The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

www.xecor.com

Tokyo, Japan

A

101-250 Employees

2014

Key takeaway

Xecor is a prominent electronic components distributor in Japan, offering a wide range of high-quality components and solutions tailored to meet diverse enterprise needs. Their commitment to stable supply chains and efficient delivery ensures a reliable source for rare electronic components, essential for maintaining uninterrupted production operations.

Reference

Core business

Electronic Components Distributor | Xecor

KEYENCE CORPORATION

Japan

A

5001-10000 Employees

1974

Key takeaway

KEYENCE is a prominent supplier of sensors and measuring systems, which are essential electronic components in factory automation. Their commitment to innovative and reliable products supports various manufacturing industries, highlighting their expertise in the electronics sector.

Reference

Product

Electronics

Futaba Electronics

Tsu, Japan

A

251-500 Employees

1964

Key takeaway

Futaba Electronics Industry Co., Ltd. specializes in electronic components, offering a range of products in this field.

Reference

Product

取扱商品 | フタバ電子工業株式会社

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Noritake Co., Inc. Electronics Division

Nagoya, Japan

A

11-50 Employees

1966

Key takeaway

Noritake Co., Inc. Electronics Division showcases a variety of display products, including touch TFT/LCD and VFD, which may be of interest in the electronic components sector. They also provide extensive technical support and resources to facilitate efficient development for applications.

Reference

Product

Product Model - Noritake Co., Inc. Electronics Division

Japan Aviation Electronics Industry, Ltd

Tokyo, Japan

A

251-500 Employees

1977

Key takeaway

JAE has developed the WP86SD Series Board-to-board (FPC) Connector, which features 8A power supply terminals, and the MX81 Series of compact connectors designed for automotive applications.

Reference

Core business

コネクタ メーカー 弘前航空電子

弘前航空電子株式会社の採用情報_HAE詳細がご覧いただけます。

ROHM Semiconductor

Kyoto, Japan

A

101-250 Employees

1958

Key takeaway

ROHM is a company focused on the future of semiconductors, highlighting its expertise and commitment to manufacturing power devices. Their recent collaborations and recognitions underscore their significant role in the electronic components industry.

Reference

Core business

ROHM Semiconductor - ROHM Co., Ltd.

MinebeaMitsumi

Tokyo, Japan

A

10001+ Employees

1951

Key takeaway

Ultra Precision Technologies specializes in semiconductor products, highlighting their expertise in electronic components, which is crucial for the evolving Internet of Things (IoT) landscape.

Reference

Product

半導体(エイブリック製品) - ミネベアミツミ

Tokyo Electron

Tokyo, Japan

A

10001+ Employees

1963

Key takeaway

Tokyo Electron is a semiconductor production equipment manufacturer that plays a crucial role in supporting the semiconductor industry. The company has been recognized for its commitment to sustainability and innovation, achieving 100% renewable energy usage across its group companies in Japan and receiving Intel's 2023 EPIC Outstanding Supplier Award.

Reference

Product

Service | Tokyo Electron Ltd.

About Tokyo Electron's Service

TPSCo

Japan

A

1001-5000 Employees

2012

Key takeaway

Tower Semiconductor specializes in manufacturing analog integrated circuits, making it a key player in the electronic component sector. The company offers advanced customizable technologies for various growing markets, including automotive, medical, and aerospace.

Reference

Product

Technology - Tower Semiconductor

ABLIC

Tokyo, Japan

A

501-1000 Employees

1937

Key takeaway

ABLIC Inc. specializes in developing CMOS ICs, including SPD and VPD EEPROMs used in memory modules like DIMMs and SSDs, enhancing their communication performance. With nearly 30 years of experience, ABLIC also offers battery protection ICs and temperature sensors, reinforcing its expertise in electronic components.

Reference

Product

Voltage Detectors (Reset ICs) – ABLIC Inc.

ABLIC Inc., a semiconductor manufacturer in Seiko Instruments Group, is a leading company of CMOS voltage detectors (reset ICs) that support constructing safe and secure power supply circuits.

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Automotive Engineering

Go to product

Service

Custom Electronics

Go to product

Service

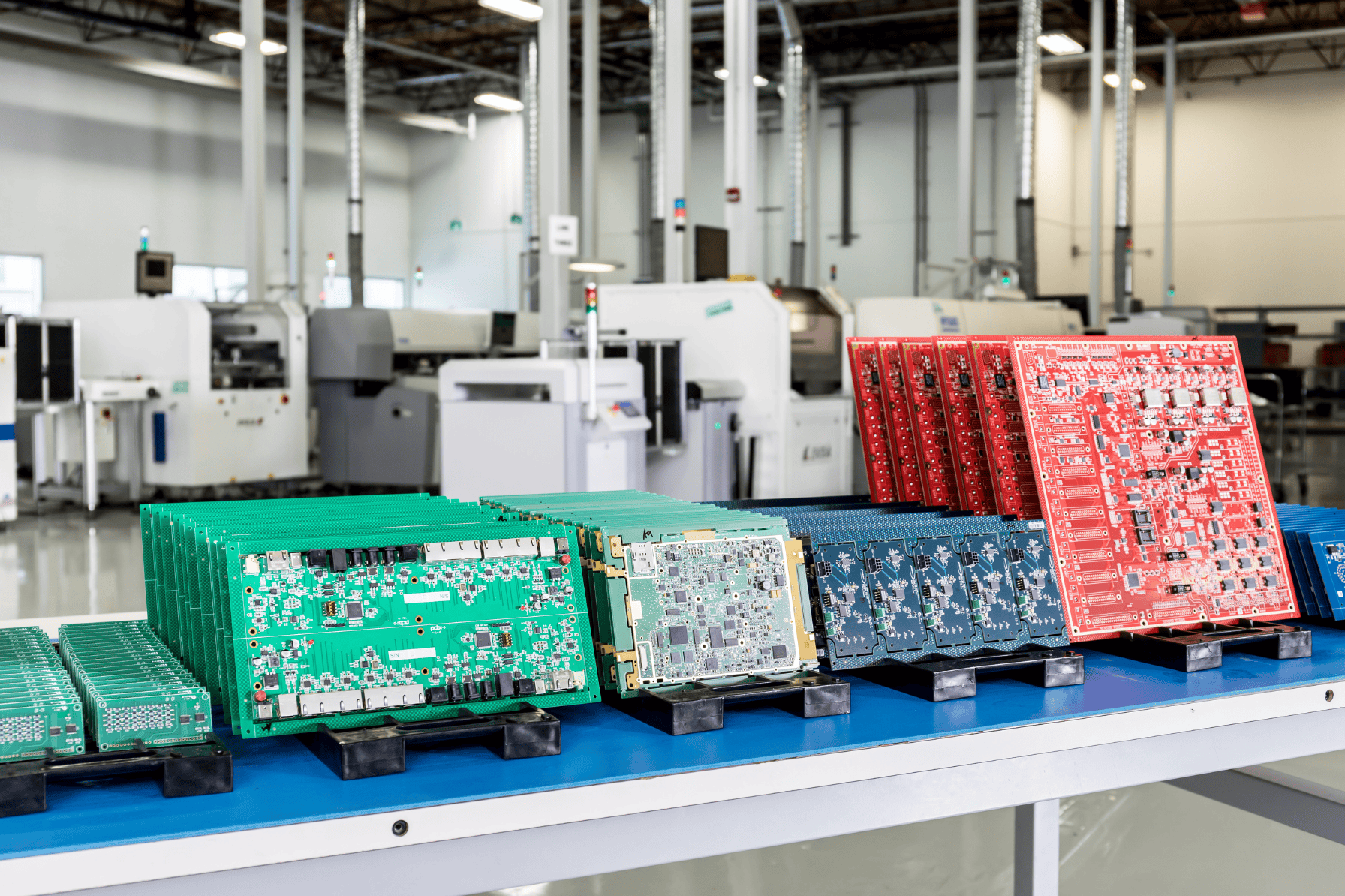

PCB assembly

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

Use case

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

When exploring the electronic component industry in Japan, several key considerations come into play. Japan is renowned for its advanced technology and innovation, making it a significant player in the global market. Understanding local regulations is crucial, as compliance with stringent safety and quality standards is mandatory. The industry faces challenges such as supply chain disruptions and increased competition from emerging markets, which can affect sourcing and manufacturing processes. However, opportunities abound in sectors like automotive electronics, IoT devices, and renewable energy technologies, driven by Japan's commitment to innovation and sustainability. Environmental concerns are gaining traction, with regulations focusing on reducing electronic waste and promoting eco-friendly practices. Companies must adapt to these evolving standards to remain competitive. The competitive landscape is characterized by a mix of established giants and agile startups, leading to a dynamic market environment. Moreover, Japan's strategic location in Asia provides access to a vast customer base, enhancing global market relevance. Investors and businesses should conduct thorough research on potential partners and suppliers, considering factors like technological capabilities, market reputation, and financial stability. By focusing on these aspects, one can better navigate the complexities of the electronic component industry in Japan and identify promising opportunities for growth and collaboration.

Some interesting numbers and facts about your company results for Electronic Component

| Country with most fitting companies | Japan |

| Amount of fitting manufacturers | 12 |

| Amount of suitable service providers | 7 |

| Average amount of employees | 501-1000 |

| Oldest suiting company | 1937 |

| Youngest suiting company | 2014 |

Some interesting questions that has been asked about the results you have just received for Electronic Component

What are related technologies to Electronic Component?

Based on our calculations related technologies to Electronic Component are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Which industries are mostly working on Electronic Component?

The most represented industries which are working in Electronic Component are Other, Semiconductor, Electronics and Electrical engineering, Wholesale, Automation

How does ensun find these Electronic Component Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.