The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

PSS Polymer Standards Service GmbH

Mainz, Germany

A

51-100 Employees

1985

Key takeaway

PSS emphasizes its commitment to quality control (QC) by developing innovative solutions and providing expert support, particularly in macromolecular liquid chromatography. With a strong foundation in material science, PSS creates powerful tools for both QC and research and development.

Reference

Service

Quality Control

Quality Control Service Consultants

United States

B

11-50 Employees

-

Key takeaway

Quality Control Service Consultants specializes in revenue recovery and medical billing services, emphasizing their commitment to maintaining HIPAA compliance. Their expertise includes identifying errors in claims processing, which directly relates to quality control in the medical billing field.

Reference

Core business

Quality Control Service Consultants LLC. - Medical Billing

CARING ABOUT PROVIDERS

Top QC

Berlin, Germany

A

1-10 Employees

-

Key takeaway

Quality Control is essential in the fresh produce industry, ensuring the integrity of products from farm to fork.

Reference

Core business

Top QC

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Mocon

Minneapolis, United States

B

501-1000 Employees

1966

Key takeaway

The company emphasizes its commitment to quality control through its new Dansensor CheckMate 4 solution, which enhances package testing efficiency and accuracy. With over 55 years of experience, they provide reliable and repeatable results that leading companies rely on to maintain product quality and integrity.

Reference

Product

Quality and process control for highest standards

Quality Control Services (Holdings) Ltd

Kowloon, China

D

251-500 Employees

1992

Key takeaway

QCS is a leading provider of quality control services, ensuring that consumer products meet the standards required by North American and European retailers. With operations in Hong Kong, China, and Thailand, QCS specializes in delivering reliable and flexible quality assurance, addressing clients' quality concerns while promoting socially accountable production practices.

Reference

Core business

Quality Control Services Ltd.

Independent QA/QC Services Inc

Scottsdale, United States

B

11-50 Employees

2005

Key takeaway

The company emphasizes its commitment to quality control throughout the entire installation process, ensuring that the final product meets specifications. They also provide advanced analytical equipment designed to detect micro contaminants in gas and water systems, with a focus on maintaining rigorous calibration standards.

Reference

Service

Testing – Independent QAQC

Footwear Inspection Service

Fuzhou City, China

D

11-50 Employees

2010

Key takeaway

Veriquality specializes in quality control services throughout all production stages, leveraging over 10 years of experience and a team of 60+ inspectors to ensure that non-food consumer products meet safety and regulatory standards. Their comprehensive offerings include product inspections and factory audits, making them a trusted partner for global sourcing quality assurance.

Reference

Core business

Veriquality: Quality Control Expert in China

Veriquality Inspection Service Co.Ltd

Fuzhou City, China

D

51-100 Employees

2010

Key takeaway

Veriquality specializes in quality control services throughout all production stages, leveraging over 10 years of experience and a team of 60+ inspectors to ensure that non-food consumer products meet safety and regulatory standards. Their comprehensive offerings include product inspections and factory audits, making them a trusted partner for quality assurance in global sourcing.

Reference

Core business

Veriquality: Quality Control Expert in China

PASILIER LIMITED

Ghana

D

11-50 Employees

2014

Key takeaway

Pasilier has established a robust Quality Management System in accordance with ISO 9001:2015, demonstrating its dedication to meeting client requirements across various sectors, including oil and gas, engineering, and renewable energy projects. The company's commitment to continuous improvement and the implementation of quality control measures ensures the delivery of high-standard services.

Reference

Product

Quality Control Services | PASILIER GROUP

PDQ Engineering

Horsham, United Kingdom

A

11-50 Employees

-

Key takeaway

PDQ Engineering is a leading UK precision engineering subcontractor known for its commitment to quality and accuracy in manufacturing complex parts across various industries. With in-house capabilities and a focus on precision, the company ensures high-quality production while minimizing lead times.

Reference

Service

Quality Control – PDQ Engineering

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Quality Management

Go to product

Service

DeviQA

Go to product

Service

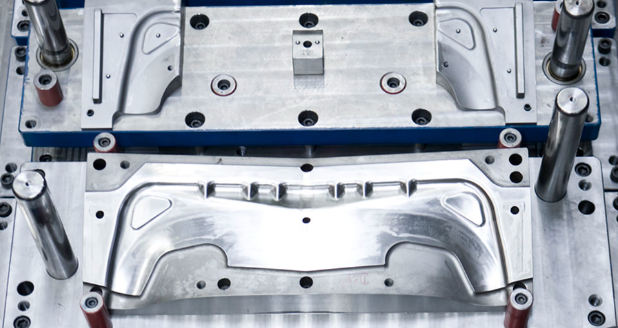

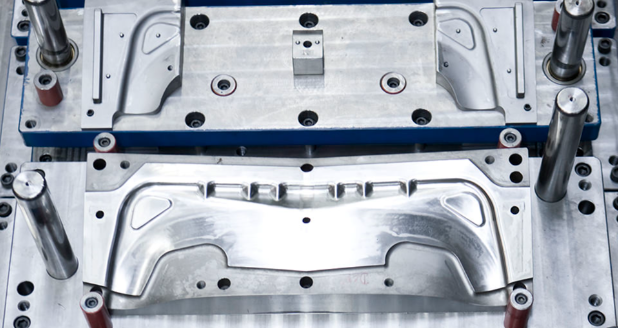

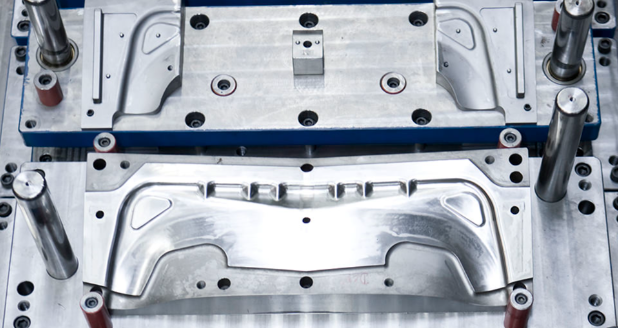

Engineering for die tooling

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

China Sourcing

Automotive, Industry, Cold Forming

At Mühlhoff, we specialize in the efficient and reliable sourcing of high-quality forming tools from China, ensuring you get the right tools for the job—on time, and at the best value. Leveraging years of experience and deep industry connections, we handle the entire procurement process for you, from supplier selection to quality assurance and logistics. With our expertise, you can rest easy knowing that every tool we source meets the highest standards of precision and durability. Why choose Mühlhoff for your tool procurement in China? Expert Knowledge: We know the Chinese market inside and out, ensuring you get the best tools available. Cost Efficiency: Access top-quality forming tools at competitive prices, without compromising on quality. Full Service: From sourcing and supplier audits to logistics and final delivery, we handle every step of the process. Quality Assurance: Rigorous inspections and testing to ensure your tools meet the highest standards. Let us simplify your supply chain and help you focus on what matters most—your production. Partner with Mühlhoff for the precision, reliability, and cost-effectiveness you need in forming tool procurement. Contact us today to learn more!

Use case

China Sourcing

Automotive, Industry, Cold Forming

At Mühlhoff, we specialize in the efficient and reliable sourcing of high-quality forming tools from China, ensuring you get the right tools for the job—on time, and at the best value. Leveraging years of experience and deep industry connections, we handle the entire procurement process for you, from supplier selection to quality assurance and logistics. With our expertise, you can rest easy knowing that every tool we source meets the highest standards of precision and durability. Why choose Mühlhoff for your tool procurement in China? Expert Knowledge: We know the Chinese market inside and out, ensuring you get the best tools available. Cost Efficiency: Access top-quality forming tools at competitive prices, without compromising on quality. Full Service: From sourcing and supplier audits to logistics and final delivery, we handle every step of the process. Quality Assurance: Rigorous inspections and testing to ensure your tools meet the highest standards. Let us simplify your supply chain and help you focus on what matters most—your production. Partner with Mühlhoff for the precision, reliability, and cost-effectiveness you need in forming tool procurement. Contact us today to learn more!

Quality control involves a systematic process that ensures products or services meet specified requirements and standards. This practice is critical in various industries, as it helps to identify defects or inconsistencies during the production process. By implementing quality control measures, businesses can enhance product reliability and customer satisfaction. The focus of quality control is to monitor and improve processes, thereby reducing waste and increasing efficiency. Techniques such as inspections, testing, and statistical process control are often employed to maintain high standards throughout the production cycle. Organizations that prioritize quality control can boost their reputation and maintain competitiveness in the market.

Quality control plays a crucial role in enhancing product standards by systematically monitoring and evaluating various aspects of production. By implementing rigorous inspection processes, businesses can identify defects and inconsistencies early in the manufacturing cycle. This proactive approach not only minimizes waste and reduces costs but also ensures that the final products meet the established specifications and customer expectations. Furthermore, quality control fosters a culture of continuous improvement within organizations. By analyzing data from quality assessments, companies can pinpoint areas that require refinement, leading to optimized processes and better resource management. Ultimately, effective quality control not only elevates product quality but also boosts consumer trust and satisfaction, reinforcing a brand's reputation in the marketplace.

1. Planning

The planning phase involves defining quality standards and criteria that must be met throughout the process. This includes establishing measurable objectives, timelines, and responsibilities for all team members involved in quality control.

2. Monitoring

Monitoring entails the continuous observation of processes and products to ensure compliance with the established quality standards. This may involve regular inspections, testing, and data collection to track performance and identify any deviations from the expected quality levels.

3. Evaluation

Evaluation focuses on analyzing the data collected during monitoring to assess whether the quality objectives are being met. This step is crucial for identifying areas for improvement and making informed decisions about necessary adjustments to processes or standards.

4. Reporting

Effective reporting communicates the findings from the evaluation phase to relevant stakeholders. This includes summarizing data, providing insights into quality performance, and highlighting any issues that require attention or corrective actions.

5. Continuous Improvement

The final component emphasizes the importance of ongoing enhancement of the quality control process. By implementing feedback loops and regularly reviewing procedures, organizations can adapt and improve their quality control measures to enhance overall product and service quality.

Quality control in manufacturing is crucial for several reasons. It ensures that products meet specific standards and specifications, which helps maintain consistency and reliability in production. By implementing quality control processes, manufacturers can identify defects early in the production cycle, reducing waste and minimizing the costs associated with rework or returns. Moreover, effective quality control enhances customer satisfaction, as products that meet quality standards lead to fewer complaints and higher trust in the brand. This positive reputation can result in increased customer loyalty and sales. Overall, quality control is a vital component that supports operational efficiency and contributes to a company’s competitive edge in the market.

Quality Control focuses on the identification and rectification of defects in products or services. It involves the operational techniques and activities used to fulfill requirements for quality. Through inspection and testing, it ensures that the final output meets specified standards. On the other hand, Quality Assurance is a proactive process that emphasizes the prevention of defects through planned and systematic activities. It encompasses the entire process of production, ensuring that quality standards are established and maintained throughout. This approach fosters overall improvement and consistency in processes, rather than merely addressing issues after they arise.

Some interesting numbers and facts about your company results for Quality Control

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 6103 |

| Amount of suitable service providers | 8972 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1966 |

| Youngest suiting company | 2014 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Quality Control

What are related technologies to Quality Control?

Based on our calculations related technologies to Quality Control are Education, Engineering Services, IT & Technology Services, Healthcare Services, Consulting

Which industries are mostly working on Quality Control?

The most represented industries which are working in Quality Control are IT, Software and Services, Other, Consulting, Construction, Healthcare

How does ensun find these Quality Control Companies?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.