Youngest suiting company | 2017 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Dry Oilless Vacuum Pump

What are related technologies to Dry Oilless Vacuum Pump?

Based on our calculations related technologies to Dry Oilless Vacuum Pump are Heat Exchangers, Hydraulic & Pneumatic Systems, Industrial Reactors, Industrial Packaging, Industrial Filters

Which industries are mostly working on Dry Oilless Vacuum Pump?

The most represented industries which are working in Dry Oilless Vacuum Pump are Manufacturing, Machinery Manufacturing, Other, Oil, Energy and Gas, Automation

How does ensun find these Dry Oilless Vacuum Pump Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.