The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Industrial Automation Supply

Portland, United States

B

11-50 Employees

1993

Key takeaway

Industrial Automation Supply is a key player in the electrical controls and automation sector, providing a comprehensive range of components that cater to Original Equipment Manufacturers (OEMs) in New England. With nearly 30 years of experience, the company offers innovative solutions and value-added services, including product design and system installation, making it an ideal partner for industrial automation needs.

Reference

Core business

Industrial Automation Supply

Automation Resources

East Whiteland Township, United States

B

11-50 Employees

2000

Key takeaway

Automation Resources is a leading system integrator in industrial automation, specializing in innovative and cost-effective integrated process control solutions. Their expert team delivers comprehensive factory automation services, including discrete machine controls and motion control, ensuring precision production that optimizes operational efficiency.

Reference

Product

Plant Automation Integrator |Process Control | Automation Resources

Automation Resources is a comprehensive production and process control system integrator with engineering talent & resources, documentation, training & technical support.

Automation and Control Systems Ltd.

Merthyr Tydfil, United Kingdom

A

1-10 Employees

2016

Key takeaway

The company specializes in Automation and Control Systems, highlighting its technical expertise and experience with leading manufacturers in the automation field.

Reference

Service

Services – Automation & Control Systems

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Process and Data Automation

Erie, United States

B

11-50 Employees

2002

Key takeaway

Process and Data Automation is a CSIA Certified industrial control systems integration firm that specializes in physical automation system design, programming, project management, and commissioning. They partner with leading technology providers and are recognized for their superior service and commitment to continuous improvement, making them a valuable resource for companies seeking to enhance their industrial automation systems.

Reference

Core business

Process and Data Automation

Expert Automation

India

D

11-50 Employees

2013

Key takeaway

Expert Automation, established in 2013, is a reputable service provider of high-quality industrial automation products, including AC/DC servo drives, PLCs, HMIs, and more. The company is committed to meeting the precise needs of its clients and aims to evolve as a leading automation service company by offering quality services at competitive prices.

Reference

Core business

Industrial Automation Products, Supplier, Service Provider, Pune, India

Industrial IT Solutions Pvt Ltd

Faridabad, India

D

51-100 Employees

2000

Key takeaway

Industrial IT Solutions Pvt Ltd is a comprehensive solution provider specializing in industrial automation, engineering, and system integration, particularly with ABB's PLCs, DCS, and SCADA systems. Their focus on Industry 4.0 technologies and customer-oriented approach positions them as a key player in optimizing industrial processes and reducing downtime.

Reference

Core business

Electrical Automation | Industrial IT Solutions Pvt Ltd | Faridabad

Industrial IT Solutions Pvt Ltd is a complete engineering house for electrical automation & control systems along with DCS, PLC, AC & DC Drives, Field Instruments, SCADA, Industrial IoT, Drive Panels, PLC Panels, Erection & Commissioning, AMC Services, and also is ABB Value Provider.

Sarla Technologies

Mumbai, India

D

101-250 Employees

1999

Key takeaway

The company is a leading provider of engineering services and solutions with extensive expertise in industrial automation, offering platform-independent engineering services and customized solutions across various industry verticals. With a team of over 450 engineers, they support clients in achieving engineering excellence through automation engineering, including systems like PLC, DCS, SCADA, and robotics.

Reference

Service

Automation Engineering - PLC, DCS, SCADA, HMI, Robotics

Engineering Services for Control Systems, Robotics, Drives and Safety Systems for Global System Integrators, EPCs, OEMs, and Solution Providers

SYNERGY AUTOMATION

New Delhi, India

D

11-50 Employees

2012

Key takeaway

Synergy Automation is a comprehensive provider of industrial automation solutions, offering services from engineering and system integration to installation. They specialize in enhancing plant efficiency through products like PLCs, DCS, VFDs, and SCADA systems, positioning themselves as a trusted open system integrator for major brands.

Reference

Core business

Synergy Automation - Industrial Automation Products supplier & Exporter of PLC AC Drives & Field Instruments

Southern Automation Solutions

Valdosta, United States

B

1-10 Employees

-

Key takeaway

Southern Automation Solutions is a control systems integrator that specializes in automation projects and offers 24/7 support for emergency breakdowns. They emphasize the importance of accurate data collection for maintaining production quality and informed decision-making.

Reference

Core business

Southern Automation Solutions

AM SYSTEMS INTEGRATION (PTY) LTD

Johannesburg, South Africa

C

11-50 Employees

2018

Key takeaway

AM Systems Integration is a leading specialist in control and instrumentation, focusing on turnkey automation solutions that enhance productivity and optimize manufacturing and processing plants. Their expert team offers tailored innovative solutions and 24/7 support, ensuring clients can confidently implement efficient automation processes.

Reference

Service

AM Systems Integration PTY LTD

Industrial Automation, Instrumentation, Siemens, Schneider, Wonderware

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Process Automation

Go to product

Service

Custom Electronics

Go to product

Service

https://www.adgenera.com/en/automation.html

Go to product

Service

PLC Programming

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

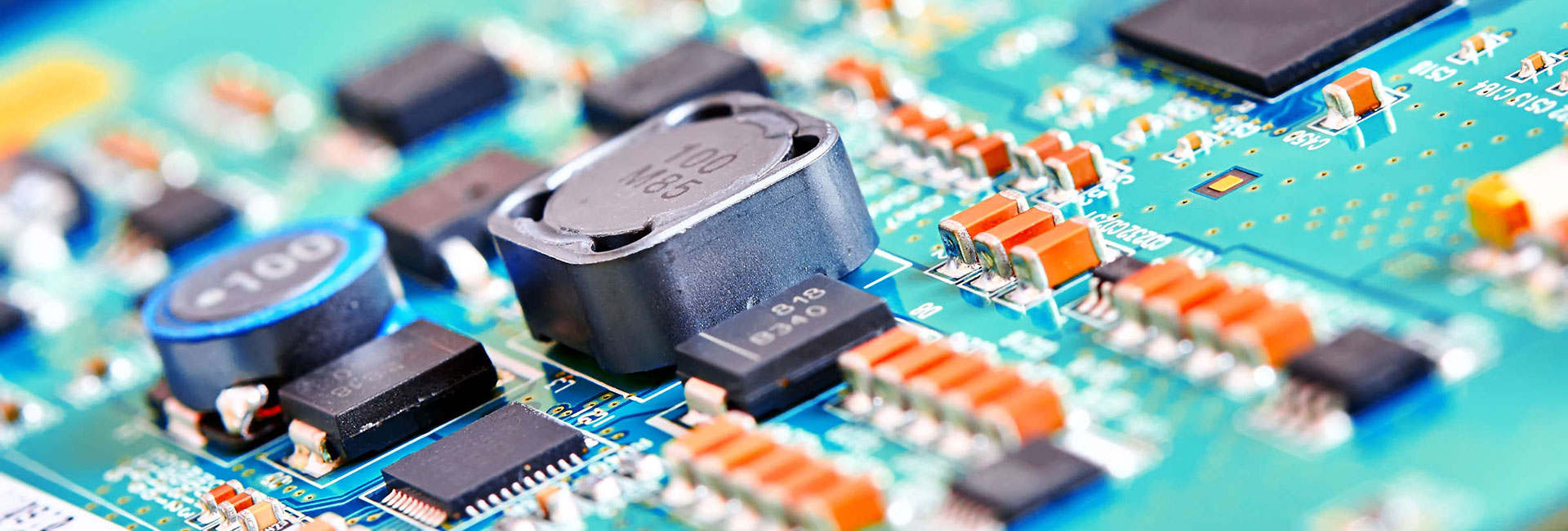

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

Use case

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

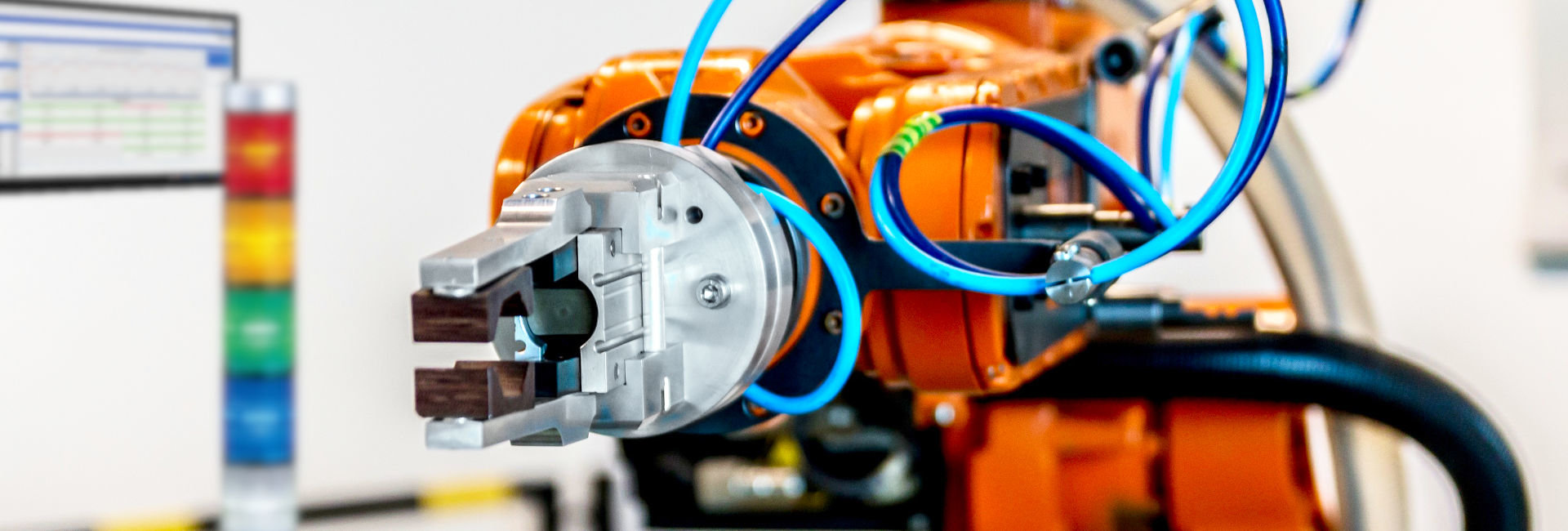

An Industrial Automation System Integrator specializes in designing and implementing automation solutions for various industrial processes. These providers assess the unique needs of a manufacturing or production environment and integrate various hardware and software systems to optimize efficiency and productivity. They typically work with programmable logic controllers (PLCs), human-machine interfaces (HMIs), and SCADA systems, ensuring seamless communication between machines and processes. By focusing on customized solutions, Industrial Automation System Integrators help companies improve operational reliability, reduce downtime, and enhance overall performance.

An Industrial Automation System Integrator plays a crucial role in enhancing manufacturing processes by implementing customized automation solutions tailored to specific operational needs. By integrating various technologies, such as robotics, control systems, and data analytics, these professionals streamline workflows, reduce manual intervention, and improve precision in production lines. Through the deployment of advanced monitoring and control systems, they enable real-time data collection and analysis, fostering informed decision-making. This leads to reduced downtime, optimized resource utilization, and increased overall efficiency, ultimately resulting in improved product quality and faster time-to-market.

1. Manufacturing

Manufacturing industries greatly benefit from industrial automation system integrators. These integrators streamline processes, enhance productivity, and reduce human error through automation technologies.

2. Food and Beverage

The food and beverage sector relies on system integrators for maintaining quality control and ensuring compliance with safety regulations. Automation helps in optimizing production schedules and inventory management.

3. Oil and Gas

In the oil and gas industry, system integrators play a crucial role in improving operational efficiency and safety. Automation systems provide real-time monitoring and control of complex processes, which is essential for reducing risks.

4. Pharmaceuticals

Pharmaceutical companies benefit from automation system integrators to ensure precision in manufacturing and stringent compliance with regulatory requirements. Automated systems help in maintaining consistent product quality and traceability.

5. Automotive

The automotive sector utilizes system integrators to enhance assembly line efficiency and reduce production costs. Automation solutions enable faster production cycles and improved quality assurance.

1. System Design and Engineering

Industrial Automation System Integrators offer comprehensive system design and engineering services. They assess the specific needs of a facility and create tailored automation solutions that enhance efficiency and productivity.

2. Installation and Commissioning

These providers handle the installation and commissioning of industrial automation systems. This includes integrating hardware and software components, ensuring that all systems work seamlessly together for optimal performance.

3. Programming and Configuration

Expertise in programming and configuration is a crucial service. System integrators develop customized software solutions that control automation processes while ensuring compatibility with existing systems.

4. Maintenance and Support

Post-installation support is vital in maintaining system performance. Integrators provide ongoing maintenance, troubleshooting, and updates to keep automation systems running efficiently over time.

5. Training and Consultation

Training staff to operate and maintain automation systems is another key service. Integrators offer consultation to help organizations understand how to maximize their investment in automation technologies.

1. Evaluate Expertise and Experience

Consider the integrator's industry experience and technical expertise. Look for providers with a proven track record in your specific sector, as they will better understand your unique challenges and requirements.

2. Assess Customization Capabilities

Choose a system integrator that offers tailored solutions. The right provider should be able to adapt their services and technologies to fit your business needs, ensuring a smooth integration process and optimal performance.

3. Review References and Case Studies

Examine past projects and client testimonials. A reputable integrator will have case studies demonstrating successful implementations, which can give you insight into their capabilities and reliability.

4. Consider Support and Maintenance Services

Ensure that the integrator provides ongoing support and maintenance. This is crucial for the longevity and efficiency of the automation systems, as timely assistance can prevent costly downtimes.

5. Analyze Communication and Collaboration

Effective communication is vital for a successful partnership. Assess how well the integrator collaborates with your team and their willingness to keep you informed throughout the project lifecycle.

Some interesting numbers and facts about your company results for Industrial Automation System Integrator

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 10000 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1993 |

| Youngest suiting company | 2018 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Industrial Automation System Integrator

What are related technologies to Industrial Automation System Integrator?

Based on our calculations related technologies to Industrial Automation System Integrator are Education, Engineering Services, IT & Technology Services, Healthcare Services, Consulting

Which industries are mostly working on Industrial Automation System Integrator?

The most represented industries which are working in Industrial Automation System Integrator are IT, Software and Services, Automation, Other, Electronics and Electrical engineering, Manufacturing

How does ensun find these Industrial Automation System Integrator Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.