The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

SyaPro Automation

Luziânia, Brazil

C

1-10 Employees

2020

Key takeaway

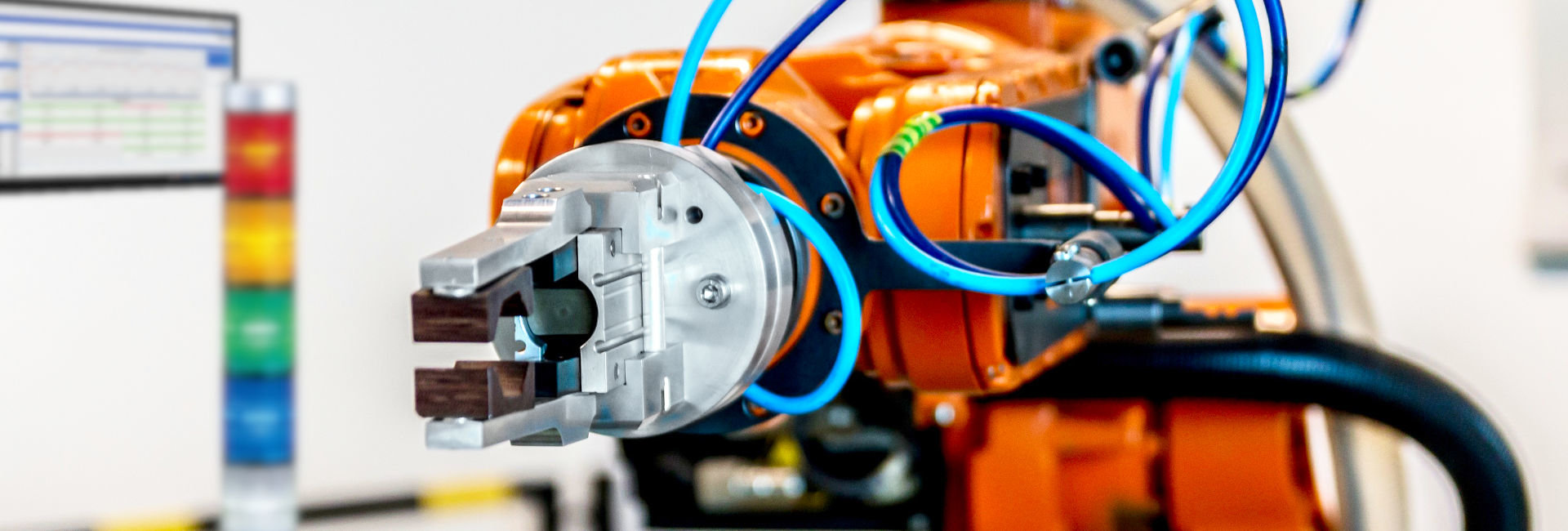

SyaPro specializes in developing reliable and efficient automation solutions, offering a range of services from robotic programming to IoT integration. Their experienced team is equipped to provide customized automation strategies using various technologies, including pneumatic and cloud-connected devices.

Reference

Core business

Industrial Automation | SyaPro | São Bernardo do Campo

Industrial Automation | SyaPro | São Bernardo do Campo

ARCEL Automação Industrial

São Paulo, Brazil

C

1-10 Employees

1989

Key takeaway

Arcel Automação Industrial has been active since 1989, focusing on transforming clients into partners by providing efficient and agile solutions for the automation of machines and industrial processes. They offer a range of high-quality products and services, including pneumatic and electronic automatic feeders, as well as electrical and electronic panels, making them a valuable resource for automation equipment.

Reference

Core business

ARCEL - Automação de Prensas: alimentadores, desbobinadores, endireitadores, guilhotinas, corte transversal

AERY

Louveira, Brazil

C

1-10 Employees

2019

Key takeaway

The company specializes in the development and manufacture of machinery and equipment, particularly in industrial automation and packaging. With expertise in Motion Control and a focus on unique solutions, they are well-equipped to address automation needs across various industries.

Reference

Core business

AERY - Software & Industrial Automation

Desenvolvimento de soluções para a automação industrial e Industria 4.0. Especialização em Motion Control.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Directa Automação

Florianópolis, Brazil

C

11-50 Employees

1988

Key takeaway

Directa Automação offers comprehensive automation services through their Directa MES system, designed for effective shop floor management and aligned with Industry 4.0 trends.

Reference

Product

Technology - Directa Automação

Simantec Automation

Manaus, Brazil

C

1-10 Employees

2013

Key takeaway

The company, Simantec Automation, offers a comprehensive range of industrial automation products, including vision systems, intelligent sensors, and various communication solutions. Their focus on providing quality solutions from recognized manufacturers highlights their commitment to enhancing automation across multiple sectors.

Reference

Core business

SIMANTEC AUTOMATION

Ontteck Automação Industrial

Iracemápolis, Brazil

C

1-10 Employees

2013

Key takeaway

Ontteck is a leader in the development of robotic cells and collaborates with top robot manufacturers. With over ten years of experience in special equipment, Ontteck designs projects across various fields, including electrical, mechanical, hydraulic, and pneumatic systems, highlighting its expertise in industrial automation.

Reference

Core business

Ontteck – Automação Industrial

Saga Automação Industrial

São Paulo, Brazil

C

11-50 Employees

1990

Key takeaway

Saga Automação Industrial offers products, software, and automated solutions that optimize the entire production line, providing the best cost-benefit ratio.

Reference

Core business

Home - Saga Automação Industrial

Inovtec Special Machines and Robotic Cells

Curitiba, Brazil

C

11-50 Employees

2006

Key takeaway

Inovtec specializes in industrial automation, offering expertise in project development, assembly, and installation. They have successfully delivered machines for product classification and load elevators, ensuring compliance with NR-12 standards, and have a diverse portfolio of robotic cells and specialized machinery.

Reference

Core business

InovTec Soluções em Automação Industrial – InovTec Soluções em Automação Industrial

Projects Automation

Itapevi, Brazil

C

1-10 Employees

2009

Key takeaway

The company specializes in the automotive industry, utilizing advanced automation technology to deliver high-quality, customized solutions for each project. Their experienced professionals ensure effective technical assistance and project execution, making them well-equipped to meet diverse automation needs.

Reference

Core business

Projects Automation & Pool

ALPHATECH Automação Industrial

Limeira, Brazil

C

11-50 Employees

2015

Key takeaway

Alphatech specializes in industrial automation, offering advanced automated machines that enhance efficiency while reducing maintenance costs. Their solutions include inspection and testing equipment with easy setup and long-range autofocus capabilities, ensuring precise control and supervision of processes.

Reference

Core business

Automação Industrial - Alphatech

Somos especialistas em Automação Industrial Nossas Soluções Nossas soluções Automação de Embalagens Dispositivos aliados ao conhecimento e aos conceitos mais atualizados do mercado, garantindo a precisão, o controle e supervisão do seu processo. Conheça mais Automação industrial Com o principal seguimeto voltado para automação, construimos maquinas automatizadas, alinhando maior eficiencia com menor custo de manutenção. …

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

Custom Electronics

Go to product

Service

https://www.adgenera.com/en/automation.html

Go to product

Product

Versacon 7

Go to product

Product

Sell to Us

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

Use case

Custom Electronic Design

automotive, E-mobility, automation, industrial automation, machinery, industrial machinery, smart industry, industry 4.0

Electronic design frameworks Electronic design starts from the component layout specification. Also, it consists in the definition of interconnections and PCB technology. Finally, component selection is formalized (BOM, Bill of Material), such as the circuit schematics and the layout of PCB traces (gerber file). If the Electronc Systems is composed of multiple circuit boards, electronic design includes the description of the interconnection schemes, and the instructions for the wiring manufacturing. Adgenera develops electronic circuits tailored and suitable for any application. It selects the most valuable technology for the peculiar field of application, in order to ensure the maximum reliability. Electronic design frameworks Custom-designed electronic solutions can be found in many sectors, covering various fields of application and meeting Client needs. The most frequent requests are: design “from the scratch” miniaturization of an existing circuit board cost Reduction electronic board update, when components are no longer available engineering a prototypal board, either partially or completely working functional improvement (for example, adding a wireless interface) performance improvement (for example, power consumption reduction) Other elements increase the complexity of the electronic design: legacy firmware for the previous version of board need for a custom / legacy interface to other electronic existing systems availability of the components on the market within a certain amount of time project constraints due to standards or certifications The steps of the Electronic Design Electronic design aims to respond to the request of designing and producing electronic circuit boards. First, the customer is interviewed on the characteristics of the electronic system to be designed.. The customer is actively involved to identify the best design choices. This preliminary phase leads to the correct identification of development times and costs, allowing the customer to verify the compliance with his needs and to create a preliminary project planning. Now the electronic scheme can be designed. Specific skills of our designers are applied to correctly select and size the components. Once the scheme has been designed, the electronic components available on the market are selected. Then, they will be soldered to the electronic board during its production phase. We select the most suitable package of components depending on the layout, the space available and the type of application. This design phase leads a draft of the BOM (Bills of Materials) necessary to supply and solder the right components. The electronic components chosen are placed on the board surface. Their positions strictly match design constraints principles to guarantee the correct functioning of the electronic system. Usually several alternative arrangements are evaluated. Finally, the chosen one is the one that leads to the best result once the electronic card is produced. Once the components are finally placed in the board, it is necessary to draw the connections (tracks) that appropriately connect the pins of the components themselves. The tracks design needs to follow many rules and best practices: although there are infinite ways to connect the chosen components, only a few solutions guarantee a good quality card. The preliminary electronic design project is ready: the first board samples are created to check the functionality and performance of the designed electronic system in the laboratory. During the tests, the laboratory instrumentation verifies that each quantity measurable on the card corresponds to the value theoretically calculated during the electronic scheme design.

When exploring the Automation Equipment industry in Brazil, several key factors are essential for informed decision-making. The regulatory environment plays a significant role, as Brazil has specific standards and certifications that manufacturers must comply with, including those related to safety and environmental impact. The industry faces challenges such as high import taxes and tariffs, which can affect the cost of equipment and overall market competitiveness. However, there are substantial opportunities for growth, particularly in sectors like agriculture, manufacturing, and logistics, where automation can enhance efficiency and productivity. Environmental concerns are increasingly relevant, with a push towards sustainable practices and eco-friendly technologies in automation solutions. The competitive landscape in Brazil is diverse, featuring both local companies and international players, which fosters innovation and strategic partnerships. Additionally, Brazil's position in the global market is significant, as it is one of the largest economies in Latin America, with a growing demand for automation driven by digital transformation trends. Understanding these considerations will provide valuable insights for anyone looking to engage with the automation equipment sector in Brazil, highlighting both the potential and the complexities of operating within this dynamic market.

Some interesting numbers and facts about your company results for Automation Equipment

| Country with most fitting companies | Brazil |

| Amount of fitting manufacturers | 22 |

| Amount of suitable service providers | 15 |

| Average amount of employees | 1-10 |

| Oldest suiting company | 1988 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Automation Equipment

What are related technologies to Automation Equipment?

Based on our calculations related technologies to Automation Equipment are Education, Engineering Services, IT & Technology Services, Healthcare Services, Consulting

Which industries are mostly working on Automation Equipment?

The most represented industries which are working in Automation Equipment are Automation, IT, Software and Services, Machinery Manufacturing, Retail, Manufacturing

How does ensun find these Automation Equipment Manufacturers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.