The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Express Technology Group

Town of Islip, United States

B

11-50 Employees

-

Key takeaway

Express Technology Group positions itself as a reliable supplier of high-quality electronic components from leading brands, emphasizing their commitment to authenticity and quality.

Reference

Core business

Wholesale Electronic Components Distributor & Parts Supplier- Express Technology

Legacy Components

Tampa, United States

B

11-50 Employees

2011

Key takeaway

The company is a trusted distributor of electronic components, actively managing long lead time parts from renowned manufacturers like TI, Onsemi, and Panasonic. They emphasize their inventory's traceability to original manufacturers and their qualifications through testing services, catering to industrial automation and defense applications.

Reference

Core business

Electronic Components Distributor

Odyssey Electronics

Tewksbury, United States

B

- Employees

1992

Key takeaway

Odyssey Electronics LTD specializes in providing high-quality automotive and aerospace electronic components, including connectors, ICs, and more. With over 30 years of experience, they are a trusted distributor known for their fast delivery and exceptional customer service.

Reference

Core business

Electronic Components Distributor - Odyssey Electronics

Electronic components distributor with a wide selection of high-quality electronic components and hard to find electronic parts. Member ERAI and Woman Owned

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

NTE Electronics

Bloomfield, United States

B

11-50 Employees

1979

Key takeaway

NTE Electronics, Inc. is a leading supplier of electronic components, boasting a diverse product line of over 23,000 devices, including NTE Brand Semiconductors. As a Master Distributor for major manufacturers, the company has established itself as a key player in the replacement electronic component industry.

Reference

Core business

NTE Electronics Inc. | Electronic Components Supplier | Semiconductors

Lectro Components

Carol Stream, United States

B

11-50 Employees

1974

Key takeaway

Lectro Components is a prominent player in the electronics distribution industry, specializing in various electronic components such as terminal blocks, relays, timers, connectors, and controls. Their commitment to quality and timely delivery ensures that they meet the diverse needs of their customers in the electronic components sector.

Reference

Core business

Electronic Components Distributor & Manufacturer | Lectro Components

Vantage Components

Town of Brookhaven, United States

B

11-50 Employees

2008

Key takeaway

Vantage Components is a leading independent distributor of electronic components, including semiconductors, passives, and interconnect products. The company specializes in obsolescence management services, ensuring a reliable supply of end-of-life products for its customers.

Reference

Product

Semiconductors Suppliers - Vantage Component

Hybrid Electronics

Casselberry, United States

B

1-10 Employees

2005

Key takeaway

Hybrid Electronics specializes in providing a wide range of electronic components, including integrated circuits, capacitors, sensors, and more, making it a strategic partner for companies across various industries.

Reference

Product

Shop Electronic Components | Hybrid Electronics

Hybrid Electronics specializes in providing a wide range of electronic components for various industries and applications.

HMB Electronics

North Haven, United States

B

1-10 Employees

2013

Key takeaway

HMB Electronics is a distributor of a wide range of electronic components, including ICs, capacitors, resistors, and connectors, from leading manufacturers like Analog Devices and Intel. They emphasize authenticity and offer expedited shipping, making them a reliable source for both current and obsolete components.

Reference

Core business

HMB Electronics - Electronic Components Distributor

HMB Electronics stocks a wide range of electronic components such as ICs, Capacitors, Resistors, and Connectors. HMB specializes in obsolete components.

Component Search

Brea, United States

B

11-50 Employees

-

Key takeaway

The company specializes in the distribution of high-quality electronic components, sourced from reliable suppliers. Their dedicated team ensures exceptional customer service and a comprehensive selection of products to meet diverse needs.

Reference

Core business

About Us | Component Search

Electroverge

Mansfield, United States

B

1-10 Employees

2011

Key takeaway

Electroverge® offers specialty electronic components that address design challenges for modern technology companies, providing an innovative online platform for easy procurement.

Reference

Core business

Electroverge | Electronic Components Industry

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Automotive Engineering

Go to product

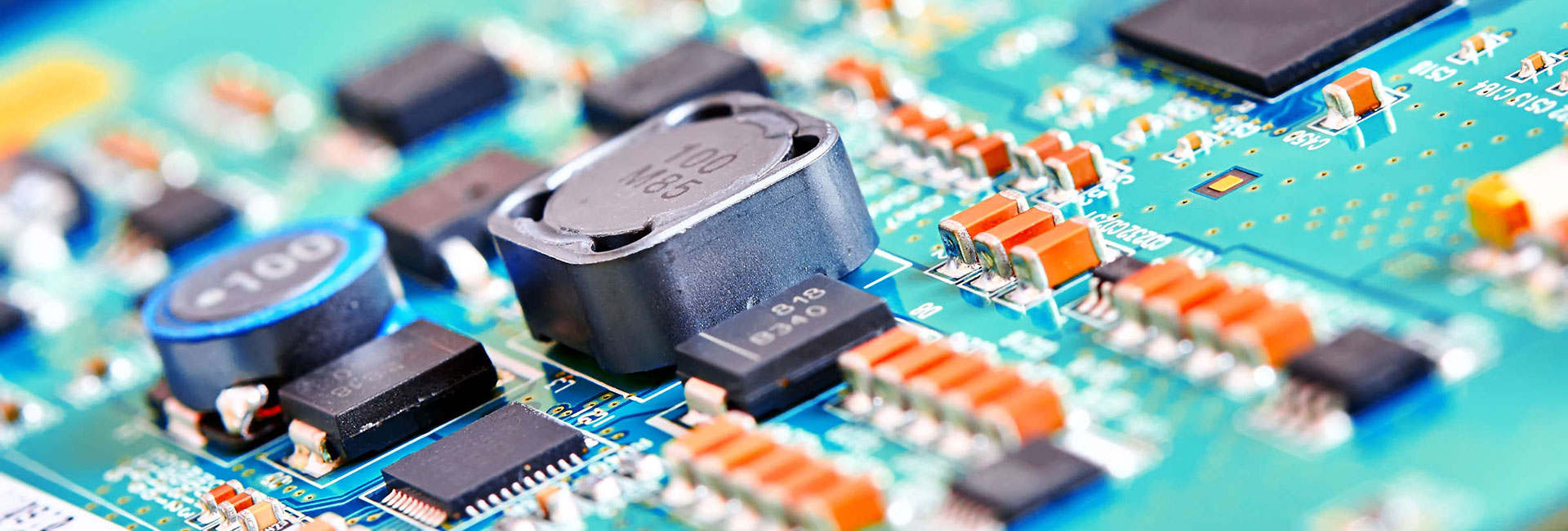

Service

Custom Electronics

Go to product

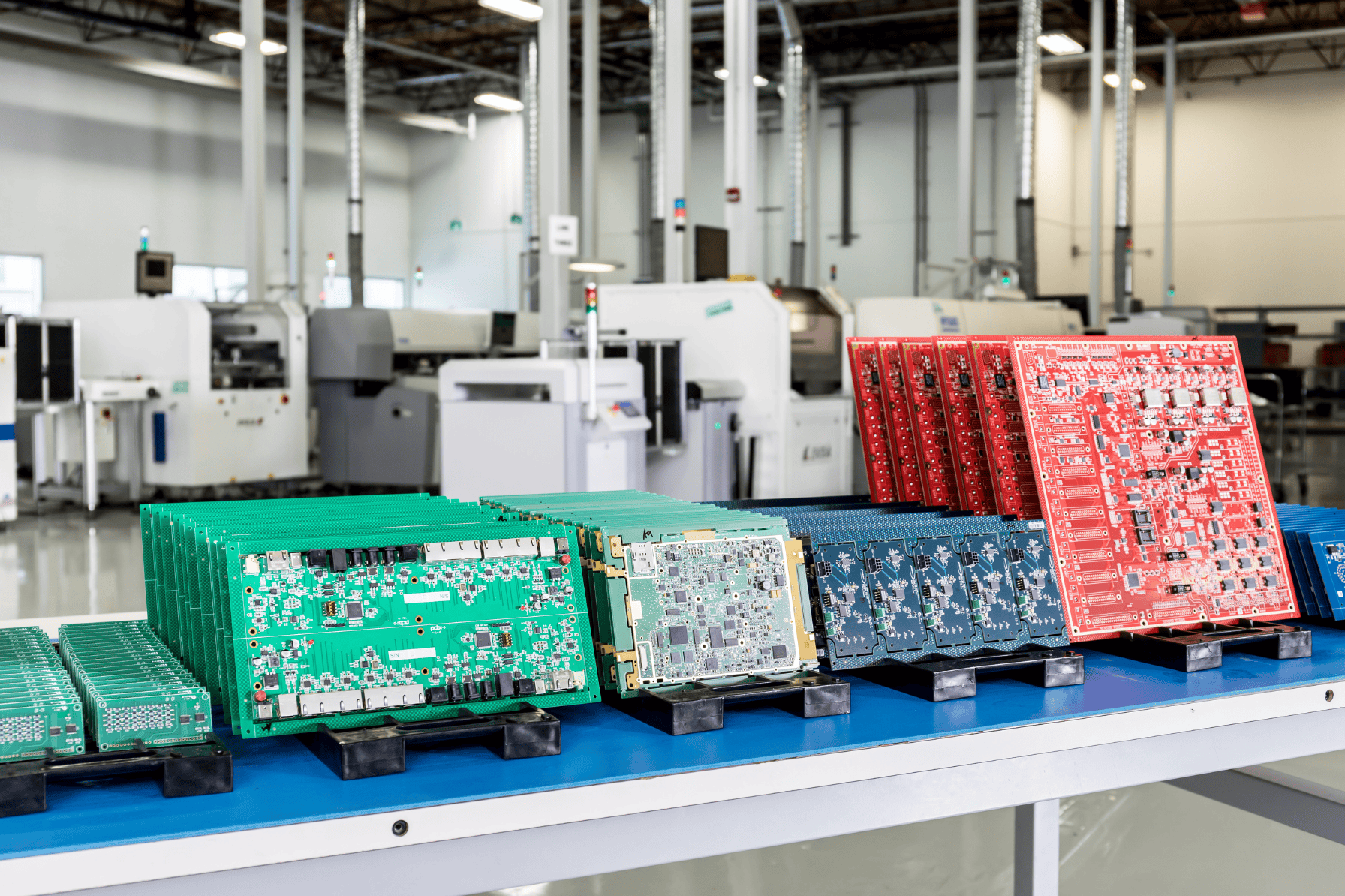

Service

PCB assembly

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

Use case

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

The Electronic Component industry in the United States is influenced by several key considerations that potential entrants should be aware of. Regulatory compliance is paramount, as the industry must adhere to strict standards set by organizations such as the Federal Communications Commission (FCC) and the Occupational Safety and Health Administration (OSHA). Understanding these regulations can affect product development and market entry strategies. Challenges include rapid technological advancements and the constant need for innovation, which can strain resources and require companies to stay agile. The competitive landscape is characterized by both established players and emerging startups, necessitating a strong differentiation strategy. Opportunities abound due to the increasing demand for electronics across various sectors, including automotive, healthcare, and consumer electronics. Additionally, the U.S. market's global relevance means that companies must also be aware of international trade policies and supply chain dynamics. Environmental concerns are increasingly shaping operational choices, pushing companies toward sustainable practices and materials. By navigating these factors effectively, stakeholders can position themselves advantageously in the evolving landscape of the Electronic Component industry in the United States.

Some interesting numbers and facts about your company results for Electronic Component

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 1562 |

| Amount of suitable service providers | 1252 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1974 |

| Youngest suiting company | 2013 |

Some interesting questions that has been asked about the results you have just received for Electronic Component

What are related technologies to Electronic Component?

Based on our calculations related technologies to Electronic Component are Water/Ocean Cleaning Technologies, Waste Management, Renewable Energy, Sustainable Fashion, Smart Grid

Which industries are mostly working on Electronic Component?

The most represented industries which are working in Electronic Component are Electronics and Electrical engineering, Other, Semiconductor, IT, Software and Services, Automation

How does ensun find these Electronic Component Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.